Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

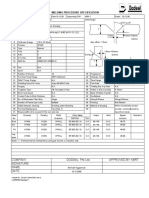

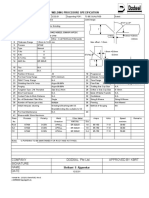

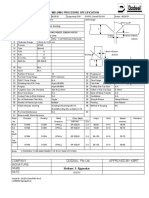

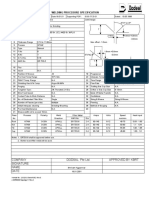

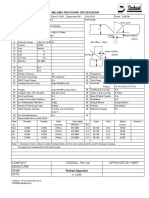

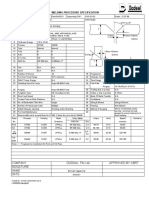

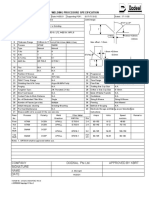

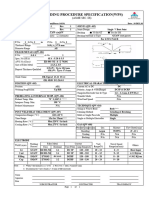

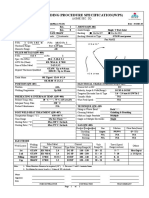

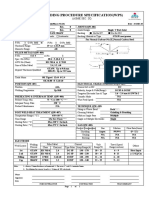

S GoudaThis document provides a welding procedure specification for a single V-groove joint between 1.6-10.16mm thick A335-P11 or A106 Gr B pipe materials. The specification calls for multiple pass gas tungsten arc welding with 2% thoriated 2.4mm diameter tungsten and ER80S-B2 filler metal in the uphill direction between 80-140 amps, 8-15 volts, and 45-120mm/min travel speed while maintaining 150C minimum preheat and 250C maximum interpass temperatures. Initial cleaning is to be done by grinding or brushing and root passes are to be back gouged where access permits prior to back welding.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- 5.4 SCADA System Functional RequirementsDocument85 pages5.4 SCADA System Functional RequirementsYinwu ZhaoNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 3att 1435070407870 Katura ResumeDocument2 pages3att 1435070407870 Katura Resumeapi-362299218No ratings yet

- Dichotic Listening El 100Document22 pagesDichotic Listening El 100Melody Jane CastroNo ratings yet

- SCH4U - Notes From Rayner RedoxDocument2 pagesSCH4U - Notes From Rayner RedoxJoiSatannNo ratings yet

- Reportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)Document38 pagesReportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)GunjeetNo ratings yet

- A Tale of Two CountriesDocument10 pagesA Tale of Two CountriesSandra BoteroNo ratings yet

- Lec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesDocument20 pagesLec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesrohitNo ratings yet

- Overcome Emotional Eating by Healthy & Psyched PDFDocument74 pagesOvercome Emotional Eating by Healthy & Psyched PDFLarissa Veres100% (1)

- Managing People - AssignmentDocument10 pagesManaging People - AssignmentayeshaNo ratings yet

- Funding Proposal: WebsiteDocument8 pagesFunding Proposal: Websitemajiamal99No ratings yet

- Historia Tartarorum EcclesiasticaDocument4 pagesHistoria Tartarorum EcclesiasticaVladimir SaricNo ratings yet

- 10594-2020.04.20 - (Public Consultation) Technical Design Reference For Private Hospital DMP (UPC)Document59 pages10594-2020.04.20 - (Public Consultation) Technical Design Reference For Private Hospital DMP (UPC)LucasNo ratings yet

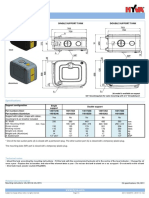

- Hyva Oil Tank: Single Support Tank Double Support TankDocument4 pagesHyva Oil Tank: Single Support Tank Double Support TankPutera Bumi NusantaraNo ratings yet

- Shamanic HealingDocument41 pagesShamanic HealingMeraki Mary50% (2)

- AAADocument12 pagesAAAMisael CamposanoNo ratings yet

- Estimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability StudyDocument8 pagesEstimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability Studyayand2005No ratings yet

- Chiari ExerciseDocument3 pagesChiari ExercisesoliverosteopathyNo ratings yet

- Risser, E. New Technique Casting Missing Areas in Glass. 1997Document9 pagesRisser, E. New Technique Casting Missing Areas in Glass. 1997Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- UKA Athletics Coach Induction Pack v2 Jan 2013Document36 pagesUKA Athletics Coach Induction Pack v2 Jan 2013gpitbullNo ratings yet

- Reasearch SummariesDocument12 pagesReasearch Summariesapi-508554918No ratings yet

- RS 232 Repeater KFD2-FF-Ex2.RS232: FunctionDocument4 pagesRS 232 Repeater KFD2-FF-Ex2.RS232: FunctionEder AlexandreNo ratings yet

- Adam S. Tricomo: Concordia University Irvine, Irvine, CADocument2 pagesAdam S. Tricomo: Concordia University Irvine, Irvine, CAapi-518371548No ratings yet

- Solar SystemDocument5 pagesSolar SystemUNLA LA CORPORATIONNo ratings yet

- KOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETDocument4 pagesKOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETguojun sunNo ratings yet

- 11th Zoology Volume 1 New School Books Download English MediumDocument240 pages11th Zoology Volume 1 New School Books Download English Mediumaishikanta beheraNo ratings yet

- Stretching ExerciesDocument2 pagesStretching ExerciesGanesh Babu100% (1)

- CVTDocument232 pagesCVTOlatunde Onakoya50% (2)

- Gas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideDocument11 pagesGas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideSandro RuizNo ratings yet

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNo ratings yet

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

10 views1 pageThis document provides a welding procedure specification for a single V-groove joint between 1.6-10.16mm thick A335-P11 or A106 Gr B pipe materials. The specification calls for multiple pass gas tungsten arc welding with 2% thoriated 2.4mm diameter tungsten and ER80S-B2 filler metal in the uphill direction between 80-140 amps, 8-15 volts, and 45-120mm/min travel speed while maintaining 150C minimum preheat and 250C maximum interpass temperatures. Initial cleaning is to be done by grinding or brushing and root passes are to be back gouged where access permits prior to back welding.

Original Description:

Original Title

PP25

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification for a single V-groove joint between 1.6-10.16mm thick A335-P11 or A106 Gr B pipe materials. The specification calls for multiple pass gas tungsten arc welding with 2% thoriated 2.4mm diameter tungsten and ER80S-B2 filler metal in the uphill direction between 80-140 amps, 8-15 volts, and 45-120mm/min travel speed while maintaining 150C minimum preheat and 250C maximum interpass temperatures. Initial cleaning is to be done by grinding or brushing and root passes are to be back gouged where access permits prior to back welding.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaThis document provides a welding procedure specification for a single V-groove joint between 1.6-10.16mm thick A335-P11 or A106 Gr B pipe materials. The specification calls for multiple pass gas tungsten arc welding with 2% thoriated 2.4mm diameter tungsten and ER80S-B2 filler metal in the uphill direction between 80-140 amps, 8-15 volts, and 45-120mm/min travel speed while maintaining 150C minimum preheat and 250C maximum interpass temperatures. Initial cleaning is to be done by grinding or brushing and root passes are to be back gouged where access permits prior to back welding.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/25 Rev.0 Date:05.02.01 Supporting PQR : 0404-1 Dated : 29.12.96

2 Joint Design Single 'v' groove Joint Design

3 Backing None 37.5° ± 2.5°

4 Joint Prep. Machining and/or Grinding

5 Base Metal Spec. P4-P1 T

6 Base Metal A335-P11, A106 Gr B

2-4mm 1.6mm +0.8mm

7 Pipe Dia >2" NB -0.8mm

8 Thickness Range 1.6 to 10.16mm. Max offset - 1.6mm

9 Process GTAW

10 Type Manual

11 F.No 6 1.6mm +0.8mm

12 A.No 3 37.5°±2.5° -0.0mm

13 S.F.A No. 5.28

14 AWS No. ER80S-B2 T 2-4mm

T

15 Flux N.A.

16 Insert N.A.

17 Position Of Groove All 18 Progression Uphill

19 Pre Heat Temp Range 150°C Minimum 20 Interpass Temp. 250°C Max.

21 PWHT Temp. Range N.A. 22 Time Range N.A.

23 Shielding Gas & % Comp Argon 99.99% Purity 24 Flow Rate 7-12LPM (15-25CFH)

25 Purging N.A. 26 Trailling Gas Cup Size N.A.

27 Tungsten Type : 2% Thoriated 2.4 dia 28 Orifice or Gas Cup Size 8-13mm

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding and/or Brushing 38 Method of Gouging where unrestricted access

permits ,root shall be back

39 Pre Heat Maintenance Yes (Note 1) 40

gouged to sound metal prior to

41 Weave width not to exceed 10mm. back welding.

Pass Process Polarity Weld Filler Metal Amps Volts Speed Remarks

No. Direction AWS No. Dia mm/min

Root GTAW DCEN UPHILL ER 80S-B2 2.4 80-140 8-15 45-80

Hot GTAW DCEN UPHILL ER 80S-B2 2.4 90-140 8-15 60-120

Fill GTAW DCEN UPHILL ER 80S-B2 2.4 90-140 8-15 60-120

Cap

GTAW DCEN UPHILL ER 80S-B2 2.4 90-140 8-15 60-120

Multi

Notes : 1. Preheat shall be maintained by using gas burners or induction coils.

2. Metrode or any of KBRT approved manufacturer filler metal shall be used.

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME Shrikant Ajgaonkar

DATE 05.02.01

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp25

You might also like

- 5.4 SCADA System Functional RequirementsDocument85 pages5.4 SCADA System Functional RequirementsYinwu ZhaoNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 3att 1435070407870 Katura ResumeDocument2 pages3att 1435070407870 Katura Resumeapi-362299218No ratings yet

- Dichotic Listening El 100Document22 pagesDichotic Listening El 100Melody Jane CastroNo ratings yet

- SCH4U - Notes From Rayner RedoxDocument2 pagesSCH4U - Notes From Rayner RedoxJoiSatannNo ratings yet

- Reportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)Document38 pagesReportable in The Supreme Court of India Criminal Appellate Jurisdiction Criminal Appeal NO. 615 of 2020 (Arising Out of SLP (CRL.) No.8260/2018)GunjeetNo ratings yet

- A Tale of Two CountriesDocument10 pagesA Tale of Two CountriesSandra BoteroNo ratings yet

- Lec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesDocument20 pagesLec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesrohitNo ratings yet

- Overcome Emotional Eating by Healthy & Psyched PDFDocument74 pagesOvercome Emotional Eating by Healthy & Psyched PDFLarissa Veres100% (1)

- Managing People - AssignmentDocument10 pagesManaging People - AssignmentayeshaNo ratings yet

- Funding Proposal: WebsiteDocument8 pagesFunding Proposal: Websitemajiamal99No ratings yet

- Historia Tartarorum EcclesiasticaDocument4 pagesHistoria Tartarorum EcclesiasticaVladimir SaricNo ratings yet

- 10594-2020.04.20 - (Public Consultation) Technical Design Reference For Private Hospital DMP (UPC)Document59 pages10594-2020.04.20 - (Public Consultation) Technical Design Reference For Private Hospital DMP (UPC)LucasNo ratings yet

- Hyva Oil Tank: Single Support Tank Double Support TankDocument4 pagesHyva Oil Tank: Single Support Tank Double Support TankPutera Bumi NusantaraNo ratings yet

- Shamanic HealingDocument41 pagesShamanic HealingMeraki Mary50% (2)

- AAADocument12 pagesAAAMisael CamposanoNo ratings yet

- Estimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability StudyDocument8 pagesEstimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability Studyayand2005No ratings yet

- Chiari ExerciseDocument3 pagesChiari ExercisesoliverosteopathyNo ratings yet

- Risser, E. New Technique Casting Missing Areas in Glass. 1997Document9 pagesRisser, E. New Technique Casting Missing Areas in Glass. 1997Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- UKA Athletics Coach Induction Pack v2 Jan 2013Document36 pagesUKA Athletics Coach Induction Pack v2 Jan 2013gpitbullNo ratings yet

- Reasearch SummariesDocument12 pagesReasearch Summariesapi-508554918No ratings yet

- RS 232 Repeater KFD2-FF-Ex2.RS232: FunctionDocument4 pagesRS 232 Repeater KFD2-FF-Ex2.RS232: FunctionEder AlexandreNo ratings yet

- Adam S. Tricomo: Concordia University Irvine, Irvine, CADocument2 pagesAdam S. Tricomo: Concordia University Irvine, Irvine, CAapi-518371548No ratings yet

- Solar SystemDocument5 pagesSolar SystemUNLA LA CORPORATIONNo ratings yet

- KOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETDocument4 pagesKOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETguojun sunNo ratings yet

- 11th Zoology Volume 1 New School Books Download English MediumDocument240 pages11th Zoology Volume 1 New School Books Download English Mediumaishikanta beheraNo ratings yet

- Stretching ExerciesDocument2 pagesStretching ExerciesGanesh Babu100% (1)

- CVTDocument232 pagesCVTOlatunde Onakoya50% (2)

- Gas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideDocument11 pagesGas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideSandro RuizNo ratings yet

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNo ratings yet