Professional Documents

Culture Documents

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

16 views1 pageThis document provides a welding procedure specification for a single V-groove joint between alloy steel pipes with diameters ranging from 1.6mm to 14.22mm thick. The joint will be welded using gas tungsten arc welding with an ER 309 filler wire in the vertical-uphill position. Multiple weld passes will be used with purging and interpass cleaning between passes. Preheating will be a minimum of 10°C and the interpass temperature must not exceed 150°C.

Original Description:

Original Title

PP33

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification for a single V-groove joint between alloy steel pipes with diameters ranging from 1.6mm to 14.22mm thick. The joint will be welded using gas tungsten arc welding with an ER 309 filler wire in the vertical-uphill position. Multiple weld passes will be used with purging and interpass cleaning between passes. Preheating will be a minimum of 10°C and the interpass temperature must not exceed 150°C.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

16 views1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaThis document provides a welding procedure specification for a single V-groove joint between alloy steel pipes with diameters ranging from 1.6mm to 14.22mm thick. The joint will be welded using gas tungsten arc welding with an ER 309 filler wire in the vertical-uphill position. Multiple weld passes will be used with purging and interpass cleaning between passes. Preheating will be a minimum of 10°C and the interpass temperature must not exceed 150°C.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

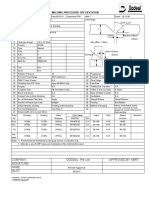

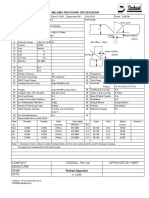

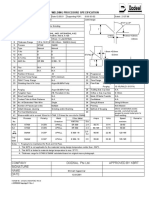

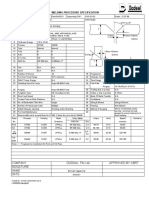

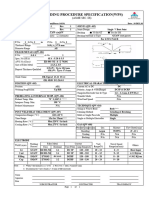

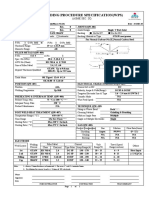

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979/G2/010 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/33 REV-1 27.04.01 Supporting PQR : DOD/Q-CHEM/PQR/05 Dated :05.04.01

2 Applicable Code ASME Sec. IX (1999 Edition) & B31.3 Joint Design

3 Joint Design Single "V" Groove 37.5° ± 2.5°

4 Backing None

5 Joint Prep. Machining and/or Grinding T

6 Base Metal Spec. P45 - P1 (Alloy20 - CS)

7 Base Metal B464 N08020, B462 N08020, B366GR.WP20C 2-4mm 1.6mm +0.8mm

B366 GR.WP20 CRW To A53 Gr.B, A106 Gr.B

A139 Gr.B, A105, A234WPB -0.0mm

8 Pipe Dia Range All

9 Thickness Range 1.6mm to 14.22 mm

10 Process GTAW

11 Type Manual 1.6mm +0.8mm

12 F.No 6 37.5°±2.5° -0.0mm

13 A.No 8

14 S.F.A No. 5.9 T 2-4mm

15 AWS No. ER 309 T

16 Flux N.A.

17 Insert N.A. Max offset:As per PFI Tolerance

18 Position Of Groove All 19 Progression Vertical Uphill

20 Pre Heat Temp Range 10°C minimum 21 Interpass Temp. 150°C Max.

22 PWHT Temp. Range N.A. 23 Time Range N.A.

24 Shielding Gas & % Comp Argon 99.99% 25 Flow Rate Shielding 8-12 LPM Purging 10-20LPM

26 Purging Argon 99.99% 27 Trailling Gas Cup Size N.A.

28 Tungsten Type : 2% Thoriated Size Dia 2.4mm 29 Orifice or Gas Cup Size 8-13mm

30 Wire Feed Speed N.A. 31 Mode Of Metal Transfer N.A.

32 Contact Tube to Work Distance N.A. 33 Oscillations N.A.

34 No. of Electrodes/ Filler Wire Single 35 String & Weave String & Weave

36 Number of Passes (per side) Multiple 37 Peening Not Allowed

38 Initial/ interpass cleaning Grinding & Brushing with SS 39 Method of Gouging NA

Brush&Grinding Disc suitable to SS

40 Pre Heat Maintenance N.A. 41

42 Weave width 10mm Maximum.

Pass Process Polarity Weld Filler Metal Amps Volts Speed Remarks

No. Direction AWS No. Dia mm/min

Root GTAW DCEN Vertical Uphill ER 309 2.4 85-115 9-14 40-60

Hot GTAW DCEN Vertical Uphill ER 309 2.4 85-115 9-14 60-100

Fill

(multi

) GTAW DCEN Vertical Uphill ER 309 2.4 87-120 9-13 60-90

Cap

(multi

) GTAW DCEN Vertical Uphill ER 309 2.4 80-130 9-14 60-90

Notes 1) PURGING TO BE MAINTAINED FOR ROOT AND HOT PASS.

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME Shrikant S Ajgaonkar

DATE 27.04.01

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp33-1.xls

You might also like

- Dairy Farming PPT 57fcdDocument16 pagesDairy Farming PPT 57fcdNaveen ArumugamNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- MuboboboDocument8 pagesMuboboboMartín Real L.No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Notified Vide SRO No. 575 Dated 22 May 2019Document3 pagesNotified Vide SRO No. 575 Dated 22 May 2019Hussain RahibNo ratings yet

- Homework 1 Modulo 8Document6 pagesHomework 1 Modulo 8Eliab OrellanaNo ratings yet

- WELDING ELECTRODE ACA 384 EnglishDocument3 pagesWELDING ELECTRODE ACA 384 EnglishGerman KodzhebashNo ratings yet

- Astm A325Document8 pagesAstm A325Nacer KisyNo ratings yet

- P 1 December 01Document1 pageP 1 December 01laldinmawiahlondoNo ratings yet

- Earthquake Drill OrientationDocument41 pagesEarthquake Drill OrientationRyan Q. Blanco100% (1)

- Contoh Soal IELTS Writing IdeaDocument4 pagesContoh Soal IELTS Writing Ideaagus setiawanNo ratings yet

- 20T Wheat Flour Milling PlantDocument12 pages20T Wheat Flour Milling Plantshio29100% (2)

- Body of Research Paper 2Document5 pagesBody of Research Paper 2uxy lolNo ratings yet

- Summative - Flowring Plant Reproduction 4Document3 pagesSummative - Flowring Plant Reproduction 4Maya GunawanNo ratings yet

- Cannele de Bordeaux 1Document4 pagesCannele de Bordeaux 1nadine marchandNo ratings yet

- Celebrating The Life Of: Arthur Kinyanjui KimaniDocument32 pagesCelebrating The Life Of: Arthur Kinyanjui KimaniKinuthia MathewNo ratings yet

- Criminal Law 2008 Zone B PaperDocument5 pagesCriminal Law 2008 Zone B Paperశ్రీ లత Sri Lata100% (1)

- Hypertension Dash DietDocument32 pagesHypertension Dash DietKAUSHAL ARYA100% (1)

- 80cc (LT80 2002-2006)Document42 pages80cc (LT80 2002-2006)DanyNo ratings yet

- Govt Rajaji TB Hospital Trichy: Name of The InstitutionDocument7 pagesGovt Rajaji TB Hospital Trichy: Name of The InstitutionprastacharNo ratings yet

- Wordlist Level2Document3 pagesWordlist Level2SamiyaNo ratings yet

- Bulleh Shah's Poems ExplanationDocument4 pagesBulleh Shah's Poems Explanationmmuhammadwaleed786No ratings yet

- Petron Plustm Formula 7 Diesel Engine ConditionerDocument2 pagesPetron Plustm Formula 7 Diesel Engine ConditionerwellblablablaNo ratings yet

- MTD REPAIR MANUAL FOR P90 ENGINE 769 - 06294 - p90 - EngineDocument120 pagesMTD REPAIR MANUAL FOR P90 ENGINE 769 - 06294 - p90 - EngineMalte BreitlowNo ratings yet

- Honda PDFDocument20 pagesHonda PDFAyan DuttaNo ratings yet

- 11.utilization of Demolished Concrete Waste For New ConstructionDocument6 pages11.utilization of Demolished Concrete Waste For New Constructionhasnath kpNo ratings yet

- National Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuDocument14 pagesNational Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuKatNo ratings yet

- Scissor Lifts enDocument8 pagesScissor Lifts enrezaNo ratings yet

- Problem Set No.1Document3 pagesProblem Set No.1paolo sulitNo ratings yet

- Principles Practices and Pragmatics New Models of Coteaching Friend and CookDocument33 pagesPrinciples Practices and Pragmatics New Models of Coteaching Friend and CookEFL Classroom 2.0100% (1)

- Latihan Autocad KIMI-A2 - PlanDocument1 pageLatihan Autocad KIMI-A2 - PlanMuhd HakimieNo ratings yet

- Audi A6 EuroncapDocument3 pagesAudi A6 EuroncapcarbasemyNo ratings yet