Professional Documents

Culture Documents

Vibration Pads: Mason Industries, Inc

Vibration Pads: Mason Industries, Inc

Uploaded by

bman00514010 ratings0% found this document useful (0 votes)

40 views2 pagesMason Industries manufactures vibration control products including various types of vibration pads. The document summarizes five main types of pads: BBNR Bridge Bearing Pads for high load applications; NK Rubber & Cork Sandwich Pads for acoustical isolation; HL Rubber Impregnated Duck Pads that maintain alignment; W Neoprene Waffle Pads with high load capacity and built-in sealing; and assemblies using multiple W pads for wall isolation. Each pad type is designed for specific vibration or noise control applications.

Original Description:

Original Title

MP-440-1-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMason Industries manufactures vibration control products including various types of vibration pads. The document summarizes five main types of pads: BBNR Bridge Bearing Pads for high load applications; NK Rubber & Cork Sandwich Pads for acoustical isolation; HL Rubber Impregnated Duck Pads that maintain alignment; W Neoprene Waffle Pads with high load capacity and built-in sealing; and assemblies using multiple W pads for wall isolation. Each pad type is designed for specific vibration or noise control applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

40 views2 pagesVibration Pads: Mason Industries, Inc

Vibration Pads: Mason Industries, Inc

Uploaded by

bman0051401Mason Industries manufactures vibration control products including various types of vibration pads. The document summarizes five main types of pads: BBNR Bridge Bearing Pads for high load applications; NK Rubber & Cork Sandwich Pads for acoustical isolation; HL Rubber Impregnated Duck Pads that maintain alignment; W Neoprene Waffle Pads with high load capacity and built-in sealing; and assemblies using multiple W pads for wall isolation. Each pad type is designed for specific vibration or noise control applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

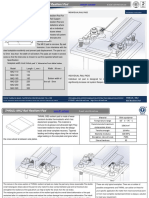

MASON INDUSTRIES, Inc.

Manufacturers of Vibration Control Products

BBNR– Bridge Bearing

NK– Rubber & Cork VIBRATION

PADS

350 Rabro Drive 2101 W. Crescent Ave., Suite D

Hauppauge, NY 11788 Anaheim, CA 92801 HL– Rubber Impregnated Duck

631/348-0282 714/535-2727 W– Neoprene Waffle

FAX 631/348-0279 FAX 714/535-5738

NI– Nitrile Waffle

Info@Mason-Ind.com • www.Mason-Ind.com BULLETIN MP-440-1-1

Vibration Pads are used to reduce noise and vibration and use of either rubber or spring mountings. As a general rule,

to eliminate the need for bolting down. The flat configuration pads are recommended to eliminate high frequency noise,

minimizes machine elevation. This low cost method conve- bolting, minor vibration problems in upper stories or for

niently solves or prevents problems that do not warrant the ground floor and non critical applications.

BBNR– Bridge Bearing Pads

We use the term “Bridge Bearing” as an indication of quality. All bearings

that support bridges or highway overpasses use Neoprene or Natural

Rubber compounds, so the molded product has high tensile and elongation

characteristics and minimal permanent set or creep. Similarly, they must pass

rigid tests for ozone and oxygen resistance.

When the pads are used for vibration isolation in supporting entire buildings,

components such as structural floors or secondary floating floors, “Dynamic

Stiffness” is another specified characteristic. This is important as the Dynamic

Stiffness, Deflection and the shape of the Load Deflection curve control

frequency.

Bearing pads are always solid pads (unlike our waffle pads), because loadings

per square inch are high, often in the range of 1000psi 70kg/cm2. BBNR Pads

have a shallow waffle pattern on both faces to aid in gripping surfaces.

Capacities are controlled by area, hardness (durometer), thickness and

perimeter relative to the loaded area.

BBNR–

Most of the time we design and mold these pads to specific requirements as Bridge Bearing Natural Rubber Pads

explained in Architectural Bulletin AB-104-2, but we thought it would be helpful

to offer some stock sizes for immediate shipment. Max. Max.

Size Load Defl.

While they are used in acoustical applications, there is a constant demand Type (in) (mm) (lbs) (kgs) (in) (mm)

for high capacity pads for pipe supports, structural supports, etc., in this load

range. 10x10x1 250x250x25 25000 11340

8x8x1 200x200x25 16000 7257 1/8 3.2

Pads can be stacked with 1/8” 3mm steel plates between them for higher BBNR- 6x6x1

150x150x25 7900 3583

deflections and greater efficiency. Higher loadings per square inch cm2 require 4x4x1 100x100x25 2400 1089

bonded inserts to avoid pancaking.

NK– Rubber & Cork Sandwich Pad NK–

Neoprene & Cork Pad

Type “NK” pads are isolation sandwiches made by

laminating a thick cork center core between two neoprene Max.

pads. This arrangement of the materials forces sound to Size Load

Type (in) (mm) (psi)(kg/cm2)

pass through zones of different density with subsequent

power losses because of the change in velocity. This 18x18x1 450x450x25

12x12x1 300x300x25

pad is primarily recommended for acoustical rather than NK- 6x6x1 150x150x25 50 3.5

vibration problems when it is desirable to use a thick 4x4x1 100x100x25

economical pad. Standard materials are loaded 50 psi 3x3x1 75x75x25

3.5 kg/cm2. Pads are 1” 25mm thick and can be furnished 2x2x1 50x50x25

18”x 18” 450x450mm or cut to exact size in addition to the

tabulated sizes.

HL– Rubber Impregnated Duck Pads

Type “HL” pads are manufactured by impregnating layer on HL–

Rubber or Neoprene

layer of woven cotton duck with natural rubber or neoprene. Duck Pads

This process is carried on in a rubber press where the heat

Max.

and pressure produces an extremely tough final product that Thickness Load

is particularly suited to applications where alignment must be Type (in) (mm) (psi)(kg/cm2)

maintained. Typical applications are drop hammer anvil pads, 1/4 6

printing press column supports, bridge roadway bearing 3/8 10

pads, craneway supports, etc. Maximum loading is 1000 HL- 1/2 13 1000 70

psi 70 kg/cm2. Pads are always furnished cut to size in the 5/8 16

3/4 19

required thickness. The advantage of HL pads is consistent

loading per square inch cm2 unaffected by area as capacity is

dependent on the layers of cotton duck only.

Vibration Pads MP-440-1-1 MASON INDUSTRIES

W– Neoprene Waffle Pads

The Type “W” Neoprene Waffle Pad has greater carrying capacity

per square inch, increased holding power and a built in contamination

seal. Identical rubber grids are molded back to back for maximum

rubber contact area and resistance to rib collapse or hinging. The

interconnections form suction pockets for gripping smooth steel as well

as rough surfaces and also act as dirt and oil dams at the perimeter

regardless of how the pad is cut. The square waffle pattern is laid out on

1/2” 13mm centers to facilitate cutting pads to size in the field without the

need for measuring with a tape measure.

While there is no need for bolting or cementing on most installations, Type

“W” Adhesive may be used for securing machines that have exceptionally Waffle Pattern

large horizontal forces. The adhesive is also useful when the pad is made Top and Bottom

part of an assembly or shipped cemented to machinery legs.

Waffle Pad is stocked in both 40 and 50 durometer Neoprene. The high

tensile black stock has been selected for its oil resistance and physical

specifications. Natural Rubber, Hycar, Butyl, Silicone or other of the

Elastomers can be furnished for special conditions. Pricing would be

dependent on material and quantity. Standard pads are 5/16” 8mm thick

and may be purchased 24” x 48” 600 x 1200mm, 24” x 24” 600 x 600mm,

18” x 36” 450 x 900mm, 18” x 18” 450 x 450mm or cut to size. LOAD

lbs/ kg/ LOAD DEFLECTION

W pads are often used in 2 or 3 layers cemented to 16 gauge steel plates in2 cm2

CURVES 60 Duro

between layers to form SWW wall supports. Assemblies are normally 6’ 180 12.7

1.8m long and 6, 8, 10 or 12” 150, 200, 250 or 300mm wide to match wall 160 11.3

width. 50

140 9.8 Duro

SWW 120 8.4

Wall Isolators 100 7.0

40

Duro

80 5.6

TYPE W LOAD RATINGS 30

Brick 60 4.2 Duro

Ties Recommended Max.

Duro- Loading Load 40 2.8

meter (psi)(kg/cm2) (psi)(kg/cm2)

20 1.4

Two 30 40 2.8 55 3.8

16 gauge 5/16”8mm 40 60 4.2 85 6.0 0

Steel Waffle Pads 50 90 6.3 120 8.4 DEFLECTION– .01 .02 .03 .04 .05 .06 .07 .08

.25 .51 .76 1.02 1.27 1.52 1.78 2.03

60 120 8.4 170 12.0 INCHES

Avg Max.

MM Load Load

Ni– Nitrile Waffle Pads

Nitrile has the best oil resistance of all the natural and synthetic rubber materials. It is

superior to Neoprene and recommended for all locations where there is constant or

intermittent exposure to oil, grease or gasoline.

Mason type “Ni” Nitrile pads provide friction and avoid bolting as well as vibration

isolation under:

• Drill presses • Milling machines • Shears

• Lathes • Punch presses • And similar machines

May be used in multi layers separated by 16 gauge steel plates for greater efficiency.

Ni–

Nitrile Waffle Pads

Max.

Size Load Thickness Color

Type (in) (mm) (psi)(kg/cm2) (in)(mm) Code

18x18 450x450 50 3.5 5/16 8 Black

6x6 150x150 50 3.5 5/16 8 Black

18x18 450x450 100 7.0 5/16 8 Brown

Ni- 6x6

150x150 100 7.0 5/16 8 Brown

18x18 450x450 200

14.0 5/16 8 Blue

6x6 150x150 200

14.0 5/16 8 Blue

Waffle Pattern 18x18 450x450 280

19.7 1/2 13 Green

Top and Bottom 6x6 150x150 280

19.7 1/2 13 Green

3/14

Wu1403

You might also like

- The Rich Get Richer and The Poor Get PrisonDocument1 pageThe Rich Get Richer and The Poor Get PrisonGunasundaryChandramohanNo ratings yet

- MBrace Fibre PDFDocument4 pagesMBrace Fibre PDFFrancois-No ratings yet

- Forestry and Logging Tools CatalogDocument16 pagesForestry and Logging Tools Catalogbman0051401No ratings yet

- The Occult Origins of The Bank of EnglandDocument7 pagesThe Occult Origins of The Bank of EnglandMarbleManNo ratings yet

- African American InventorsDocument14 pagesAfrican American Inventorshandyhandline100% (2)

- MA-4 Carb ManualDocument34 pagesMA-4 Carb Manualayazkhan797100% (1)

- GSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsDocument12 pagesGSO-1909-2009-E - Requirements For Handling of Ready To Eat FoodsANSAR100% (1)

- Vibration PadDocument2 pagesVibration PadzampacaanasNo ratings yet

- Benchmark TileDocument2 pagesBenchmark TileCernomodiac NicolaeNo ratings yet

- Canon imagePROGRAF PRO-4100 ResultsDocument2 pagesCanon imagePROGRAF PRO-4100 ResultsLeckraj PursenoraNo ratings yet

- MBrace FibreDocument4 pagesMBrace FibreaahtagoNo ratings yet

- Catalogo Alsina Basics 2020 ENGDocument20 pagesCatalogo Alsina Basics 2020 ENGhiral.bluebellNo ratings yet

- Mbrace Fibre: Unidirectional Carbon Fibre Sheeting Glass and Aramid Sheeting Used With Resin Lay Up MethodDocument4 pagesMbrace Fibre: Unidirectional Carbon Fibre Sheeting Glass and Aramid Sheeting Used With Resin Lay Up MethodbudiNo ratings yet

- Bison Panel Cement Bonded Particle BoardDocument16 pagesBison Panel Cement Bonded Particle BoardafifkadriNo ratings yet

- Sikawrap®-900 C: Product Data SheetDocument4 pagesSikawrap®-900 C: Product Data SheetnovitaapriyaniNo ratings yet

- SikaWrap 231 C PDS PDFDocument4 pagesSikaWrap 231 C PDS PDFMohit KohliNo ratings yet

- DuFlex, Lightweight Composite PanelsDocument16 pagesDuFlex, Lightweight Composite PanelsDennys RamirezNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- Datenblatt Topline enDocument2 pagesDatenblatt Topline enL.kolekarNo ratings yet

- Compressed Product Brochure 1Document16 pagesCompressed Product Brochure 1Binha VargheseNo ratings yet

- Topspan 22 40Document6 pagesTopspan 22 40bradrimmNo ratings yet

- Tecstrip Flat & Flexible Phenolic Insulating Strip: Linda B - We Simplif y Const Ruc T IonDocument2 pagesTecstrip Flat & Flexible Phenolic Insulating Strip: Linda B - We Simplif y Const Ruc T IonThẩm Trần Thanh PhongNo ratings yet

- Plascore MarineDocument8 pagesPlascore MarineSaud MaulaviNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- Sikawrap - 300 C NW: Stitched, Carbon Fiber Fabric For Structural StrengtheningDocument4 pagesSikawrap - 300 C NW: Stitched, Carbon Fiber Fabric For Structural StrengtheningHenri DormoyNo ratings yet

- Spokane Ind WearParts SiTecDocument10 pagesSpokane Ind WearParts SiTecballesterosa545No ratings yet

- Sikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningDocument3 pagesSikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningBudhi KurniawanNo ratings yet

- Doka Birch Plywood Specs - 18 MMDocument2 pagesDoka Birch Plywood Specs - 18 MMAnupam GhoshNo ratings yet

- Double TeeDocument3 pagesDouble TeeAdil ImtiazNo ratings yet

- Submat BrochureDocument19 pagesSubmat BrochureReju Kumar NediyamNo ratings yet

- PDS Polyken 955 20 V1 Apr16 Aarps 0916Document2 pagesPDS Polyken 955 20 V1 Apr16 Aarps 0916JorgeNo ratings yet

- GratingDocument4 pagesGratingMauricio AdameNo ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CJhune UrabaNo ratings yet

- TSNZ Brochure March 2017Document24 pagesTSNZ Brochure March 2017arlene joy paredesNo ratings yet

- Sikawrap 300 CDocument5 pagesSikawrap 300 CAkram ShakirNo ratings yet

- FASARA Tech Data SheetDocument12 pagesFASARA Tech Data Sheetvlade naumovskiNo ratings yet

- Sveza Deck 350 BrochureDocument4 pagesSveza Deck 350 Brochureineboluu100% (1)

- GreenPro UltraTech Xtralite AACDocument4 pagesGreenPro UltraTech Xtralite AACmaazdixitNo ratings yet

- SikaWrap®-900 CDocument4 pagesSikaWrap®-900 CN.J. PatelNo ratings yet

- Frond Flexiform PDFDocument3 pagesFrond Flexiform PDFzenislerNo ratings yet

- Rubber Conveyor Belts ElevatorsDocument4 pagesRubber Conveyor Belts Elevatorsrido nofendriNo ratings yet

- Foam Types TermpaperDocument6 pagesFoam Types TermpaperRolaxNo ratings yet

- Interior Wall FinishesDocument16 pagesInterior Wall FinishesPriyesh Dubey100% (1)

- MArket Survey GRP 10Document9 pagesMArket Survey GRP 10shraddhaNo ratings yet

- Michelin X Tweel Airless Radial Tire BrochureDocument8 pagesMichelin X Tweel Airless Radial Tire BrochureArup DeyNo ratings yet

- Sunku Eco Friendly InorganicDocument8 pagesSunku Eco Friendly InorganicchauhannishargNo ratings yet

- SikaWrap 600C PDSDocument4 pagesSikaWrap 600C PDSFranco VasquezNo ratings yet

- RhinoboardDocument16 pagesRhinoboardraditanka aobakweNo ratings yet

- PDS Ultrablade DFE Extreme 42 0417Document2 pagesPDS Ultrablade DFE Extreme 42 0417Turfscape TurfscapeNo ratings yet

- ORI - Maxx AromourDocument4 pagesORI - Maxx Aromourjose castilloNo ratings yet

- Elephant Gypsum Boards Specification - Moistbloc BoardDocument1 pageElephant Gypsum Boards Specification - Moistbloc BoardDilon Fernando0% (1)

- Lysaght Trimdek: Subtle Square Fluted Steel CladdingDocument6 pagesLysaght Trimdek: Subtle Square Fluted Steel Claddingfahim007No ratings yet

- Conveyor BeltDocument54 pagesConveyor BeltDhruv PanchalNo ratings yet

- Processing of Sandwich Structures: by Dr. Laraib Alam KhanDocument25 pagesProcessing of Sandwich Structures: by Dr. Laraib Alam KhanMuhammad TanveerNo ratings yet

- Rsi 2018Document2 pagesRsi 2018Bruno SantosNo ratings yet

- Sikawrap - 301 CDocument4 pagesSikawrap - 301 Cemiliani kristinaNo ratings yet

- Crane Rail Pads MK2Document2 pagesCrane Rail Pads MK2Mukty BaktiarNo ratings yet

- MGM Presentation Gurpreet Singh FlyashDocument15 pagesMGM Presentation Gurpreet Singh FlyashBalaji RathinavelNo ratings yet

- SawmillDunl 20240226062549.993 XDocument1 pageSawmillDunl 20240226062549.993 XRedaNo ratings yet

- HangerDocument8 pagesHangerbnreddy1992No ratings yet

- BISON PANEL Product GuideDocument24 pagesBISON PANEL Product Guideg_periwal_pune9635No ratings yet

- Armstrong Classic LiteDocument2 pagesArmstrong Classic LiteSinar MichaelNo ratings yet

- ThickSlick Tech SheetDocument1 pageThickSlick Tech SheetWalter GardnerNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- Bauer 1997 Plastic Modulus AiscDocument4 pagesBauer 1997 Plastic Modulus Aiscbman0051401No ratings yet

- AB-024 - Introductory Gear EquationsDocument6 pagesAB-024 - Introductory Gear Equationsbman0051401No ratings yet

- Absolute Temperature and ConversionsDocument1 pageAbsolute Temperature and Conversionsbman0051401No ratings yet

- Tire Survey Results HPDocument2 pagesTire Survey Results HPbman0051401No ratings yet

- Wbi & WBD: Mason Industries, IncDocument2 pagesWbi & WBD: Mason Industries, Incbman0051401No ratings yet

- Kelvin ScaleDocument10 pagesKelvin Scalebman0051401No ratings yet

- Seismic Sway Brace SystemDocument4 pagesSeismic Sway Brace Systembman0051401No ratings yet

- Format Text As Superscript or Subscript - Office SupportDocument4 pagesFormat Text As Superscript or Subscript - Office Supportbman0051401No ratings yet

- Pipe Data: Mason Industries, IncDocument2 pagesPipe Data: Mason Industries, Incbman0051401No ratings yet

- Mason-Mercer: Test Data Stainless Steel & Bronze VeesDocument8 pagesMason-Mercer: Test Data Stainless Steel & Bronze Veesbman0051401No ratings yet

- Mason-Mercer: Stock Ball JointsDocument4 pagesMason-Mercer: Stock Ball Jointsbman0051401No ratings yet

- Directly Proportional and Inversely ProportionalDocument5 pagesDirectly Proportional and Inversely Proportionalbman0051401No ratings yet

- ss-28-4 WebDocument4 pagesss-28-4 Webbman0051401No ratings yet

- Mason Industries, Inc.: Full Vacuum Rating - 30" HGDocument1 pageMason Industries, Inc.: Full Vacuum Rating - 30" HGbman0051401No ratings yet

- Ancra - Catalog 214-EDocument12 pagesAncra - Catalog 214-Ebman0051401No ratings yet

- Supporting Shallow Foundation Systems When Subjected To Lateral LoadsDocument12 pagesSupporting Shallow Foundation Systems When Subjected To Lateral Loadsbman0051401No ratings yet

- Shape Factor & Modulus of Elasticity Urethane RubberDocument6 pagesShape Factor & Modulus of Elasticity Urethane Rubberbman0051401No ratings yet

- EPDM Properties Unreinforced General Information Designation Ethylene - Course HeroDocument2 pagesEPDM Properties Unreinforced General Information Designation Ethylene - Course Herobman0051401No ratings yet

- Dixie Ratchet Turnbuckles: When You Need The BestDocument6 pagesDixie Ratchet Turnbuckles: When You Need The Bestbman0051401No ratings yet

- Lift-It Round Sling CoversDocument2 pagesLift-It Round Sling Coversbman0051401No ratings yet

- Forged Steel Structural Hardware SINCE 1864Document20 pagesForged Steel Structural Hardware SINCE 1864bman0051401No ratings yet

- GripperSlings WEBDocument8 pagesGripperSlings WEBbman0051401No ratings yet

- INF Update Utility - For Intel x79 ChipsetDocument2 pagesINF Update Utility - For Intel x79 Chipsetbman0051401No ratings yet

- Round Sling Endless Specifications: (Choker/Vertical) (Basket) (Bearing To Bearing)Document1 pageRound Sling Endless Specifications: (Choker/Vertical) (Basket) (Bearing To Bearing)bman0051401No ratings yet

- Warning: Company Profile Disclaimer of Warranties and Limitation of LiabilityDocument10 pagesWarning: Company Profile Disclaimer of Warranties and Limitation of Liabilitybman0051401No ratings yet

- Types of Business WritingDocument103 pagesTypes of Business WritingJoe San JuanNo ratings yet

- EMDocument41 pagesEMle.nhu.quynh.lqdNo ratings yet

- 3600 M Service Manual PDFDocument102 pages3600 M Service Manual PDFudthanhson100% (1)

- DLP TLE Grade7 Carpentry 5S JH 012319Document1 pageDLP TLE Grade7 Carpentry 5S JH 012319Jonathan Magtibay HusainNo ratings yet

- New Challenges 3 Kl.8 3rd PeriodDocument4 pagesNew Challenges 3 Kl.8 3rd Period5sn7rp7xssNo ratings yet

- How To Uncompress and List An Initramfs Content On LinuxDocument10 pagesHow To Uncompress and List An Initramfs Content On Linuxvpalmar8871No ratings yet

- EBTax Tax Simulator Webcast 16 Jul 14pdfDocument49 pagesEBTax Tax Simulator Webcast 16 Jul 14pdfM.MedinaNo ratings yet

- The Anatomy and Physiology of The HorseDocument383 pagesThe Anatomy and Physiology of The HorseserjutoNo ratings yet

- Identifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahDocument12 pagesIdentifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahMawarniwati Waruwu Undiksha 2019No ratings yet

- Lva1 App6892Document146 pagesLva1 App6892Adam Shahabuddin Abdul RazakNo ratings yet

- BC23000122Document1 pageBC23000122azharNo ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet

- Phu Kien Khuon Song Ngu - 20190921Document3 pagesPhu Kien Khuon Song Ngu - 20190921Loc NguyenNo ratings yet

- JPM Mexico Equity Strategy 2022-08-18 4136815Document28 pagesJPM Mexico Equity Strategy 2022-08-18 4136815Pedro K. LatapíNo ratings yet

- Distortion in Music ProductionDocument306 pagesDistortion in Music ProductionjansolostarNo ratings yet

- Reinterpretation of Jesus in John's GospelDocument3 pagesReinterpretation of Jesus in John's GospelJaison Kaduvakuzhiyil VargheseNo ratings yet

- The Position of The Bioeconomy in The NetherlandsDocument8 pagesThe Position of The Bioeconomy in The NetherlandsMaryam AsdNo ratings yet

- Chapter-I Elections of 1936-37 and Muslim LeagueDocument63 pagesChapter-I Elections of 1936-37 and Muslim LeagueAdeel AliNo ratings yet

- Flexible Assessment Activities and Flexible Learning StrategiesDocument5 pagesFlexible Assessment Activities and Flexible Learning StrategiesAisa EdzaNo ratings yet

- Improving Machine Translation With Conditional Sequence Generative Adversarial NetsDocument10 pagesImproving Machine Translation With Conditional Sequence Generative Adversarial Netsmihai ilieNo ratings yet

- Calculating The Temperature RiseDocument8 pagesCalculating The Temperature Risesiva anandNo ratings yet

- 1COR22 - New in Christ - Notes PDFDocument2 pages1COR22 - New in Christ - Notes PDFeliastemer6528No ratings yet

- Cono Rc-45-Ii, Serie 52378Document50 pagesCono Rc-45-Ii, Serie 52378omar muñoz100% (1)

- National Open University of Nigeria: Wallet Payment StatusDocument4 pagesNational Open University of Nigeria: Wallet Payment Statusokoro collinsNo ratings yet

- Garden Seed Handbook Part 31Document5 pagesGarden Seed Handbook Part 31gezarolNo ratings yet