Professional Documents

Culture Documents

Customer Complaint Register

Customer Complaint Register

Uploaded by

Karthik MadhuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Complaint Register

Customer Complaint Register

Uploaded by

Karthik MadhuCopyright:

Available Formats

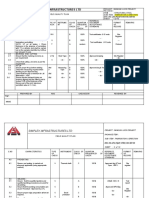

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.

2017

CUSTOMER COMPLAINT REGISTER

Sr. No. Customer Name DATE PART NO. PART ISSUE REPORT MODE OF DEFECT DESCRIPTION REJECTION ROOT CAUSE ICA PCA Attachment

DESCRIPTION BY COMMUNICATION QTY

1. trolley for proper handling of parts .

2. Leak ok Identification mark to be provided for avoid

skipping from leak testing .

Shell Vacume Due to hitting heavily from handling also skipped from leak 1. All available stocks in customer end 24 nos checked 3. 100% inspection carried out by the final PDI and

1 Ashok Leyland 17.09.2019 471112VE1A tank Kumar mail Vacum tank tube puncher 1 testing process because of not providing identification mark 0 defect found identification mark will be provided. Leyland\Sep 2019\1.JDI -Vaccum tank tube Puncher.pptx

for leak ok parts. 2. in inhouse total 18 nos checked 0 defect 4. Checkspoint will be added in the checksheet .

Flange stud M6x14 & M6x20 is chance to mixup in supplier Fuel tank mtg brkt stud length 100% inspection carriout by

90ltr Tank Assy 90ltr fuel tank stud length end, So all the current stock studs are checked & verified, All available parts in customer end 100 stock , 0 defects supplier end with commitment mark (All the flange stud in

2 Ashok Leyland 17.09.2019 172022VE1A -Fuel Kumar Mail short 1 and 100% visual inspection carried out with marking after and in-house 300 stock available checked 0 defects, stock checked ok on supplier end) Leyland\Sep 2019\2.JDI 90 ltr fuel tank flange height short.

the assembly 100% visual inspection done by PDI inspector with

commitment mark on tank assembly

Due to using chisel for removing weld spatters on neck

welding process and also unawarness of operator about All available stocks in customer end 60 nos checked 2 Part identification provided on FG storage trolley of SWC Dost

Dost fuel tank near neck that dent mark occuring due to using chisel for removing & Dost+

3 Ashok Leyland 13.09.2019 172022VA1A Dost Fuel Tank Kumar Mail 2 spatters , Awarness given to operator about that dent mark defect found and in inhouse total 120 nos checked 0 100% visual inspection will be carried out by PDI, with date Leyland\Sep 2019\3.JDI -Tank near neck area dent.pptx

area dent and shielding provided on neck area for avoiding spatters defect found. and intiial on sticker

on neck area.

Improper butting due to gudie pin less now guide pin

increased and butting place will be changed to slot position 1.In press shop 100% checked and self certified.

90 lt mtg bkt cotter pin All available parts in customer end 60 stock , 0 defects 2.100% visual inspection will be carried out by PDI, with date

4 Ashok Leyland 24.09.2019 174212VE0D 90 lt mtg bkt Kumar Whatsapp group taper entry 1 and in-house 75 stock available checked 0 defects and intial on it.

Leyland\Sep 2019\5.JDI 90 lt mtg bkt cotter pin taper issue.p

New end seaming MFDC used instead of AC end seaming.

1.100 % leak/seepage testing will be carried out in process

90 lt Tank End seam machine controller probolem , seepage not All available parts in customer end 6 stock , 0 defects and PDI. with soap water test alos.

5 Ashok Leyland 17.10.2019 172022VE1A assy fuel Kumar Whatsapp group fuel seeapge 1 detected in leak testing. and in-house 8 stock available checked 0 defects, 2. Leak testing will be carried out with 0.5 bar.instead of 0.3 Leyland\oct 2019\1.JDI fuel seepage 90lt tank.pptx

bar.

To provided the lcating pin on 90ltr piercing tool, so there is

90 ltr mtg brkt piercing hole shifted due to no locating pin no chnages to wrong piercing on mtg brkt

fuel tank support on piercing tool,To provided the lcating pin on 90ltr All available parts in customer end 25 stock , 0 defects

6 Ashok Leyland 17.10.2019 1742212VE0D Brkt(90 lt mtg Kumar Whatsapp group mtg hole shifted due to 1 piercing tool, so there is no chnages to wrong piercing on and in-house 40 stock available checked 0 defects, 1.To provided new checking gauge to PDI inspector, So easily Leyland\oct 2019\2.JDI 90 lt mtrg bkt 6 hole piercing shifted

improper loading find out the hole offset on mt brkt

bkt) mtg brk 2.100% gauge inspection done by PDI inspector with mark

To be maintained SWC width is within minimum tolerance

only

WC cotter pin not entery due to SWC width in max 1. 100 % cotter pin width insepection done at final checking

All available parts in customer end 36 nos stock , 0

7 Ashok Leyland 18/11/19 572102VA0A SWC assembly Kumar Whatsapp group SWC assembly Cotter pin 1 tolerance values from spec value , So we maintained only defects and in-house 45 nos stock available checked 0 gauge on inprocess operator. Leyland\Nov 2019\2.SWC - COTTER PIN ENTRY TAPER.pptx

not entery minimum tolerance spec value defects, 2. 100% cotter pin width Inspection carried out by PDI

Inspector with commitment mark

Width taperness will be reduced.

Welding fixture modified to avoid the tire fix brkt slot under

size ( Pin type to Slot profile type will be modified)

SWC-Tire fix brkt Tire fix brkt slot size is less at mouth area due to handling All available parts in customer end 52 stock , 0 defects 1.100 % inspection carried out on PDI inspector by using T-bolt Leyland\Nov 2019\3.SWC - T BOLT NOT ENTRY.pptx

8 Ashok Leyland 20/11/19 572102VA0A Kumar Whatsapp group Tire fix brkt slot size less 1 damages , So slot type of checking is introduce in final and in-house 80 stock available checked 0 defects, inspection & do comitment mark..

inspection gauge (wedling shop) 2.Punch size will be corrected in tool Target date to complete

15/12/19.

New fixture using on hose cutting & neck collar werlding

operation to avoid the tapper cutting & inclined of neck now

All available parts in customer end 30 checked 0 defect, corrected in supplier end(ref supplier 8D report

9 Ashok Leyland 20/11/19 1702022VE0B 90Ltr Fuel tank Kumar Whatsapp group 90ltr Neck assy inclined 1 Olld part mixed up (ICA not effectively done) ,and in-house 24 stock available checked 0 defects 100% given welding fixture used no taper will be occur ref

Leyland\Nov 2019\4.90LTR P - NECK INCLINED.pptx

attached welding jig.

100% inspection done with given gauge ensure the 90deg.

SWC Assy - Height After tube bending , tube spring back issue, height variation After tube bending revising process added before welding, to

Carr. assy , inclinded All available parts in customer end 20 stock , 0 defects

10 Ashok Leyland 4/12/2019 572102VA0A sparewheel - Sankaran Whatsapp group variation/inclined 1 and in-house 25 stock available checked 0 defects arrest the spring back.100% visual inspection before welding , Leyland\Dec 2019\2.SWC IFS - HEIGHT VARIATION.pptx

seating of the tube, no up down movement.

Bull bar mtg brkt with After Spatter removal no self certiifying not done / near All available parts in customer end 40 checked 0 Awareness given to operator to ensure the free from spatter

11 Ashok Leyland 9/12/2019 620642VA0A Bull Bar Assy Thirumal Whatsapp group spatter near slot area 1 bracket area/ spatter not cleaed fully near slot area defect, ,and in-house 30 stock available checked 0 and selff certifying after spatter removal by the opertor. Leyland\Dec 2019\3.BULLBAR - RECT PLATE SPATTER.pptx

defects 1.100% ensure in welding line as well as final PDI.

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

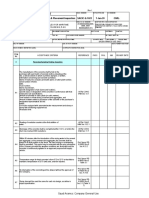

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

able mtg brkt flange tip forming tool implemented to avoid

Cable mtg brkt flange tip offset due to improper folding of the improper folding of tip forming

To endure the 100% cable mtg brkt flange tip forming at 90°

LHD cable mtg LHD cable mtg brkt flange flange tip, in final forming tool unable to fold the tip at 90° ICA: All available parts in customer end 36 checked 0 by PDI inspector

12 Ashok Leyland 07.02.2020 344482VEOB Sankaran Whatsapp group 8 so flange tip forming tool is implemented to avoid the defect, ,and in-house 50 stock available checked 0 Leyland\feb 2020\1.JDI LHD cable mtg brkt flange not locate

bkt tip offset improper folding & offset issues defects In blank tool 2.0mm reducedflange tip height. . TDC-

10.2.2020

Training given to the welder and displayed one point lesson

Profile variation (wrong welding) occured due to welder and VCS on tack welding stage.

Carr. assy made it in offline already poke-yoke available in fixture. Our end sub assy stock 300 nos. checked and found 0

13 Ashok Leyland 13/6/2020 572102VA0A sparewheel - Thirumal Whatsapp group SWC - Profile variation 1 defects and in FG 70 nos. checked and found 0 defects. Instructions given to PDI inspectors to ensure the bottom side Leyland\jun 2020\2.JDI -SWC - Profile variation - holder wro

Dost Holder wrongly welded Porper training given to welder and one point lesson also provided with commitment mark.

displayed in the stage.

1. Holding clamp provided in tack welding fixture to arrest the

Small tube height variation occured due to there is no height variation.

clamp provided in tack welding fixture , clamp provided and All available parts our end checked 350 nos and found 0 Now Dim arraived - 44.5±1.0.mm

Pipe rad. lwr - BS6 radiator pipe small issue is arrested. defects. 2. Awareness given to our PDI inspectors and VCS displayed in

14 Ashok Leyland 23/6/2020 215372VA0B BS6 Sankaran Whatsapp group tube height variation and 59 For welding defects proper training given to PDI inspectors, In supplier end 500 nos. checked and found 2 inspection area, 100% inspection will be carried out Leyland\jun 2020\1.JDI-Radiator small tube height variation

welding defects welders and rework person. defects. /ht viariation effectively.

3. Awareness given to welder and rework person in supplier

end.

Radiator pipe stopoper distance variation from 2 to 5 mm

because of radiator pipe length variation found at bending Stopper provided on both side of pipe locating area on

Pipe rad. lwr - Radiator pipe stopper stage, so same dimension reflect on stopper distence. So Customer end & inhouse stock all are checked & defect stopper welding fixture to avoid excess length of pipe not

15 Ashok Leyland 14.7.2020 215372VA0B BS6 Sankaran Whatsapp group distance variation (part to 36 stopper provided on radiator pipe both side on welding parts are cleared seated on fixture & also stopper welding distance not varied

Leyland\July,2020\1.BS6 Radiator pipe stopper dist variation

part) fixture to arrest the stopper distance variation Pipe length variation avoided on

Bin System Implemented.

part identifaction not followed effectively as of this spot All available FG and child parts in our end 120 nos After spot welding identification mark to be done and moved

16 Ashok Leyland 04.09.2020 FHV00913 Stap -Fuel Tank Sankaran Whatsapp group Spot welding Not Done 1 weld missed parts mixed and passed to next stage same checked found zero defects to next process. Leyland\Aug 2020\JDI Spot welding miss12.9.20.pptx

100% visual inspection not followed efeectively. At the time of dispatch 100% visual inspection done and

identfication mark provide on the surface.

Center brkt piercing die , part placed improper butting with

All available FG and child parts in our end 200 nos operator and -Completed. • at D&S combination locating pin

17 Ashok Leyland 21-Sep-20 130482VA2A PIPE ASSY COMP Thirumal Whatsapp group Hole offset 1 locating guide pins. analysed that part gravitationally down, checked found zero defects. • sub -suplier end stock provided in welding fixture so that opertator can use two pin Leyland\Aug 2020\JDI CCB hole offset updated.pdf

if part not hold by manual.. • working level training is not found zero at a time to avoid use of single pin.

effective

at the time sample drawn in heating condtion in process, checking guge provide on both supplier & in-house.

which resulted shrinkage happen inbetwen time same not process awarness to given at supplier end same inhouse

ensured at supplier end 100% insepection not followed All available FG and child parts in our end 200 nos inspection awarness given.

18 Ashok Leyland 29-Sep-20 172442VE1B INSUL-FUEL TANK Sankaran Whatsapp group Rubber width Variation 3 effectively. checked found zero defects At the time of dispatch 100% Guage & visual inspection done

Leyland\Aug 2020\JDI Insul Rubber Strap Width Undersize.p

At DS PDI visual inspection not effective. and identfication mark provide.

LOCK PLATEFUEL Fuel tank Mounting lock

19 Ashok Leyland 29-Sep-20 FME00513 TANK AND Sankaran Whatsapp group plate powder coating peel 1

MOUNT off.

20 Ashok Leyland 21-Sep-20 572102VA0B CARR ASSY - Sankaran Whatsapp group SWC Open out 1

SPARE WHEEL

CARR ASSY - Weld Broken due to

23 Ashok Leyland 12.10.2020 572102VA0B SPARE WHEEL Sankaran Whatsapp group blowhole 1

22 Ashok Leyland 15.10.2020 130482VA2A PIPE ASSY COMP Sankaran Whatsapp group Bolt inclined entry due to 1

inclined retap done

Fender fouling due to Brkt

21 Ashok Leyland 16.10.2020 638552VE1A BRkt Assy-FR FDR Sankaran Whatsapp group profile varation 1

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

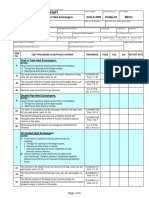

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

25 Ashok Leyland 16-Nov-20 215372VA0B PIPE RAD LWR Sankaran Whatsapp group tube line mark/crack 1

26 Ashok Leyland 28-Nov-20 172022VA1A TANK ASSY - FUEL Sankaran Whatsapp group BOLT NOT ENTER, STUD 3

BROKEN

27 Ashok Leyland 28-Nov-20 172022VE1A TANK ASSY FUEL Sankaran Whatsapp group HEAVY BURR 1

Ashok Leyland 28-Nov-20 180202VE1A Brkt Accl Mntg Sankaran Whatsapp group WELD NUT MISS 1

Ashok Leyland

Ashok Leyland

Ashok Leyland

Ashok Leyland

Ashok Leyland

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

CUSTOMER COMPLAINT REGISTER

Sr. No. Customer Name DATE PART NO. PART DESCRIPTION ISSUE MODE OF DEFECT DESCRIPTION REJECTIO ROOT CAUSE ICA PCA

REPORT BY COMMUNICATION N QTY

Tank less contact area this tends to tank

elongate /bulge near seam welding operation, Custromer End stock Check 20parts fround 8 Operator awareness given, Shell cut to length will

1 DICV- India 04.09.2019 A4004704901 ZB FULE TANK/265D Vignesh Mail Bump observed near 8 which cause bump (tank seating area improved part Not Ok, inhouse 10 part checked found be more/Diagonal wise varition in shell length,Tank DICV\Sep 2019\Problem Solvin

edge seam welding seating improved in sequence change of seam

when we change the sequence of seam welding ok welding

refer- ppt before/after)

Operator awareness given. (for cleaning with 3 in 1

Custromer End stock Check 10parts fround 3 solution & cleaned with cotten duster, fixed skilled

2 DICV- India 09.10.2019 A4004702501 ZB FULE TANK/330D Vignesh Mail Paint peel off issue during 1 There is no sequence of cleaning /WI not provided. part Not Ok, inhouse 20 part checked found operator. DICV\Oct 2019\8D neck area p

product audit. ok Painting gun will be used instead of spray during

paint touch up (color matched)

Custromer End stock Check 16 parts fround 4

4 DICV- India 07.12.2019 A4004703801 ZB FULE TANK/380lt Vignesh Mail Fuel tank edge bend/ 4 No proper handling system provided from one part Not Ok, inhouse 18 part checked found Tank Handling method to be changed instead of DICV\Dec 2019\2. 8D analysis

edge paint scratches place to one place ok manual handling now provided the troely

5 DICV- India 27.01.2020 A4004700801 ZB Fuel Tank/200L Vignesh Whatsapp group 2

Improper torque applied Inadequate checking method ,Final inspection Now Leak testing pressue increased 0.4 to 0.55 bar

in drain bolt due skipped,Seepage was unable to detect due to less Custromer End stock Check 25parts fround 4 and esure with soap water test twice. DICV\Jan 2020\Seepage issue

6 DICV- India 27.01.2020 A4004700601 ZB Fuel Tank/160L Vignesh Whatsapp group 1 part Not Ok

Drainplug seepage duration

ZB Fuel

7 DICV- India 27.01.2020 A4004701701 Tank/200L/Circular Vignesh Whatsapp group 1

1. Shell drawing has been revised.

25nos Checked at inhosue found ok.

8 DICV- India 20.02.2020 A4004707001 ZB Fuel tank/200L/BS6 Vignesh Whatsapp group Neck orientation shifted 2 Neck hole piercing is wrong in shell & neck welding @ customer End 20 nos checked found 18nos 2. Neck welding fixture has been modified and DICV\Feb 2020\8D analysis Pro

Rv10 fixture is improper (holding). rejection improved the holding.

3. Checking gauge is provided in process to ensure.

ZB Fuel tank/200L/BS6

9 DICV- India 10.03.2020 A4004707001 Vignesh Whatsapp group Neck orientation shifted 16 Feb20 month rejection accounted at March'20 by customer , Reference Feb Attchement

Rv10

DICV Stock Check 18 nos found 1 nos NC Sandaring the GA coating over the shell jioning area

10 DICV- India 21.7.2020 A4004700801 ZB Fuel Tank Vignesh Whatsapp group Fuel seepage from end 1 Material outer GA coating affect the weld quality / @ D&S Stock checked 28 nos found Zero & endcover area of GA tank before the shell joining DICV\JUly 2020\0801 - End sea

seam welding Changes to Operator poor vision

Defect process to increase the weldability of GA tanks

Locations will be defined for all baffle inserting

gauges - model wise, colour coding will be given for

easy identification

Fuel tank 200ltr Self certified skipped from this stage, no detection DICV Stock Check 22 nos found 1 nos NC Detection method will be implemented in next

11 DICV- India 01.08.2020 A4004708601 Vignesh Whatsapp group Baffle offset - 70mm 1 @ D&S Stock checked 34 nos found Zero DICV\Aug 2020\2.8D report Ba

circular method in other stages. Defect stage (baffle spotting)

Matchiing part given in process to check and

ensure the parts before moving to PC

DICV Stock Check 20 nos found 1 nos NC Check point added in process.

12 DICV- India 10.08.2020 A4004705601 ZB FULE TANK Vignesh Whatsapp group flange hole offset 1 The process is not effective @ D&S Stock checked 8 nos found Zero DICV\Aug 2020\3.8D analysis P

Defect

fuel tank drain plug DICV Stock Check 16 nos found 2nos NC Job setup done on the smal sample cutpice instated of DICV\Aug 2020\1. 0801 drain

13 DICV- India 27.08.2020 A4004708401 ZB FUEL TANK Vignesh Whatsapp group welding/Pin hole welding 2 Job setup rework traning not effetive.

@ D&S Stock checked 17nos found Zero Defect tanks.

rework issue

Forming tool not re-polyished due to this crack Tool history card to be updated & Tool Re-polyishing to

DICV Stock Check 15 nos found 1nos NC

DICV- India 28.10.2020 A4004707001 ZB FUEL TANK Vignesh Whatsapp group Hose Bracket teared 1 generated while forming opertion same not ensured in @ D&S Stock checked 12nos found Zero Defect be done

PDI . Working level Awarness taning to given PDI inspectore

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

41

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

DICV\Oct 2019\1.1 Work Instruction for 3 in 1 solution.pptx

DICV\Dec 2019\2.1 edge bend & edge paint scratches.pptx

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

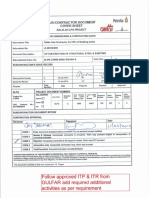

CUSTOMER COMPLAINT REGISTER

Sr. Customer MODE OF REJECTIO

DATE PART NO. PART DESCRIPTION ISSUE REPORT BY COMMUNICATION DEFECT DESCRIPTION ROOT CAUSE ICA PCA

No. Name N QTY

Isuzu Motors

1 6.9.2019 8974461061 Neck Saravanan Mail Fuel neck rust 1 Inside Painting not done Commerical issue- Mail Communication

India Pvt Ltd

Water contamination inside fuel tank due ICA-1:- Customer end stock checked 125nos + yard 1.After breather tube full welding self certified with tick mark. (Refer PPT)

to improper weld in breather pipe vehicle around 959 with VIN no details given to 2. Leak testing before and after powder coating commitment paint mark

customer, 0 nos defects observed. provided near breather tube after powder coating paint commitment mark

ICA - 2:- In D&S Stock - 92 nos checked provided. (Refer PPT)

Isuzu Motors zero defiects found. 3.In final PDI commitment provided every co2 welding area - full round

2 20.11.2019 8974497242 TANK ASM;FUEL,FO Saravanan Veribal Breather hose pipe welding miss 1 checked two lines on every co2 tube welding area. (Refer PPT) Izusu\2 .IMI PPRC 19-494 c

India Pvt Ltd

Suction tube was blocked due to dust

particles / mud found inside the tube.( see

pics below)

Isuzu Motors Small forign particle passed out from mesh Checked all hoses at Customer End and In house also. Introduced new size of mesh , whose cross section area is so less instead of Izusu\3.IMI PPRC 19-495 Br

3 22.11.2019 8974461072 NECK -Yacha Saravanan Veribal Hole on hose 1

India Pvt Ltd during to cover operation at supplier end old mesh, So small particle also filter easily.

Improper zinc coating due to touch up

Customer end stock checked 70 nos , 1 nos defects

paint peel off . Current stocks materials are replating done

Touch up paint not adhesion to plating observed. 2. Minimum qty of parts plating materials to be stocked

Isuzu Motors ICA - 2:- In D&S Stock In final PDI area checked -

4 25/02/2020 8974461061 Neck -Crew Saravanan Mail Improper Zinc Coating in fuel neck 15 Touchup done due to plating shade not 3.If plating shade miss match replating to be done ( paint Touch up process Izusu\4.IMPROPER Zn COAT

India Pvt Ltd 105 nos OK, defect part-Zero

proper deleted)

ICA- 3:-In supplier end all the parts checked no defect 4.PDI 100 % self Inspection done before dispatch

found

ICA-1:- Customer end stock checked 35 nos , 1 nos 1. supplier end fallen part in plating tank to be checked visuall as any

defects observed.

Vehicle not getting start due to fuel forgine material presence.supplier rework procedure

Isuzu Motors ICA - 2:- In D&S Stock In final PDI area checked -

5 07.09.2020 8974497243 Tank Asm Fuel Saravanan Mail flow not in available from fuel tank 1 Izusu\5.IMI PPRC 20-068 (1

India Pvt Ltd 65nos OK, defect part-Zero

delivery hose 2. Before float unit assembly tube to be checked with air passing. (ensure

ICA- 3:-In supplier end all the parts checked no defect

free from foreign particles inside)

found

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd Seems there was more

dust particles present inside the fuel

tank ,during plating part fallen in platining

tank and dust accumulated and dried .

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Isuzu Motors

India Pvt Ltd

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

DALI AND SAMIR ENGG. PVT. LTD. Format No.:FM / QA / 23, Rev No., Date : 01, 01.06.2017

Izusu\2.ISUZU - ACTION PLAN -co2 welding missing.pptx

Izusu\3.1 Countmeasure for Hole in Hose.pptx

Prepared By: Tatyaba Handal Approved By : Alkesh Chambhare

You might also like

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky50% (2)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- 3 - Hdpe - Itp Pipe WeldingDocument2 pages3 - Hdpe - Itp Pipe Weldingasif712100% (6)

- CAPE 2015 - Suggested AnswersDocument16 pagesCAPE 2015 - Suggested Answerssoumya12355% (11)

- SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingDocument2 pagesSACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingShohrab JiNo ratings yet

- Afic M 001Document2 pagesAfic M 001Basir AhmadNo ratings yet

- Engineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020Document2 pagesEngineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020dada khalandarNo ratings yet

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- QAP - Rubber liningBORLDocument1 pageQAP - Rubber liningBORLdada shaikNo ratings yet

- Hydrostatic Test Procedure For Fire Water TankDocument15 pagesHydrostatic Test Procedure For Fire Water TankMohamedNo ratings yet

- SFQP-MECH With NDT-SILO-2Document8 pagesSFQP-MECH With NDT-SILO-2Dhananjay BalkiNo ratings yet

- Mehak Industries: Quality Assurance Plan For Logitudinal/Circumferential Welded M.S. PipeDocument1 pageMehak Industries: Quality Assurance Plan For Logitudinal/Circumferential Welded M.S. PipeSadiq ShakilNo ratings yet

- BST Gen Cns Mos Aip 10003 10002 00 Pin BrazingDocument67 pagesBST Gen Cns Mos Aip 10003 10002 00 Pin BrazingRao DharmaNo ratings yet

- Certificate TPI HIAB 8597 RK Feb22 AbrajDocument2 pagesCertificate TPI HIAB 8597 RK Feb22 AbrajSavad TSNo ratings yet

- Fullreport Ci Bulk Carrier 09102016 09102016Document44 pagesFullreport Ci Bulk Carrier 09102016 09102016Diana MoralesNo ratings yet

- Caliper Pigging Specification of Mecon .2020 - Rev C.Borhan-458-467Document10 pagesCaliper Pigging Specification of Mecon .2020 - Rev C.Borhan-458-467Md. BorhanNo ratings yet

- Nit 2800 3 PDFDocument7 pagesNit 2800 3 PDFAnonymous uXdS9Y7No ratings yet

- QM C 7.1 Ab 0001 LDocument3 pagesQM C 7.1 Ab 0001 LalokrajamanNo ratings yet

- Certificate SupercitoDocument1 pageCertificate Supercitojrrd4191No ratings yet

- Sil FQP - STRUDocument19 pagesSil FQP - STRUPrasanta ParidaNo ratings yet

- SACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Document2 pagesSACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Muhammad AbrarNo ratings yet

- Pipes Backfilling Release Check List 2inch Air LineDocument1 pagePipes Backfilling Release Check List 2inch Air LineAnwar QaisNo ratings yet

- SACIC-Q-1022 Rev.01 Precast Concrete Sampling, Testing & Placement InspectionDocument4 pagesSACIC-Q-1022 Rev.01 Precast Concrete Sampling, Testing & Placement InspectionMuhammad AbrarNo ratings yet

- 1.lifeboat 5 Yearly Cert 2022Document6 pages1.lifeboat 5 Yearly Cert 2022Lim LikweeNo ratings yet

- SACIC-CV-0005 Rev.04 Packer TestsDocument2 pagesSACIC-CV-0005 Rev.04 Packer TestsEr Nizamuddin AliNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Op2 Rev 6Document12 pagesOp2 Rev 6AmirSyafiqNo ratings yet

- QAP For FlangesDocument2 pagesQAP For FlangesGOPINATH KRISHNAN NAIRNo ratings yet

- 50H EngineDocument3 pages50H EngineAmirSyafiqNo ratings yet

- Concreting Inspection FormDocument2 pagesConcreting Inspection FormralphNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- Strip Check - EIL - TQ PDFDocument2 pagesStrip Check - EIL - TQ PDFpl_arunachalam79No ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Ragab EisaNo ratings yet

- Pipeline Stalk Fabrication Plan For Wp2: Etame Expansion Project Offshore Installation 12022Document25 pagesPipeline Stalk Fabrication Plan For Wp2: Etame Expansion Project Offshore Installation 12022William O OkolotuNo ratings yet

- Part A Report Gas LPG Sample - Compressed 1Document26 pagesPart A Report Gas LPG Sample - Compressed 1Joel Jeffery SarkarNo ratings yet

- CHL-0714 60181509Document1 pageCHL-0714 60181509Femi AgbanaNo ratings yet

- Customer Complaint Log 2019Document18 pagesCustomer Complaint Log 2019Vikas KunduNo ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- ITP-Joint Box - FAT PDFDocument3 pagesITP-Joint Box - FAT PDFPrabhakar SvNo ratings yet

- ITP-Joint Box - FATDocument3 pagesITP-Joint Box - FATPrabhakar SvNo ratings yet

- Fire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSADocument7 pagesFire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSAMiqdadNo ratings yet

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocument2 pagesSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22No ratings yet

- Vaalco Etame Pipeline NDE SOW - Rev ADocument8 pagesVaalco Etame Pipeline NDE SOW - Rev AWilliam O OkolotuNo ratings yet

- Focus Assessment FADocument2 pagesFocus Assessment FAkousick sundararajanNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Visual Kod Gen Qua Pro 00013 NDT Visual Testing ProcedureDocument6 pagesVisual Kod Gen Qua Pro 00013 NDT Visual Testing ProcedureTotan KarNo ratings yet

- 100H EngineDocument3 pages100H EngineAmirSyafiqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Isuzu sr2021Document115 pagesIsuzu sr2021Karthik MadhuNo ratings yet

- Layer Chage OptionDocument36 pagesLayer Chage OptionKarthik MadhuNo ratings yet

- Source Change ProcesdDocument7 pagesSource Change ProcesdKarthik MadhuNo ratings yet

- LayerDocument36 pagesLayerKarthik MadhuNo ratings yet

- The Origin of The Earth's Atmosphere: Still Many UncertaintiesDocument50 pagesThe Origin of The Earth's Atmosphere: Still Many UncertaintiesKarthik MadhuNo ratings yet

- Earth Moon Sun RelationshipDocument12 pagesEarth Moon Sun RelationshipKarthik MadhuNo ratings yet

- BNB CoinDocument1 pageBNB CoinKarthik MadhuNo ratings yet

- Test Report Chage RequestDocument1 pageTest Report Chage RequestKarthik MadhuNo ratings yet

- Daily Rejection MonitoringDocument3 pagesDaily Rejection MonitoringKarthik MadhuNo ratings yet

- Fix Tube Sheet Heat Exchanger MaintenanceDocument10 pagesFix Tube Sheet Heat Exchanger MaintenanceKarthik MadhuNo ratings yet

- Cells Structure and Investigating Cells QuestionsDocument17 pagesCells Structure and Investigating Cells QuestionsstelapalencarNo ratings yet

- Viledon Air Filter: Synthetic Non-Woven FabricsDocument12 pagesViledon Air Filter: Synthetic Non-Woven FabricsYudhi YudadmokoNo ratings yet

- Foundry Notes by ShiftyDocument22 pagesFoundry Notes by ShiftyRaiyan Shifty100% (1)

- AP Chemistry MC WorkshopDocument6 pagesAP Chemistry MC WorkshopSNIGDHA PATLOLANo ratings yet

- CsherbalplantationDocument66 pagesCsherbalplantationkrish47mkNo ratings yet

- Experiment 4: Water Analysis Solids Gallardo, Hans Tristan MDocument7 pagesExperiment 4: Water Analysis Solids Gallardo, Hans Tristan Mjamila milanoNo ratings yet

- RoCide LCDocument1 pageRoCide LCeduardoNo ratings yet

- Cementing OverviewDocument40 pagesCementing OverviewImanossNo ratings yet

- 7.1 Valence Electron & Lewis StructureDocument1 page7.1 Valence Electron & Lewis StructureNURBALQIS BINTI ZAILAN KMNSNo ratings yet

- Uganda Lower Secondary Certificate of Education. Chemistry Senior Two End of Term One 2023Document12 pagesUganda Lower Secondary Certificate of Education. Chemistry Senior Two End of Term One 2023Owani Jimmy100% (1)

- CertificateDocument28 pagesCertificateKhaldi KaisNo ratings yet

- Session No. 2.2. Biological Molecules - Proteins and EnzymesDocument39 pagesSession No. 2.2. Biological Molecules - Proteins and EnzymesShekaina Faith Cuizon LozadaNo ratings yet

- Module #4 WEATHERING AND SOIL-FORMING ROCKS AND MINERALSDocument2 pagesModule #4 WEATHERING AND SOIL-FORMING ROCKS AND MINERALSMa. Diana Joy MamansagNo ratings yet

- Pipes and FittingsDocument9 pagesPipes and FittingsRaquel MonsalveNo ratings yet

- The Core Competencies of XYZ CoDocument2 pagesThe Core Competencies of XYZ CoSajid SarwarNo ratings yet

- Practical Paper 4questions - 1 PDFDocument78 pagesPractical Paper 4questions - 1 PDFhiyaa 15-15No ratings yet

- Introduction and Formulation: Preparation of SuppositoryDocument52 pagesIntroduction and Formulation: Preparation of SuppositoryImam BisriNo ratings yet

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument16 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyGuillaume Hervé POH'SIÉNo ratings yet

- 04 - Week 05Document85 pages04 - Week 05Shaina CruzNo ratings yet

- Chemistry Reviewer AnswerDocument7 pagesChemistry Reviewer AnswerLeticia CarandangNo ratings yet

- Lansium Domesticum Corr. Leaf Extract Spray As Bioinsecticide For Aedes Aegypti Mosquito ControlDocument9 pagesLansium Domesticum Corr. Leaf Extract Spray As Bioinsecticide For Aedes Aegypti Mosquito ControlPeterson RonquilloNo ratings yet

- Liquid Penetrant Inspection 20 Question QuizDocument2 pagesLiquid Penetrant Inspection 20 Question QuizKaynnaNo ratings yet

- Science 2 ProjectDocument5 pagesScience 2 ProjectNarendra JadhavNo ratings yet

- CE8005 QB Air Pollution and Control Engineering PDFDocument13 pagesCE8005 QB Air Pollution and Control Engineering PDFRohini meeraNo ratings yet

- Say NO To PVC Concrete Spacers PDFDocument1 pageSay NO To PVC Concrete Spacers PDFSOURAV RANJAN KHANRANo ratings yet

- ZL-W01, Pentel Co., LTD., 3, 2014/04/24, 1/5Document5 pagesZL-W01, Pentel Co., LTD., 3, 2014/04/24, 1/5robinson carrascoNo ratings yet

- Unit4 - Ionic BondDocument16 pagesUnit4 - Ionic BondGeyson MaquineNo ratings yet

- Operation Manual: Rotavapor® R-300Document122 pagesOperation Manual: Rotavapor® R-300Stalyn Vera AngamarcaNo ratings yet

- Boudouard ReactionDocument2 pagesBoudouard ReactionLopezNgelekaNo ratings yet