Professional Documents

Culture Documents

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

Uploaded by

Risdy GinCopyright:

Available Formats

You might also like

- Through-Tubing Gravel Packs Performed by Electric Wireline-Case HistoryDocument11 pagesThrough-Tubing Gravel Packs Performed by Electric Wireline-Case HistoryApukiNo ratings yet

- Coffee Proposal TedyDocument17 pagesCoffee Proposal Tedysajidaliyi100% (1)

- TT 501Document0 pagesTT 501perico1962No ratings yet

- Sopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilDocument6 pagesSopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilGinaAliyaSophaNo ratings yet

- Pricelist 2020 Bahan Farmasi - 1Document7 pagesPricelist 2020 Bahan Farmasi - 1ningsih rezekiNo ratings yet

- Katalog Mata Kuliah ICE Institute Semester 2023 - 2 - DownloadDocument9 pagesKatalog Mata Kuliah ICE Institute Semester 2023 - 2 - DownloadGamaliel Anugerah Lumbaa 211No ratings yet

- Proposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewDocument8 pagesProposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Australian Standard: Coal and Coke-Analysis and Testing Part 25: Coal-Durham Cone Handleability TestDocument8 pagesAustralian Standard: Coal and Coke-Analysis and Testing Part 25: Coal-Durham Cone Handleability TestSAI Global - APACNo ratings yet

- DSAASTAT - by Andrea OnofriDocument10 pagesDSAASTAT - by Andrea OnofridunnavijayNo ratings yet

- Goat Manure and Coconut Farm By-ProductsDocument2 pagesGoat Manure and Coconut Farm By-Productscdwsg254No ratings yet

- Uptake and Use Efficiencies of Nutrients by SesameDocument23 pagesUptake and Use Efficiencies of Nutrients by SesameSolomon AdejoroNo ratings yet

- Typical Process in The MillDocument4 pagesTypical Process in The MillFauzan MuzakkiNo ratings yet

- Final Attachment Published A 5777 6089603e9087340b9bdcbbb1Document7 pagesFinal Attachment Published A 5777 6089603e9087340b9bdcbbb1SESHADHIRI KIS-GROUPNo ratings yet

- Buffalo Bulletin (July-September 2020) Vol.39 No.3 Original Article Chemical Composition, in Vitro and In-Sacco Degradability of Dry Matter of ApbnDocument5 pagesBuffalo Bulletin (July-September 2020) Vol.39 No.3 Original Article Chemical Composition, in Vitro and In-Sacco Degradability of Dry Matter of ApbnarbiansyahNo ratings yet

- Fraser Et Al-2000-The Plant JournalDocument9 pagesFraser Et Al-2000-The Plant JournaladrianNo ratings yet

- Comparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueDocument6 pagesComparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueFaldy LeimenaNo ratings yet

- Mixed Compostingof Palm Oil Empty Fruit BunchDocument11 pagesMixed Compostingof Palm Oil Empty Fruit BunchSari Farah DinaNo ratings yet

- 1generation of Biogas Via Organic MaterialsDocument13 pages1generation of Biogas Via Organic MaterialsOKORIENo ratings yet

- RS - Volume 9 - Issue 4 - Pages 378-391Document14 pagesRS - Volume 9 - Issue 4 - Pages 378-391samirNo ratings yet

- Effect of Composting of Palm Oil Mill Wastes and Cow Dung or Poultry Manure On Amaranthus Hybridus Growth and YieldDocument10 pagesEffect of Composting of Palm Oil Mill Wastes and Cow Dung or Poultry Manure On Amaranthus Hybridus Growth and YieldNicoleta UngureanuNo ratings yet

- Fraser2008 PDFDocument8 pagesFraser2008 PDFAnnisa RamadhantyNo ratings yet

- Hasanah 2019 IOP Conf. Ser. Earth Environ. Sci. 260 012147Document7 pagesHasanah 2019 IOP Conf. Ser. Earth Environ. Sci. 260 012147Anis KhanNo ratings yet

- Biogas From NapierDocument14 pagesBiogas From NapierThainich PunchangNo ratings yet

- Anaerobe: E. Gozde Ozbayram, Sabine Kleinsteuber, Marcell Nikolausz, Bahar Ince, Orhan InceDocument9 pagesAnaerobe: E. Gozde Ozbayram, Sabine Kleinsteuber, Marcell Nikolausz, Bahar Ince, Orhan InceSivakumarNo ratings yet

- Vermial and Microbial Composting of Leaf Litter Waste: Indian Journal of Ecology January 2009Document6 pagesVermial and Microbial Composting of Leaf Litter Waste: Indian Journal of Ecology January 2009Lima CostaNo ratings yet

- Efecto de Un Aditivo Microbiológico Comercial Sobre El Compost de Estiércol de Res en El Proceso de CompostajeDocument4 pagesEfecto de Un Aditivo Microbiológico Comercial Sobre El Compost de Estiércol de Res en El Proceso de CompostajeRoberto José Haro SevillaNo ratings yet

- 1digestion of Oil Palm Effluent With Animal Dung For BiogasDocument13 pages1digestion of Oil Palm Effluent With Animal Dung For BiogasOKORIENo ratings yet

- Abdallafilho2016, Performance, Metabolic Variables and Enteric MethaneDocument9 pagesAbdallafilho2016, Performance, Metabolic Variables and Enteric MethaneGerardo Ordaz OchoaNo ratings yet

- Enhancing Methane Production From Rice Straw by Extrusion PretreatmentDocument8 pagesEnhancing Methane Production From Rice Straw by Extrusion PretreatmentHenry VilchezNo ratings yet

- Comparative Evaluation of The Nutritional QualityDocument7 pagesComparative Evaluation of The Nutritional QualityZihni MuftiNo ratings yet

- Carbohydrate Polymers: Swambabu Varanasi, Leeav Henzel, Scot Sharman, Warren Batchelor, Gil GarnierDocument8 pagesCarbohydrate Polymers: Swambabu Varanasi, Leeav Henzel, Scot Sharman, Warren Batchelor, Gil GarnierAathira AjeeshNo ratings yet

- Purnomo 2018 IOP Conf. Ser.: Earth Environ. Sci. 141 012024 PDFDocument12 pagesPurnomo 2018 IOP Conf. Ser.: Earth Environ. Sci. 141 012024 PDFagus purnomoNo ratings yet

- 1646 5909 1 PB PDFDocument12 pages1646 5909 1 PB PDFpradeep jatranaNo ratings yet

- Better Crops International 1998-2 p25Document3 pagesBetter Crops International 1998-2 p25Prachi AggarwalNo ratings yet

- Studies On Some Physicochemical Properties of Native and Modified Starches From Digitaria Iburua and Zea MaysDocument4 pagesStudies On Some Physicochemical Properties of Native and Modified Starches From Digitaria Iburua and Zea MaysMirdo Rohi RmCf100% (1)

- The Potential of Treated Palm Oil Mill Effluent (Pome) Sludge As An Organic FertilizerDocument13 pagesThe Potential of Treated Palm Oil Mill Effluent (Pome) Sludge As An Organic FertilizerIsroi.comNo ratings yet

- Cjas81 026Document6 pagesCjas81 026Cleber CuriNo ratings yet

- Operational Application of Bio Based Activated Carbon and Solid Acid As Integrated Approach For Maximizing Bioethanol ProductionDocument1 pageOperational Application of Bio Based Activated Carbon and Solid Acid As Integrated Approach For Maximizing Bioethanol ProductionDawit FiremichaelNo ratings yet

- Compost Manures For The Qualitative and Quantitative Improvement of Trigonella (Trigonella Foenum-Graecum L.)Document7 pagesCompost Manures For The Qualitative and Quantitative Improvement of Trigonella (Trigonella Foenum-Graecum L.)MogleNo ratings yet

- Pembentukan Asam Humat Dan Fulvat Selama Pembuatan Kompos J Erami PadiDocument6 pagesPembentukan Asam Humat Dan Fulvat Selama Pembuatan Kompos J Erami PadiFan PhotographNo ratings yet

- Chemical Composition ofDocument6 pagesChemical Composition ofGoodnessNo ratings yet

- Soil Acidification Under Oil Palm: Rates and Effects On YieldDocument4 pagesSoil Acidification Under Oil Palm: Rates and Effects On YieldPutri Indra NovianiNo ratings yet

- Potential of Mangaba (Hancornia Speciosa), Mango (Mangifera Indica L.), and Papaya (Carica Papaya L.) Seeds As Sources of Bioactive CompoundsDocument9 pagesPotential of Mangaba (Hancornia Speciosa), Mango (Mangifera Indica L.), and Papaya (Carica Papaya L.) Seeds As Sources of Bioactive CompoundscleyslaNo ratings yet

- 1 s2.0 S0921448820300407 MainDocument19 pages1 s2.0 S0921448820300407 MainHenry Daniel Ruiz AlbaNo ratings yet

- Yield Attributes and Yield of Fenugreek (Trigonella Phosphorus, Molybdenum and Inoculation ofDocument5 pagesYield Attributes and Yield of Fenugreek (Trigonella Phosphorus, Molybdenum and Inoculation ofHarini anuNo ratings yet

- Rodiah 2021 J. Phys. Conf. Ser. 1943 012185Document6 pagesRodiah 2021 J. Phys. Conf. Ser. 1943 012185Jr BagaporoNo ratings yet

- Rumen RDocument9 pagesRumen RnazkasihNo ratings yet

- 103488-Article Text-278562-1-10-20140518Document22 pages103488-Article Text-278562-1-10-20140518jamali ayifimiNo ratings yet

- Effect of Use Organic Fertilizer On Yield Component Yield and Quality of Hatri 10, Hatri 475 Rice On Chau Phu A Giang, VietnamDocument9 pagesEffect of Use Organic Fertilizer On Yield Component Yield and Quality of Hatri 10, Hatri 475 Rice On Chau Phu A Giang, VietnamMamta AgarwalNo ratings yet

- 2 Biogas ProductionDocument13 pages2 Biogas ProductionOKORIENo ratings yet

- (Zeitschrift Für Naturforschung C) Constituents of Cocoa HusksDocument8 pages(Zeitschrift Für Naturforschung C) Constituents of Cocoa HusksMorrayNo ratings yet

- Poster Upic4ir201986Document1 pagePoster Upic4ir201986Widayat WahyuNo ratings yet

- Evaluación de Compuestos Bioactivos y Actividades Biológicas Del Propóleo Tunecino PDFDocument9 pagesEvaluación de Compuestos Bioactivos y Actividades Biológicas Del Propóleo Tunecino PDFFabiola González PirelaNo ratings yet

- Physico-Chemical and Toxicological Studies On Afzelia Seed and OilDocument5 pagesPhysico-Chemical and Toxicological Studies On Afzelia Seed and OilPaul EjikemeNo ratings yet

- Formulation of Wild Sunflower (Tithoniadiversifolia) - Based Compost in La Trinidad, Benguet, PhilippinesDocument7 pagesFormulation of Wild Sunflower (Tithoniadiversifolia) - Based Compost in La Trinidad, Benguet, PhilippinesInternational Journal of Multidisciplinary Research and Explorer (IJMRE)No ratings yet

- Comparative Effectiveness of Animal Manures On Soil Chemical Properties, Yield and Root Growth of AMARANTHUS (Amaranthus Cruentus L.)Document8 pagesComparative Effectiveness of Animal Manures On Soil Chemical Properties, Yield and Root Growth of AMARANTHUS (Amaranthus Cruentus L.)Anne HathawayNo ratings yet

- Purine Metabolism and The Biosynthesis of Caffeine IN Mati? LeavesDocument4 pagesPurine Metabolism and The Biosynthesis of Caffeine IN Mati? LeavesNatália AguiarNo ratings yet

- Rumen Fermentation Kinetics and Microbial Biomass Synthesis of Super Napier Silage, CoFS 29 Silage, Tur Pods and Concentrates by in Vitro Gas Production Techniquevitro Article PHDDocument5 pagesRumen Fermentation Kinetics and Microbial Biomass Synthesis of Super Napier Silage, CoFS 29 Silage, Tur Pods and Concentrates by in Vitro Gas Production Techniquevitro Article PHDRavindra DombarNo ratings yet

- 10.1007@s40495 020 00220 XDocument10 pages10.1007@s40495 020 00220 XRina HerowatiNo ratings yet

- Physicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootDocument9 pagesPhysicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootSamir Eduardo Suarez MendezNo ratings yet

- Industrial Crops & Products: A A B A A A ADocument6 pagesIndustrial Crops & Products: A A B A A A AZimila HercilioNo ratings yet

- We Don't Have 2. I Bought 3. They Have 4. She Doesn't Want 5. He Would Like 6. Can I Have 7. I Haven't Got 8. 9. He Has 10. She Tried OnDocument2 pagesWe Don't Have 2. I Bought 3. They Have 4. She Doesn't Want 5. He Would Like 6. Can I Have 7. I Haven't Got 8. 9. He Has 10. She Tried OnJasmina PedišićNo ratings yet

- Sambucus NigraDocument10 pagesSambucus NigraTio PrasetyoNo ratings yet

- Project Feasibility Study & Evaluation (Agricultural Product)Document124 pagesProject Feasibility Study & Evaluation (Agricultural Product)krisawat77% (22)

- Product Line: Caterpillar Machines, Engines and Work ToolsDocument24 pagesProduct Line: Caterpillar Machines, Engines and Work Toolsagegnehutamirat100% (1)

- Ekstrom Thesis Part 2 As of Feb 19Document29 pagesEkstrom Thesis Part 2 As of Feb 19Kristine TendenciaNo ratings yet

- GR L-13298 Case DigestDocument2 pagesGR L-13298 Case DigestMarifel Lagare100% (1)

- Manual On Good Agricultural Marketing Practices For ChilliDocument23 pagesManual On Good Agricultural Marketing Practices For ChilliNasir AhmedNo ratings yet

- Inception Report Rev 2Document33 pagesInception Report Rev 2mattNo ratings yet

- CusienDocument2 pagesCusiennamratavohra18No ratings yet

- A Study On Marketing Mix at HeritageDocument75 pagesA Study On Marketing Mix at HeritageNagireddy Kalluri50% (2)

- Gujarat 2015Document46 pagesGujarat 2015rohitindiaNo ratings yet

- Penguin - Aza - 2005Document142 pagesPenguin - Aza - 2005Christian MendozaNo ratings yet

- Andaya, 'Orang Asli and Melayu Relations'Document23 pagesAndaya, 'Orang Asli and Melayu Relations'ben_geoNo ratings yet

- Gender Responsive Technology For Poverty Alleviation in Thailand - Part 1Document10 pagesGender Responsive Technology For Poverty Alleviation in Thailand - Part 1ChristinaThiesenNo ratings yet

- Ecological IndicatorDocument10 pagesEcological IndicatorUsdiyantoNo ratings yet

- Agriculture Mcqs PDFDocument4 pagesAgriculture Mcqs PDFAbdul QudoosNo ratings yet

- Picture Cards Categorising Game TimeDocument98 pagesPicture Cards Categorising Game Timepammiefisher100% (1)

- Tle 9Document13 pagesTle 9Byron DizonNo ratings yet

- 09 Social Science Key Notes Geo ch6 PopulationDocument3 pages09 Social Science Key Notes Geo ch6 PopulationSaket SharmaNo ratings yet

- Agricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersDocument11 pagesAgricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersSabrina ajaNo ratings yet

- Orange (Fruit) - Wikipedia, The Free EncyclopediaDocument36 pagesOrange (Fruit) - Wikipedia, The Free Encyclopedialucifer_1261994No ratings yet

- The Sloop's Log Fall 2012Document24 pagesThe Sloop's Log Fall 2012Chebeague Island Historical SocietyNo ratings yet

- Ujian BHS Inggris RamlahDocument16 pagesUjian BHS Inggris RamlahRamlah RastyNo ratings yet

- Ch. 6 Study of Continents: Asia Questions/AnswersDocument7 pagesCh. 6 Study of Continents: Asia Questions/AnswersLisa SinhaNo ratings yet

- Shrub Encroachment BhutanDocument24 pagesShrub Encroachment BhutanSrijana JoshiNo ratings yet

- Civilizations Rise and Fall On The Quality of Their SoilDocument1 pageCivilizations Rise and Fall On The Quality of Their SoilTiger LillyNo ratings yet

- EIA of Flour MillsDocument62 pagesEIA of Flour Millsrabeea ahmed100% (3)

- Cholpon Chotaeva HISTORY OF KYRGYZSTANDocument136 pagesCholpon Chotaeva HISTORY OF KYRGYZSTANMalika100% (1)

- Coffee TanzaniaDocument64 pagesCoffee Tanzaniarobert.delasernaNo ratings yet

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

Uploaded by

Risdy GinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

IOPC 2006 Poster - RecyclingOilPalmBunchNutr

Uploaded by

Risdy GinCopyright:

Available Formats

RECYCLING OIL PALM BUNCH NUTRIENTS

Noto E. Prabowo, Hugh L. Foster and Abner Johan S.

INTRODUCTION

Four field trials carried out in different regions in North Sumatra by BLRS, PT. PP. London Sumatra In addition to the oil and kernel, processed bunches in the mill result in nutrient-rich by-

Indonesia Tbk., have shown tremendous positive effects of fertiliser nutrients on oil palm FFB (fresh products such as EFB (empty fruit bunches) and POME (palm oil mill effluent) which can be

fruit bunches) yields. There is a considerable nutrient recovery in the above-ground palm tissues, applied to the field as:

particularly in bunches which accounts for more than 40% of the total nutrients taken up by the •Direct application, or

palms. This indicates a high potential loss of nutrients through harvested bunches. Therefore bunch •Enriched mulch (EM) after composting

nutrient recycling to the field is encouraged since the nutrients – assuming no losses - can replace In this paper the potential bunch nutrients which could be recycled to the fields are compared

100% inorganic fertilizer requirement. with current actual practices.

METHODS

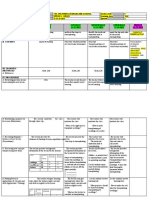

% nutrient recovery in palm components

50

N P K Mg

Returning the bunch nutrients to the field means

A thorough laboratory nutrient analysis was carried out for 206 FFB samples from each individual

40 sustainable estate practices in terms of:

plot of the NPKMg fertilizer trials. The samples were separated into 5 different components viz

•Solution to disposal problem for oil palm

stalk, staminode, mesocarp and shell plus kernel. Then composite samples were made by mixing

30 mill,

a certain proportion of each component for nutrient analysis. A number of 84 EFB and 77 POME

•Minimization of possible environmental

samples were collected from Begerpang palm oil mill in North Sumatra. Moreover, a

20 pollution due to regular use of inorganic

representative number of EM samples was also collected and analysed regularly from a trial on

fertilisers,

EFB and POME composting (Abner and Foster, 2006).

10 •Reduction or replacement of the use of

expensive and increasing price of All samples were dried in an oven at 70oC for 16 hours prior to analysis. N content was

0 inorganic fertilizers, determined by the Kjeldahl method whilst P, K and Mg was analysed by dry ashing and uptake in

Bunch Leaf Rachis Trunk Male Inf. •Lower manuring costs. mineral acid.

NUTRIENT RECOVERY IN BUNCHES, MILL WASTE AND ENRICHED MULCH (COMPOST)

Compared with the leaf, rachis, trunk and male

inflorescence, accumulation of nutrients is found in

greatest amount in the bunches. It is also obvious that the

modern tenera bunches are much richer in nutrients

compared with the amounts previously reported for Dura

material (Ng and Thamboo, 1967) which indicates possible

higher nutrient export via harvested bunches.

Mill processes

At commercial fertiliser rates the annual removal of N, P, K

and Mg in modern tenera bunches is approximately as

follows:

FFB N P K Mg The EFB can be returned to the field for mulching or incinerated to produce bunch ash, whilst

These amounts are approximately Content (kg/ t FFB) 5.03 0.66 5.26 0.76 the POME can be used to fertigate the palms. The amount of nutrients found in these two waste

equivalent to the annual fertiliser products in this investigation were as follows:

Content (kg/ ha) 134 17 141 20

rates typically applied to oil palm in

North Sumatra (except for Eg. Urea RP MOP Kies. EFB + POME N P K Mg

phosphate which is a bit lower in Rate (kg/ palm) 2.2 1.0 2.1 0.9 EFB content (kg/ t FFB) 0.75 0.070 1.58 0.13

the bunches).

POME content (kg/ t FFB) 0.74 0.154 1.98 0.21

This shows that the nutrient requirement of an oil palm field can actually be supplied by the

%Nutrient recovery (EFB + POME) 30 34 68 45

nutrients contained in the bunches harvested from the same field.

These results show that approximately 30-70% of bunch nutrient is lost during mill processes

The quantity of empty fruit bunches (EFB) produced by a mill ranges from 22-25% of the weight

which greatly reduces the capability of EFB+POME to supply and recycle the nutrients to the

of FFB whilst the amount of POME produced depends on the milling techniques used, but is

field.

commonly taken as 67% of FFB processed.

Comparison of the %inorganic fertilisers which can be replaced if different FFB components are The high moisture content (60-70%) and hence

returned to the field is shown in the following table: transportation cost limits the direct use of oil palm

waste, particularly EFB, to far off oil palm fields. In

FFB components returned Kg N % Inorganic addition it is not practical to pump POME to fields far

returned fertiliser

to the field per hectare replaced from the mill or where topography is not flat. An

attractive alternative is to make enriched mulch (EM)

1. All fresh fruit bunches (FFB) 120 100

commonly known as compost, by combining the empty

2. FFB less exported CPO and kernels 104 87 bunches and raw effluent, which because of its richer

3. FFB less CPO, kernels, shell and fibre 83 69 content is much easier and cheaper to distribute

4. Compost (processed in dry season) 32 27 widely.

5. Compost (processed in wet season) 26 22 Trials carried out by PTPP Lonsum (Abner and Foster, 2006) have shown that a satisfactory

6. Empty fruit Bunches (EFB) 18 15 compost for field application to oil palm can be produced by application of 100 litres POME

every day to 1 tonne of chopped EFB in open fields in only 30 days. Turning the compost before

Return of all the EFB to the field would replace 15% of the inorganic fertilisers. On the other POME application only twice per week was found to be optimal. The nutrient content of the final

hand compost processed in the dry season, which is much easier to transport and apply, can compost produced varies with seasons - wet (>234 mm rain/ month) and dry (<57 mm rain/

replace almost 30% of inorganic fertilisers. It appears that a massive 40% of the N is lost during month) as shown below:

mill processing and a further 18% if the shell and fibre is burnt. Whilst losses of P and K in the

mill are less (35% and 26% respectively) there is potential to save a large amount of these EM (Enriched Mulch) N P K Mg

nutrients as well. It is suggested that the losses of nutrients in the mill should be investigated to Content (kg/ t FFB); dry 1.35 0.20 2.71 0.31

see if they can be reduced and the fibre and bunch ash should be included in the compost

Content (kg/ t FFB); wet 1.10 0.17 2.31 0.30

materials. It may then be possible to replace as much as 70% of fertilisers.

CONCLUSIONS

1. Fertilisers very significantly increase the levels of P, K and Mg in oil palm bunches.

2. More than 40% of all the major nutrients taken up by oil palms are found in the bunches.

3. The nutrient levels in bunches of well fertilised modern Tenera material are much higher than previously reported for Dura material.

4. If all the FFB (fresh fruit bunches) were returned to the soil it is estimated that there would be no need to apply any fertilisers to oil palm in North Sumatra.

5. In contrast if all the EFB (empty fruit bunches) produced were returned to the fields, this would replace no more than 15% of inorganic fertilisers.

6. A considerable improvement is achieved by composting the EFB and POME over 30 days, which produces a material which can replace fertilisers in almost 30% of fields.

7. There is a massive unaccountable 40% loss of N and an unaccountable 15% loss of P and K during mill processing; plus a further approximate 15% loss of all these nutrients if all the

shell and fibre are burnt and the ash is not recovered.

8. Although fertiliser use for oil palms can currently be reduced by almost one third through composting mill wastes, it is concluded that savings on fertiliser could be increased much further

(up to at least two thirds perhaps), if nutrient losses in the mill could be prevented.

PT. PP. LONDON SUMATRA INDONESIA TBK REFERENCES

BAH LIAS RESEARCH STATION 1. Abner, J. S. and Foster, H. L. (2006). Efficient Production of compost from oil palm waste. In Proc. 2006. Int. Oil Palm Conference, Nusa

Jl Jend A Yani No 2 • PO Box 1154 • Medan 20111 • Indonesia Dua, Bali.

Tel: +(62) 622 96492 • Fax: +(62) 622 96694

2. Ng, S. K. and Thamboo, S. (1967). Nutrient contents of oil palms in Malaya. I. Nutrients required for reproduction: Fruit bunches and

e-mail: blrs@londonsumatra.com

www.londonsumatra.com male inflorescence. The Malaysian Agricultural Journal, 46. p. 3-45.

You might also like

- Through-Tubing Gravel Packs Performed by Electric Wireline-Case HistoryDocument11 pagesThrough-Tubing Gravel Packs Performed by Electric Wireline-Case HistoryApukiNo ratings yet

- Coffee Proposal TedyDocument17 pagesCoffee Proposal Tedysajidaliyi100% (1)

- TT 501Document0 pagesTT 501perico1962No ratings yet

- Sopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilDocument6 pagesSopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilGinaAliyaSophaNo ratings yet

- Pricelist 2020 Bahan Farmasi - 1Document7 pagesPricelist 2020 Bahan Farmasi - 1ningsih rezekiNo ratings yet

- Katalog Mata Kuliah ICE Institute Semester 2023 - 2 - DownloadDocument9 pagesKatalog Mata Kuliah ICE Institute Semester 2023 - 2 - DownloadGamaliel Anugerah Lumbaa 211No ratings yet

- Proposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewDocument8 pagesProposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Australian Standard: Coal and Coke-Analysis and Testing Part 25: Coal-Durham Cone Handleability TestDocument8 pagesAustralian Standard: Coal and Coke-Analysis and Testing Part 25: Coal-Durham Cone Handleability TestSAI Global - APACNo ratings yet

- DSAASTAT - by Andrea OnofriDocument10 pagesDSAASTAT - by Andrea OnofridunnavijayNo ratings yet

- Goat Manure and Coconut Farm By-ProductsDocument2 pagesGoat Manure and Coconut Farm By-Productscdwsg254No ratings yet

- Uptake and Use Efficiencies of Nutrients by SesameDocument23 pagesUptake and Use Efficiencies of Nutrients by SesameSolomon AdejoroNo ratings yet

- Typical Process in The MillDocument4 pagesTypical Process in The MillFauzan MuzakkiNo ratings yet

- Final Attachment Published A 5777 6089603e9087340b9bdcbbb1Document7 pagesFinal Attachment Published A 5777 6089603e9087340b9bdcbbb1SESHADHIRI KIS-GROUPNo ratings yet

- Buffalo Bulletin (July-September 2020) Vol.39 No.3 Original Article Chemical Composition, in Vitro and In-Sacco Degradability of Dry Matter of ApbnDocument5 pagesBuffalo Bulletin (July-September 2020) Vol.39 No.3 Original Article Chemical Composition, in Vitro and In-Sacco Degradability of Dry Matter of ApbnarbiansyahNo ratings yet

- Fraser Et Al-2000-The Plant JournalDocument9 pagesFraser Et Al-2000-The Plant JournaladrianNo ratings yet

- Comparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueDocument6 pagesComparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueFaldy LeimenaNo ratings yet

- Mixed Compostingof Palm Oil Empty Fruit BunchDocument11 pagesMixed Compostingof Palm Oil Empty Fruit BunchSari Farah DinaNo ratings yet

- 1generation of Biogas Via Organic MaterialsDocument13 pages1generation of Biogas Via Organic MaterialsOKORIENo ratings yet

- RS - Volume 9 - Issue 4 - Pages 378-391Document14 pagesRS - Volume 9 - Issue 4 - Pages 378-391samirNo ratings yet

- Effect of Composting of Palm Oil Mill Wastes and Cow Dung or Poultry Manure On Amaranthus Hybridus Growth and YieldDocument10 pagesEffect of Composting of Palm Oil Mill Wastes and Cow Dung or Poultry Manure On Amaranthus Hybridus Growth and YieldNicoleta UngureanuNo ratings yet

- Fraser2008 PDFDocument8 pagesFraser2008 PDFAnnisa RamadhantyNo ratings yet

- Hasanah 2019 IOP Conf. Ser. Earth Environ. Sci. 260 012147Document7 pagesHasanah 2019 IOP Conf. Ser. Earth Environ. Sci. 260 012147Anis KhanNo ratings yet

- Biogas From NapierDocument14 pagesBiogas From NapierThainich PunchangNo ratings yet

- Anaerobe: E. Gozde Ozbayram, Sabine Kleinsteuber, Marcell Nikolausz, Bahar Ince, Orhan InceDocument9 pagesAnaerobe: E. Gozde Ozbayram, Sabine Kleinsteuber, Marcell Nikolausz, Bahar Ince, Orhan InceSivakumarNo ratings yet

- Vermial and Microbial Composting of Leaf Litter Waste: Indian Journal of Ecology January 2009Document6 pagesVermial and Microbial Composting of Leaf Litter Waste: Indian Journal of Ecology January 2009Lima CostaNo ratings yet

- Efecto de Un Aditivo Microbiológico Comercial Sobre El Compost de Estiércol de Res en El Proceso de CompostajeDocument4 pagesEfecto de Un Aditivo Microbiológico Comercial Sobre El Compost de Estiércol de Res en El Proceso de CompostajeRoberto José Haro SevillaNo ratings yet

- 1digestion of Oil Palm Effluent With Animal Dung For BiogasDocument13 pages1digestion of Oil Palm Effluent With Animal Dung For BiogasOKORIENo ratings yet

- Abdallafilho2016, Performance, Metabolic Variables and Enteric MethaneDocument9 pagesAbdallafilho2016, Performance, Metabolic Variables and Enteric MethaneGerardo Ordaz OchoaNo ratings yet

- Enhancing Methane Production From Rice Straw by Extrusion PretreatmentDocument8 pagesEnhancing Methane Production From Rice Straw by Extrusion PretreatmentHenry VilchezNo ratings yet

- Comparative Evaluation of The Nutritional QualityDocument7 pagesComparative Evaluation of The Nutritional QualityZihni MuftiNo ratings yet

- Carbohydrate Polymers: Swambabu Varanasi, Leeav Henzel, Scot Sharman, Warren Batchelor, Gil GarnierDocument8 pagesCarbohydrate Polymers: Swambabu Varanasi, Leeav Henzel, Scot Sharman, Warren Batchelor, Gil GarnierAathira AjeeshNo ratings yet

- Purnomo 2018 IOP Conf. Ser.: Earth Environ. Sci. 141 012024 PDFDocument12 pagesPurnomo 2018 IOP Conf. Ser.: Earth Environ. Sci. 141 012024 PDFagus purnomoNo ratings yet

- 1646 5909 1 PB PDFDocument12 pages1646 5909 1 PB PDFpradeep jatranaNo ratings yet

- Better Crops International 1998-2 p25Document3 pagesBetter Crops International 1998-2 p25Prachi AggarwalNo ratings yet

- Studies On Some Physicochemical Properties of Native and Modified Starches From Digitaria Iburua and Zea MaysDocument4 pagesStudies On Some Physicochemical Properties of Native and Modified Starches From Digitaria Iburua and Zea MaysMirdo Rohi RmCf100% (1)

- The Potential of Treated Palm Oil Mill Effluent (Pome) Sludge As An Organic FertilizerDocument13 pagesThe Potential of Treated Palm Oil Mill Effluent (Pome) Sludge As An Organic FertilizerIsroi.comNo ratings yet

- Cjas81 026Document6 pagesCjas81 026Cleber CuriNo ratings yet

- Operational Application of Bio Based Activated Carbon and Solid Acid As Integrated Approach For Maximizing Bioethanol ProductionDocument1 pageOperational Application of Bio Based Activated Carbon and Solid Acid As Integrated Approach For Maximizing Bioethanol ProductionDawit FiremichaelNo ratings yet

- Compost Manures For The Qualitative and Quantitative Improvement of Trigonella (Trigonella Foenum-Graecum L.)Document7 pagesCompost Manures For The Qualitative and Quantitative Improvement of Trigonella (Trigonella Foenum-Graecum L.)MogleNo ratings yet

- Pembentukan Asam Humat Dan Fulvat Selama Pembuatan Kompos J Erami PadiDocument6 pagesPembentukan Asam Humat Dan Fulvat Selama Pembuatan Kompos J Erami PadiFan PhotographNo ratings yet

- Chemical Composition ofDocument6 pagesChemical Composition ofGoodnessNo ratings yet

- Soil Acidification Under Oil Palm: Rates and Effects On YieldDocument4 pagesSoil Acidification Under Oil Palm: Rates and Effects On YieldPutri Indra NovianiNo ratings yet

- Potential of Mangaba (Hancornia Speciosa), Mango (Mangifera Indica L.), and Papaya (Carica Papaya L.) Seeds As Sources of Bioactive CompoundsDocument9 pagesPotential of Mangaba (Hancornia Speciosa), Mango (Mangifera Indica L.), and Papaya (Carica Papaya L.) Seeds As Sources of Bioactive CompoundscleyslaNo ratings yet

- 1 s2.0 S0921448820300407 MainDocument19 pages1 s2.0 S0921448820300407 MainHenry Daniel Ruiz AlbaNo ratings yet

- Yield Attributes and Yield of Fenugreek (Trigonella Phosphorus, Molybdenum and Inoculation ofDocument5 pagesYield Attributes and Yield of Fenugreek (Trigonella Phosphorus, Molybdenum and Inoculation ofHarini anuNo ratings yet

- Rodiah 2021 J. Phys. Conf. Ser. 1943 012185Document6 pagesRodiah 2021 J. Phys. Conf. Ser. 1943 012185Jr BagaporoNo ratings yet

- Rumen RDocument9 pagesRumen RnazkasihNo ratings yet

- 103488-Article Text-278562-1-10-20140518Document22 pages103488-Article Text-278562-1-10-20140518jamali ayifimiNo ratings yet

- Effect of Use Organic Fertilizer On Yield Component Yield and Quality of Hatri 10, Hatri 475 Rice On Chau Phu A Giang, VietnamDocument9 pagesEffect of Use Organic Fertilizer On Yield Component Yield and Quality of Hatri 10, Hatri 475 Rice On Chau Phu A Giang, VietnamMamta AgarwalNo ratings yet

- 2 Biogas ProductionDocument13 pages2 Biogas ProductionOKORIENo ratings yet

- (Zeitschrift Für Naturforschung C) Constituents of Cocoa HusksDocument8 pages(Zeitschrift Für Naturforschung C) Constituents of Cocoa HusksMorrayNo ratings yet

- Poster Upic4ir201986Document1 pagePoster Upic4ir201986Widayat WahyuNo ratings yet

- Evaluación de Compuestos Bioactivos y Actividades Biológicas Del Propóleo Tunecino PDFDocument9 pagesEvaluación de Compuestos Bioactivos y Actividades Biológicas Del Propóleo Tunecino PDFFabiola González PirelaNo ratings yet

- Physico-Chemical and Toxicological Studies On Afzelia Seed and OilDocument5 pagesPhysico-Chemical and Toxicological Studies On Afzelia Seed and OilPaul EjikemeNo ratings yet

- Formulation of Wild Sunflower (Tithoniadiversifolia) - Based Compost in La Trinidad, Benguet, PhilippinesDocument7 pagesFormulation of Wild Sunflower (Tithoniadiversifolia) - Based Compost in La Trinidad, Benguet, PhilippinesInternational Journal of Multidisciplinary Research and Explorer (IJMRE)No ratings yet

- Comparative Effectiveness of Animal Manures On Soil Chemical Properties, Yield and Root Growth of AMARANTHUS (Amaranthus Cruentus L.)Document8 pagesComparative Effectiveness of Animal Manures On Soil Chemical Properties, Yield and Root Growth of AMARANTHUS (Amaranthus Cruentus L.)Anne HathawayNo ratings yet

- Purine Metabolism and The Biosynthesis of Caffeine IN Mati? LeavesDocument4 pagesPurine Metabolism and The Biosynthesis of Caffeine IN Mati? LeavesNatália AguiarNo ratings yet

- Rumen Fermentation Kinetics and Microbial Biomass Synthesis of Super Napier Silage, CoFS 29 Silage, Tur Pods and Concentrates by in Vitro Gas Production Techniquevitro Article PHDDocument5 pagesRumen Fermentation Kinetics and Microbial Biomass Synthesis of Super Napier Silage, CoFS 29 Silage, Tur Pods and Concentrates by in Vitro Gas Production Techniquevitro Article PHDRavindra DombarNo ratings yet

- 10.1007@s40495 020 00220 XDocument10 pages10.1007@s40495 020 00220 XRina HerowatiNo ratings yet

- Physicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootDocument9 pagesPhysicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootSamir Eduardo Suarez MendezNo ratings yet

- Industrial Crops & Products: A A B A A A ADocument6 pagesIndustrial Crops & Products: A A B A A A AZimila HercilioNo ratings yet

- We Don't Have 2. I Bought 3. They Have 4. She Doesn't Want 5. He Would Like 6. Can I Have 7. I Haven't Got 8. 9. He Has 10. She Tried OnDocument2 pagesWe Don't Have 2. I Bought 3. They Have 4. She Doesn't Want 5. He Would Like 6. Can I Have 7. I Haven't Got 8. 9. He Has 10. She Tried OnJasmina PedišićNo ratings yet

- Sambucus NigraDocument10 pagesSambucus NigraTio PrasetyoNo ratings yet

- Project Feasibility Study & Evaluation (Agricultural Product)Document124 pagesProject Feasibility Study & Evaluation (Agricultural Product)krisawat77% (22)

- Product Line: Caterpillar Machines, Engines and Work ToolsDocument24 pagesProduct Line: Caterpillar Machines, Engines and Work Toolsagegnehutamirat100% (1)

- Ekstrom Thesis Part 2 As of Feb 19Document29 pagesEkstrom Thesis Part 2 As of Feb 19Kristine TendenciaNo ratings yet

- GR L-13298 Case DigestDocument2 pagesGR L-13298 Case DigestMarifel Lagare100% (1)

- Manual On Good Agricultural Marketing Practices For ChilliDocument23 pagesManual On Good Agricultural Marketing Practices For ChilliNasir AhmedNo ratings yet

- Inception Report Rev 2Document33 pagesInception Report Rev 2mattNo ratings yet

- CusienDocument2 pagesCusiennamratavohra18No ratings yet

- A Study On Marketing Mix at HeritageDocument75 pagesA Study On Marketing Mix at HeritageNagireddy Kalluri50% (2)

- Gujarat 2015Document46 pagesGujarat 2015rohitindiaNo ratings yet

- Penguin - Aza - 2005Document142 pagesPenguin - Aza - 2005Christian MendozaNo ratings yet

- Andaya, 'Orang Asli and Melayu Relations'Document23 pagesAndaya, 'Orang Asli and Melayu Relations'ben_geoNo ratings yet

- Gender Responsive Technology For Poverty Alleviation in Thailand - Part 1Document10 pagesGender Responsive Technology For Poverty Alleviation in Thailand - Part 1ChristinaThiesenNo ratings yet

- Ecological IndicatorDocument10 pagesEcological IndicatorUsdiyantoNo ratings yet

- Agriculture Mcqs PDFDocument4 pagesAgriculture Mcqs PDFAbdul QudoosNo ratings yet

- Picture Cards Categorising Game TimeDocument98 pagesPicture Cards Categorising Game Timepammiefisher100% (1)

- Tle 9Document13 pagesTle 9Byron DizonNo ratings yet

- 09 Social Science Key Notes Geo ch6 PopulationDocument3 pages09 Social Science Key Notes Geo ch6 PopulationSaket SharmaNo ratings yet

- Agricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersDocument11 pagesAgricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersSabrina ajaNo ratings yet

- Orange (Fruit) - Wikipedia, The Free EncyclopediaDocument36 pagesOrange (Fruit) - Wikipedia, The Free Encyclopedialucifer_1261994No ratings yet

- The Sloop's Log Fall 2012Document24 pagesThe Sloop's Log Fall 2012Chebeague Island Historical SocietyNo ratings yet

- Ujian BHS Inggris RamlahDocument16 pagesUjian BHS Inggris RamlahRamlah RastyNo ratings yet

- Ch. 6 Study of Continents: Asia Questions/AnswersDocument7 pagesCh. 6 Study of Continents: Asia Questions/AnswersLisa SinhaNo ratings yet

- Shrub Encroachment BhutanDocument24 pagesShrub Encroachment BhutanSrijana JoshiNo ratings yet

- Civilizations Rise and Fall On The Quality of Their SoilDocument1 pageCivilizations Rise and Fall On The Quality of Their SoilTiger LillyNo ratings yet

- EIA of Flour MillsDocument62 pagesEIA of Flour Millsrabeea ahmed100% (3)

- Cholpon Chotaeva HISTORY OF KYRGYZSTANDocument136 pagesCholpon Chotaeva HISTORY OF KYRGYZSTANMalika100% (1)

- Coffee TanzaniaDocument64 pagesCoffee Tanzaniarobert.delasernaNo ratings yet