Professional Documents

Culture Documents

Final Q.C MANUAL

Final Q.C MANUAL

Uploaded by

Rana NaveedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Q.C MANUAL

Final Q.C MANUAL

Uploaded by

Rana NaveedCopyright:

Available Formats

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Forward

Consequent upon the resolution, dated April 30th, 2019 passed by the board

of Directors of the company " Himalayan Edibles Private Limited" Pakistan in its meeting held on

April 30th, 2019 at Lahore, it was resolved that company being engaged in manufacturing edible salt

must introduce a laboratory manual for observing standard testing procedures in the laboratory

established at manufacturing plant site. These standard testing procedures shall be followed strictly

by the lab attendants while performing quality control tests of iodine fortified salt.

In view of forgoing instant laboratory manual has been prepared consulting

requirements for iodized food grade salt defined by " PAKISTAN STANDARDS AND

QUALITY CONTROL AUTHORITY, (Standards Development Centre), through PS-

1669-2008, and consulting Mr. Nisar Ahmad, M.Sc Chemistry Punjab University Lahore,

and consulting World Health Organization (W.H.O) publications as under;

1. Salt reduction and iodine fortification strategies in public health. (March 2013)

2. Sodium intake for adults and children. Geneva, World Health Organization

(WHO), 2012. (Reprinted in 2014)

3. Potassium intake for adults and children Geneva, World Health Organization

(WHO), 2012. (Reprinted in 2014)

Instant laboratory manual shall be a useful technical literature for

performing chemical analysis of iodized salt as well as quantifying presence of various

impurities that may exists in salt and the document would be helpful in proper quality

control of product and ensuring production of healthy salt for public use.

Engr. Rana Naveed Ahmad

Chief Executive Officer,

Himalayan Edibles (Pvt) Limited, Pakistan

C.E.O

Himalayan Edibles Private Limited Page 1

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

TABLE OF CONTENTS

Sr.No. DESCRIPTION Page

1 Definitions 3

2 Edible Salt Chemistry 4

3 a Natural Salt Reserves in Pakistan 5

b Himalayan Pink Salt 6

c Physical Properties of Rock Salt 7

4 a Pakistan Standard P.S-1669-2008 8-9

b World Health Organization CODEX STAN 192-1995 (Standard 10-11

food additives for salt.)

c Iodine fortification 12

d Iodine fortification process 13-22

e Double Fortification 22

f Triple Fortification 22-23

g Building Requirements 23

h Nutrition Facts Table Salt 24

5 In house Laboratory facilities for Salt manufacturing. 25-30

6 a Iodometric Lab test 31

b Reagents and Reagent preparation for Iodometric Lab test 31-32

c Iodometric Titration test procedure 33-34

d Table Of Iodine Content (In Ppm) 35-36

e Salt Iodometric Lab test report form. 37

7 a Determination of Sodium Chloride 38-43

b Analytical requirements for edible salt. 44-45

Himalayan Edibles Private Limited Page 2

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

1 DEFINITIONS

Rock Salt Natural form of Salt mined from Salt mines also called Halite.

Fortification Fortification is the practice of deliberately increasing the content

of an essential micronutrient, i.e. vitamins and minerals

including trace elements in a food to improve the nutritional

quality and provide a public health benefit.

ppm This is an abbreviation for "parts per million"

It is also can be expressed as milligrams per liter (mg/L) or

mass of a chemical or contaminate in mg / kg.

density Density, mass of a unit volume of a material substance.

density = d = M/V, (M is mass, and V is volume.)

Expressed as units of grams per cubic centimeter.

Density describes how compact or concentrated something is

Solubility Solubility is the property of a solid, liquid or gaseous chemical

substance called solute to dissolve in a solid, liquid or gaseous

solvent. The resulting solution is called a saturated solution.

mesh one of the openings between the threads or cords of a net. often

used to designate screen size as the number of openings per

linear inch.

Crystal A crystal consists of substance that is formed from an ordered

arrangement of atoms, molecules, or ions. there are repeated

units, crystals have recognizable structures well-defined angles

and faces.

Himalayan Edibles Private Limited Page 3

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

2. EDIBLE SALT CHEMISTRY

Edible Salt also known as table salt is a mineral composed primarily of sodium

chloride (NaCl). It is an inorganic chemical compound. The structure of NaCl is formed

by repeating the face centered cubic unit cell. It has 1:1 stoichiometry ratio of Na:Cl with

a molar mass of 58.4 g/mol.

Rock Salt crystal lattice structure (cubic structure)

The natural form of salt is a crystalline mineral, known as "Rock Salt"

or "Halite" found or mined in various mines in Tehsil Pind Dadan Khan, District Jehlum,

District Khushab and District Mianwali. Following is Rock Salt bolders obtained from

Salt mine.

sodium chloride Salt is the main mineral constituent of sea water. The concentration of

salt in sea water as about 35 grams (1.2 oz) of solids per liter of sea water.

Himalayan Edibles Private Limited Page 4

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3.a NATURAL SALT RESERVES IN PAKISTAN

Pakistan is having the world's largest natural rock salt reserves. The reserves of about 10

billion ton in three mines including more than 6.687 billion ton only in the Khewra salt

mine, other salt mines are Warcha and Kalabagh, located in Salt Range, series of hills and

low mountains between the valleys of the Indus and Jhelum rivers, northern part of the

Punjab region of Pakistan. Pakistan Mineral Development Corporation (PMDC) is

managing Khewra salt mine. The production of salt during the year 2018-19 at Khewra is

about 382,155 tons.

Salt occurs in the form of an irregular dome like structure. There are seven thick salt

seams with cumulative thickness of about 150 meters. At places rock salt is 99% pure.

Salt is transparent, white, pink, reddish to beef red color.

Himalayan Edibles Private Limited Page 5

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3.b HIMALAYAN PINK SALT

Pink Himalayan salt is naturally in beef red color and it is mined from Kalabagh

mines. This rock salt becomes naturally pink in color when crushed into small particles. It

is worldwide known as much healthier salt than regular table salt. and provides

incredible health benefits due to trace minerals: calcium, iron, zinc, chromium,

magnesium and sulfate, all at safe levels below 1%. The taste is delicious.

Himalayan Edibles Private Limited Page 6

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3.c PHYSICAL PROPERTIES ROCK SALT

(i) MINERAL CLASSIFICATION

Rock salt is sedimentary, the mineral name of halite. It is found in hard layers

underground. sedimentary salt is found in locations of former seas.

( ii ) DENSITY

Bulk density of Rock Salt = 2.163 g/cm³

Grain density of powdered Rock Salt = 2.191 g/cm³

( iii ) HARDNESS AND WEIGHT

Mineralogists rate rock salt at 2 to 2.5 for hardness. This means it is quite soft, its

surface able to be scratched with a fingernail. It is rated 2.1 to 2.3 for "specific

gravity" meaning it is light in weight.

( iii ) STRUCTURE

Rock salt forms in crystals with a simple cubic symmetry. When it is broken, it

will break evenly into cubes and when it shatters, the pieces will be of different

sizes and shapes.

( iv ) COMPRESSIVE STRENGTH:

The unconfined compressive strength of rock salt is 21.58 MPa. or 3129.9144 Psi

Changes of the compressive strengths are fairly minor when increasing the

confining pressure from 15 MPa to 40 MPa.

(v) LATTICE ENERGY:

lattice energy of a crystalline Rock Salt −786 kJ/mol

The lattice energy of a crystalline solid is a measure of the energy released when ions are

combined to make a compound. It is a measure of the cohesive forces that bind ions.

Lattice energy is relevant to many practical properties including solubility, hardness, and

volatility. The lattice energy is usually deduced from the Born–Haber cycle.

( vi ) POROSITY: Porsity = 1 - (Bulk desity/Grain Density)

Porosity of rock salt below 12 meter depth = Zero

( vii) DYNAMIC COMPRESSIVE STRENGTH OF ROCK SALTS:

Quasi-static UCS range for bedded salt is 16 to 32 MPa

or = 19.6 MPa = 2842.74 Psi

Himalayan Edibles Private Limited Page 7

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

4.a PAKISTAN STANDARDS PS: 1669-2008

STANDARD SPECIFICATIONS FOR IODIZED FOOD GRADE SALT

1. VISUAL APPEARANCE:

The Salt should be white crystalline substance, free from any visible impurities

and harmful / toxic substances.

2. PURITY:

Sodium Chloride content (as NaCl) percent by mass shall be Min. 98%.

3. SOURCE OF THE SALT:

It is obtained from the drying sea water in specially developed ponds,

From rocks salt deposits

From natural brine

4. MOISTURE CONTENTS:

The salt shall not contain more than 3.0 percent by mass of moisture.

Moisture contents shall evaluated using standard method prescribed in

PS:ISO:2483 – 1973 for Determination of loss of mass at 110º C.

Dried in accordance with the method prescribed in PS : 3746 – 1996

5. PARTICLE SIZE:

99% of the salt material shall preferably pass through 1.00 mm PS: Sieve.

6. IODINE CONTENT:

Iodine contents at manufacturing stage shall not be lower than 30 ppm

Potassium Iodate (KIO3) shall not be lower than 50 ppm on dry weight

basis with one year of manufacture.

Iodine contents at distribution channel and at retail level 15 to 25 parts per

million on dry weight basis.

7. FOOD ADDITIVES:

Food additives listed in tables 1 & 2 of the Codex General Standard for Food

additives (CODEX STAN 1-192-1995) in Food Category 12.1.1 (Salt) may be used

in foods subject to this standard.

8. CONTAMINANTS:

Iodized Food Grade Salt shall not contain contaminants in amounts and in such

form that may be harmful to the health of the consumer. In particular the

following maximum limits shall not be exceeded.

9. ARSENIC:

Not more than 0.5 mg/kg expressed as As.

Himalayan Edibles Private Limited Page 8

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

10. COPPER:

Not more than 2.0 mg/kg expressed as Cu.

11. LEAD:

Not more than 2.0 mg/kg expressed as Pb.

12. CADMIUM:

Not more than 0.5 mg/kg expressed as Cd.

13. MERCURY:

Not more than 0.1 mg/kg expressed as Hg.

14. HYGIENE:

In order to ensure that proper standards of food hygiene are maintained until the

product reaches the consumer, the method of production, packing, storage and

transportation of Iodized Food Grade Salt shall be such as to avoid any risk of

contamination.

Himalayan Edibles Private Limited Page 9

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

4.b World Health Organization CODEX STAN 192-1995

(Standard food additives for salt.)

World Health Organization (WHO) publication "CODEX STAN 192-1995"

presents international food standards in a specific Food Category System. Specific code

numbers have been assigned to each category of food.

Standard No Codex Standard Title Food Cat. No.

150-1985 Food Grade Salt 12.1.1

LIST OF STANDARD ADDITIVES FOR SALT

CODEX STAN 192-1995, Ref: Table 1 & 2, page # 406/480 may be used in foods subject to

this standard. All additives used shall be of food grade quality.

1 CALCIUM CARBONATE (CaCO3) Year of adoption: 2006

INS # 170(i)

Functional Class: Acidity regulator, Anticaking agent, Colour, Firming agent, Flour

treatment agent, Stabilizer

Max. Lavel: GPM (Good Manufacturing Practice)

2 CALCIUM SILICATE Year of adoption: 2006

INS # 552

Functional Class: Anticaking agent

Max. Lavel: GPM (Good Manufacturing Practice)

3 FERROCYANIDES Year of adoption: 2006

INS # 535, 536, 538

Functional Class: Anticaking agent

Max. Lavel: 14 mg/kg

Note 24: As anhydrous sodium ferrocyanide.

Note 107: Except for use of sodium ferrocyanide (INS 535) and potassium ferrocyanide

(INS 536) in food-grade dendridic salt at 29 mg/kg as anhydrous sodium ferrocyanide.

4 MAGNESIUM CARBONATE Year of adoption: 2006

INS # 504(i)

Functional Class: Acidity regulator, Anticaking agent, Colour retention agent.

Max. Lavel: GPM (Good Manufacturing Practice)

5 MAGNESIUM OXIDE Year of adoption: 2006

INS # 530

Functional Class: Acidity regulator, Anticaking agent.

Max. Lavel: GPM (Good Manufacturing Practice)

Himalayan Edibles Private Limited Page 10

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

6 MAGNESIUM SILICATE SYNTHETIC. Year of adoption: 2006

INS # 553(i)

Functional Class: Anticaking agent.

Max. Lavel: GPM (Good Manufacturing Practice)

7 PHOSPHATES Year of adoption: 2006

INS # 338; 339(i)-(iii); 340(i)- (iii); 341(i)-(iii); 342(i)- (ii); 343(i)-(iii); 450(i)- (iii),(v)-

(vii), (ix); 451(i),(ii); 452(i)-(v); 542

Functional Class:.

Max. Lavel: 8800 mg/kg

Note: As phosphorus.

8 POLYSORBATES Year of adoption: 2006

INS # 432-436

Functional Class:

Max. Lavel: 10 mg/kg

9 SALTS OF MYRISTIC, PALMITIC AND STEARIC ACIDS WITH

AMMONIA, CALCIUM, POTASSIUM AND SODIUM

INS # 470(i) Year of adoption: 2006

Functional Class: Anticaking agent, Emulsifier, Stabilizer

Max. Lavel: GPM (Good Manufacturing Practice)

Note 71: Calcium, potassium and sodium salts only.

10 SILICON DIOXIDE, AMORPHOUS Year of adoption: 2006

INS # 551

Functional Class: Anticaking agent, Antifoaming agent, Carrier.

Max. Lavel: GPM (Good Manufacturing Practice)

11 SODIUM ALUMINO SILICATE. Year of adoption: 2013

INS # 554

Functional Class:

Max. Lavel: 1000 mg/kg

Note-6: As aluminium.

Note-254: For use in salt applied to dry salted cheeses during manufacturing only.

Good Manufacturing Practice (GMP)

All food additives subject to the provisions of this Standard shall be used under conditions of good

manufacturing practice, which include the following:

a) The quantity of the additive added to food shall be limited to the lowest possible level necessary

to accomplish its desired effect.

b) The quantity of the additive that becomes a component of food as a result of its use in the

manufacturing, processing or packaging of a food and which is not intended to accomplish any

physical, or other technical effect in the food itself, is reduced to the extent reasonably possible;

c) The additive is of appropriate food grade quality and is prepared and handled in the same way

as a food ingredient.

Himalayan Edibles Private Limited Page 11

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

4.c IODINE FORTIFICATION

Fortification of salt with iodine, termed 'salt iodization' is one of the main means of

increasing a population's iodine intake and reducing the risk of Intellectual and

developmental disabilities (IDDs) (WHO 2007b). Universal iodization of salt is the

preferred strategy for the control of IDD in most countries. Intellectual and

developmental disabilities are disorders that are usually present at birth and that

negatively affect the trajectory of the individual’s physical, intellectual, and/or emotional

development. Many of these conditions affect multiple body parts or systems.

All food-grade salt, used in household and food processing should be fortified with

iodine as a safe and effective strategy for the prevention and control of iodine deficiency

disorders in populations.

Iodine contents at manufacturing stage shall not be lower than 30 ppm. Potassium

Iodate (KIO3) shall not be lower than 50 ppm on dry weight basis with one year of

manufacture. Iodine contents at distribution channel and at retail level 15 to 25 parts per

million on dry weight basis.

Note: 1 ppm = 1mg/Kg or 1 mg / Liter

Iodization agent.

1. Potassium Iodate (KIO3), Calcium Iodate may be used for iodine fortification of salt.

Potassium Iodate and Calcium Iodate do not need stabilization agent

2. Potassium Iodide (KI) may be used for iodine fortification of salt but it needs

stabilization agent.

Himalayan Edibles Private Limited Page 12

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

4.d IODINE FORTIFICATION PROCESS:

Iodine is added as potassium iodate (KIO3) to salt after process of refining and

drying and before packing. There are dry or wet mixing methods for adding iodine in

salt.

Dry Mixing

This process is suitable for fine and even-grained salt with a grain size of less than 2 mm.

Step-1

Make Dry Mixture (KIO3)

(Anti-caking agents)

Calcium Carbonate

Potassium iodate (KIO3) Or

Tricalcium phosphate

Or

Magnesium carbonate

Ratio 1 : 9

Step-2

Make Premix (KIO3)

Dry Mixture (KIO3) Bulk Salt

(one Part) (Ten Part)

Ratio 1 : 10

Step-3

Salt Iodization

Premix (KIO3) Bulk Salt

Both introduced in Screw Conveyor at

constant rate in appropriate ratio

Caution: Thorough mixing of the salt after the addition of the potassium iodate is necessary to

ensure even penetration of the potassium iodate. The insufficient mixing may result wide variation in

product. Practice

adopted in South and Central America i/c Argentina, Bolivia, Guatemala and Peru.

Himalayan Edibles Private Limited Page 13

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Dry Mixing method in China

China unique and compact type of dry mixing machine as shown below.

Premix Salt

KIO3+ Salt

Bulk Salt

(Ratio 1:2000)

Rotary Valve

to Adjust Ratio

Dry mixing of salt with KIO3 is possible only if the salt is dry and finely ground.

Otherwise the KIO3, having a finer particle size and being heavier than salt, will settle at

the bottom of the container. This method is therefore not recommended for the unrefined

coarse salt that is commonly used in developing countries.

Himalayan Edibles Private Limited Page 14

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Wet Mixing

In the wet method, potassium iodate is first dissolved in water to make a concentrated

solution. This solution can be either dripped or sprayed on the salt at a uniform rate.

1. Drip Feed Addition

This process is commonly used for iodization of crystalline salt. The drip-feed system is

the simplest and cheapest. It is suitable for coarse salt with uniform particles of a size up

to 1 cm and a moisture content of up to 5%. However, when the particle size of the salt is

very fine (less than 2 mm), the drip feed system is not suitable because it does not disperse

the iodate solution with sufficient uniformity.

Step.1 The Salt is fed into a hopper (capacity of about 300 kg) that discharges at a

uniform rate onto a belt conveyor, about 35-40 cm wide and 5.5 m long inclined at a slope

of about 20 degrees. The conveyor is equipped with a tensioning device. The rate of salt

flow onto the conveyor is controlled by a slide valve.

Step.2 Flexible rubber curtains on three sides shape the salt into a narrow band 10-12 cm

wide and 2 cm deep on the conveyor belt and prevent it from spilling over the edge.

Step.3 The KIO3 solution is stored in two 200 litre polyethylene stock tanks with

discharge valves at the bottom to permit the filling of two 25 litre feed bottles, mounted to

ensure a continuous circulation of solution from the main tank to the feed bottles.

Step.4 The solution continuously drips at the desired rate onto the salt crystals.

Step.5 The iodized salt falls into a discharge hopper for collection in bags. For continuous

operation the hopper should have a twin spout with a diversion valve.

Note- i : The capacity of 5 tons per hour is ideal for a drip feed system, which requires

only a low pressure head to maintain the required flow rate.

Note-ii : This method is used in some Asian countries, for example, Indonesia. The drip

feed system is simple and cheap and is often used for iodizing moist crude salt crystals

and even refined powder salt.

Note-iii : In a simplified system used in India, the drip system is introduced into the feed

point of a salt grinder. The drip feed system followed by grinding often yields consistent

iodate dispersion.

Himalayan Edibles Private Limited Page 15

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

2. Spray Mixing

when the particle size of the salt is very fine (less than 2 mm), the spray-mix

method is better because it atomizes the iodate solution and sprays it as a mist, thus

mixing it uniformly with the salt. The spray-mix method is also preferable to the drip feed

system when the salt varies in particle size and moisture content, as frequently occurs

when the iodizing plant receives salt from a number of different sources.

Iodization is to be integrated with existing salt production and refining systems.

The salt slurry from a thickener is dewatered in a centrifuge and then dried in a rotary or

fluid bed drier. Into this system a sensor installed on the thickener can send a signal to the

solution dosing pump that sprays iodate solution at a rate proportional to the flow rate of

solids to the centrifuge.

Salt iodization plants is required where refining equipment is not available. Large

salt lumps are crushed to a coarse powder in impact crusher and roller mill and after

passing through vibrating screen, fed into a feed hopper fitted. A rotary valve is fitted in

the outlet of the hopper and regulates the flow onto an inclined conveyor belt. The shafts

are driven by a variable speed drive system and the rate of rotation is adjusted to give the

required discharge.

The sheet of salt discharging from the belt into the spray chamber receives a fine

atomized spray of potassium iodate solution from two nozzles, at a pressure of 1.4 kg/cm2.

The spray nozzles are designed to deliver a flattened spray that spreads over the entire

width of the salt stream. The concentration of solution and the spray rates are adjusted to

yield the required dosage of iodate in the salt. The iodate solution is kept under pressure

in two stainless steel drums, each of about 80 liters capacity. The pressure in the drums is

maintained constant by an air compressor with a regulator. The salt with added

potassium iodate falls into a screw conveyor 20-25 cm wide and 2.5-3.0 m long. Travel

through the screw provides uniformity of mixing. The screw conveyor discharges into

twin outlets where bags are kept ready for filling. All the parts coming into direct contact

with salt are made of stainless steel, to minimize corrosion.

A spray mixing type of plant built to UNICEF specifications operates at 6

tons/hour or about 12,000 tons per year. This method is being increasingly preferred in

Asia, South America, and Africa.

Himalayan Edibles Private Limited Page 16

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3. Batch Type Mixing.

A batch-type version has been developed in India for small manufacturers who

cannot afford or do not need continuous spray mixing plants. It consists of a ribbon

blender fitted with an overhead drip or spray arrangement. A pre-weighed quantity of

salt is fed into the blender. The blender is operated and a prefixed quantity of iodate is

sprayed through overhead nozzles using a hand pump or compressor as mixing proceeds.

After iodization, the batch is discharged and packed.

RIBBON BLENDER

The blenders are powered by suitable motors. The rotation is reduced through a

suitable gear box to give a speed of 20-30 rpm. The speeds and power requirements of

blenders of different capacities are given below:

Batch Capacity Power drawn Required power

125 kg 2.2 KW 3 HP

250 kg 3.7 KW 5 HP

500 kg 3.7 KW 5 HP

+ 1.5 kw (Elevator) +2 HP (Elevator)

Note: In smaller blenders, salt is fed manually

Himalayan Edibles Private Limited Page 17

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

BATCH BLENDER CAPACITY

The quantity of salt that can be produced by a batch blender is determined by the

cycle time and batch capacity. Assuming:

1. Loading: 3 min

2. Mixing: 10 min

3. Unloading: 2 min

4. Relax: 5 min

5. Total time for a single batch would be 20 minutes.

6. There will be 3 cycles per hour.

7. Yielding a daily 8-hour iodization capacity

reflected in the following table:

Batch Capacity Production Production Production

capacity/hr capacity/shift capacity/yr (250

days)

125 Kg 0.375 ton 3 ton 750 ton

250 Kg 0.750 ton 6 ton 1500 ton

500 Kg 1.500 ton 12 ton 3000 ton

The spray system atomizes the iodate solution and disperses it uniformly on the

salt crystals, thus ensuring much more uniform mixing when compared to the drip feed

system for all kinds of salt. The equipment requirements for the spray system and their

maintenance are a little more elaborate.

This method is simple to operate in the capacity range 0.5-3 tons/hour. It is already

being used in India, Peru, Vietnam.

Himalayan Edibles Private Limited Page 18

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Amount of KIO3 solution in L/hr for 5 ton/hr spray mixing plant

Iodization gram Strength of Strength of Strength of

level KIO3 KIO3 solution KIO3 solution KIO3 solution

10 gram/Ltr. 20 gram/Ltr. 30 gram/Ltr.

20 ppm 100 10.0 5.0 3.3

30 ppm 150 15.0 7.5 5.0

40 ppm 200 20.0 10.0 6.7

50 ppm 250 25.0 12.5 8.3

60 ppm 300 30.0 15.0 10.0

70 ppm 350 35.0 17.5 11.7

80 ppm 400 40.0 20 13.3

90 ppm 450 45.0 22.5 15.0

100 ppm 500 50.0 25.0 16.7

VOLUME OF KIO3 SOLUTION TO OBTAIN 50 PPM SALT

Batch Strength of KIO3 Strength of KIO3 Strength of KIO3

Qty. solution 10 g/L solution 20 g/L solution 30 g/L

125 Kg 625 ml 313 ml 208 ml

250 Kg 1250 ml 625 ml 416 ml

500 Kg 2500 ml 1250 ml 833 ml

Himalayan Edibles Private Limited Page 19

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Comparison of Iodization methods

Method Criterion Drip Spray Dry Mix

Salt Type: Refined powder, dry Fair Good Good

Salt Type: Unrefined powder, dry Fair Good Good

Salt Type: Unrefined powder, moist Fair Fair Fair

Salt Type: Unrefined crystals, dry Fair Fair Poor

Salt Type: Unrefined crystals, moist Poor Fair Poor

Cost: Capital cost Medium Med High

Cost: Operating cost Medium Medium High

Cost: Cost to consumer Medium Medium High

Simple Methods for Salt Iodization at the Village Level

The simplest method is the dry mixing of sodium chloride with KIO 3, or with KI.

For an iodization level of 50 ppm (1:20,000), one needs to add 84 mg of KIO3 for each kg

of sodium chloride.

Since the amount of KIO3 is so small, it will have to be supplied in pre-weighed packets

because accurate balances will virtually never be available in villages choosing this

approach.

Himalayan Edibles Private Limited Page 20

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Operations Control - Spray Mixing Process (batch and continuous)

The success of the spray-mixing process depends on ensuring a steady and

uninterrupted flow of salt from the conveyor belt. The spray should cover the entire

width of the sheet of salt falling into the chamber. The movement of the belt must be even

and the speed uniform. The belt tension should be checked to ensure that the throughput

rate does not fluctuate owing to belt slippage. Care should be taken to see that the air

pressure is

maintained at the desired level (25 psi).

The KIO3 solution should be prepared by dissolving the pre-weighed quantity of

iodate powder in water(preferably distilled) and filtering it through a fine cloth to avoid

clogging the nozzles with any undissolved crystals and extraneous matter, and then

analyzed to check the concentration. For a quick check, the concentration can also be

measured with a precision hydrometer. An iodate solution concentration of 25-30 gms per

litre is recommended. Evaporation of the iodate solution and crusting in the nozzle

present the danger of clogging the nozzles. It is therefore advisable to check the nozzles

every day and to clean them by immersion in boiling distilled water for 30 minutes

whenever necessary, or at least once a week. The nozzles may have to be replaced once a

year.

The chemist should collect samples of iodized salt at regular intervals as it flows

out of the chutes. He should analyze them immediately for iodine content, and advises the

plant operator to take corrective measures, as needed, by adjusting the flow of salt/spray.

This analysis must be very prompt to permit effective control of levels.

Iodized salt should be collected into bags directly as it flows out of the chutes

instead of allowing it to fall onto the ground, because any moist crystals may pick up dust

and dirt.

Maintenance of Iodization Equipment

All parts of the plant that are not stainless steel should be regularly cleaned with

rags to brush away salt particles and given a coat of anti-corrosive paint periodically as

outlined below.

Maintenance painting is necessary to protect equipment of mild steel (carbon steel)

from saline corrosion. This involves surface preparation and coating. Surface preparation

and application are as important to the successful life of a coating as the coating itself.

Without proper surface preparation, the most resistant coating will fail in service. After

hand cleaning the steel of scale, dirt and grease, the surface has to be sand blasted to near

Himalayan Edibles Private Limited Page 21

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

white metal. Where the surface is small, it has to be thoroughly scraped with a steel wire

brush.

For coating, a paint based on epoxies, neoprene chloroprene, chlorinated rubber,

polyvinylidene chloride, or polyvinyl chloracetates is recommended. The proper coating

procedure begins with two primer coats, including a first coat of 2-component cold-curing

epoxy resin-based primer with zinc chromate, color grey and a second coat of the same

primer, but of grey colour with bluish tinge, to give a total thickness of two coats not less

than 80 microns, followed by two final coats of two- component cold-curing epoxy-based

paint.

All the bearings should be well greased so that the operational efficiency of the

plant is maintained. Jammed rollers and slow-moving belt conveyors will give uneven

iodization.

4.e Double Fortification

Salt is an ideal carrier of micronutrients. The double fortification of salt with

both iodine and iron is an attractive approach to the reduction of both anemia and iodine-

deficiency disorders.

Folate, also known as vitamin B9 and folacin, is one of the B Vitamins manufactured folic

acid, which is converted into folate by the body, is used as a dietary supplement and

in food fortification as it is more stable during processing and storage. Folate is required

for the body to make DNA and RNA and metabolise amino acids necessary for cell

division. As humans cannot make folate, it is required in the diet, making it an

essential nutrient. It occurs naturally in many foods.

Folate (as a fortification ingredient, folic acid) functions in reducing blood homocysteine

levels, forming red blood cells, proper growth and division of cells and preventing neural

tube defects

4.f TRIPLE FORTIFICATION

The best formulation of 12.5 ppm folic acid, 50 ppm iodine, and 1,000 ppm iron, which

will deliver at least 50% of the Recommended Dietary Allowance (RDA): (average daily

level of intake sufficient to meet the nutrient requirements of nearly all (97%-98%)

healthy people) of the micronutrients based on a daily consumption of 10 g salt.

Himalayan Edibles Private Limited Page 22

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Building Requirements

For a 5 tons/hr plant working 8 hours a day, the daily requirement of salt is 40 tons.

Assuming a raw salt stock of 15 days and a finished product stock of 15 days, the total

storage capacity should be 1200 tons. On this basis, the building area is estimated in this

table which estimates the required building area for 5 ton/hr, single shift plant

Purpose Spaces Requirement

ton (m2)

Salt storage, 1200 tons (4 ton/m²) 300

Alleyways and passages (add 30% of storage) 90

Iodization plant and processing room 100

Office 16

Stores for spares, etc. 16

Switch room 6

Laboratory 9

Bay for loading and unloading 150

Total Area Required 687 m²

Himalayan Edibles Private Limited Page 23

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

4.g .

NUTRICIAN FACTS TABLE SALT

For a Serving Size of 1 gram

Amount per serving

Calories 0 Calories from fat 0

% Daily Value *

Total Fat 0g 0%

Saturated Fat 0g 0%

Cholesterol 0g 0%

Sodium 380 mg 15%

Total Carbohydrates 0g 0%

Dietary Fiber 0g 0%

Protein 0g 0%

Vitamin A 0% Vitamin C 0%

Calcium 0% Iron 0%

Zinc 0% Thamin 0%

Riboflavin 0% Niacin 0%

Vitamin B-6 0% Folate 0%

Vitamin B-12 0% Phosphorus 0%

Magnesium 0% Vitamin D 0%

* Percent Daily Value (%DV) are based on a 2,000-calorie diet for

healthy adults.

Dietary Guidelines recommends adults should not consume 2300 mg

of sodium per day, which is equal to 1 teaspoon or 6 gram of Salt.

Himalayan Edibles Private Limited Page 24

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

5. IN HOUSE LABORATORY FACILITIES FOR SALT

MANUFACTURING.

In this section list of laboratory equipment has been provided for performing

various chemical analysis of edible salt. The facility enables us to ensure quality of

product as food grade.

LIST OF CHEMICAL LABORATORY EQUIPMENTS

1. Analytical Balance OR

Scientific weighing scale digital.

least count 1.0 mg

(One Set With Calibration Weights)

2 Lab. Dish

Size 2 to 3 inch dia.

3 Numbers

Himalayan Edibles Private Limited Page 25

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3 Chemistry Lab Cylinder

1000 ml = 1 number

500 ml = 3 numbers

4 Chemistry Lab Reagent Bottle

1000 ml = 1 number

500 ml = 3 numbers

4 Chemistry Lab Beaker

1000 ml = 1 number

500 ml = 2 numbers

200 ml = 2 numbers

Himalayan Edibles Private Limited Page 26

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

5 Chemistry Lab Glass Stirrer

Quantity = 6 numbers

6 Chemistry Lab Glass Pippete

with cleaning brush

50 ml = 1 number

30 ml = 1 numbers

20 ml = 1 numbers

10 ml = 1 numbers

5 ml = 1 numbers

7 Chemistry Lab Volumetric

Pippete.

100 ml = 1 number

Himalayan Edibles Private Limited Page 27

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

8 Chemistry Lab Funnel

Quantity = 1 number

9 Chemistry Lab Flask

200 ml = 1 number

150 ml = 1 number

100 ml = 1 number

50 ml = 1 number

25 ml = 1 number

10 Chemistry Lab Filter Paper

Quantity = 1 box

Himalayan Edibles Private Limited Page 28

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

11 Chemistry Lab Spirit Lamp

Quantity = 1 number

12 Chemistry Lab Methylated

Spirits

Quantity = 3 Liter

13 Chemistry Lab spatula

Quantity = 6 Numbers

Himalayan Edibles Private Limited Page 29

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

14 Chemistry Lab Titration

apparatus

Buret = 1 number

Buret Stand = 1 Number

conical flask

with stopper = 1 Number

Himalayan Edibles Private Limited Page 30

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

6.a IODOMETRIC LAB TEST

PRINCIPLE:

The Iodine content in iodized salt containing potassium iodate is estimated by a

process called iodometric titration. Free iodine reacts with sodium thiosulphate solution as

follows:

2 Na2S2O3 + I2 → 2NaI + Na2S4O6

Sodium Iodine Sodium Sodium

thiosulphate iodide tetrathionate

Sulphuric acid to solution of iodized salt which liberates iodine, which is titrated with

sodium thiosulphate. Starch is used as an external indicator. Potassium iodide solution is

added to keep the Iodine in the dissolved state.

6.b REAGENTS AND REAGENT PREPARATION FOR IODOMETRIC LAB TEST

Arrange Reagents:

1. Sodium thiosulphate (Na2S2O3)

2. 2 N Sulphuric acid (H2SO4)

3. Potassium iodide (KI, AR)

4. Soluble chemical starch

5. Double Distilled Water.

Preparation of Reagents:

Sodium thiosulphate (Na2S2O3)

Dissolve 1.24 g Na2S2O3 in 1 Liter boiled, double-distilled water. This volume is sufficient

for testing 200 salt samples. Store in a cool, dark place. Properly stored, the solution can

be kept for a few months.

2 N Sulphuric acid (H2SO4)

Add 0.6 ml concentrated H2SO4 slowly To 90 ml double – distilled water. Add boiled,

double-distilled water to make 100 ml. This volume is sufficient for 100 salt samples. store

in a cool dark place. The solution may be kept indefinitely.

Himalayan Edibles Private Limited Page 31

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Caution: To avoid violent and dangerous reaction always add the acid to water, never water

to acid.

Potassium iodide (KI, AR)

Dissolve 10 g KI in 100 ml double-distilled water. This volume is sufficient for testing 20

salt samples. Store in a cool, dark place. Properly stored, the solution may be kept for 6

months.

Soluble chemical starch

Dissolve sodium chloride (NaCl) reagent (AR) in 100 ml boiled, double-distilled water.

While stirring, add NaCl until no more dissolves. Heat the contents of the beaker till

excess salt dissolves. While cooling the NaCl crystals will form on the sides of the beaker.

When it is completely cooled, decant the supernatant in a clean bottle. This can be stored

for 3 to 4 weeks.

Dissolve 1 g chemical starch in 10 ml boiling double-distilled water. Continue to boil till in

completely dissolves. Add the saturated NaCl solution to make 100 ml starch solution.

This volume is sufficient for testing 20 salt samples. Prepare fresh starch solution every

day since starch solution cannot be stored.

Himalayan Edibles Private Limited Page 32

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

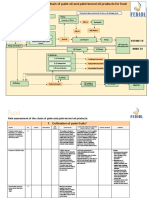

6.c IODOMETRIC TITRATION TEST PROCEDURE

Step-6 Step-5 Step-2 Step-1

Pipette out 5 ml of 10%

potassium iodide and Sulfuric Acid Double Distilled Water Salt 10

2N Boiled grams

add this to the salt

1 ml

solution (50 ml) (Sample)

Step-7 Slowly

1. The solution turns

yellow.

2. Put stopper on flask.

3. Put flask in dark for 10

minutes.

4. Bring out after 10

minutes, & Shake it.

Step-6 Step-4 Step-3

1. Titrate with Sodium Use Stirrer to

Thiosulphate (note 0"

dissolve Salt

at buret)

Completely

2. Stop Till solution

becomes pale / very

light yellow

Step-10

Step-9

1. Go on with Titration with

Add 1% starch solution Sodium Thiosulphate (from

to the flask (1 to 5 ml) buret)

till solution turns 2. Stop Till solution becomes

deep purple colorless

Step-11 (End)

Note Buret Reading

and check value

corresponds in table

for iodine PPM

Himalayan Edibles Private Limited Page 33

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

LABORATORY PROCEDURE (Pakistan Standards PS-1669-2008)

The procedure is as follows:

S.No. Procedure

1 Carefully weigh 10 g of the salt to be tested.

2 Pour the salt into a 50 ml measuring cylinder.

3 Slowly add boiled, double-distilled water

4 Shake to dissolve the salt completely

5 Add more water to make 50 ml

6 Pour the salt solution (50 ml) into a conical flask with stopper

7 Pipette out 1 ml of 2 N Sulphuric acid and add this to the salt solution

8 The solution turns yellow; Close the flask with the stopper and put it in

the dark for 10 minutes. A closed box, cupboard or drawer may be used.

9 Pipette out 5 ml of 10% potassium iodide and add this to the salt solution

10 The solution turns yellow; Close the flask with the stopper and put it in

the dark for 10 minutes. A closed box, cupboard or drawer may be used.

11 Pour sodium thiosulphate into a burette.

12 Adjust the level in the burette to ‘0’

13 After 10 minutes, take the flask out of the dark box

14 Shaking the flask, titrate the solution in the flask with sodium

thiosulphate from the burette

15 Stop titration as soon as the solution turns pale (becomes very light

yellow)

16 Add a few drops (1 to 5 ml) of 1% starch solution to the flask

17 The solution turns deep purple

18 Continue titration until the purple coloration disappears and the solution

becomes colourless

19 Note the burette reading

20 From the attached table, read the iodine content of the sample in parts

per million.

Himalayan Edibles Private Limited Page 34

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

6 d TABLE OF IODINE CONTENT (IN PPM)

Burette Parts per Burette Parts per Burette Parts per

Reading million Reading million Reading million

(1) (2) (3) (4) (5) (6)

0 0.0 4.0 42.3 8.0 84.6

01 1.1 4.1 43.4 8.1 85.7

02 2.1 4.2 44.4 8.2 86.8

03 3.2 4.3 45.5 8.3 87.8

04 4.3 4.4 46.6 8.4 88.9

05 5.3 4.5 47.6 8.5 89.9

06 6.3 4.6 48.7 8.6 91.0

07 7.4 4.7 49.7 8.7 92.0

08 8.5 4.8 50.8 8.8 93.1

09 9.5 4.9 51.9 8.9 94.2

1.0 10.6 5.0 52.9 9.0 95.2

1.1 11.6 5.1 54.0 9.1 96.3

1.2 12.7 5.2 55.0 9.2 97.3

1.3 13.8 5.3 56.1 9.3 98.4

1.4 14.8 5.4 57.1 9.4 99.5

1.5 15.9 5.5 58.1 9.5 100.5

1.6 16.9 5.6 59.2 9.6 101.6

1.7 18.0 5.7 60.3 9.7 102.6

1.8 19.0 5.8 61.4 9.8 103.7

1.9 20.1 5.9 62.4 9.9 104.7

2.0 21.2 6.0 63.5

2.1 22.2 6.1 64.5

2.2 23.3 6.2 65.6

2.3 24.3 6.3 66.7

2.4 25.4 6.4 67.7

2.5 26.5 6.5 68.8

2.6 27.5 6.6 69.8

2.7 28.6 6.7 70.9

2.8 29.6 6.8 71.9

2.9 30.7 6.9 73.0

3.0. 31.7 7.0 74.1

3.1 32.8 7.1 75.1

Column continuity, See next page

Conti…

Himalayan Edibles Private Limited Page 35

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

TABLE OF IODINE CONTENT (IN PPM)

Burette Parts Burette Parts Burette Parts per

Reading per Reading per Reading million

million million

(1) (2) (3) (4) (5) (6)

3.2 33.9 7.2 76.2

3.3 34.9 7.3 77.2

3.4 36.0 7.4 78.3

3.5 37.0 7.5 79.4

3.6 38.1 7.6 80.4

3.7 39.1 7.7 81.5

3.8 40.2 7.8 82.5

3.9 41.3 7.9 83.6

6 e IODOMETRIC LAB TEST REPORT

(FORMAT FOR SALT REPORTING)

Iodine testing is easy and takes only about twenty minutes per sample.

Maintaining accurate records is as important as the testing itself. The results are to be

recorded in a register indicating.

date of testing

sample number

batch number of the salt,

date of iodization

where the sample was taken from,

date of sampling, and finally,

level of iodine in the sample

Daily reports of the findings are made and the supervisor is to be alerted if the

iodine content is less than the prescribed level. Your report will lead to action to

protect the consumer. Delay on your part will delay these actions and harm the

consumer.

Himalayan Edibles Private Limited Page 36

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

SALT IODOMETRIC LAB TEST REPORT FORM

Date of Testing

Sample Number

Batch number of the Salt.

Date of Iodization

Where the sample was taken from?

Date of sampling.

REAGENTS DATA:

Date of preparing Sodium thiosulphate (Na2S2O3)

reagent.

Date of preparing 2 N Sulphuric acid (H2SO4) reagent.

Date of preparing Potassium iodide (KI, AR) reagent.

Date of preparing Soluble chemical starch reagent.

Water distillation.

RESULT

Titration Burette Reading.

Corresponding ppm from table of iodine contents.

Sign:

Name ________________________________

(Name and Signature of Analyst)

Himalayan Edibles Private Limited Page 37

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

7 a DETERMINATION OF SODIUM CHLORIDE

A. EQUIPMENT

Note: Equivalent apparatus may be substituted

1. Apparatus

a. Burette - Class A, Kimax

b. 300 mL Erlenmeyer flasks - Pyrex

c. 25 mL pipettes - Class A, Pyrex

d. Boiling chips - Carborundum #12 granules, Cat. No. 133-B, Hengar Co.

e. Volumetric flask - 1 L, Class A, Kimax

f. Drying oven - FREAS oven Model 625, Cat. No. 51221139, Precision

Scientific

B REAGENTS AND SOLUTIONS

Note: Equivalent reagents or solutions may be substituted

1. Reagents

a. Ferric alum indicator-Saturated aqueous solution of reagent grade

FeNH4(SO4) 2•12 H2O - ACS Grade, Cat. No. 3070, RICCA Chemical

Company

b. Nitric Acid - reagent grade (HNO3) ACS Grade, Cat. No. 9601, J.T. Baker

c. Potassium Permanganate (KMnO4) - ACS Grade, Cat. No. 7056,

Mallinckrodt

d. Diethyl Ether - reagent grade, Cat No. 9244, J.T. Baker

e. Lactose - ACS Grade, Cat. No. 2248, J.T. Baker

Himalayan Edibles Private Limited Page 38

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

f. Silver Nitrate (AgNO3) - ACS Grade, Cat. No. 2169, Mallinckrodt

g. Potassium Thiocyanate - ACS Grade, Cat. No. 7168, Mallinckrodt

h. Potassium Chloride - ACS Grade, Cat. No. 6858, Mallinckrodt

i. Potassium Chromate - ACS Grade, Cat. No. 6870, Mallinckrodt

j. Water, distilled or deionized

2. Solutions

a. Silver Nitrate (0.1000N ± 0.0005N):

Dissolve 17.04 g of AgNO3 in water in a 1 L volumetric flask. Dilute to

volume with water.

b. Potassium thiocyanate (0.1000N ± 0.0005):

Dissolve 9.72 g of reagent grade KSCN in water in a 1 L volumetric flask.

Dilute to volume with water.

c. 1:1 Nitric Acid

Add 100 mL of HNO3 to 100mL of water and mix carefully.

d. 5 % Potassium permanganate solution

Add 100 g of KMNO4 to a 2 L graduated cylinder or volumetric flask.

Dilute to volume with water. Mix well. Store in actinic glassware or

otherwise protect from light.

e. Potassium Chromate-5 % solution

Add 5 g of K2CrO4 to 100 mL volumetric flask. Dilute to volume with

water and mix.

Himalayan Edibles Private Limited Page 39

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

3. Standardization of AgNO3 and KSCN

a. Standardize the AgNO3 solution as follows

i. Weigh 0.2500 ± 0.0500 g of KCl that has been dried at 101 °±1 °C for 1

hour

± 10 min into a 250 mL Erlenmeyer flask and dissolve in 40 mL of

water.

ii. Add approximately 1 mL of K2CrO4 indicator.

iii. Titrate with the AgNO3 solution to a permanent light brown (salmon

colored) endpoint.

b. Standardize the KSCN solution as follows

i. Pipette 25 mL of standard AgNO3 solution into a 300 mL Erlenmeyer

flask.

ii. Add approximately 80 mL of water.

iii. Add 15 mL of a 1:1 HNO3.

iv. Add approximately 2 mL of the ferric alum indicator.

v. Titrate with KSCN solution to a permanent light brown (salmon

colored) end point. The ratio of the volume of KSCN to the volume of

AgNO3 should be 1:1.

C SAMPLE PREPARATION

Process samples until homogeneous.

D ANALYTICAL PROCEDURE

1. Determination

a. Weigh 2.5-3.0 g of finely comminuted and thoroughly mixed sample into a

300 mL Erlenmeyer flask. Run a reagent blank and a previously analyzed

sample as a recovery with each set of samples.

Himalayan Edibles Private Limited Page 40

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Note: For country ham and cured products, weigh out 1.0 to 1.5 g. For

“seasoning” samples weigh 10 g into a 100 mL volumetric flask and

dilute to volume with water. Pipet a 1.0 mL aliquot into a 300 mL

Erlenmeyer flask and record the weight as 0.10 g.

b. Add 25.0 mL of 0.1000 ± 0.0005 N AgNO3 solution, swirl flask until sample

and solution are in intimate contact, and then add 15 mL of conc. HNO3.

c. Add sufficient boiling chips and boil until meat digests. Add a small amount

of lactose to the reagent blank.

d. Note: Solution will turn from a cloudy white color to yellow.

e. Add KMnO4 solution in small portions while boiling to turn solution dark

brown.. Continue boiling until color disappears. Continue adding small

portions of KMnO4 until solution retains dark color for several minutes

before clearing. Wash sides of flask with water..

NOTE: If solution retains color and will not become colorless, add a small

amount of lactose until color disappears.

e. Add approximately 25 mL of water; boil for approximately 5 min, cool

to room temperature in the fume hood, rinse the neck of the flask and

dilute to approximately 150 mL with water.

f. Add approximately 5 mL of diethyl ether (optional), approximately 2

mL of the ferric alum indicator, and swirl to coagulate the precipitated

AgCl. (If results are rounded to 0. 1 %, the diethyl ether need not be

added.)

g. Titrate the excess AgNO3 with KSCN solution to a permanent, salmon

colored, end point.

NOTE: If titration with KSCN is less than 2 mL, repeat with a smaller

sample weight.

Himalayan Edibles Private Limited Page 41

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

E CALCULATIONS

1. Procedure

[25.0 ml - (ml KSCN)(R)](N AgNO3)(5.85)

Percent NaCl = -----------------------------------------------------------

Sample Weight

ml AgNO3

where R = ratio of ----------------------

ml KSCN

F SAFETY INFORMATION AND PRECAUTIONS

1. Required Protective Equipment — Safety glasses, heat-resistant gloves, and lab

coat.

2. Hazards

Procedure Step Hazard Recommended Safe

Procedure

Ferric alum May irritate skin, eyes, or respiratory Prepare and use in a fume

FeNH4(SO4) 2•12H2O system hood.

Nitric Acid - reagent Will cause severe burns to all body Prepare solutions in a

grade (HNO3) tissue. May be fatal if swallowed or fume hood. Store out of

inhaled. direct sunlight. Regulate

Will react with water or steam to contact with heat, water,

produce heat and toxic and corrosive and incompatible

fumes. materials.

Potassium Oxidizer, contact with reducing agents

Permanganate or combustibles may cause ignition or

(KMnO4) extremely violent combustion. Causes

burns to all tissue. Toxic metal fumes

may form when heated to

decomposition.

Himalayan Edibles Private Limited Page 42

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

Procedure Step Hazard Recommended Safe

Procedure

Diethyl Ether Flammable liquid and vapor. After Use in fume hood. Protect

long standing or after exposure to air from exposure to air. Do not

or light it may form explosive evaporate to near dryness.

peroxides that are sensitive to

mechanical impact and static

discharge.

Harmful if swallowed, inhaled, or

absorbed through the skin.

Inhalation of vapors may cause

dizziness and unconciousness. May

explode on contact with nitric acid.

Silver Nitrate Corrosive, causes burns to all tissue.

(AgNO3) May be fatal if swallowed. Oxidizer,

contact with reducing agents or

combustibles may cause ignition.

Reacts with ammonia to form

explosive residues.

Potassium Harmful if swallowed or inhaled.

Thiocyanate Causes irritation to the skin, eyes, and

respiratory tract.

Potassium Chromate May be harmful if absorbed through

skin or swallowed.

May cause eye and skin burns. May

cause respiratory tract irritation.

Potassium Chloride May cause irritation to the skin, eyes,

and respiratory tract.

Himalayan Edibles Private Limited Page 43

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

7 b ANALYTICAL REQUIREMENTS FOR EDIBLE SALT.

(World Food Program Version 13.1, dated 26 March 2013)

The principal tests must be performed to check the quality of Iodized Salt to meets

requirements. Additional analyses/stringent requirement shall be followed in case of

Country Specific regulatory requirements on Iodized Salt.

List of compulsory tests and reference method

S.No. Parameter / Test Requirements Analytical Method

(or Equivalent)

1 Organoleptic Smell :Normal

Colour : White

10g of salt in 100 ml water

shall give a colourless

solution having a neutral

reaction

2 Particle Size min 85 % pass through

1.00 mm sieve

max 20 % pass through

0.212 mm sieve

Or: as per specified in the

purchase

Min 97.0 % (m/m, on dry ISO 2481

3 Sodium chloride (NaCl)

(Sodium chloride for matter)

industrial use,

Determination of halogens,

expressed as chlorine --

Mercurimetric method)

4 Moisture content Max 3.0 % (m/m) ISO 2483:1973

(determination of the loss of

mass at 110 degrees oC)

5 Water insoluble matter Max 0.2 % (m/m) ISO 2479

(Sodium chloride for industrial

use, Determination of matter

insoluble in water or in acid and

preparation of principal solutions

for other determinations)

Himalayan Edibles Private Limited Page 44

STANDARDS & QUALITY CONTROL

MANUAL

for EDIBLE SALT manufacturing

HIMALAYAN EDIBLES PRIVATE LIMITED PAKISTAN

www.himalayanedibles.com

6 Iodine 39.0 – 65.0 mg/kg ESPA/CN 109/84

(Based on estimated salt

consumption 3-5g

per day, WHO 2014

Guidelines)

7 Alkalinity (as Na2CO3) Max 0.1 % (m/m) ISO 3196

Sodium hydroxide for industrial

use — Determination of

carbonates content — Titrimetric

method

8 Acid insoluble matter Max 0.15 % (m/m) ISO 2479

Sodium chloride for industrial

use — Determination of matter

insoluble in water or in acid and

preparation of principal solutions

for other determinations

9 Sulphate (as SO4) Max 0.5 % (m/m) ISO 2480

Sodium chloride for

industrial use —

Determination of sulphate

content — Barium sulphate

gravimetric method

10 Arsenic (As) Max 0.5 mg/kg ECSS/SC 312-1982

11 Copper (Cu) Max 2.0 mg/kg ECSS/SC 144-1977

12 Lead (Pb) Max 2.0 mg/kg ECSS/SC 313-1982

13 Cadmium (Cd) Max 0.5 mg/kg ECSS/SC 314-1982

14 Mercury (Hg) Max 0.1 mg/kg ECSS/SC 312-1982

Himalayan Edibles Private Limited Page 45

You might also like

- Full Download Consumer Behaviour 6th Edition Schiffman Solutions ManualDocument36 pagesFull Download Consumer Behaviour 6th Edition Schiffman Solutions Manualntunroulia100% (45)

- IAL Chemistry SB2 Answers Topic11Document7 pagesIAL Chemistry SB2 Answers Topic11salmaNo ratings yet

- Book of Specification of Kampot Pepper - English PDFDocument10 pagesBook of Specification of Kampot Pepper - English PDFErasmus MondusNo ratings yet

- Ready-Mixed White and Yellow Traffic Paints: Standard Specification ForDocument3 pagesReady-Mixed White and Yellow Traffic Paints: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Training Manual For DFS Production For The Salt ProcessorsDocument115 pagesTraining Manual For DFS Production For The Salt ProcessorsSyed AhamedNo ratings yet

- CWMay 2013Document70 pagesCWMay 2013Clint FosterNo ratings yet

- (Vol XI), 2014 Rules For Approval of Manufacturers and Service Suppliers, 2014Document49 pages(Vol XI), 2014 Rules For Approval of Manufacturers and Service Suppliers, 2014Khaeru RoziqinNo ratings yet

- PH Calibration LogDocument1 pagePH Calibration LogAlfred RangelNo ratings yet

- PS 1669-2008 For Iodized Salt Food Grade (2nd Rev.)Document13 pagesPS 1669-2008 For Iodized Salt Food Grade (2nd Rev.)ARIB ALI0% (1)

- Analytical Procedure For Testing Iodine by WYDDocument3 pagesAnalytical Procedure For Testing Iodine by WYDALIYNo ratings yet

- Article Weigh Filling Vs Volumetric Filling SystemDocument2 pagesArticle Weigh Filling Vs Volumetric Filling SystemMayank ShekharNo ratings yet

- Certificate of Analysis Certificate of Analysis: Tests Results SpecificationsDocument1 pageCertificate of Analysis Certificate of Analysis: Tests Results SpecificationsarunNo ratings yet

- Salt Large Internal Monitoring QAQCDocument28 pagesSalt Large Internal Monitoring QAQCHenok DireNo ratings yet

- ASTM Iodine TestDocument7 pagesASTM Iodine TestMoaz Siddig0% (1)

- COA Himalayan SaltDocument4 pagesCOA Himalayan SaltMNo ratings yet

- Format Issue RecordDocument4 pagesFormat Issue RecordBharatNo ratings yet

- (PRPS) ListDocument9 pages(PRPS) ListDeepak MoreNo ratings yet

- Qaqc Manual ArtemisDocument29 pagesQaqc Manual ArtemisKim BalagtasNo ratings yet

- Haccp Documents 1Document26 pagesHaccp Documents 1olivia domingoNo ratings yet

- Quality Control - Equipment List - EHI: #Code Designation Photo Quantity Estimated Price in CHFDocument1 pageQuality Control - Equipment List - EHI: #Code Designation Photo Quantity Estimated Price in CHFalfaroq_almsryNo ratings yet

- Ims Procedure ListDocument1 pageIms Procedure ListRaja RehaNo ratings yet

- Pfi IpmDocument7 pagesPfi IpmRugadya PaulNo ratings yet

- Food Testing Laboratory Food and Foods Administration Idgah Hills, Bhopal, M.PDocument5 pagesFood Testing Laboratory Food and Foods Administration Idgah Hills, Bhopal, M.PTrivesh SharmaNo ratings yet

- Povidone IP SpecificationDocument10 pagesPovidone IP SpecificationadmissionsGNM NSNNo ratings yet

- SOP OP-0100 Rev 0Document3 pagesSOP OP-0100 Rev 0Joe Reaction-NutritionNo ratings yet

- TQM Practices of Aci Salt Industries BangladeshDocument21 pagesTQM Practices of Aci Salt Industries Bangladeshacidreign100% (2)

- UntitledDocument9 pagesUntitledJinna SmaNo ratings yet

- Profile On Table SaltDocument14 pagesProfile On Table SaltAbdisa GemechuNo ratings yet

- Iodized Salt Spec - Testing and Sampling MethodDocument9 pagesIodized Salt Spec - Testing and Sampling MethodHenok DireNo ratings yet

- 0 Himalayan Rock Salt Products Catalog CompDocument30 pages0 Himalayan Rock Salt Products Catalog CompNgô Xuân HàNo ratings yet

- KalaNamak COADocument1 pageKalaNamak COAJanaswami Ramana MurtiNo ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- Goodrich SOPDocument51 pagesGoodrich SOPShikha DhakreNo ratings yet

- Smart Weigh ProjectsDocument6 pagesSmart Weigh ProjectsTCRemziCelikNo ratings yet

- K00326 - 20181121132815 - Lab Manual SKU1023Document26 pagesK00326 - 20181121132815 - Lab Manual SKU1023Kamilia AfiqahNo ratings yet

- Ebook - Hacks On Biofloc Technology For Indoor Shrimp FamingDocument12 pagesEbook - Hacks On Biofloc Technology For Indoor Shrimp Famingadhil paNo ratings yet

- Henok Shiferaw BestDocument156 pagesHenok Shiferaw BestabrhamNo ratings yet

- Arman - Master Control Document - DraftDocument155 pagesArman - Master Control Document - Draftswarnambikafoods2013No ratings yet

- Ludhiana Flour & General Mills Private Limited: Annexures of Haccp SystemDocument2 pagesLudhiana Flour & General Mills Private Limited: Annexures of Haccp SystemMilan BankNo ratings yet

- Iodine Value SOPDocument3 pagesIodine Value SOPsuresh kumarNo ratings yet

- SOP For Rawmaterial SievingDocument2 pagesSOP For Rawmaterial SievingarunNo ratings yet

- SOP FinalDocument11 pagesSOP Finalkishan chiraniaNo ratings yet

- Manual of Labratory Methods For Fortified Foods - Part IDocument23 pagesManual of Labratory Methods For Fortified Foods - Part IHenok DireNo ratings yet

- Formulation Checklist For Plant SuperDocument3 pagesFormulation Checklist For Plant SuperWilfred AlexanderNo ratings yet

- Salt Codex AlimentariaDocument5 pagesSalt Codex AlimentariaMindy GuzmanNo ratings yet

- ADMN-2-002, Issue 01, Procedure For Personal Hygiene, Employee Facility and HousekeepingDocument4 pagesADMN-2-002, Issue 01, Procedure For Personal Hygiene, Employee Facility and Housekeepingsajid waqasNo ratings yet

- QMS-F-PCMR - Pest Control Monitoring RecordDocument4 pagesQMS-F-PCMR - Pest Control Monitoring RecordRajkumar PrajapatiNo ratings yet

- Seid and AbduDocument16 pagesSeid and Abdumuluken walelgnNo ratings yet

- UrlDocument42 pagesUrlmaraki998100% (1)

- Synthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)Document2 pagesSynthetic Food Grade Grease Synthetic Food Grade Grease: (NSF Certified (NSF Certified, Category H1, REGN NO. 147065)mayurghule19100% (1)

- SOP Facility and Equipment HygieneDocument6 pagesSOP Facility and Equipment HygieneHenry Taguma100% (1)

- Specs of ProductDocument4 pagesSpecs of ProductashishNo ratings yet

- Audit RequirementsDocument4 pagesAudit RequirementsarunNo ratings yet

- Sunflower Oil: Material Safety Data SheetDocument3 pagesSunflower Oil: Material Safety Data SheetAlegal EximenteNo ratings yet

- Parker - Compressed Air For Food GMPsDocument8 pagesParker - Compressed Air For Food GMPsXavierNo ratings yet

- Bakels MSDSDocument4 pagesBakels MSDSMd. Hafijur Rahman PlabonNo ratings yet

- Basic Questionnaire For Kosher Certificate 2Document1 pageBasic Questionnaire For Kosher Certificate 2C P TiwariNo ratings yet

- Risk Assessment Palm Food FEDIOL Final 160522Document18 pagesRisk Assessment Palm Food FEDIOL Final 160522Jayashri chitteNo ratings yet

- Sursagar Dairy: WadhwanDocument14 pagesSursagar Dairy: Wadhwanbhavesh1994No ratings yet

- Fumigation With Phosphine - A Perspective: Indian Journal of Entomology January 2016Document7 pagesFumigation With Phosphine - A Perspective: Indian Journal of Entomology January 2016Sheryl RJ LeysaNo ratings yet

- Iota Carragenan Struktur KimiaDocument8 pagesIota Carragenan Struktur KimiasejatiirpanNo ratings yet

- Is 6795 2007Document10 pagesIs 6795 2007TruptiNo ratings yet

- Food AdditivesDocument143 pagesFood AdditiveslongchinNo ratings yet

- Synthetic Approaches Towards Tubulysins and Derivatives ThereofDocument19 pagesSynthetic Approaches Towards Tubulysins and Derivatives ThereofNgô Tuấn KiệtNo ratings yet

- Alkynes and RadicalsDocument7 pagesAlkynes and RadicalsArmando Shehi SayhellotogoodbyeNo ratings yet

- Peru 120W Solar All in One V2.0Document6 pagesPeru 120W Solar All in One V2.0luciano añorgaNo ratings yet

- Salt Number 4 (22-23) DocxDocument4 pagesSalt Number 4 (22-23) DocxBoves AlexNo ratings yet

- Berke, 1992, Estimating Life CycleDocument25 pagesBerke, 1992, Estimating Life CycleÁlvaro MendozaNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- CF India - Extinguishers - Price List - 4.8.21 PDFDocument33 pagesCF India - Extinguishers - Price List - 4.8.21 PDFSanjay Kumar (G K)No ratings yet

- Hydrolysis Rate Improvement in Hydrogen Generation System Fueled by Powdery Sodium Borohydride For Fuel-Cell VehicleDocument8 pagesHydrolysis Rate Improvement in Hydrogen Generation System Fueled by Powdery Sodium Borohydride For Fuel-Cell VehicleNomi WahlaNo ratings yet

- November 2010 Paper 3 Mark Scheme (66Kb)Document5 pagesNovember 2010 Paper 3 Mark Scheme (66Kb)Hin Wa LeungNo ratings yet

- T.Y.B.Sc. 4.1.3 DTA Analysis PPT TYDocument32 pagesT.Y.B.Sc. 4.1.3 DTA Analysis PPT TYmohamed arifNo ratings yet

- ARTIficial IntelligenceDocument4 pagesARTIficial IntelligenceKrupa BrNo ratings yet

- Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using A Coulometric SensorDocument7 pagesOxygen Gas Transmission Rate Through Plastic Film and Sheeting Using A Coulometric SensorlexandroNo ratings yet

- 05-06-2022 SR - Super60 (Incoming) - Jee-Adv (2020-P1) - WTA-29 Q.PAPERDocument18 pages05-06-2022 SR - Super60 (Incoming) - Jee-Adv (2020-P1) - WTA-29 Q.PAPERHarshithNo ratings yet

- Sikalastic 625 UK PDS - Metal & Asbestos RoofsDocument12 pagesSikalastic 625 UK PDS - Metal & Asbestos RoofsstilpgNo ratings yet

- ISO 10414 2 2002 EN FR PreviewDocument11 pagesISO 10414 2 2002 EN FR PreviewRosario PachecoNo ratings yet

- NoPhalt Case StudyDocument1 pageNoPhalt Case Studymmhassan54No ratings yet

- Point GP Assignments and Character TablesDocument23 pagesPoint GP Assignments and Character Tablescescaisabelle19No ratings yet

- 11th Chemistry Book Back 1 Mark Questions (English Medium) Mr. E. Muthusamy Vol 1Document15 pages11th Chemistry Book Back 1 Mark Questions (English Medium) Mr. E. Muthusamy Vol 1MANAVAN IJMHSS0% (1)

- Kinetic Modeling of The Hydrolysis of By: Sucrose InvertaseDocument16 pagesKinetic Modeling of The Hydrolysis of By: Sucrose InvertaseAndrés SánchezNo ratings yet

- A Brief About TundishDocument16 pagesA Brief About TundishOm Prakash Tenduwe100% (3)

- Research Article: The Effect of Thermal Processing On The Saponin Profiles ofDocument7 pagesResearch Article: The Effect of Thermal Processing On The Saponin Profiles ofOktavio Salsabila PutriNo ratings yet

- ST Methods Method 4500 - FluorideDocument8 pagesST Methods Method 4500 - FluoridelaboratoriopcmNo ratings yet

- Pharma Manual PDFDocument24 pagesPharma Manual PDFLawrence Agada88% (8)

- Blood Glucose Measurement by Sweat Using Arduino: K. Nivetha, N. Ramya, R. Thendral & A. GopikrishnanDocument8 pagesBlood Glucose Measurement by Sweat Using Arduino: K. Nivetha, N. Ramya, R. Thendral & A. GopikrishnanWael Abdelgadir AbdelazizNo ratings yet

- Worksheet 11 KeyDocument8 pagesWorksheet 11 KeyNguyễn Minh AnhNo ratings yet

- CNT-chemical SensorsDocument65 pagesCNT-chemical Sensorsqwe qwerNo ratings yet

- Chemistry Icse Class 10 Past Year Board Question SDocument9 pagesChemistry Icse Class 10 Past Year Board Question Ssharmajay1611No ratings yet