Professional Documents

Culture Documents

FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021

FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021

Uploaded by

kbpatel123Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021

FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021

Uploaded by

kbpatel123Copyright:

Available Formats

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/007

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 30/04/2021

Project: Central 48’’ Rich and Lean Gas Segregation Pipe

Manufacturer: M/s. Jindal Saw Ltd.

Line Project

Supply Intended For: OQ Gas Network (OGC) Order No/ LOA No: OGC-21-2019-LOA-92091

Inspection Ordered By: M/s. Jindal Saw Ltd. Place with: OQ Gas Network (OGC) to Jindal Saw Ltd.

Supplier: M/s. Jindal Saw Ltd. Supply / Item: Bare LSAW Pipes

Performing Office (PO): BV – Gandhidham Contracting Office (CO): BV – Ahmedabad

Drawing No: -N.A.- Rev.: -N.A.- ITP No. : Q-OGC-2020NS Rev. : C Dated : 07/07/2020

A] Measuring Instruments Used (including satisfactory verification of suitability)

Please refer Plant Calibration Record Report No. JSLM/ICR/J3/21/016 Dated 25.04.2021

Please refer Lab Calibration Record Report No. JSLM/LAB/CALIBRATION LIST/2021/08 Rev.00 Provided Dated 25.04.2021

Please refer NDT Equipment Calibration Record updated on Dated 23.04.2021

Quantity Offered: Quantity Accepted: Quantity Rejected:

As per “Today’s Qty” of Table – 1 As per “Today’s Qty” of Table – 1 Nil

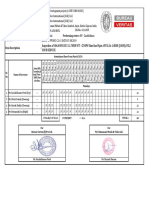

TABLE – 1: LOA Status (Cumulative Qty is accepted qty from Final Visual & Dimensional Inspection)

Ordered

Ordered Previous Today’s Cumulative Balance

Qty

Qty Qty Qty Qty Qty

Sr. combined %

Item Description

No. In Meters In Meters In Meters Completed

In In

(No's of (No's of (No's of In Meters

Meters Meters

Pipe) Pipe) Pipe)

48" Pipe, 20.6 mm WT, API 5L

1 4200 0.000 0.000 0.000 0.000 0.00%

Gr. X70MS / L485MS, PSL2, SAWL

26700

48" Pipe, 20.6 mm WT, API 5L

2 22500 0.000 0.000 0.000 0.000 0.00%

Gr. X70MS / L485MS, PSL2, SAWL

48" Pipe, 23.8 mm WT, API 5L

*** 3 39000

Gr. X70MS / L485MS, PSL2, SAWL

48" Pipe, 23.8 mm WT, API 5L 39670 0.000 398.595 398.595 39271.405 1.00%

*** 4 300

Gr. X70MS / L485MS, PSL2, SAWL

48" Pipe, 23.8 mm WT, API 5L

*** 9 370

Gr. X70MS / L485MS, PSL2, SAWL

48" Pipe, 27.0 mm WT, API 5L

*** 5 60

Gr. X70MS / L485MS, PSL2, SAWL

338 0.000 261.120 261.120 76.880 77.25 %

48" Pipe, 27.0 mm WT, API 5L

*** 8 278

Gr. X70MS / L485MS, PSL2, SAWL

52" Pipe, 28.6 mm WT, API 5L

6 72 72 73.555 0.000 73.555 -1.555 100%

Gr. X70MS / L485MS, PSL2, SAWL

48" Pipe, 34.0 mm WT, API 5L

*** 7 36 36 49.180 11.545 60.725 NIL 100.00 %

Gr. X70MS / L485MS, PSL2, SAWL

16" Pipe, 10.0 mm WT, API 5L

10 60 60 0.000 0.000 0.000 0.000 0.00%

Gr. X70MS / L485MS, PSL2, SAWL

TOTAL 66876 66876 0.000 73.555 73.555 66802.445 0.11%

*** - Total Completed % acceptable subject to test results of Mechanical test results of MPQT and RP.

Production Status - For Production status please see on Daily Production report.

B] Details of Inspection Carried out :

For Manufacturing Procedure Qualification Pipe Size: 48” OD X 34.0 MM WT.

Selected MPQT Pipe No. L321D17777, L321D17778, L321D17781.

Selected PUT calibration Plate No.425030-01.

Selected FUT calibration Pipe No. Trial-01.

Witnessed All WELD tensile test as per ITP Sr.No.B.21- Found meeting the requirements.

Witnessed Guided bend test as per ITP Sr.No.15.A.7- Found satisfactory.

Format FIR r5 – 19th Aug 2015 Page 1 of 4

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/007

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 30/04/2021

B] Details of Inspection Carried out :

For Manufacturing Procedure Qualification Pipe Size: 48” OD X 27.0 MM WT.

Selected MPQT Pipe No. L321D17788, L321D17790, L321D17792.

Selected RPQT Pipe No. L321D17811.

Selected PUT calibration Plate No.420065-01.

Selected FUT calibration Pipe No. Trial-01.

Verified sampling activity as per sample plan.

For Manufacturing Procedure Qualification Pipe Size: 48” OD X 23.80 MM WT.

Selected MPQT Pipe No. L321D17825, L321D17827, L321D17829.

Selected PUT calibration Plate No. 422245-02.

Selected FUT calibration Pipe No. Trial-01.

Witnessed visual inspection of inside and outside pipes as per ITP Sr.No. 10.1- No injures surface defect

observed.

Witnessed pipe inspection for the dents as per ITP Sr.No. 10.2- No found dent.

Witnessed radial offset of plate edges as per ITP Sr.No. 10.3- Found satisfactory.

Witnessed misalignment of weld bead as per ITP Sr.No. 10.4- Found within acceptable limit.

Witnessed height of weld bead (inside& outside) as per ITP Sr.No. 10.5- Found within acceptable limit.

Witnessed pipe inspection for the hard spot as per ITP Sr.No. 10.6- No hard spot observed.

Witnessed visual inspection for free from cracks, sweats and leaks as per ITP Sr.No. 10.7- No injures surface

defect observed.

Witnessed visual inspection for lamination as per ITP Sr.No. 10.8- Found satisfactory.

Witnessed weld inspection for undercuts as per ITP Sr.No. 10.9- Found satisfactory.

Witnessed other surface imperfections as per ITP Sr.No. 10.10- Found satisfactory.

Witnessed visual inspection for arc burns as per ITP Sr.No. 10.11- Found satisfactory.

Witnessed wall thickness of pipe as per ITP Sr.No. 11.1- Found within acceptable limit.

Witnessed pipe length as per ITP Sr.No. 11.2- Found within acceptable limit.

Witnessed straightness of pipe as per ITP Sr.No. 11.3- Found within acceptable limit.

Verified during visual inspection for no jointers as per ITP Sr.No. 11.4- Found satisfactory.

Witnessed inside diameter at pipe ends as per ITP Sr.No. 11.5- Found within acceptable limit.

Witnessed outside diameter at pipe body as per ITP Sr.No. 11.6- Found within acceptable limit.

Witnessed out of roundness at pipe end for inside diameter as per ITP Sr.No. 11.7- Found within acceptable limit.

Witnessed out of roundness at pipe body for outside diameter as per ITP Sr.No. 11.8- Found within acceptable

limit.

Witnessed peaking and flat sports at end at pipe ends as per ITP Sr.No. 11.9- Found acceptable limit.

Witnessed weight of pipes as per ITP Sr.No. 11.10- Found within acceptable limit.

Witnessed bevel angle and root face as per ITP Sr.No. 12.1- Found within acceptable limit.

Witnessed end squareness as per ITP Sr.No. 12.2- Found within acceptable limit.

Witnessed inside and outside weld bead grinding before MPI as per ITP Sr.No. 12.3- Found within acceptable

limit.

For Regular Production Pipe Size: 48” OD X 34 MM WT, 48” OD X 27 MM WT & 48” OD X 23.80 MM WT,

Surveillance visual & dimensional inspection of incoming plats as per ITP Sr. No. 2.1 – Found within tolerance.

Reviewed reports for control Chemical analysis as per ITP Sr.No.2.2 - Found within acceptable limit.

Reviewed reports for control Tensile test as per ITP Sr.No.2.3 - Found meeting the requirements.

Format FIR r5 – 19th Aug 2015 Page 2 of 4

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/007

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 30/04/2021

B] Details of Inspection Carried out :

Random witnessed Calibration of Plate Ultrasonic testing as per ITP Sr.No.2.4 - Found satisfactory.

Random witnessed Plate Ultrasonic testing as per ITP Sr.No.2.4 - No significant defect observes.

Monitoring Edge milling as per ITP Sr.No.3.1 - Found satisfactory.

Monitoring Crimping of plates as per ITP Sr.No.3.2 - Found satisfactory.

Monitoring JCO forming as per ITP Sr.No. 3.3 - Found Satisfactory.

Monitoring welding consumable of wire, Flux & Electrode as per approved WPS and as per ITP Sr.No.4.2 - Found

Satisfactory.

Reviewed WPS & PQR for Process and Welder operator qualification as per ITP Sr.No.4.2 - Found in order.

Reviewed welding consumable of wire, Flux & Electrode MTC as per ITP Sr.No.4.2 - Found meeting the

requirements.

Monitoring Automatic tack welding as per ITP Sr.No. 4.3- Found satisfactory.

Monitoring Tab welding for GMAW welding as per ITP Sr.No. 4.4- Found satisfactory.

Monitoring Automatic submerged arc welding as per ITP Sr.No. 4.5 - Found satisfactory.

Monitoring preliminary visual inspection as per ITP Sr.No.4.6 - No injurious surface observed.

Monitoring straightness of pipe as per ITP Sr.No.6.0 - Found within acceptable limit.

Random witnessed Cold expansion as per ITP Sr.No.7.0 - Found satisfactory.

Random witnessed weekly Pressure gauge calibration as per ITP Sr.No. 8.0 - Found satisfactory.

Random witnessed hydrostatic test as per ITP Sr.No.8.0 - Neither pressure drop nor leakage observed during

holding time of 10 seconds minimum.

Random witnessed calibration of pipe for final automatic Ultrasonic testing as per ITP Sr.No. 9.1 - Found

satisfactory.

Random witnessed Final Automatic Ultrasonic testing as per ITP Sr.No. 9.1 - No significant defect observes.

Random witnessed calibration of MUT as per ITP Sr.No. 9.2 - Found satisfactory.

Random witnessed MUT untested weld length of 250mm mini. and AUT indication by angle probe as per ITP

Sr.No. 9.2 - No significant defect observes.

Random witnessed MUT circumference direction for longitudinal defect detection 25 mm mini. angle probe as

per ITP Sr.No. 9.2 - No significant defect observes.

Random witnessed MUT circumference up to 110mm mini. by TR Probe as per ITP Sr.No. 9.2 - No significant

defect observes.

Reviewed x ray film and reports as per ITP Sr.No. 9.3- Found satisfactory.

Random witnessed magnetic particle inspection as per ITP Sr.No. 9.4 - No significant defect observes.

Random witnessed residual magnetism as per ITP Sr.No. 9.5 - Found within acceptable limit.

Random witnessed visual inspection of inside and outside pipes as per ITP Sr.No. 10.1- No injures surface defect

observed.

Random witnessed pipe inspection for the dents as per ITP Sr.No. 10.2- No found dent.

Random witnessed radial offset of plate edges as per ITP Sr.No. 10.3- Found satisfactory.

Random witnessed misalignment of weld bead as per ITP Sr.No. 10.4- Found within acceptable limit.

Random witnessed height of weld bead (inside& outside) as per ITP Sr.No. 10.5- Found within acceptable limit.

Random witnessed pipe inspection for the hard spot as per ITP Sr.No. 10.6- No hard spot observed.

Random witnessed visual inspection for free from cracks, sweats and leaks as per ITP Sr.No. 10.7- No injures

surface defect observed.

Random witnessed visual inspection for lamination as per ITP Sr.No. 10.8- Found satisfactory.

Random witnessed weld inspection for undercuts as per ITP Sr.No. 10.9- Found satisfactory.

Random witnessed other surface imperfections as per ITP Sr.No. 10.10- Found satisfactory.

Random witnessed visual inspection for arc burns as per ITP Sr.No. 10.11- Found satisfactory.

Random witnessed wall thickness of pipe as per ITP Sr.No. 11.1- Found within acceptable limit.

Random witnessed pipe length as per ITP Sr.No. 11.2- Found within acceptable limit.

Random witnessed straightness of pipe as per ITP Sr.No. 11.3- Found within acceptable limit.

Verified during visual inspection for no jointers as per ITP Sr.No. 11.4- Found satisfactory.

Random witnessed inside diameter at pipe ends as per ITP Sr.No. 11.5- Found within acceptable limit.

Random witnessed outside diameter at pipe body as per ITP Sr.No. 11.6- Found within acceptable limit.

Random witnessed out of roundness at pipe end for inside diameter as per ITP Sr.No. 11.7- Found within

acceptable limit.

Random witnessed out of roundness at pipe body for outside diameter as per ITP Sr.No. 11.8- Found within

Format FIR r5 – 19th Aug 2015 Page 3 of 4

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/007

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 30/04/2021

B] Details of Inspection Carried out :

acceptable limit.

Random witnessed peaking and flat sports at end at pipe ends as per ITP Sr.No. 11.9- Found acceptable limit.

Random witnessed weight of pipes as per ITP Sr.No. 11.10- Found within acceptable limit.

Random witnessed bevel angle and root face as per ITP Sr.No. 12.1- Found within acceptable limit.

Random witnessed end squareness as per ITP Sr.No. 12.2- Found within acceptable limit.

Monitoring inside and outside weld bead grinding before MPI as per ITP Sr.No. 12.3- Found within acceptable

limit.

Monitoring both pipes end covered with metallic bevel protector as per ITP Sr.No. 12.4- Found satisfactory.

Random verified sampling activity as per sample plan.

Note: -

Reviewed raw material test certificates for plates – Found meeting the requirements except below point

incorporate in RMTC. (Continuous casting method not specified)

As per Physical plate Marking verification and RMTC provided data some points not match (Heat No. 6 digit after

4 more numbers are available and as per marking RMTC number not match with RMTC) - same as conformation

required by plate manufacturer and client concern required.

27mm WT – RPQT Done Sampling Not Completed, testing balance for repair approval.

Identification: Nil

Remark: Photographs not attached due to USB access not permitted to JSL premises.

Attending Inspectors: Kaushikkumar Patel & Nimesh Patel (Day Shift) & Mohit Solanki (Night Shift)

Category: (1) Accepted, (2) Conditionally Accepted, (3) Re-Inspection Required, (4) Rejected, (5) Advice / Instruction from Client Required.

Inspection Date(s): ANY NON Yes

28/04/2021 to

CONFORMITY

29/04/2021

FOUND? No

Complete

Inspection Place(s): Kaushikkumar Patel

ORDER

JCO – III, Jindal Saw Date: 30.04.2021

STATUS

Ltd, Nanakapaya, Balance Supplier’s Signature & Date Mobile No. +91-9687000073

Mundra Telephone No.

Format FIR r5 – 19th Aug 2015 Page 4 of 4

You might also like

- Business Plan CircularCarbon 01.08.Document42 pagesBusiness Plan CircularCarbon 01.08.lepezNo ratings yet

- Final Wellhead ReportDocument53 pagesFinal Wellhead ReportAli BoubeniaNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-114 Insp. Date. 25.09.2020Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-114 Insp. Date. 25.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-148 Insp. Date. 09.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-148 Insp. Date. 09.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021kbpatel123No ratings yet

- StatementDocument2 pagesStatementamit singhNo ratings yet

- Irn - GEMSCAB INDUSTRIES LTD - OMTECH ONGC CGS BOKARO 22 23 064 - 9152022 - 9222022ICSE-1250Document1 pageIrn - GEMSCAB INDUSTRIES LTD - OMTECH ONGC CGS BOKARO 22 23 064 - 9152022 - 9222022ICSE-1250QAQC OmtechNo ratings yet

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- Section 2: Schedule 80 CPVC Piping System Serviced by GF Little RockDocument28 pagesSection 2: Schedule 80 CPVC Piping System Serviced by GF Little RockArnold Ochochoque ArcosNo ratings yet

- Resultado Sala MaquinaDocument8 pagesResultado Sala Maquinajunioralamo17No ratings yet

- Statement 23Document4 pagesStatement 23amit singhNo ratings yet

- Name of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUDocument45 pagesName of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUTuara sangmaNo ratings yet

- Xxxx-Spe-Xxx - Mto FormatDocument10 pagesXxxx-Spe-Xxx - Mto FormatVijay GaikwadNo ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021kbpatel123No ratings yet

- Justification of Rates S. No. Description Qty. Unit Unit Rate (RS.) in FigureDocument6 pagesJustification of Rates S. No. Description Qty. Unit Unit Rate (RS.) in Figurekiran raghukiranNo ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021kbpatel123No ratings yet

- RFQ 16012023 BestrackDocument6 pagesRFQ 16012023 BestrackKasarachi AmadiNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- Rahman Heritage Tower, TangailDocument4 pagesRahman Heritage Tower, TangailHunter gamingNo ratings yet

- FP - Fire Pump 2023-00769-02Document6 pagesFP - Fire Pump 2023-00769-02Johnny SarioNo ratings yet

- Battery Limits 1 Technical Offer A Scope of Delta Saras Piping PVT LTD 1. Delta Saras Scope of InstallationDocument8 pagesBattery Limits 1 Technical Offer A Scope of Delta Saras Piping PVT LTD 1. Delta Saras Scope of InstallationSmit BhivgadeNo ratings yet

- Pdi 5Document1 pagePdi 5antNo ratings yet

- 7.1-16'' 10K Double Ram BOP Operation ManualDocument18 pages7.1-16'' 10K Double Ram BOP Operation ManualrahulNo ratings yet

- Hydrant System OfferDocument5 pagesHydrant System OfferMd. Sujaur RahmanNo ratings yet

- Hydrant System OfferDocument5 pagesHydrant System OfferMd. Sujaur RahmanNo ratings yet

- Cost Sheet For NPLDocument10 pagesCost Sheet For NPLSachin MishraNo ratings yet

- Hydac Testpoint PDFDocument4 pagesHydac Testpoint PDFEsteve CastilloNo ratings yet

- Vattigudipadu Bore Driling Motor and Pump Estimate-Gollapalli Xroad 27.02.24Document5 pagesVattigudipadu Bore Driling Motor and Pump Estimate-Gollapalli Xroad 27.02.24vattigudipadugpsNo ratings yet

- Customer Information Consolidated Report: Company Name: MULT TEC AddressDocument7 pagesCustomer Information Consolidated Report: Company Name: MULT TEC AddressLeandro MagriNo ratings yet

- Millsheet Pipa Spindo - 01Document4 pagesMillsheet Pipa Spindo - 01Mellany SeprinaNo ratings yet

- Piping MTO-Pipes & FittingsDocument2 pagesPiping MTO-Pipes & FittingsAnonymous bySKOTNo ratings yet

- Customer Information Consolidated Report: Company Name: MULT TEC AddressDocument7 pagesCustomer Information Consolidated Report: Company Name: MULT TEC AddressLeandro MagriNo ratings yet

- SprinklerDocument6 pagesSprinklernomarblesNo ratings yet

- A3a PDFDocument7 pagesA3a PDFJaved MohammedNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Daily Report-018 (Su Jinlong)Document8 pagesDaily Report-018 (Su Jinlong)sujinlongNo ratings yet

- 1Document2 pages1sachinrmishraNo ratings yet

- Deep Tube Well BoringDocument5 pagesDeep Tube Well BoringHabibNo ratings yet

- Revised PM Is 12786 August 2020Document8 pagesRevised PM Is 12786 August 2020Mahesh YadavNo ratings yet

- 6.new Catalog For Diesel Parts Test BenchDocument50 pages6.new Catalog For Diesel Parts Test BenchUliAlejandroRodriguezCorianga50% (2)

- Medical Mo QuoteDocument5 pagesMedical Mo QuoteSam PattnaikNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- Truflo PipesDocument12 pagesTruflo Pipesnatarajan palanisamy25% (4)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- FIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021kbpatel123No ratings yet

- Procurement Services: Industry & Facilities DivisionDocument10 pagesProcurement Services: Industry & Facilities Divisionkbpatel123No ratings yet

- Chandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979Document13 pagesChandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- Steelbird - Faceshield BillDocument1 pageSteelbird - Faceshield Billkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- Inspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour ServiceDocument1 pageInspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour Servicekbpatel123No ratings yet

- Curriculum Vitae: Total Experience 18.1 YearsDocument7 pagesCurriculum Vitae: Total Experience 18.1 Yearskbpatel123No ratings yet

- Inspection Certificate: IC No.: Date: Page 1 of 3Document3 pagesInspection Certificate: IC No.: Date: Page 1 of 3kbpatel123No ratings yet

- Curriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting EquipmentDocument4 pagesCurriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting Equipmentkbpatel123No ratings yet

- Foa Jindal SawDocument2 pagesFoa Jindal Sawkbpatel123No ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Ts LSAW SpecificationDocument40 pagesTs LSAW Specificationkbpatel123No ratings yet

- Ts Scope of Work and SupplyDocument12 pagesTs Scope of Work and Supplykbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020kbpatel123No ratings yet

- JS1034-XX-F06-0001. A1Document107 pagesJS1034-XX-F06-0001. A1Pawan Gosavi100% (1)

- Product Primer PaaplusDocument9 pagesProduct Primer PaaplusHeddy RoaringNo ratings yet

- Procedural Report CraniectomyDocument3 pagesProcedural Report CraniectomyAubrey UniqueNo ratings yet

- Product Decors and Services BrochureDocument76 pagesProduct Decors and Services BrochureAleksandr LesnikNo ratings yet

- GYQ Guayaquil 080219Document14 pagesGYQ Guayaquil 080219Fundación Esperanza Vida y Amor EcNo ratings yet

- Ra-253-Ma DB Us en PDFDocument12 pagesRa-253-Ma DB Us en PDFbadesharamkNo ratings yet

- A. Steps For Initiation of Criminal Machinery: 1. Cases in Which PCR Call Was MadeDocument4 pagesA. Steps For Initiation of Criminal Machinery: 1. Cases in Which PCR Call Was MadeAnchit Jassal100% (1)

- Buy Lizol Floor Cleaner 5000 ML Online - GeMDocument4 pagesBuy Lizol Floor Cleaner 5000 ML Online - GeMHimanshu ShuklaNo ratings yet

- Assignment Ahamadul Islam Ananna ID: 19304077 Section: 3 Course: ANT101 Fall 2020Document3 pagesAssignment Ahamadul Islam Ananna ID: 19304077 Section: 3 Course: ANT101 Fall 2020Ahamadul Islam OnonnoNo ratings yet

- Oxidation (Myers)Document10 pagesOxidation (Myers)YouTibeNo ratings yet

- Dinner MenuDocument3 pagesDinner MenueatlocalmenusNo ratings yet

- Sensor IKR 251 Pfeiffer Metalizadora BuhllerDocument24 pagesSensor IKR 251 Pfeiffer Metalizadora BuhllerRafael OliveiraNo ratings yet

- Nalco Spec Sheet Water Saver SPEC 623 PDFDocument3 pagesNalco Spec Sheet Water Saver SPEC 623 PDFBryar MuhsinNo ratings yet

- Aldobash The Osha Ppe StandardsDocument12 pagesAldobash The Osha Ppe StandardsRaad AljuboryNo ratings yet

- Pic152a ViDocument2 pagesPic152a Viiyappan5016100% (1)

- Kite Corporate Presentation 4-15-15 - Jefferies Immuno-Oncology SummitDocument27 pagesKite Corporate Presentation 4-15-15 - Jefferies Immuno-Oncology SummitJake MannNo ratings yet

- BoltCalcs R5Document4 pagesBoltCalcs R5Homer SilvaNo ratings yet

- GEAR BOX Service ManualDocument66 pagesGEAR BOX Service ManualJon Mo86% (7)

- 2014 Icd Handbook - CompressedDocument490 pages2014 Icd Handbook - CompressedSheri WilliamsNo ratings yet

- The POD of Metabical Is ThatDocument1 pageThe POD of Metabical Is ThatAsma GhaziNo ratings yet

- Research Narrative EssayDocument4 pagesResearch Narrative Essayafhbctdfx100% (2)

- Ahbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupDocument3 pagesAhbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupWaqi WaqiNo ratings yet

- Molar Volume of OxygenDocument5 pagesMolar Volume of OxygenGeorgeNo ratings yet

- GA CPPU + Fruit + BlueberriesDocument6 pagesGA CPPU + Fruit + BlueberriesAnonymous qWrIJh3No ratings yet

- Photosynthesis PDFDocument22 pagesPhotosynthesis PDFbhaskar rayNo ratings yet

- Protease ELU Activity AssayDocument2 pagesProtease ELU Activity AssayYunita KurniatiNo ratings yet

- Solvent Evaporation: Fast, Reliable and AffordableDocument24 pagesSolvent Evaporation: Fast, Reliable and Affordablepandiya rajanNo ratings yet

- GE MAC 5000 ECG MantenimientoDocument160 pagesGE MAC 5000 ECG Mantenimientomoises100% (1)

- DARAN (Research Activity)Document14 pagesDARAN (Research Activity)Jeanette Fernandez DNo ratings yet