Professional Documents

Culture Documents

Datasheet Bredel - 40 50

Datasheet Bredel - 40 50

Uploaded by

Giorgi GhambashidzeCopyright:

Available Formats

You might also like

- 19 Participant WorkbookDocument45 pages19 Participant WorkbookBibin Chacko Mammen60% (5)

- Manuale 24kv tpr6 24 - Globale - Ed04-LightDocument92 pagesManuale 24kv tpr6 24 - Globale - Ed04-LightJulio A Manzini ColinaNo ratings yet

- Daimler Ir Mercedes Benz Strategy Update 2020 PresentationDocument79 pagesDaimler Ir Mercedes Benz Strategy Update 2020 PresentationabcdNo ratings yet

- Calcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanDocument2 pagesCalcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanGiorgi GhambashidzeNo ratings yet

- WD Duconite 25 32 GB 03Document2 pagesWD Duconite 25 32 GB 03Jorge Luis BriceñoNo ratings yet

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- Bomba Bredel CaracteristicasDocument2 pagesBomba Bredel CaracteristicasFelipe MelgarejoNo ratings yet

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- Wd-Duconite 10 15 20-gb-03Document2 pagesWd-Duconite 10 15 20-gb-03Jorge Luis BriceñoNo ratings yet

- Bredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsDocument2 pagesBredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsAtaa AssaadNo ratings yet

- S1F Non-Metallic Pump: Technical Data SheetDocument3 pagesS1F Non-Metallic Pump: Technical Data SheetspattacutNo ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- Pile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Document2 pagesPile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Chiranjaya HulangamuwaNo ratings yet

- WG DF972Document1 pageWG DF972USINART RETIFICA DE MOTORESNo ratings yet

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- KHF Series Fan CurvesDocument3 pagesKHF Series Fan CurvesGonzalo Villalobos SanchezNo ratings yet

- Operating Instructions: 1" Elima-Matic Bolted PumpDocument13 pagesOperating Instructions: 1" Elima-Matic Bolted PumpJOSE INESNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- HDF1 M HdflapDocument2 pagesHDF1 M HdflapAlvaro Iparraguirre NavarroNo ratings yet

- All Terrain Hydraulic CraneDocument18 pagesAll Terrain Hydraulic CraneJulio torresNo ratings yet

- Use of Inverters Stream Compressors Technical Information enDocument9 pagesUse of Inverters Stream Compressors Technical Information enIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Bredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsDocument2 pagesBredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsMaximiliano BettarelNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- FRCC Ei 003 A6 02Document3 pagesFRCC Ei 003 A6 02mahmoudgaber1279No ratings yet

- Catalog 2017Document26 pagesCatalog 2017iasampestudioNo ratings yet

- Slnc125-250a-110-2 GaDocument2 pagesSlnc125-250a-110-2 GaPiyarat SuwannakhaNo ratings yet

- Current Models: Size Type FinishesDocument10 pagesCurrent Models: Size Type FinishesQuinnNo ratings yet

- Technical Data Sheet For: AUMA India Multi-Turn Worm GearboxesDocument2 pagesTechnical Data Sheet For: AUMA India Multi-Turn Worm GearboxesGilbert Retamal SilvaNo ratings yet

- 2000w-2-Ohms-90v-Supply-Audio-Power-Amp - Bc-2000-2-2012-Rev-1Document1 page2000w-2-Ohms-90v-Supply-Audio-Power-Amp - Bc-2000-2-2012-Rev-1Memet Al AjmiNo ratings yet

- S270P New Tech Sheet ¿ ®Document2 pagesS270P New Tech Sheet ¿ ®truong nguyenNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- Contactors and Contactor Assemblies: SiriusDocument33 pagesContactors and Contactor Assemblies: SiriuschochoroyNo ratings yet

- Performance CurvesDocument2 pagesPerformance CurvesYohan ManaligodNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- System Design PresentationenDocument14 pagesSystem Design PresentationenVaibhav ChaudharyNo ratings yet

- iK60N iC60N-iC60H-iC60L C120Document11 pagesiK60N iC60N-iC60H-iC60L C120Long Nguyễn Đặng ThànhNo ratings yet

- Heat Pump COP From Definition To Sales ArgumentDocument4 pagesHeat Pump COP From Definition To Sales ArgumentValentin MalihinNo ratings yet

- Fundamentals of Centrifugal Pumps PDFDocument7 pagesFundamentals of Centrifugal Pumps PDFÁlvaro Martínez FernándezNo ratings yet

- 40 4112 - 4030 - 60Hz - 1 5x1x8 - Performance - CurvesDocument2 pages40 4112 - 4030 - 60Hz - 1 5x1x8 - Performance - CurvesShane BirdNo ratings yet

- d722 E4bDocument2 pagesd722 E4bBaggerkingNo ratings yet

- Binks AX260L Air Motor BreakdownDocument11 pagesBinks AX260L Air Motor BreakdownAryo KamandanuNo ratings yet

- F4 4-ModelDocument1 pageF4 4-Modelmrcv72jgrc72gmail.com 1304010772No ratings yet

- Plastic Shrinkage Cracking (BPS)Document36 pagesPlastic Shrinkage Cracking (BPS)shingkeongNo ratings yet

- Curvas de DesempeñoDocument116 pagesCurvas de DesempeñoRene RodriguezNo ratings yet

- SB12 6 - SB12 6L1 PDFDocument1 pageSB12 6 - SB12 6L1 PDFЙордан ЙордановNo ratings yet

- 2000w-2-Ohms-90vdc-Supply-Audio-Power-Amp - Dos-V-U1-2000-Ls2-2013-Se-Rev-2.pdf Version 1Document2 pages2000w-2-Ohms-90vdc-Supply-Audio-Power-Amp - Dos-V-U1-2000-Ls2-2013-Se-Rev-2.pdf Version 1Rhenz TalhaNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- Performance Curves: Rotary Lobe Pumps SCPP 2/015Document15 pagesPerformance Curves: Rotary Lobe Pumps SCPP 2/015Angel CoesNo ratings yet

- VTF 2500Document1 pageVTF 2500JULIOALBANo ratings yet

- SLNC250-315C-55-4 GaDocument2 pagesSLNC250-315C-55-4 GaPiyarat SuwannakhaNo ratings yet

- Assignment 5 - BushardDocument5 pagesAssignment 5 - Bushardapi-594060005No ratings yet

- Avensis DieselDocument2 pagesAvensis DieselzoltanpolyakNo ratings yet

- MPU Brochure ZF TRWDocument4 pagesMPU Brochure ZF TRWWong DaNo ratings yet

- Adobe Scan 04-Oct-2023Document1 pageAdobe Scan 04-Oct-2023NinadNo ratings yet

- QL Series - Positive Displacement PumpsDocument10 pagesQL Series - Positive Displacement Pumpsmauricio cardenasNo ratings yet

- Ups Up-Pw1245 Panasonic PDFDocument2 pagesUps Up-Pw1245 Panasonic PDFPurnomo NugrohoNo ratings yet

- 36-401 Modern Regression HW #7 Solutions: Problem 1 (40 Points)Document12 pages36-401 Modern Regression HW #7 Solutions: Problem 1 (40 Points)SNo ratings yet

- 750wrms For 2ohm 75vdc Af Pa Fpa Ab 750 l2 Ab 2e STD Rev 2Document2 pages750wrms For 2ohm 75vdc Af Pa Fpa Ab 750 l2 Ab 2e STD Rev 2Nanang Rachman0% (1)

- 10US 50 Ssu CurveDocument1 page10US 50 Ssu CurveHermanto penjolbaeNo ratings yet

- Deepwll Turbine Pump (Final PDFDocument12 pagesDeepwll Turbine Pump (Final PDFAsif MaqboolNo ratings yet

- 911.5 60 HZ End Suction Fire Pump Curves - AuroraDocument30 pages911.5 60 HZ End Suction Fire Pump Curves - AurorazaccNo ratings yet

- Elec Telecom Yi1qea 4Document23 pagesElec Telecom Yi1qea 4Mohammed ShakilNo ratings yet

- Beverage Application Guide: Cellulose GumDocument4 pagesBeverage Application Guide: Cellulose GumGiorgi GhambashidzeNo ratings yet

- 10 - Beer Stabilization Technology-Clearly A Matter of ChoiceDocument42 pages10 - Beer Stabilization Technology-Clearly A Matter of ChoiceGiorgi GhambashidzeNo ratings yet

- 02 - Haze FormationDocument22 pages02 - Haze FormationGiorgi GhambashidzeNo ratings yet

- 023101.101 Hardness CorrectionDocument5 pages023101.101 Hardness CorrectionGiorgi GhambashidzeNo ratings yet

- RFM PhaseGuard 11027E-1Document90 pagesRFM PhaseGuard 11027E-1Giorgi GhambashidzeNo ratings yet

- Instruction Manual: Phaseguard C/ T/ HTDocument32 pagesInstruction Manual: Phaseguard C/ T/ HTGiorgi GhambashidzeNo ratings yet

- High Level Lubricant Switch: Pump Type Order Code Construction Float Switch (A230 002)Document1 pageHigh Level Lubricant Switch: Pump Type Order Code Construction Float Switch (A230 002)Giorgi GhambashidzeNo ratings yet

- Aa 7 1 Sys Conf RCMDN GuidDocument29 pagesAa 7 1 Sys Conf RCMDN GuidOscar Alberto ZambranoNo ratings yet

- PrePoMax-v1 3 3-ManualDocument43 pagesPrePoMax-v1 3 3-ManualMarcelo ResendeNo ratings yet

- ABB - MNS - Service Manual - EN - 1SXH900002M0208 - REV G 02-2023Document64 pagesABB - MNS - Service Manual - EN - 1SXH900002M0208 - REV G 02-2023Donald FotsoNo ratings yet

- Ericsson Thesis WorkDocument5 pagesEricsson Thesis Workkristenwilsonpeoria100% (2)

- Laporan 2Document7 pagesLaporan 2Cindy Ingientd Ddya S'lalueNo ratings yet

- Raspberry Pi OverviewDocument20 pagesRaspberry Pi OverviewAJOY BANIKNo ratings yet

- Brochure PDFDocument4 pagesBrochure PDFAmel Ben YahiaNo ratings yet

- Gcse Geometry Vector Operations ExerciseDocument6 pagesGcse Geometry Vector Operations ExerciseGodfred WelbeckNo ratings yet

- Ethiopian Common and Emerging Maize DiseaseDocument14 pagesEthiopian Common and Emerging Maize DiseasedagneNo ratings yet

- Urschel DicerDocument268 pagesUrschel DicerGoker UyarerNo ratings yet

- YESPL IMS Manual Cover Pages v1.0Document2 pagesYESPL IMS Manual Cover Pages v1.0GVSRAO venkatNo ratings yet

- 5ccfcbc1e4b0a4eb53be4158 Original PDFDocument45 pages5ccfcbc1e4b0a4eb53be4158 Original PDFPoonam SachdevNo ratings yet

- Organizational Effectiveness and PerformanceDocument5 pagesOrganizational Effectiveness and PerformanceDung, DoanNo ratings yet

- A Level Mathematics Practice Paper E - Pure MathematicsDocument6 pagesA Level Mathematics Practice Paper E - Pure MathematicsZaka Ahmed33% (3)

- The Smart Next Generation PGNAA Cross-Belt Elemental AnalyserDocument5 pagesThe Smart Next Generation PGNAA Cross-Belt Elemental AnalyserDatNo ratings yet

- Adaptive Control Design and AnalysisDocument45 pagesAdaptive Control Design and Analysishind90No ratings yet

- Electronic Multi-Measuring Instrument ME96SS: Factory AutomationDocument40 pagesElectronic Multi-Measuring Instrument ME96SS: Factory AutomationMạnh Toàn NguyễnNo ratings yet

- 4TNE98Document21 pages4TNE98Noor Sa'adahNo ratings yet

- ScriptDocument2 pagesScriptLAKIESHANo ratings yet

- UTech CMP1025 Tutorial 3Document2 pagesUTech CMP1025 Tutorial 3Leia MichaelsonNo ratings yet

- @BIM Communication With BCF EnglishDocument2 pages@BIM Communication With BCF EnglishTomasz WiatrNo ratings yet

- 25m Tower Light With 12pcs 400w Led Flood Lights - BR SolarDocument15 pages25m Tower Light With 12pcs 400w Led Flood Lights - BR SolarNdubisi AgomoNo ratings yet

- Automatic Gearbox 0CTDocument113 pagesAutomatic Gearbox 0CTkilermaniaNo ratings yet

- LCPC 100-12 Gel Battery: Technology DataDocument2 pagesLCPC 100-12 Gel Battery: Technology DataZudeky LeónNo ratings yet

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p021Document1 pageToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p021sơn forkliftNo ratings yet

- Auto TransformerDocument9 pagesAuto TransformershathaNo ratings yet

- Imouse-1230732021628253-1.Ppt (Compatibility Mode) (Repaired)Document24 pagesImouse-1230732021628253-1.Ppt (Compatibility Mode) (Repaired)umesh kumarNo ratings yet

Datasheet Bredel - 40 50

Datasheet Bredel - 40 50

Uploaded by

Giorgi GhambashidzeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet Bredel - 40 50

Datasheet Bredel - 40 50

Uploaded by

Giorgi GhambashidzeCopyright:

Available Formats

Bredel

Bredel 40 and Bredel 50

series

hose pumps

Bredel Hose Pumps

FEATURES AND BENEFITS

• Sealless, valveless pumping principle for reliable, low maintenance

metering, dosing and transfer

• Flow rates up to 17,500 L/hr (77.1 USGPM) and pressures up to

16bar (232 psi)

• Dry running and self-priming, with up to 9.5 meters (30 foot) suction

lift capability

• Robust design for aggressive chemicals or abrasives

• Compact direct coupled design to maximise gearbox life

• Simple hose change decreases cost of ownership, downtime and

need for parts inventory

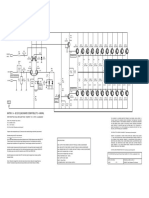

PERFORMANCE

Required Bredel 40

motor power kW (hp)

3.0 (4.02hp)

i) si)

si)

ps

i)

3p

ps

2p

09 (7

45

(1

23

Pa

(1

2.5 (3.35hp) a k

a(

kP 0

a

50

kP

0 Product

kP

75

00

00

temperature C (F)

10

16

2.0 (2.68hp)

40 (104F)

1.5 (2.01hp) 5 50 (122F)

3 2 4 60 (140F)

1.0 (1.34hp)

70 (158F)

80 (176F)

0.5 (0.67hp) Continuous Duty

100 kPa = 1 bar

1 6 Intermittent Duty*

Pump speed rpm 20 40 60 80 100 120 * Maximum 2 hours operation followed by minimum

Capacity L/h 1600 3200 4800 6400 8000 9600 1 hour stop

Capacity USGPM 7.0 14.1 21.1 28.2 35.2 42.3

1. Flow required indicates pump speed

2. Calculated discharge pressure

3. Net motor power required

Required Bredel 50

motor power kW (hp)

4. Product temperature

7.0 (9.38hp) 5. Calculated discharge pressure

i) si)

ps

i)

i)

3p

ps

ps

9 7

10 a( 6. Maximum recommended pump speed

32

45

6.0 (8.04hp) ( P

a

0k

(1

(2

kP 50

a

a

0

kP

kP

75

00

00

5.0 (6.70hp) Product

10

Note: The area of continuous operation

16

temperature C (F)

diminishes with increased product

4.0 (5.36hp) 40 (104F)

temperatures.

5 4 50 (122F)

3.0 (4.02hp) For product temperatures >40C (104F), the

3 2 60 (140F) area of continuous operation is limited by the

2.0 (2.68hp) 70 (158F) corresponding red temperature line.

1.0 (1.34hp) 80 (176F)

100 kPa = 1 bar

1 6

Pump speed rpm 20 40 60 80 100

Capacity L/h 3500 7000 10500 14000 17500

Capacity USGPM 15.4 30.8 46.2 61.6 77.1

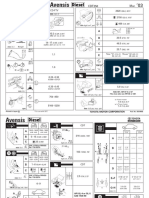

DIMENSIONS

B

C L1 L2

4x øQ

ON BC.R

H1

4x øP

E

F J K M O

G N

A L

Type A B C D E F G H H1 J K Lmax L1 L2max M N O ØP ØQ R

Type705 A412 B 2.5 C 430 D E F490 G 540H H1 J K73 L L1906 L2 M N

Bredel 40 (mm) 110 643 325 84 91 301 O 300 P 120 Q30 R18 18 110

Bredel 40 (inches) 27.8 16.2 0.09 16.9 4.3 19.3 21.3 25.3 12.8 2.9 3.3 35.7 3.6 11.9 11.8 4.7 1.2 0.71 0.71 4.3

Bredel 50 (mm) 838 475 3 554 143 620 680 811 420 84 95 975 112 339 380 155 40 18 18 125

Bredel 50 (inches) 32.9 18.7 0.12 21.8 5.6 24.4 26.8 31.9 16.5 3.3 3.7 38.4 4.4 13.3 15 6.1 1.6 0.71 0.71 4.9

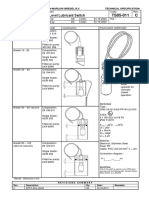

TECHNICAL SPECIFICATIONS

Bredel 40 Bredel 50

Flow range up to 9,600 L/hr (2,536 USGPM) up to 17,500 L/hr (4,623 USGPM)

Capacity 1.33 L/rev (0.35 G/rev) 2.92 L/rev (0.77 G/rev)

Minimum starting torque 320Nm (2,832 inch-lbs) 620Nm (5,487 inch-lbs)

Hose lubricant required 5 litres (1.32 USG) 10 litres (2.64 USG)

Pumphead weight 121kg (267lbs) 227kg (500lbs)

Common features

Max inlet pressure 2.5 bar abs (38 psia)

Suction pressure 0.05bar abs (0.73 psia)

Maximum discharge pressure 1,600 kPa (16 bar) (232psi)

Product temperature range* -10C up to 80C (14F up to 176F)

Ambient temperature range** -20C up to 45C (-4F up to 113F)

*Please consult your Bredel representative for lower or higher temperature operation.

**Allowable ambient temperature is based on pump capabilities and may be further limited by gearbox ambient capabilities

MATERIALS OF CONSTRUCTION

wd-bredel_40_50-gb-01 © Copyright 2013 Watson-Marlow Pumps Group

Components Materials Options Features

Pump housing Cast iron Available hose materials NR, NBR, F-NBR, EPDM, CSM

Rotor Cast iron Available flanges ANSI, EN DIN, JIS

Pressing shoes Aluminium or epoxy Available inserts Bredel standard or with sanitary

Cover Mild steel connectors

Brackets Galvanized steel or AISI 316 High level float switch Max. 2A, 230 V AC/DC, max. 40VA

Low level float switch ATEX: max. 50 mA, max. 28V AC/DC

Flanges Galvanized steel or AISI 316

Inserts AISI 316, PVC, PP, PVDF Integrated FI for stand alone Factory programmable from 12-80 Hz

speed control

Support frame Galvanized steel or AISI 316

Revolution counter For maintenance intervals and /or

Hose clamps Galvanized steel or AISI 316

metering

Shaft Alloy steel

Vacuum assist For difficult suction conditions and high

Seals Neoprene or nitrile

viscosity fluids

Cover lifting device For one-man pump maintenance

The information contained in this document is believed to be correct at the time of publication, but Watson-Marlow Bredel BV wmpg.com

accepts no liability for any error it contains, and reserves the right to alter specifications without prior notice. All mentioned

values in this document are values under controlled circumstances at our test bed. Actual flow rates achieved may vary +44 (0)1326 370 370

because of changes in temperature, viscosity, inlet and discharge pressures and/or system configuration. APEX, DuCoNite®,

Bioprene® and Bredel are registered trademarks. info@wmpg.com

You might also like

- 19 Participant WorkbookDocument45 pages19 Participant WorkbookBibin Chacko Mammen60% (5)

- Manuale 24kv tpr6 24 - Globale - Ed04-LightDocument92 pagesManuale 24kv tpr6 24 - Globale - Ed04-LightJulio A Manzini ColinaNo ratings yet

- Daimler Ir Mercedes Benz Strategy Update 2020 PresentationDocument79 pagesDaimler Ir Mercedes Benz Strategy Update 2020 PresentationabcdNo ratings yet

- Calcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanDocument2 pagesCalcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanGiorgi GhambashidzeNo ratings yet

- WD Duconite 25 32 GB 03Document2 pagesWD Duconite 25 32 GB 03Jorge Luis BriceñoNo ratings yet

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- Bomba Bredel CaracteristicasDocument2 pagesBomba Bredel CaracteristicasFelipe MelgarejoNo ratings yet

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- Wd-Duconite 10 15 20-gb-03Document2 pagesWd-Duconite 10 15 20-gb-03Jorge Luis BriceñoNo ratings yet

- Bredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsDocument2 pagesBredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsAtaa AssaadNo ratings yet

- S1F Non-Metallic Pump: Technical Data SheetDocument3 pagesS1F Non-Metallic Pump: Technical Data SheetspattacutNo ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- Pile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Document2 pagesPile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Chiranjaya HulangamuwaNo ratings yet

- WG DF972Document1 pageWG DF972USINART RETIFICA DE MOTORESNo ratings yet

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- KHF Series Fan CurvesDocument3 pagesKHF Series Fan CurvesGonzalo Villalobos SanchezNo ratings yet

- Operating Instructions: 1" Elima-Matic Bolted PumpDocument13 pagesOperating Instructions: 1" Elima-Matic Bolted PumpJOSE INESNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- HDF1 M HdflapDocument2 pagesHDF1 M HdflapAlvaro Iparraguirre NavarroNo ratings yet

- All Terrain Hydraulic CraneDocument18 pagesAll Terrain Hydraulic CraneJulio torresNo ratings yet

- Use of Inverters Stream Compressors Technical Information enDocument9 pagesUse of Inverters Stream Compressors Technical Information enIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Bredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsDocument2 pagesBredel: Bredel 65, Bredel 80 and Bredel 100 Hose PumpsMaximiliano BettarelNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- FRCC Ei 003 A6 02Document3 pagesFRCC Ei 003 A6 02mahmoudgaber1279No ratings yet

- Catalog 2017Document26 pagesCatalog 2017iasampestudioNo ratings yet

- Slnc125-250a-110-2 GaDocument2 pagesSlnc125-250a-110-2 GaPiyarat SuwannakhaNo ratings yet

- Current Models: Size Type FinishesDocument10 pagesCurrent Models: Size Type FinishesQuinnNo ratings yet

- Technical Data Sheet For: AUMA India Multi-Turn Worm GearboxesDocument2 pagesTechnical Data Sheet For: AUMA India Multi-Turn Worm GearboxesGilbert Retamal SilvaNo ratings yet

- 2000w-2-Ohms-90v-Supply-Audio-Power-Amp - Bc-2000-2-2012-Rev-1Document1 page2000w-2-Ohms-90v-Supply-Audio-Power-Amp - Bc-2000-2-2012-Rev-1Memet Al AjmiNo ratings yet

- S270P New Tech Sheet ¿ ®Document2 pagesS270P New Tech Sheet ¿ ®truong nguyenNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- Contactors and Contactor Assemblies: SiriusDocument33 pagesContactors and Contactor Assemblies: SiriuschochoroyNo ratings yet

- Performance CurvesDocument2 pagesPerformance CurvesYohan ManaligodNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- System Design PresentationenDocument14 pagesSystem Design PresentationenVaibhav ChaudharyNo ratings yet

- iK60N iC60N-iC60H-iC60L C120Document11 pagesiK60N iC60N-iC60H-iC60L C120Long Nguyễn Đặng ThànhNo ratings yet

- Heat Pump COP From Definition To Sales ArgumentDocument4 pagesHeat Pump COP From Definition To Sales ArgumentValentin MalihinNo ratings yet

- Fundamentals of Centrifugal Pumps PDFDocument7 pagesFundamentals of Centrifugal Pumps PDFÁlvaro Martínez FernándezNo ratings yet

- 40 4112 - 4030 - 60Hz - 1 5x1x8 - Performance - CurvesDocument2 pages40 4112 - 4030 - 60Hz - 1 5x1x8 - Performance - CurvesShane BirdNo ratings yet

- d722 E4bDocument2 pagesd722 E4bBaggerkingNo ratings yet

- Binks AX260L Air Motor BreakdownDocument11 pagesBinks AX260L Air Motor BreakdownAryo KamandanuNo ratings yet

- F4 4-ModelDocument1 pageF4 4-Modelmrcv72jgrc72gmail.com 1304010772No ratings yet

- Plastic Shrinkage Cracking (BPS)Document36 pagesPlastic Shrinkage Cracking (BPS)shingkeongNo ratings yet

- Curvas de DesempeñoDocument116 pagesCurvas de DesempeñoRene RodriguezNo ratings yet

- SB12 6 - SB12 6L1 PDFDocument1 pageSB12 6 - SB12 6L1 PDFЙордан ЙордановNo ratings yet

- 2000w-2-Ohms-90vdc-Supply-Audio-Power-Amp - Dos-V-U1-2000-Ls2-2013-Se-Rev-2.pdf Version 1Document2 pages2000w-2-Ohms-90vdc-Supply-Audio-Power-Amp - Dos-V-U1-2000-Ls2-2013-Se-Rev-2.pdf Version 1Rhenz TalhaNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- Performance Curves: Rotary Lobe Pumps SCPP 2/015Document15 pagesPerformance Curves: Rotary Lobe Pumps SCPP 2/015Angel CoesNo ratings yet

- VTF 2500Document1 pageVTF 2500JULIOALBANo ratings yet

- SLNC250-315C-55-4 GaDocument2 pagesSLNC250-315C-55-4 GaPiyarat SuwannakhaNo ratings yet

- Assignment 5 - BushardDocument5 pagesAssignment 5 - Bushardapi-594060005No ratings yet

- Avensis DieselDocument2 pagesAvensis DieselzoltanpolyakNo ratings yet

- MPU Brochure ZF TRWDocument4 pagesMPU Brochure ZF TRWWong DaNo ratings yet

- Adobe Scan 04-Oct-2023Document1 pageAdobe Scan 04-Oct-2023NinadNo ratings yet

- QL Series - Positive Displacement PumpsDocument10 pagesQL Series - Positive Displacement Pumpsmauricio cardenasNo ratings yet

- Ups Up-Pw1245 Panasonic PDFDocument2 pagesUps Up-Pw1245 Panasonic PDFPurnomo NugrohoNo ratings yet

- 36-401 Modern Regression HW #7 Solutions: Problem 1 (40 Points)Document12 pages36-401 Modern Regression HW #7 Solutions: Problem 1 (40 Points)SNo ratings yet

- 750wrms For 2ohm 75vdc Af Pa Fpa Ab 750 l2 Ab 2e STD Rev 2Document2 pages750wrms For 2ohm 75vdc Af Pa Fpa Ab 750 l2 Ab 2e STD Rev 2Nanang Rachman0% (1)

- 10US 50 Ssu CurveDocument1 page10US 50 Ssu CurveHermanto penjolbaeNo ratings yet

- Deepwll Turbine Pump (Final PDFDocument12 pagesDeepwll Turbine Pump (Final PDFAsif MaqboolNo ratings yet

- 911.5 60 HZ End Suction Fire Pump Curves - AuroraDocument30 pages911.5 60 HZ End Suction Fire Pump Curves - AurorazaccNo ratings yet

- Elec Telecom Yi1qea 4Document23 pagesElec Telecom Yi1qea 4Mohammed ShakilNo ratings yet

- Beverage Application Guide: Cellulose GumDocument4 pagesBeverage Application Guide: Cellulose GumGiorgi GhambashidzeNo ratings yet

- 10 - Beer Stabilization Technology-Clearly A Matter of ChoiceDocument42 pages10 - Beer Stabilization Technology-Clearly A Matter of ChoiceGiorgi GhambashidzeNo ratings yet

- 02 - Haze FormationDocument22 pages02 - Haze FormationGiorgi GhambashidzeNo ratings yet

- 023101.101 Hardness CorrectionDocument5 pages023101.101 Hardness CorrectionGiorgi GhambashidzeNo ratings yet

- RFM PhaseGuard 11027E-1Document90 pagesRFM PhaseGuard 11027E-1Giorgi GhambashidzeNo ratings yet

- Instruction Manual: Phaseguard C/ T/ HTDocument32 pagesInstruction Manual: Phaseguard C/ T/ HTGiorgi GhambashidzeNo ratings yet

- High Level Lubricant Switch: Pump Type Order Code Construction Float Switch (A230 002)Document1 pageHigh Level Lubricant Switch: Pump Type Order Code Construction Float Switch (A230 002)Giorgi GhambashidzeNo ratings yet

- Aa 7 1 Sys Conf RCMDN GuidDocument29 pagesAa 7 1 Sys Conf RCMDN GuidOscar Alberto ZambranoNo ratings yet

- PrePoMax-v1 3 3-ManualDocument43 pagesPrePoMax-v1 3 3-ManualMarcelo ResendeNo ratings yet

- ABB - MNS - Service Manual - EN - 1SXH900002M0208 - REV G 02-2023Document64 pagesABB - MNS - Service Manual - EN - 1SXH900002M0208 - REV G 02-2023Donald FotsoNo ratings yet

- Ericsson Thesis WorkDocument5 pagesEricsson Thesis Workkristenwilsonpeoria100% (2)

- Laporan 2Document7 pagesLaporan 2Cindy Ingientd Ddya S'lalueNo ratings yet

- Raspberry Pi OverviewDocument20 pagesRaspberry Pi OverviewAJOY BANIKNo ratings yet

- Brochure PDFDocument4 pagesBrochure PDFAmel Ben YahiaNo ratings yet

- Gcse Geometry Vector Operations ExerciseDocument6 pagesGcse Geometry Vector Operations ExerciseGodfred WelbeckNo ratings yet

- Ethiopian Common and Emerging Maize DiseaseDocument14 pagesEthiopian Common and Emerging Maize DiseasedagneNo ratings yet

- Urschel DicerDocument268 pagesUrschel DicerGoker UyarerNo ratings yet

- YESPL IMS Manual Cover Pages v1.0Document2 pagesYESPL IMS Manual Cover Pages v1.0GVSRAO venkatNo ratings yet

- 5ccfcbc1e4b0a4eb53be4158 Original PDFDocument45 pages5ccfcbc1e4b0a4eb53be4158 Original PDFPoonam SachdevNo ratings yet

- Organizational Effectiveness and PerformanceDocument5 pagesOrganizational Effectiveness and PerformanceDung, DoanNo ratings yet

- A Level Mathematics Practice Paper E - Pure MathematicsDocument6 pagesA Level Mathematics Practice Paper E - Pure MathematicsZaka Ahmed33% (3)

- The Smart Next Generation PGNAA Cross-Belt Elemental AnalyserDocument5 pagesThe Smart Next Generation PGNAA Cross-Belt Elemental AnalyserDatNo ratings yet

- Adaptive Control Design and AnalysisDocument45 pagesAdaptive Control Design and Analysishind90No ratings yet

- Electronic Multi-Measuring Instrument ME96SS: Factory AutomationDocument40 pagesElectronic Multi-Measuring Instrument ME96SS: Factory AutomationMạnh Toàn NguyễnNo ratings yet

- 4TNE98Document21 pages4TNE98Noor Sa'adahNo ratings yet

- ScriptDocument2 pagesScriptLAKIESHANo ratings yet

- UTech CMP1025 Tutorial 3Document2 pagesUTech CMP1025 Tutorial 3Leia MichaelsonNo ratings yet

- @BIM Communication With BCF EnglishDocument2 pages@BIM Communication With BCF EnglishTomasz WiatrNo ratings yet

- 25m Tower Light With 12pcs 400w Led Flood Lights - BR SolarDocument15 pages25m Tower Light With 12pcs 400w Led Flood Lights - BR SolarNdubisi AgomoNo ratings yet

- Automatic Gearbox 0CTDocument113 pagesAutomatic Gearbox 0CTkilermaniaNo ratings yet

- LCPC 100-12 Gel Battery: Technology DataDocument2 pagesLCPC 100-12 Gel Battery: Technology DataZudeky LeónNo ratings yet

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p021Document1 pageToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p021sơn forkliftNo ratings yet

- Auto TransformerDocument9 pagesAuto TransformershathaNo ratings yet

- Imouse-1230732021628253-1.Ppt (Compatibility Mode) (Repaired)Document24 pagesImouse-1230732021628253-1.Ppt (Compatibility Mode) (Repaired)umesh kumarNo ratings yet