Professional Documents

Culture Documents

Design and Implementation of A Semi-Automated Truck/Shovel Dispatching System

Design and Implementation of A Semi-Automated Truck/Shovel Dispatching System

Uploaded by

ffOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Implementation of A Semi-Automated Truck/Shovel Dispatching System

Design and Implementation of A Semi-Automated Truck/Shovel Dispatching System

Uploaded by

ffCopyright:

Available Formats

LIZOTTE, Y., BONATES, E. and LECLERC, A. Design and implementation of a semi-automated truck!

shovel

dispatching system. APCOM 87. Proceedings of the Twentieth International Symposium on the Application of

Computers and Mathematics in the Mineral Industries. Volume I: Mining. Johannesburg, SAIMM, 1987.

pp. 377 - 387.

Design and Implementation of a Semi-automated

Truck/Shovel Dispatching System

Y. LIZOTTE*, E. BONA TES* and A. LECLERC**

*Department oj Mining & Metallurgical Engineering, McGill University, Montreal, Canada

**Chiej Mining Engineer, Black Lake Operation, LAB Chrysotite Inc., Black Lake, Canada

This paper describes the design and implementation of the dispatching system

at LAB Chrysotile Inc.' s Black Lake Mine Operation, Quebec, Canada. The

initial system uses a computer in a passive role, to record and display infor-

mation in ongoing operations. Simulation studies were undertaken at McGill

University to assess various heuristic dispatching rules which can be program-

med and inserted into the dispatching system. The computer can then suggest

to the operator where a truck should be sent to maximize productivity or im-

prove fleet efficiency.

The study stresses the importance of considering the effects of implement-

ing computerized systems on those individuals who must use these systems

in their daily ~ork. The roles of individuals from the industry and the university

in this joint project are also highlighted.

Introduction

Truck/ shovel operations are undoubtedly the major form Many of the features of expensive, fully automated

of materials handling system used in open-pit operations dispatching systems can be incorporated into micro-

throughout the world. Substantial progress has been made computer based semi-automated systems. Accepting speci-

in alternative forms, most recently involving to a greater fic limitations, the computer system can assist a dispatcher

extent continuous systems. Nevertheless, truck/shovel in compiling production statistics and monitoring opera-

systems will continue being important materials handling tions as well as suggest truck allocations for routine deci-

systems throughout this century. sions. The Black Lake dispatching system is micro-compu-

Haulage costs in truck/ shovel systems constitute a ter based and is now being transformed from a passive

major portion of total expenditures. Costs have been system to one which can suggest truck allocations to in-

reduced in the past by improving machinery performance, crease fleet productivity and efficiency.

machinery reliability, operating procedures and increas-

ing unit capacities to achieve economies of scale. One can

only expect marginal cost reductions to be achieved by Dispatching systems

these methods in the future. Potentially larger savings can There are three principal types of dispatching systems in

be realized by closer dynamic control of the on-going pro- use in open-pit operations.

cess. This goal can be only partly fulfilled by a 'human'

supervisor: computer monitoring and control is indicated Manual dispatching

as a method of increasing fleet productivity and efficiency. Since the early 1960s two-way radio communications have

Investment in a computerized dispatching system is been used to keep dispatch operators in contact with pro-

rapidly recovered by increasing productivities. Large duction and support equipment personnel. Often manual

systems developed in the late 1970s have been proved suc- dispatching systems involve operating trucks in 'fixed' or

cessful in large mining operations but cannot be eco- 'locked-in' dispatching; trucks are assigned to specific

nomically justified for small to medium size operations. shovels for the duration of the shift and are only changed

Fortunately, there have been tremendous decreases in when equipment failure arises.

computer hatdware costs since the early 1980s, simul- Mueller1 demonstrates the use of a dispatching board,

taneous with greater emphasis being placed on increas- used as an analog computer, to help dispatch operators

ing mine productivity due to poor mineral commodity keep track of truck locations and guide the operator for

markets. Micro-computers have been well accepted by the improving dynamic truck assignments.

mining industry.

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 377

Semi-automatic dispatching or mainframe computer is in communication with equip-

In this form of dispatching the dispatch operator con- ment, receiving status information and transmitting

tinues to communicate truck destinations directly to the assignments. Numerous publications describe these sys-

operators based on information received by radio. The tems: White et al.,1 Byles, 8 Crosson et at., 9 Hagenbuch lO

computer can simply record and display current infor- to name but a few. All of these systems have specific

mation - passive role - or be programmed to suggest methods of deciding on best truck assignments. Dispatch-

to dispatch operators 'best' assignments. ing procedures range from simple relative priority rules 9

The system previously used at Bougainville Copper Ltd. to solving linear programming-network flow formula-

(Swain2) is an active system which recommends action to tionsIO or, more recently, a three-part procedure in-

be taken throughout the shift. Hodson and Barke2 volving consideration of long-term objectives, non linear

describe the upgrading of a semi-automated system from programming and the classic assignment problem describ-

'passive' to 'active' and detail an elaborate procedure ed by Soumis et al. 11

tailor-made for their mining operation. Although the A fully-automated system is without doubt the best

authors are aware of a few other semi-automated systems method of monitoring and controlling a production fleet.

in operation, there are surprisingly few publications The system can virtually become a 'mine management

describing them. The system in use at Black lake since system' and with dispatching procedures that have achiev-

1982 is semi-automated, soon to be upgraded from ed a high degree of sophistication human intervention is

'passive' to 'active' .4,5,6 seldom warranted. Unfortunately, a fully automated

system requires a high capital outlay, ranging from $0,5 M

Fully automated dispatching to $3,6 M (US 1983 $s) according to Arnold and White. 12

No human intervention is necessary during routine opera- This cost would include a mini-computer (at least) and

tions with a fully-automated dispatching system. A mini- electronic hardware capable of withstanding rugged con-

SHOVEL

~ §J ~ ~ ~

WAITING

~ ~

! I

I

I ~I II

I I

I §] I I

I I

I I I

~I ~ I

I I

I

I I

I

I

§) I I

I

I

I~ ~

I

I

I

§JlI

I

I ~§] ~ 1 I§J

~

NORTH

DUMP

SOUTH

DUMP

CRUSHER

~

STATION 1 §]

STATION 2

GARAGE

PRODUCTION RETURN

FIGURE 1. Simplified main screen display of dispatching system

378 MINING: CONTROL OF MINING OPERATIONS

ditions. The capital costs will most likely decline in the allocate trucks to shovels when shovel moves, shovel

foreseeable future, but until then small and medium size breakdowns, coffee breaks, lunches, etc. occur during the

open-pit operations cannot justify more than investment shift. Inasmuch as possible, trucks operate with a desig-

in semi-automated systems. nated shovel for the shift (based on production schedule

requirements) during routine operations. This policy

relieves the dispatcher of constantly reassigning trucks so

The Black Lake dispatching system he can devote greater attention to the special circum-

The Black Lake Operation of LAB Chrysotile Inc. is a stances which arise.

medium size open-pit asbestos mine located in Black A menu at the bottom of the screen allows the dis-

Lake, Quebec, Canada. Materials handling capacity is patcher to switch to other screen displays by hitting

about 46 000 mt (ore and waste) per day. Mixed fleets of dedicated function keys on the keyboard. When the pro-

loaders and haulers have been used in the past: 4,5 and gram system is loaded, only numeric and function keys

11 cu. yd shovels, 10 and 11 cu. yd. loaders, 45, 85 and can be used as the dispatcher need not worry about in-

100 ton trucks. The objective has been to gradually elimi- advertently hitting the wrong key and crashing the system.

nate the smaller capacity equipment. The areal extent of The other screen displays show the production report in-

the operation is approximately 1,6 km by 6 km. The formation being compiled throughout the shift. The dis-

average haulage distance is approximately 2500 m with patcher can verify individual equipment performance and

a 100 m lift in elevation. spot unusual trends. At the end of the shift, hard copy

A Hewett Packard 9845C was purchased in 1982. High reports are printed showing productions, scheduled and

resolution of the colour monitor was an important fac- unscheduled breaks, fuel reports, etc.

tor in the selection of this computer. The project was in- All of the operations were very satisfied with the system

ternally sponsored (by A. Leclerc) and all the software and it was demonstrated that the 'passive' system increas-

developed in-house. The success of the initial system is ed fleet production by approximately 507o, easily justify-

strongly attributable to this fact. At that time there was ing a relative small capital outlay in less than one year.

no other operating dispatching system based on such a The logical step in improving the system is to make it 'ac-

small (187 K byte RAM) computer. The initial goal set tive', to suggest to dispatchers 'best' truck assignments.

was to develop a 'passive' system which could display Caution was to be exercised since any rejection from the

materials handling machinery status and automatically operators would render the effort useless. The research

produce (reliable) daily production reports. component of this task was undertaken in collaboration

From the outset the system was tailor-made for specific with McGill University.

use at the Black Lake mine, with all the specific work

procedures (idiosyncrasies) of a mine in production for

nearly 30 years. Caution was exercised in presenting the Simulation studies

system to the mine operators since it was their first ex- A stochastic simulation program was developed in order

posure to computers. While the system was being develop- to test, in a controlled environment, the effects of various

ed, it was seen to that dispatch operator suggestions were dispatching procedures on fleet productivity and utiliza-

rapidly implemented - insuring that a sense of participa- tion. This approach is well indicated and several publica-

tion was shared by all. tions attest to the success of this method (Kim and

Figure 1 illustrates the main screen display, the most Ibarra,13 Brake and Chatterjee,14 Wilke and Heck,15 Tu

important feature of the' graphic system', which appears and Hucka,16 to name but a few). It was felt essential to

throughout the shift. The dispatch operator knows all use statistical distributions to represent activity times since

equipment status and approximate locations from one the stochasticity of the real process is often the cause of

glance of the main screen display. Instead of a plan view the imbalances which occur during operations.

representation, necessitating constant updating as haulage Figure 2 illustrates the general structure of the simula-

configurations are modified, a summary board-type of tion program. An 'advance-clock' approach was adopted

display was selected. It is similar to a 'dispatch board' since dispatching procedures can easily be inserted into

where the program indicates truck and shovel activity the 'second-by-second viewing' the program performs.

based on information manually input by the dispatcher. The actual dispatching procedures tested are only visible

Truck and shovel numbers are displayed on the screen. in a single subroutine (DECISION) called when a truck

Since dispatch operators are familiar with daily opera- is available for the next assignment. Certain complexities

tions (shift bosses alternate as dispatchers), shovelloca- of the real operating system were not incorporated, bear-

tions and travel distances are known without actually ap- ing in mind that the objective was restricted to verifying

pearing on the screen. Truck travel times are estimated results achieved on average with specific procedures. The

and truck numbers are moved up or down the screen when impact of these simplifications was subsequently discussed

updating is done. Figure 1 is a simplification of the main when considering implementation of the procedures in

screen display since colour is used to add information and the real system.

make the display pleasant to look at for an eight hour

shift. Blue indicates waste removal handling, red indicates Dispatching procedures

ore handling and white is used for returning empty trucks. From a purely scientific point of view the study of dis-

A soft green background is used. patching procedures is intellectually stimulating for in-

The dispatcher uses the information displayed to re- dividuals involved in Operations Research. Numerous at-

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 379

INPUT DATA

TITLE, RANDOM NUMBER GENERATOR SEED DURATION

CLOCK INCREMENT, SHOVELS DUMP POINTS, TRUCKS,

LOAD AND DUMP PARAMETERS, ARRA Y OF TRAVEL

TIMES START POINT, NUMBER OF TRUCKS SHOVELS

INITIALIZATION

SET CLOCK

GENERATE TRAVEL TIMES

INITIALIZE PRODUCTION STAT. ARRA Y

CLOCK ADVANCE

I

~

I

ADVANCE CLOCK BY SET INCREMENT

I

VERIFY IF A TRUCK VERIFY THAT A TRUCK CAN

IS READY TO LOAD COMPLETE CYCLE BEFORE

TRAVEL FULL, DUMP f- END OF SIMULATION, BASED

OR TRAVEL EMPTY ON AVERAGE ACTIVITY TIMES

GENERATE APPROPRIATE ACTIVITY TIMES USING

R.N. GENERATOR AND STATISTICAL PARAMETERS

UPDATE PRODUCTION STATISTICS:

SHOVEL PRODUCTION, TRUCK PRODUCTION,

SHOVEL AND TRUCK IDLE TIMES

-1 VERIFY MASTER CLOCK TIME j.

OUTPUT DATA

PRINT INPUT DATA FOR CURRENT SIMULATION

PRINT PRODUCTION STATISTICS

OPTION: COMPLETE LIST OF ALL TRUCK

ASSIGNMENTS FOR THE SHIFT

FIGURE 2. General strurture of simulation program

tempts have been made at applying a multitude of O.R. at the mine precluded implementation of sophisticated

techniques (heutistic rules, queueing theory, linear, non- procedures. Secondly, in view of the system development

linear and dynamic programming, etc.) and simulation to date, only a suggestion was required by the computer:

is employed to study the procedures. In addition, the pro- it could not replace the operator's intuitive abilities to

cedures must be implemented on real systems and be ac- consider certain factors influencing his decisions which

cepted by the operators using the results. cannot be translated into computer code. A simpler pro-

Most of the dispatching procedures were analyzed in cedure which the dispatcher could easily understand had

the research done at McGill University. However it was a greater chance of being accepted.

decided to restrict the in-depth study to three relatively

simple heuristic decision rules: maximize truck, maximize Maximize truck

shovel and match factor. The study was restricted in this This procedure involves constantly reassigning trucks,

way for two reasons. Firstly, the computer capabilities when available, to the shovel where it is most likely to

380 MINING: CONTROL OF MINING OPERATIONS

T

~~H~VE~

I

I I

I I

I I

I I t2

I I I

I I I

I I I

It 1 I I

I I t3 )

I I 1

I I /

I I /

I I /

I I /

I I 1

I 1/

I 11

I (.;\ TRUCK TO BE

I

L- _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

q:;

J

DISPATCHED,

FIGURE 3. Maximize truck dispatching rule

TRUCK TO BE

DISPATCHED

FIGURE 4. Maximize shovel dispatching rule

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 381

be loaded first. It is a simple heuristic procedure which this procedure. A variation of the maximize shovel rule

does not guarantee optimality since assignments are based is used in Ebasco's Automated Truck Dispatch (Sas-

on average conditions and future events (i.e. the next 'n' SOSI7) •

trucks to be assigned) are not considered. Figure 3 sche-

matizes the decision process involved. Each time a truck Match factor

is available calculations are performed, based on averaged Match factor (MF) is a dimensionless number which at-

values, to determine at which shovel a truck can be served tempts to quantify the apparent balance which exists be-

first; travel times of empty trucks en route, trucks waiting tween the number of loading devices and the number of

and trucks being served must be considered for each haulage devices in a system. It can be computed by:

shovel.

The maximize truck rule will produce substantial in- (No. of haulers) (Loader cycle time)

creases in total productivity compared to fixed dispatch- MF

(No. of loaders) (Hauler cycle time)

ing, compensating for slow shovels by avoiding long

waiting lines. However, shovel utilization is disbalanced

because the procedure favors truck assignments to shorter The cycle times in either case do not include any waiting

circuits as stated by Tu and Hucka. 16 Also, productivi- time at the loading area for either unit. A MF below 1,0

ty is undifferentiated and specific desired production ob- indicates under-trucking, MF greater than 1,0 means

jectives, such as grade requirements and waste/ore ratios, system over-trucking.

are not accounted for. Hagenbuch lO attempts to com- The MF is used as a dispatching procedure by measur-

pensate for this shortfall in an operating system by adding ing MF values for sub-systems or individual shovels and

relative priority values to individual shovels. assigning trucks accordingly in various ways. MF values

have been applied explicitly in dispatching decisions by

Maximize shovel Swain2 and Hodson and Barker. 3 Other authors have

This procedure dictates available truck assignment to the applied variations of the MF procedure, referring to it

shovel which has been waiting the longest or expected to simply as a 'shovel coverage' rule. In this simulation study

be idle next. Figure 4 schematizes the decision process the procedure consisted in computing current MF values

involved. In this case truck travel to each shovel is not based on the last five event times for each cycle. Current

considered and the criterion adopted in case of conflicts MF values are compared to desired coverage, and the

is to allocate the truck to the shovel which has been idling shovel with the lowest ratio is selected. Similar to the max-

the longest to best reflect the underlying intent of the pro- imize shovel procedure, the MF rule tends to produce

cedure. A more uniform shovel utilization is expected with uniform shovel utilization.

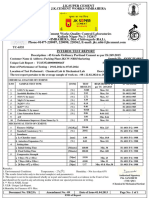

TABLE 1. summary of input data6

Initial truck assignment

for 13 to 21 trucks

Shovel Dump Travel time Travel from Travel time

number number empty other dumps full 13 15 17 19 21

D2 7,15

5,00 6,34 2 2 2 3 3

D3- 7,47

D2 12,24

2 7,27 17,28 2 4 4 4 4

D3 9,87

D1 5,79

3 2 6,20 10,73 2 3 4 3 4

D3 8,25

D1 9,64

4 2 7,10 11,99 4 3 4 4 4

D3 12,24

Dl 4,25

5 3 6,71 9,55 3 3 3 5 6

D2 13,11

Duration of simulations: 400 minutes

Travel empty coefficient of variance: 0,10

Travel full coefficient of variance: 0,11

Average load time = 4,17 minutes

Average dump time = 0,74 minutes

Load parameters (Weibull): ALPHA = 1,475 BETA = 2,344 GAMMA = 2,150

Dump parameters (Weibull): ALPHA = 1,730 BETA = 0,232 GAMMA = 0,534

NOTE: Crusher is dump point number 1

North Dump is dump point number 2

South Dump is dump point number 3

382 MINING: CONTROL OF MINING OPERATIONS

TABLE 2. Summary of simulation results 6

Total Average Shovel production Shovel idle Total

Number Dispatch production Standard truck idle (tonnes) time (min.) shovel idle

of trucks rule* (tonnes) deviation time (min.) 2 3 4 5 2 3 4 5 time (min.)

A 18624 168 11,1 3978 2163 2967 5032 4484 199 283 247 140 166 1035

13 B 20056 179 15,9 5332 1335 5762 1175 6452 136 335 114 341 81 1007

C 18517 171 6,9 4848 3230 4352 3086 3001 161 240 186 246 252 1085

D 17498 171 13,1 3366 2899 3957 3506 3770 229 255 208 228 211 1131

A 20898 176 11,7 3965 4225 4365 3821 4522 197 182 173 201 168 921

15 B 22624 222 18,9 5912 2129 6252 1624 6707 106 295 90 313 72 876

C 21148 169 10,3 5525 3659 5053 3396 3515 124 220 152 235 228 959

D 20316 186 16,8 4790 3664 4157 3727 3978 164 220 196 212 201 993

A 23503 189 14,7 3961 4246 5703 5058 4535 196 181 106 142 167 792

17 B 24956 261 22,6 6116 2814 6702 2435 6889 95 261 66 278 58 758

C 23741 236 14,7 6146 3974 5784 3914 3923 95 205 117 207 208 832

D 22704 205 19,8 4921 4059 4777 4467 4480 157 197 166 175 181 876

A 25879 348 33,6 5725 3196 4365 5024 7569 105 230 171 141 11 658

19 B 27256 319 27,5 6537 3430 6821 3251 7217 77 226 61 240 44 648

C 26146 284 20,6 6719 4275 6248 4322 4582 69 189 88 15 173 704

D 24956 204 22,6 5096 4620 5308 4773 5159 146 171 135 164 149 765

A 28325 237 33,7 5802 4220 5733 5027 7543 102 179 106 138 11 536

21 B 29402 350 32,2 6792 4127 7059 4097 7327 67 194 47 195 32 535

C 28407 208 25,1 7102 4760 6809 4760 4976 50 165 63 163 150 591

D 27340 227 27,3 5814 5041 5695 5295 5495 114 150 116 134 135 649

*Dispatching rules: A = Locked-in, B = Maximize Truck, C = Maximize Shovel, D = Match Factor

Simulation results

Several simulations were performed to assess the effects ductivity than fixed dispatching. Surprisingly, the MF rule

of the dispatching procedures on fleet productivity and consistently yields a lower fleet productivity than fixed

individual shovel productivity and utilization. 6 The case dispatching. This is explained by the fact that the deci-

study presented below is typical of these analyses. Because sion is made based on a ratio computation for shovels

of the stochastic nature of the process it was necessary requiring quite different coverages. However the benefit

to base conclusions on average values, thus requiring of the MF rule is apparent in Figure 7 which illustrates

several simulation program runs to obtain representative the maximum difference in shovel production encounter-

values. ed. For this purpose, the MF rule is more efficient than

Table 1 is the summary of the input data required for the maximize shovel rule. The irregularities of values for

400 simulation program runs. The initial truck assign- fixed dispatching shown in Figure 7 indicate the problem

ments indicated are used throughout the shift for the associated with being limited to 'integer' numbers of

'fixed' dispatching rule. It was decided to compare results trucks assigned to shovels for entire shifts.

to fixed dispatching since the intricacies of the real pro- In all of the previous examples the activity times were

duction system (including dispatcher decisions) could not only allowed to vary within the bounds of specific distri-

be integrated into the simulation program. Travel times butions. Since the fixed dispatching assignments were

to and from shovels were modelled with normal distribu- based on average values of these distributions, the full

tions, values obtained with time study results and com- potential of the dispatching procedures could not be ascer-

pleted with a deterministic simulator. Load and dump tained. In normal operations several occurrences can

time distributions were modelled with three-parameter modify activity times, such as shovels experiencing dif-

Weibull distributions assessed with time study results. The ficulties in loading or sudden deterioration of haul road

study was further simplified by assuming only one truck surfaces. To approximate the effects of such perturb a-

and one shovel capacity. tions another study was accomplished using the data

A summary of the simulation results is presented in presented in Table 1. Table 3 summarizes the results of

Table 2. A range of 13 to 21 trucks was examined for simulations in which travel time distributions are modified

locked-in dispatching, maximize truck, maximize shovel after half a shift. These results show that the' active' rules

and match factor dispatching rules. Figure 5 illustrates compensate for changes - which the fixed dispatching

total fleet productivity for each dispatching rule; these cannot do. A dispatcher may not notice (and take ade-

results are as expected but only show the general tenden- quate action concerning) these changes occurring during

cy. Figure 6 indicates much better the effect of each a shift until much later than the computer which can con-

dispatching procedure compared to fixed dispatching. The stantly monitor activity times and update with 'moving

maximize truck rule generates as much as 80/0 higher pro- averages' .

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 383

30

28

Z

'"'

0

I-

'"

"0

c 26

C\l

()

::J '"

:J

0

Cl

0

er:

0..

-

.s:::

......

Cl)

24

LU 22

I- z III Fixed

W z

W 0

....J I- • Truck

I.!..

20

18

•

...

Shovel

Match

13 15 17 19 21

NO. OF TRUCKS IN OPERATION

FIGURE 5. Total system production results of simulations6

I- 6

en

0 ,..,

....J ?f.

..... 4

......

Z LU

(!J

<C « 2

(!J I-

Z

W LU

(!J () 0

<C Cl:

I- LU

Z a.. -2

W

()

-4

er:

W

0..

• Shovel

-6 • Truck ... Match

13 15 17 19 21

NO. OF TRUCKS IN OPERATION

FIGURE 6. Percentage change in system production compared to fixed dispatching

System integration and future research The preliminary structure of the integrated dispatching

Based on the results of the research project it was decid- system is presented in Figure 8. The modules are logical-

ed to integrate the dispatching rules into the semi- ly divided into three types: dynamic, operational, and

automated system. Although the maximize truck rule was analytical. The dynamic components relate mainly to the

recommended as the most appropriate at this time, it was set-up and operation of the main screen display previously

felt that the additional programming effort to insert the described. This remains the 'heart' of the system. Only

other procedures as options was worthwhile. Since the dynamic output required is for production reporting and

system is to be modified to accommodate dispatching occasionally for additional automated time studies. Dis-

rules it was also felt worthwhile to restructure the entire patching procedures are integrated as modules, activated

system, inserting modules for analytical work as well as or not to suggest assignments. Modules for production

some degree of generalization. Experience gained from reporting will be generalized.

operating the system for nearly five years would be useful The modules in the analytical component are of par-

in this respect. ticular relevance to the University side of this University-

384 MINING: CONTROL OF MINING OPERATIONS

Z 5.5

0

I-

0

:::> 4.5

Cl .....

0 (/)

"0

a:: c Il!I Fixed • Shovel

0.. (\l

(/)

....I ~

3.5 ell Truck A Match

UJ 0

.c

> ....

'-"'

0 Cl)

I w 2.5

Cl)

z

Z

z

0

I-

UJ

0 1.5

Z

UJ

a::

UJ 0.5

IJ..

IJ.. 13 15 17 19 21

-Cl

NO. OF TRUCKS IN OPERATION

FIGURE 7. Maximum difference in shovel production6

TABLE 3. Results of modified event times during shift6

Total Shovel production Shovel idle time

Dispatch production Standard (tonnes) (minutes)

Case rule* (tonnes) deviation 2 3 4 5 2 3 4 5

250/0

Decrease

travel A 23962 189 3910 4097 5078 5457 4420 196 179 80 112 166

times for B 25925 292 5602 2167 7089 4641 6426 123 298 51 165 82

Shovels C 24837 228 6001 3978 6375 4522 3961 109 210 92 173 215

I and 2 D 23613 142 4973 4224 4956 4845 4615 161 195 154 165 173

25%

Increase

travel A 21956 191 3927 4055 5134 4454 4386 199 181 128 156 165

times for B 24327 308 6214 3170 5984 2023 6936 96 248 107 298 61

Shovels C 23188 166 6077 4131 5338 3604 4038 103 200 148 218 210

I and 2 D 22075 80 4871 4055 4607 4259 4283 166 204 175 195 189

* Dispatching rules: A= Locked-in B = Maximize Truck

C = Maximize Shovel D= Match Factor

Industry cooperation, although the integrated system will that the benefits achieved with costly fully automated

have these modules available at the mine site. Parts of systems could be strived for in this way.

these modules have already been developed. The focus

of proposed resarch is to improve the dispatching pro- Conclusions

cedures. A foreseen method of accomplishing this is to A semi-automated dispatching system is a viable alter-

develop a mathematical programming module to study native for small to medium size open-pit operations.

equipment locations and assignments to meet medium- Economic analysis of alternatives should be done on an

term production planning objectives. Results could pro- incremental cost basis. It is primordial to consider the

vide more refined parameters to integrate into the dis- human element in the system, both for initial system

patching rules. For example, mathematical programming development and implementation of automated dis-

can indicate average desired shovel coverage which can patching procedures.

be used to adjust match factor values or heuristic priority Thus the development of a dispatching system is a com-

adjustment factors in'the maximize truck rule. It is felt plete Operations Research problem involving not only

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 385

SYSTEM INITIALIZATION

I

INITIALIZATION OF

t t

INITIALIZATION OF

PRODUCTION MAIN SCREEN

REPORT FORMS DISPLAY

,It ,,. ~If

,

SHIFT ADDITIONAL

PRODUCTION - SHIFT SET UP OF MAIN OUTPUT FOR

REPORTING SCREEN DISPLAY STUDY

COMPILING

-

-

ROUTINE INPUT-OUTPUT

DYNAMIC OPERATION

ACTIVE PROGRAM USE

.

PURPOSES

STATISTICAL

PRODUCTION FOR SUGGESTING TRUCK ANALYSIS

STATISTICS MODULE

FOR SHIFT ALLOCATIONS

t

LONG-TERM

- DISPATCHING PROCEDURES

WITH SPECIFIC t

PARAMETER RANGES MATHEMATICAL

PRODUCTION PROGRAMMING

COMPILING MODULE

h

t

STATISTICAL ANALYSIS OF

't

STOCHASTIC

J!'

LONG TERM PRODUCTION SIMULATION

RESULTS MODULE

J.I DISPATCHING

ANALYSIS OF EQUIPMENT

" PROCEDURES ~

PERFORMANCE

DETERMINISTIC

SIMULATION

MODULE

OPERATIONAL DYNAMIC ANALYTICAL

FIGURE 8. Structure of integrated dispatching system

mathematical tools/formulations but also implementa- 4. LIZOTTE, Y., SCOBLE, M. and BONATES, E.,

tion in a real system. It can be postulated that a not so Application of simulation to assess truck shovel

sophisticated but well tailor-made system may produce dispatching policies. Mining Equipment Selection

benefits comparable to top of the range systems. Symposium, University of Calgary & CANMET,

Calgary, November 1985. Paper no. 24.

References 5. LIZOTTE, Y. and BONATES, E. Truck/shovel

1. MUELLER, E.R. Simplified dispatching board dispatching rules assessment using simulation. SME

boosts truck productivity at Cyprus Pima. Mining of AIME, Fall Meeting, St Louis, Mo., September

Engineering, August 1977. pp. 40-43. 1986. Preprint no. 86 - 354.

2. SWAIN, H.D. Bougainville's EDP techniques up 6. BONATES, E., Analysis oftrucklshovel dispatching

mine productivity, simplify planning. Mining policies using computer simulation. M.Sc. thesis,

Engineering, March 1979. pp. 265 - 268. McGill University, Department of Mining & Metal-

3. HODSON, D.1. and BARKER, K.S. The design and lurgical Engineering, August 1986. 209 pp.

development of a computerized truck despatching 7. WHITE, J.Wm., ARNOLD, J.A. and CLEVEN-

system. Mining Conference '85, Birmingham, United GER, J.G. Automated open-pit truck dispatching at

Kingdom, June 1985. pp. 83 - 90. Tyrone. E&MJ, June 1982. pp. 76 - 84.

386 MINING: CONTROL OF MINING OPERATIONS

8. BYLES, R.D. The installation of a fully automatic 13. KIM, Y.C. and IBARRA, M.A. Truck dispatching

truck despatch system at Bougainville Copper Limit- by computer simulation. Bulk Solids Handling, vol.

ed. Joint Meeting of the Australasian Institute of 1, no. 1, February 1981.

Mining and Metallurgy, Bougainville, Papua New 14. BRAKE, D.J. and CHATTERJEE, P.K. Evaluation

Guinea, October 1984. of truck dispatching and simulation methods in large-

9. CROSS ON, C.C., TONKING, M.J.H. and MOF- scale open-pit operations. 16th APCOM, AIME,

FAT, W. G. Palabora system of truck control. Mining New York, 1979. pp. 375 - 383.

Magazine, February 1977. pp. 74 - 82. 15. WILKE, F.L. and HECK, K. Simulation studies on

10. HAGENBUCH, L.G. An integrated truck manage- truck dispatching. 17th APCOM, AIME, New York,

ment information system (Truck MIS) concept. CIM 1982. pp. 620-626.

Bulletin, August 1986. pp. 62 - 68. 16. TU, H.J. and HUCKA, V.l. Analysis of open-pit

11. SOUMIS, F. et al. A new method of automatic truck truck haulage system by use of a computer model.

dispatching in an open-pit mine. SME of AIME, Fall CIM Bulletin, July 1985. pp. 53-59.

Meeting, St Louis, Mo., September 1986. Preprint 17. SASSOS, M.P. Reserve's mine management system.

no. 86-359. E&MJ, September 1984. pp. 42-49.

12. ARNOLD, M.J. and WHITE, J.Wm. Computer-

based truck dispatching. World Mining, April 1983.

pp. 53-57.

A SEMI-AUTOMATED TRUCK/SHOVEL DISPATCHING SYSTEM 387

You might also like

- Caso COLCHERTER LATHE-PROJECT SCAMP FMSDocument11 pagesCaso COLCHERTER LATHE-PROJECT SCAMP FMSTeam Winter FiveNo ratings yet

- Mitigation of Environmental Impacts of TransportationDocument7 pagesMitigation of Environmental Impacts of Transportationhiraya_musiaNo ratings yet

- DASA - DevOps Fundamentals Mock ExamDocument22 pagesDASA - DevOps Fundamentals Mock ExamUnes WachaouNo ratings yet

- CSI:Lab - Lesson Plan & Facilitator Guide: Purpose & PreparationDocument25 pagesCSI:Lab - Lesson Plan & Facilitator Guide: Purpose & PreparationPonHarshavardhananNo ratings yet

- Glaxosmithkline Project ReportDocument87 pagesGlaxosmithkline Project ReportShanky Rana69% (16)

- Mint's Original Marketing PlanDocument6 pagesMint's Original Marketing PlanCorey RecvloheNo ratings yet

- Chapter 2 - ApplicationsDocument18 pagesChapter 2 - ApplicationsWILSON CALDERONNo ratings yet

- Truck Shovel Dispatching Rules Assessment Using SimulationDocument13 pagesTruck Shovel Dispatching Rules Assessment Using SimulationJoshua DavisNo ratings yet

- HEC Cargomax For Windows - Users ManualDocument62 pagesHEC Cargomax For Windows - Users ManualEnder BolatNo ratings yet

- Cheriton 1995Document4 pagesCheriton 1995Ravi JhaNo ratings yet

- SPE/lADC 29388 Low Cost Slim Hole Drilling System: SPEIIADC MembsrsDocument12 pagesSPE/lADC 29388 Low Cost Slim Hole Drilling System: SPEIIADC Membsrsfiroz989No ratings yet

- T Hip Pay A 96255413184Document2 pagesT Hip Pay A 96255413184Ismet Erdi SomuncuogluNo ratings yet

- ITO Memo Dated August 26, 2022Document3 pagesITO Memo Dated August 26, 2022COA Regional Office IIINo ratings yet

- Acidentes Com CaminhõesDocument13 pagesAcidentes Com CaminhõesAmilton filhoNo ratings yet

- Dot 13474 DS1Document40 pagesDot 13474 DS1MDLNo ratings yet

- Automation in Port Container TerminalsDocument10 pagesAutomation in Port Container Terminalsa123123123No ratings yet

- Subject Code:: C C CCDocument23 pagesSubject Code:: C C CCMithesh KumarNo ratings yet

- UK Airborne AESA Radar Research: "Future Proof'Document7 pagesUK Airborne AESA Radar Research: "Future Proof'Ahmed HussainNo ratings yet

- The Future of Automated Ports FinalDocument10 pagesThe Future of Automated Ports FinalRabie MachloukhNo ratings yet

- Chapter 1Document7 pagesChapter 1Kimberly Shawn Nicole SantosNo ratings yet

- ICAO Aerodrome Design Manual Part 2Document160 pagesICAO Aerodrome Design Manual Part 2rafaaspireNo ratings yet

- Carsim. Car-Following Model For Simulation of Traffic in Normal and Stop-And-Go ConditionsDocument14 pagesCarsim. Car-Following Model For Simulation of Traffic in Normal and Stop-And-Go ConditionsAg PradhiNo ratings yet

- Managing The Tug-of-War Between Supply and Demand in The ServiceDocument14 pagesManaging The Tug-of-War Between Supply and Demand in The ServiceJonathan D. PortaNo ratings yet

- Evaluation of SRP ComputerizedsDocument12 pagesEvaluation of SRP ComputerizedsBram ANo ratings yet

- Generic Simulation For Rail-Road Container TerminalsDocument5 pagesGeneric Simulation For Rail-Road Container TerminalstrpevskikdNo ratings yet

- Gauri 2018Document6 pagesGauri 2018Janki KaushalNo ratings yet

- Optimization of Handling Equipment in The Container Terminal of The Port of BarcelonaDocument8 pagesOptimization of Handling Equipment in The Container Terminal of The Port of BarcelonaAlejandra Rodriguez VasquezNo ratings yet

- Sensors For Autonomous Systems MQP ReportDocument98 pagesSensors For Autonomous Systems MQP ReportHarsha MetiNo ratings yet

- The Insertion of A Satellite Terminal in Port Operations - Port Economics, Management and PolicyDocument5 pagesThe Insertion of A Satellite Terminal in Port Operations - Port Economics, Management and PolicymerrwonNo ratings yet

- Performance Simulations of Twin-Screw Compressors With EconomizerDocument15 pagesPerformance Simulations of Twin-Screw Compressors With EconomizerJason LimNo ratings yet

- Air Cargo: Growth and IssuesDocument44 pagesAir Cargo: Growth and IssuesvivekimdrNo ratings yet

- Unit 3 ISO and Wholesale Market CharacterisiticDocument8 pagesUnit 3 ISO and Wholesale Market Characterisiticchokkakulasagar1810No ratings yet

- Simulation Model For Maritime Container TerminalDocument9 pagesSimulation Model For Maritime Container TerminalIonut AlexandruNo ratings yet

- Icoa Manual 1Document12 pagesIcoa Manual 1yadukulbNo ratings yet

- A Transnational Approach of Research Developments in Maritime TransportDocument9 pagesA Transnational Approach of Research Developments in Maritime Transportcristina.cristinaNo ratings yet

- Chapter 17Document4 pagesChapter 17MonaliSa P BarusNo ratings yet

- A Multioutput Cost Function For Port Terminals: Some Guidelines For RegulationDocument27 pagesA Multioutput Cost Function For Port Terminals: Some Guidelines For RegulationjmsrsNo ratings yet

- Orapa 3 Plant Conceptual Design Evolution in Action (Let The Ore Dictate The Plant That You Build!!)Document28 pagesOrapa 3 Plant Conceptual Design Evolution in Action (Let The Ore Dictate The Plant That You Build!!)ndishematengeNo ratings yet

- A Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsDocument15 pagesA Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsSofiene GuedriNo ratings yet

- An Airline Scheduling Model and Solution AlgorithmDocument11 pagesAn Airline Scheduling Model and Solution AlgorithmPieter LourensNo ratings yet

- Mechatronic Systems - With Applications For CarsDocument6 pagesMechatronic Systems - With Applications For CarsBruce MartinNo ratings yet

- Coordinating Vessel Traffic To Improve Safety and EfficiencyDocument10 pagesCoordinating Vessel Traffic To Improve Safety and EfficiencyJoan CedyNo ratings yet

- Student Name Student ID Course Name Course Code DateDocument7 pagesStudent Name Student ID Course Name Course Code Datemona asgharNo ratings yet

- July 1998 IffDocument64 pagesJuly 1998 IffBig ZamNo ratings yet

- ESCAP 2398 Ch1-IntroDocument2 pagesESCAP 2398 Ch1-Introaccount_meNo ratings yet

- Colreg Guide - Deni̇zde Çatişmayi Önleme KlavuzuDocument29 pagesColreg Guide - Deni̇zde Çatişmayi Önleme KlavuzuFuat TİMUR100% (9)

- CH - in Management: Introduction To SupplyDocument13 pagesCH - in Management: Introduction To SupplyShiella Andrea TorresNo ratings yet

- Ship Borne RFTracking SystemDocument11 pagesShip Borne RFTracking SystemDpt HtegnNo ratings yet

- Shipcost - Vessel and Voyage Costing Model: Arnold, JR., John Panagakos, GeorgeDocument9 pagesShipcost - Vessel and Voyage Costing Model: Arnold, JR., John Panagakos, GeorgeRavikiran PatilNo ratings yet

- Agecon TRF 1023Document13 pagesAgecon TRF 1023Xuyên TrươngNo ratings yet

- Railway OperationsDocument33 pagesRailway OperationsELSA SHABRINA QAMARANINo ratings yet

- Evolution and Development of Multi-Airport SystemsDocument9 pagesEvolution and Development of Multi-Airport SystemsMiguel GallegoNo ratings yet

- Lesson 2 Electronic1Document11 pagesLesson 2 Electronic1Peter Adrian NgoNo ratings yet

- ToR MarCom WG 208 Planning For Automation of Container TerminalsDocument2 pagesToR MarCom WG 208 Planning For Automation of Container TerminalsAl-Razzaq Al-WahhabNo ratings yet

- Airport Authority of IndiaDocument50 pagesAirport Authority of IndiaKuldeep GuptaNo ratings yet

- Indian Railways - PresentationDocument18 pagesIndian Railways - PresentationManu TomarNo ratings yet

- AIS Manual - 1Document215 pagesAIS Manual - 1Rajiv KumarNo ratings yet

- 1 s2.0 S0360835218304777 MainDocument12 pages1 s2.0 S0360835218304777 Mainroi.ho2706No ratings yet

- 3D Evaluation Approach of Practical Airside CapacityDocument5 pages3D Evaluation Approach of Practical Airside Capacitylia bayuNo ratings yet

- Parts: Uniform System of AccountancyDocument36 pagesParts: Uniform System of AccountancyINFO STATIONERSNo ratings yet

- Chapter 15 Agile PortDocument3 pagesChapter 15 Agile PortMoulay Ahmed Charif ElidrissiNo ratings yet

- Telecommunications Traffic : Technical and Business ConsiderationsFrom EverandTelecommunications Traffic : Technical and Business ConsiderationsNo ratings yet

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Mine Engineer in TrainingDocument2 pagesMine Engineer in TrainingffNo ratings yet

- Development of A Computer Oriented Algorithmic Approach For Opencast Mine Dispatch SystemDocument50 pagesDevelopment of A Computer Oriented Algorithmic Approach For Opencast Mine Dispatch SystemffNo ratings yet

- Jasduarte 10Document7 pagesJasduarte 10ffNo ratings yet

- Central Dispatch Strategy To Optimize Dispatch at Teck CoalDocument63 pagesCentral Dispatch Strategy To Optimize Dispatch at Teck CoalffNo ratings yet

- Biography Hatta RajasaDocument2 pagesBiography Hatta RajasaEvanNo ratings yet

- Approve Budget For The ContractDocument6 pagesApprove Budget For The ContractBea Therese VillanuevaNo ratings yet

- (MIÑOZA - Wen Roniel Badayos) - PKYF 2023 Application EssayDocument3 pages(MIÑOZA - Wen Roniel Badayos) - PKYF 2023 Application EssayWen MinozaNo ratings yet

- G. Ra 9003 RevisedDocument93 pagesG. Ra 9003 Revisedjohne jossef medranoNo ratings yet

- PF Aquaforte Brochure - 04.04.12Document2 pagesPF Aquaforte Brochure - 04.04.12ukalNo ratings yet

- Free TradeStation EasyLanguage TutorialsDocument15 pagesFree TradeStation EasyLanguage TutorialszzzebrabNo ratings yet

- Je Hyung Yoo ComplaintDocument11 pagesJe Hyung Yoo ComplaintEmily Babay0% (1)

- All Cement Formulae PDFDocument163 pagesAll Cement Formulae PDFGanapathy SubramaniamNo ratings yet

- Certificate of Annual InspectionDocument1 pageCertificate of Annual InspectionJc JüsäyänNo ratings yet

- Top 10 Philippine EntrepreneursDocument26 pagesTop 10 Philippine EntrepreneursElton PapaNo ratings yet

- Philippine Buildings + ArchitectsDocument12 pagesPhilippine Buildings + ArchitectsKristineNo ratings yet

- SPBA208RDocument129 pagesSPBA208RLAVANYANo ratings yet

- Astm A335 PDFDocument11 pagesAstm A335 PDFJACILDO SOARES CAVALCANTE100% (1)

- Deviser S20Document5 pagesDeviser S20Alexander WieseNo ratings yet

- Sand ColumnDocument16 pagesSand ColumnZulfadli MunfazNo ratings yet

- Summative Test Module 4 Tle Ict CSS 9Document2 pagesSummative Test Module 4 Tle Ict CSS 9Ronaldo Oloroso Abinal Jr.No ratings yet

- Second Revision) : Countersunk Flat Head Screws (Common Head Style) With Type HOR Type Cross Recess - Product Grade ADocument10 pagesSecond Revision) : Countersunk Flat Head Screws (Common Head Style) With Type HOR Type Cross Recess - Product Grade Akumar QANo ratings yet

- AWS Certified Solutions Architect Professional Slides v2.0Document724 pagesAWS Certified Solutions Architect Professional Slides v2.0John Nguyen100% (1)

- AVDI DiagnosticsDocument7 pagesAVDI DiagnosticsFlorin MoneaNo ratings yet

- 06 US V ANG TANG HO Digest With Full CaseDocument14 pages06 US V ANG TANG HO Digest With Full CaseThirdy DemonteverdeNo ratings yet

- Module 1Document35 pagesModule 1anjuNo ratings yet

- TM-2107 Hull Detailed Design - Plate Nesting-Rev4.1Document75 pagesTM-2107 Hull Detailed Design - Plate Nesting-Rev4.1sabarna1No ratings yet

- Mark Scheme (Results) Summer 2015Document12 pagesMark Scheme (Results) Summer 2015NourNo ratings yet

- FinalDocument86 pagesFinalSunil RamchandaniNo ratings yet

- Tata Institute of Social Sciences, Mumbai: Gcs Medical College, Hospital & Research Center, Ahmedabad, GujaratDocument32 pagesTata Institute of Social Sciences, Mumbai: Gcs Medical College, Hospital & Research Center, Ahmedabad, GujaratDr.Marufa FaruqiNo ratings yet

- Opc JK Super MTC (4) 25.02.2024Document1 pageOpc JK Super MTC (4) 25.02.2024msconstu2No ratings yet