Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 views202012211044

202012211044

Uploaded by

Tengku Nizarul AslamiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Draft Report RLA Pipeline PDFDocument47 pagesDraft Report RLA Pipeline PDFTengku Nizarul AslamiNo ratings yet

- DTP-201939-R001 Reva PDFDocument68 pagesDTP-201939-R001 Reva PDFTengku Nizarul AslamiNo ratings yet

- A1.01 Layout Spbu Shell SemperDocument1 pageA1.01 Layout Spbu Shell SemperTengku Nizarul Aslami100% (2)

- Bat Rotating Bob PT BSPDocument2 pagesBat Rotating Bob PT BSPTengku Nizarul Aslami100% (1)

- Laporan Level Tangki T 302Document12 pagesLaporan Level Tangki T 302Tengku Nizarul Aslami100% (1)

- 1776279Document82 pages1776279Tengku Nizarul AslamiNo ratings yet

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Tengku Nizarul AslamiNo ratings yet

- Pump Balancing Test Report001Document6 pagesPump Balancing Test Report001Tengku Nizarul Aslami100% (1)

202012211044

202012211044

Uploaded by

Tengku Nizarul Aslami0 ratings0% found this document useful (0 votes)

10 views66 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views66 pages202012211044

202012211044

Uploaded by

Tengku Nizarul AslamiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 66

xsa b,. in

4. require, na fern the pling ee oe: Fern the piping),

B

1g. 7 rterin tne piping

(C1 on ree gine 2 ee)

se fer with dn wie mean Gres wd 05 mm, wie mete 025 wom at

‘omen resstan matra

Ute th er aes tres tnes the crsssecon of he lpn,

Conia tershete proved tee

5. Comed the pump rae tothe ng

‘Aggresive fing ul and pling agent.

Mach he cleaning operation med nd duration of ushing and peti to

{he casing materia and ve teria ed

|

2aot00 RH

5.4.2 Pomisble fre an oman a the mp nozzles

“1 [Biharge nozzle

snare

at ee

“The jmp casings ae designed to withstand tice the pig eee and piping

nent reared y 1610.

Forigher forces and moment cont the manufacture,

es

RH rsoteo

xsab,) Sintaon a She

lol

ae

maizelaat

0 | 20 | 160

‘ro 50a fu |

ok arias one a

[asroo |e | [a0 [360 |

mop

ico bur

olasonh

sk sre tht the baie hid or quene gd ate compte with the fd

Fale to use or imarrc use of airy connection (ng bar hid hing

Iu te)

kf nary from escaping ih

A Matnction of he pm

* Refer fo the general arangement drawing the pping layout and pump

‘orkng an forte quaniy mens ad iran of sla

rot RH

xsab,) Staton atte

55 Encosure/insultion

so potently explosive stophere de to nient venting

Speen hava)

© Mae sur the pace between the casing covrichage cme andthe besing

‘neeieathty ete

Mev le cover the peroatin ofthe being bracket guards (eg by

‘nation.

The ot casing and casingecharge overtake onthe same temperature the |

Iidhoniod

kf burt

* late the oie casing

protein equipment

eat bulapin the bearing racket.

‘amage tothe bearing

5.6 checking the coupling alignment

| &

Inne empresa he oig oben tomato the

.

ton

ike bur

Make sure that he coupling ieonecty aligned tl ines

Mal gument of pump and motor shafts

Damage te pump matr and ouping!

Always check the coupling after the pump hes been tale ad connected to

‘hepirine

Aso heckte coupling of pump st supied with ump and motor mounted

nthesame basen

>

RH 270800

xseb,

Siuliaton a ste

‘Cec the ouping signa with da gauge

q i ti

"ig checking the spacerype caupng with dal gauge

1. ork the instalation potion ofthe coupling by dating marks (balnce

“Snaion

2. emove the counting pce.

fo

\Whie the pus coupling dngoge also check the dveaon of tation

(CSecon3a age 0)

5. Ghd the ana ofthe coupling hale witha dal gouge Gee drawing

eck the spacer ype cup wt dl grey

“hermanimum aisle orto the couping ae a a rm

“hemaxinum ads ada devton mea ove the complete

unfree, els 02

hesing the coupling lgnent with axa tot

caupkag lignan may a be cece with ater oo Ober the

‘dcurenaton proved by the manufocore the mcruring tment

5: Aligning the pump and motor

_Atorhaing ised he pup sta conte the piping check he couphing

Signet an equ Yeah the pup tthe ik,

‘ny ferencesin shat ents eight betwee he pop andthe motor ae

‘Competed by means of tne

He

Fi. team set thin

(1 Sim - 1

7 Te coupling gr andi oto a

1. hc thecuping signet

2. Len he ego en bas the meta

3 esi underneath the moter fet wt the ferenceln shat ceine

4: tighten the heragen ead bol,

5 Check oper tnctoning of coping

‘Gk that eupinghtcan easy be ate by and.

not

RH

xsab,) Stslaton tt

‘Unprotected rotating coving

iskot njury by eating sats

© Aways operate the pm st with 3 coupling usr

Ifthe cstome specie requests ot nie 9 ouping gud Kes

‘elven then the operator mor pene

= Dbsere al evant regulations for slecting a counting gu

6 Fitthe coupling guard ard ootoar any

7. chuck the tance between coupling and coupling gsr

“he coupling guard mnt not tou the coupng

isk ition by onl pars

phon zara

choos coupling guard moter that nonspaking inthe event of

58 ec connection

ctl connection wrk by ungualifed pesonnel

Rik of fatal ry de told

© Aways hve the elec comeaians tale by tan and uaied

ftecttean

Ober egutins IK 0864 ad, fo exsexionproot made, EN Ge,

Wcoret connection tthe mins

‘Damage othe mais eter, shart dct!

+ here he eh peieatins ofthe loc nergy sp companies,

1. Gc he valle mains oage gat the data onthe motor name plate

2. Sect an sppropate starting method

ssn

0

Damage tothe pump tt

© Connect the PE condor to the earthing terminal roid

Recta cheng

ploion hand!

«Pride fo potential equation betwen the pump et an foundation.

xsab,) Sitaon she

S582connecng the motor

Incemplanc with IE 640348, nee phase motor ae aby wired for clokwise

rotaon toting atthe mote shat

Thepump’s dredion of tations ndcted by an row onthe pap

1. ath the motors edtan ef eation otha of he pump

2. Observe the manuacuer’ product este supped withthe motor.

5.9 checking the direction of rotation

Tamperatue meee resting rom conte between rotting and sttonory

Eplsion haar

Damage tothe pump set!

ever check the divecton of rotation by tring up te anf pump st

+ Sarthe pup rom the ota to ec he den of rion

ands inside the pur csing|

kf nue, damage tthe punt

dina connect the pump om the power spl and cue against

eitetianal stat up before inserting your hander eter objets ts the

Ris] |orateinoton tm thay penn

Danette pot

*saparate the pup tom the motor occ the deton of rotation

van PN ri wan cn rotten

ha] [Sons

to mndnig deo orton one pine.

hack th drt of eation. required chet the elect conection and

“te thediacton of ton,

{he caret rection of ation of motor ond pur sin dace Seton Geen

tom te motor nh

1. Sarthe pump se and tap it again ined to etermin the stor’

2 Cc he deston foto,

“Themoto' det felon must match the som nating theron

‘rotation onthe pump.

3. the dren of rotation since, heck th connection of the motor and

fesertehgeo any

soot e0 rw

xssb,) conmisonngStar-u/Shtdewn

6 Commissioning/Start-up/shutdown

641 Commissoning/tartp

6.1.1 Frerequiter for commisiningltarop

foe commisioninghitaing pte pump st, make sue that the allowing

+ The punpsethat been mechanic connected es spt

thos ben propel cnc t the power spy ad equ

Ppoteion dees (2 Secon 8 Page 39)

“ve pump hasbaen pine with tefl tobe handed, The pump hes been

ted > ssn oh age 35

+ Tyedveaion of rotation hat been checked. (2 Section 5, Poe 0)

‘Malin connections required ar conneted and opertional,

+ Te beans have been decd

‘ter prolnged shutdown ofthe pump (the ates requires fr eturing

‘he equipment toserce have been caved out > Secon Page)

Filing the constant ovel ler wth eating (lath scat brings on)

~ Tre conan level leis sewed into the up tpg hale of the eoting|

io

cantante le i provided on the ber

teadn the mddleo he level og

mute quay abating inh ese of te onsale oer

fas Damage othe berg

* Raga hac he ol

» aye ithe ol reer completely,

aap the ol reser propel ila tal ines

rH arots0

xseb,) omitrngtistudonn

Fig 1 Bearing bracket wth constant ler

1 [Constoncieweioier [2 Neng —

3 Comecton lbow ofthe cnsiont —¢ Sew pag

[2 pewter" SPP" a)

[5 faening bracst | oi tsigntgis |

hs temove he potecive ape

2. Unscrew the vent pl

3. ing do the ese ofthe conta av ole (9) or the being

Iwotet 6) an held tinh poston

4 Tain ai rh he hoe fo the wert pag nti he ol eahes he conection

‘how of tessa eel er

‘5. Completely fi th tees he ontant ee oe)

{6 snap the constant el oer) bakin operating poston,

1 sae the vent plug 0 back,

1 Tethe protectvecaoe

5. After appronatlys minutes, chek theo level the ater of the

erstanvl ler (h

‘hol sore must be propelled al nest roe constant ot

Sb Rept steps T= 8 neces

10,Jo hac the funtion of he constant ee er sly dain some ola he

re pl (ol a bubs canbe seen inthe revo

‘A exces ih lec ld ta terpertre it and to leakage of the

‘ishonded or

not RH

xsab,) {ConmisionngStarp/Shtdown

i ls

‘anrecing the mist ition stm (fr ili bitin ony)

ae eon 10 S88 ona

—— fy eS]

Ge

‘wal

i

8s

Fla. 1 oti bration

“Away observe the nrc of he hsctng yptem manufac

(peiatvon dosing no ua

1 famove plug 91682.

2. connec the tne ofthe lis urication stem.

5. Femove dan pig 916.46

4 Comect the dann turing the ol back into theo it stem)

5 srewin pug 9168

a

613 Sats

Shaft sel ae ited porto deliv

‘ls the src on dsmatng (Seton 7.46, Page 1 or aiseby

Scan 983 age 38)

Reservoir of nan 1 spplcabl fi the ere of nar prescient hi in cordance with

‘pressurised enteral ld. the gosralarangemen cng

Double mechanical sl Pre testing up the pump, poly baer restr os psd in the gene

ronan crowing

xterm tld feedApaly he quis a

rangement rang.

rss specie in he data sheet athe genra

"Mae sure that the bare fad r quench iu ae compat wth he Hid

adie

RH note

xsab, conminioingstetown

sk of potently explosive a

phere inside the ump

[Spleion hat

"The pump ness in contact th the fi tae handed ndng the sea

‘amber aio tens tbe fie hte fs tobe hed ot ot

times

» Pode fico inet presi

"Movie an appro monitoring ster.

‘Sal seal fare oused by nsuticent abaton

ote oie fi cod apa

Darage tothe pnp!

* ere string up te par at enh pp ad scion iene

1. Yenthe pump and svt lin nal prime oth with he di ta be andl

2. fly pen he shut-of element inthe ston ine.

3. fly penal asi comerins a hid sing iu et

1. femeve the upg gua ar is Footioad any,

2 Check the coupling alignment realign the opin

3. Check reper futioning of coup

‘heck tat coupon soy rotate by hand.

4, fete coupling guard and it footboard tay

5. check the tance teen coping and cuping guar

‘he ouping guard must no tout te coupling

Dene frming, agressive coling water

Damage tothe pnp!

Observe the cooking water ui.

‘Ober the allowing qual data ofthe colng water

+ Not depst-forming

+ notagorsive

+ re rom spend sald

+ Hedneson erage Sa (1 mot

+ Canioned an neta with regard to mechanical coroson

+ in temperature 030°

let eget ae nes

617 coating ofthe pum

The ang cover, the eating ack the ang spar onthe aspen be

toate

Morea rw

xssb, ‘conminoingstvaptuonn

‘bso the folowing gusty dats ofthe coning water:

* Maximum permsibe cooling iu presi: ba

+ Naximm permis coating au ts pres: 15 ba

+ Observe the spect coking ld quant.

{1.5 oolng ofthe sata

Damage tthe shat saliamp!

= esata quant of oling quid ae table.

| Q ==

-thevporsation presi ve depending onthe fd handed the em

Prete andthe steal of te sa seal fh ate).

EN Voporiaation presse of id handled higher than atmosphere pressure

o

Table 2: Coting gil quantios

| Fi erperatire | Gooting quid quantities |

ea ES cea eee

(csr cover } — 7

coring bracket amas NOSIS |

if Da |

(Support on basepiate | 2250 a2

1 Cooling ofthe heat exernger

For mhancl ses wit product elation ober th fllowing othe est

G9 Heating

Enledon heer

ko bur

» chsre the permis temperate das (2 Section 292, age 18)

union thie Bering ey 9 8 ot ces om 250°

3) ater cot Ganon estos

RH asof00

xse 6, 6 connionng aps

ie or warming up the pump to shore

* heck that the pumps sient warmed yp ought

‘The eing cover ont hested vith hot water rtm Obseve the alawng dats

ford heating esi

+ Naiman permssbe temperate = 150°C

+ Naximum prmissbiepresure p= 10 bat

===

ts

othe ppl

"rove suientqunte of atl heating medion

£..:0seng apes wa te amo Ged

EN fe -

‘Baage othe pump!

= Por to pup start-up, heat yp the pump a devcrbed nthe mana

‘bse the following when eating yp the pump Gt an keting it wan

+ Hake sre thatthe temperature rinsed continuo

+ ax heating speed 10 Chin (10K)

id temperatures above, Wher the ump ius or ang this at tmpeatres stove 150" make se

350°C tht We pump hasbeen ested Uoughout bear ring

“Tempertredifrence The temperate ference een the pumps site and heft handed mst

not exe! 00 TOD) whon hep Stored os

‘NonO

©

Ferraton of potently explosive atmospheres the pump

[Splion azaat

ig tale a mest pvt nig of

‘pump (e.. fill level monitoring). "

aeort0

PH

xsab,

Scommisioning/Staruprshutdwn

‘Opa outside the permisible bent temperature

‘amape tothe amp Get!

= Observe the pee nits fr permis ambien temperatures.

‘Observe the followin parameters and values ring operation:

Table Permian tempertures

a

‘a | ae |

[ein See dataset a

622%rqsang fats

xc siface teat of the motor

plesion za

Danageto the mat

© neat of eposon proof motors observe the frequen of tart specie in

‘hemonifecure's produc Herre

‘he fever of satis uly determined bythe mannan emperor cease

‘fthemotr Tis orgy depend onthe power reserves a the motrin tag

Sategperaton and onthe starting condone (BOL war deta maments fe,

‘1. Ft starts ar evenly spoced oer he pari inated, he ong nits

Servos entation erst up wth he charges gte vale sgh ope

Tablets: Fequeney aso __

IMoterating oxi requaney of are

ecartng while motors sti runing dow

Dango the punp Get

+ Donot restart the pump set efore the pump rte has come to

6623 ld hated

623.1 Row

nls pete othe in the carci curves or inthe dat het the

‘otowing spies

Se characteristic cues

10) Frome wih 29}4DALU AEX upon Desa High ane emp pind ca

Petree pen

19 Mot pean ate

Pe ssoten

xseb. 6 cnmisionngstarp/sutdon

auto240,!

‘he cata eer to water and watered Longer opeating rods with these

{strands the wr tendered il ot ove on aan increase in he

tempratres ante pum surface Hower the sal popes ofthe fs

Iaed dif tam tose of water, the cain formula below mst be wad

‘hed ion atienl het bp ma eat a dangerous temperature ness at

the pump sua necesoy, the minimum ow mst be ineased

10-2 gy

on

Tale key

Bz iescinon Unit

© Spetcheat apadty akg

[9 tatatont constant

[emperor )

T,__Tempeatre tthe sing sree x

[a ump eticenc at ty oi. i |

Ad Tempuratre ference 1

6252 ensiy of the ad aad

‘The rump input power changes in proportion tothe deny ofthe hi handed

Imps high dens of he ld Hanae

Benet exced the maximum permis sols content sedi inthe dat sheet

‘Whe he pump hanes dr conahing aban wbstanee ened wee ofthe

hye ytem aa shtesea oe tobe expects In ths case, rede te comeanly

‘commended rapection eae

63 shutdowystorage/preservation

{2.1 measres tobe thon fr shutdown

“The pum et ramsins insta

Safin tdi sop forthe operation check un ofthe pune.

1. for roland shutdoun periods tart up the pump et regan beeen |

Sree oot an once ery thee mans for prone fve mite

Inve we,

xseb, cooing ttaown

‘The pump (et) is vemoved fom the pipe and stored

The pump hasbeen propery ined (> Seton 73, age 48)

~ say uc o nating he pen heen hee

Seaton Page 5)

"rayon nmi af hep ing ann pay, he np

2 tet errant ore als meee

1ivaaaeto then doe te pump nomi: es, wth asic Sp

3: ir grease al exposed machined pats and suraces ofthe pump (ith

Scone lc reas fo aprove If eure to pote them seat

tere the ator isrctions on preservation. (2 Section 33, age 14)

he pun seo be stored temporary, ony reser he wetted components

‘nai of owl mates. Commoreay alate essence ed or

‘pomore Observe he mantarrersnucton for pplestriemar

64 netuming to service

Fer returning he equipment to sve aaa the sections on commisioninghtat-

‘par te operating mts. {2 ection 6, Page 3 Seton 2, Page 3)

Indo, cary ut al sevicmaintenance operation bere rearing the

ise Geto sere. Set Page)

Fale torent or reat protective devices

Feo nu from moving parts o xing ict

© soon the work completed, esa andre aevate ey stetyroevant

Sees ond protective deers

th pump has Ben out of sence for mare than ane yet, replace al elomer

ia

>

o

RH srote0

xseb,

TSeniingNsintennes

©

7 Servicing/Maintenance

74 Safety regulations

of outed pump sraces

‘peso harardby slerosatiduchorge!

© When leaning coated pump surfaces in aespheres of Explsion group

‘ie auate asta Cement

ps produced durin sein work

plein azar

"Observe he safety regulations in force atthe place of talon

* Aas perform maintenance wrk a an explson poo! pump ft oti of |

ote explve atmosphere

PO ©

Improper serviced pump set

‘poson hazard

pare amintananc ede with spec emphasis on icant shat sea

rbecuing

>

‘The eperator eres that maintenance inspection andntalation performed by

there ied spelt personnel who re thoroughly fra th the

irtntiona stat ofthe pump set

iat ny by moving components andshok caren

Caste thatthe pap setcanmot be tate ninety

> Alay ink se the eect connections are dcennstd before caring

tut eran the ump st

>

les hale, consomables and supplies which ae hot andor pose health

Observe al rleven lv

+ Deconainate pum which hand de psig a hea haz

oH

xsab,

TSenidnynsintenanes

>

Tne sai

Fiskot causing hands apa fet

™ Ding asentydunaing secre the pa Ge paso prevent

i

Arey ieee wl paid epre eas a coin o

Innimor of erngmsinteancsependtre ad wore

‘A maintenance work, service work nd italaon wor canbe ced out by KB

Senice or eshorsed workshop For contact deta plems teer fo the enclosed

aes" boolet ov wns icbeomonant othe mere

©

Neve ue fore wen dann and vessel he pomp et

172 erviingnspection

12.Supaniion of operation

set potently exposive tnosphereinie the pum

Depion hazard

The pup internals in contac withthe fad o be had inutng the sea

‘hamba nd susan sytem mat heed wath had beh at

rove sufient et pressure

ove a appropiate montrng ster.

PO

‘acuietonperatire a ae eninge rnin at detective bing

Piplaionhazarat

‘arape othe pump sett

ik fbr

fag dec he cant eve

teguy check healing element bering for rnsing nis,

bo

)

comet seed shaft cet

olson heer

Hot tnt hd exapingt

Darige tthe pump set!

agua sevice the sf

ew aoteo

xsab,

7 Senengnsintnance

PbO

nce sevice bar fd syst

{Splaion hard)

otandor on ie exaping!

"Raglan the bare syste

Monitor theta fd pre

g

nceeed wer de ody rng

Damage ta the pump et

ever operate the pump se without gid fl

eves the shutoff lament inthe ston ne nae supe in dna

mpemisy high temperate offhand

Damage othe parol

= Prolonged operation aga closed shutoff lemet snot permed

Iheseng ape e hsd

* Obserethetmpeatr int the dat het ad inthe seton on

‘porating i (Secon €2, age 2)

aot

hie tne parp isin operation, etre and check he folowing

+The pump must un uta ref vibrant ll tine.

+ neato olin, nae theo eve correc.

+ check te shat el

+ Check the state seating elements for eakge

+ Check heroling ment beaings or ruming nie.

‘pnating conditions inate wea Seca ag ern

+ Monier the eect fuetining fay ously connections.

+ eating stem

‘ace the pp ou of eve

Seem

+ Meir he andy pun.

emote that andy pups ree fer opration sr tem pone 8

+ Kee he tana by pump war

(iserve the faloning ands to make sre stan by pupae aperationl

Sate: wate

~ Alcon pins rein operation,

~The permis orl forces nd moment ae not exceed

east once year to thoreughl dean he cooling

‘Te berng tenpratre mus not exceed 80° (eseredon the oui ofthe

rng bracket

RH

xsa b,

kes

‘Opeuton aus the permisbe bering temperate

©The bearing temperature ofthe ump (trust neve xen 90 (ese

the ute the boeing bee.

>O

sve temperetues used by ft, impact or Won! ate

22:2Inspecton work

pesion hazbea

Frehaza

Damage othe emp set!

equal check he coupling guar, lsc components and othe guards of

‘salting prs for detomatonandaufcan lance ats tating par

| .

&)

‘tat choraing de to lmtient potential equation

plion hazard

‘onde

9 the canneton between pump and bselt select

ces beeen inp

“Sutionskde aig wer ing

72.2.1 Checking the euping

hac the tle sleent of the coupling Replace the relevant petin due inet

{herets any san of wear ad chek the agen

172.2..cheking the deaences

For cei the ceoances gps remove inl 230 requred

(2 sean ae

Five dearnce sage than perited (ae the following tbl) replace ai

‘wearing $02013902 anor mpl wearing SosaNeanae,

‘he earances gen fet the dameter

es ct

in [ie

50 | 060

950 | 060

Diane denance

a0 oe

350 | 089

ast | an |

ae an |

ae | 0 |

[oe |

[oe [am

xsab,) 1 Senki steance

suc ste ng wearing |

ie | bm! dere

dlometer | assole

Diharge le cing wearing)

Dimer eran

‘sword | Worn

is Nominal [in Ma i,

soao | 10 | 0f0 | 070 060

om

{000 fo;

[aa

[sea

xsab, 1 sengeinnane

7225 Cleaning fee

‘sfc inlet pressure due wo dogged ter i the ston ne

nis Darage tothe pump

" Mantr contamination a fier with utable eens 5 ditfrentalpresore

moe

7.2.3 tulbicaton and abet eange of ling lean bongs

xcs temperatures as 9 result of benings running hat or dtetv eaing

pion asad

Aegulaty hack the oti of he aca,

bo

723401 bation

Therling lent bearings are aay bate With inet

72.314 mene

Tae 1 ol change nerve

[Temper ashe) Fstlihonge [Ainge

rng hanger

‘eto 70'C | After 300 operating hours [tery 540 operating hours

70*C- 60°C | Ae 30 operating hous [ve 4200 operating hous

20°C | Ate 20 operating hours [ey 200 operating hs

7231201 qty

inqusiy Tobe mov avelyy -

[Dasa 2 | “Gare

nr ae

oss eet

cose | Fish pinto a8

ozo sae | | "eoatany 4

| Solidi pot | ABE

‘pour ein)

‘option, Wah than |

| | | settnanie—| parma being

| | “apenas |

15] Forombntwnpuatues bow 10°Cuse a ieee sutabe ype ot biting ona 3B.

a aroteo

xsab,) 2 seinen

72.313 01 ony

{ eating bracket ‘iT quonty being bracket |

" a ae

— ——| =

[a — =

12.314 hanging the ot

Lubin posing «healt zal andor ho bias

ozo pes ed the envionment!

* wen esining the brant take appropiate measures to protec peron nd

‘Ne enaronment

© ar safey doting and a protective mak i eed.

Caleta pore of any bia.

= aon allege regulations on

4

1. Hace the container undemeath the ce pg.

2. nd sew pag) t baring bracket (9) an dain he

2. Once being bracket) has eh dane reser andthe re pl

@.

4 fet i

aaote0 a

xsa 6.) senators

73 Drainage/ceaning

{his and consimables a supe ih are aor pos helt

ane to person nthe environment

callet and propery poe of hing i and any ses.

Wea sfety doting and a protective mask rele

+ Observe algal requlatinson the disposal offs posing a ath hazard

fhe pump set has handed fa wore rds cold ed to caren damage in

the sence af atmosparc hum oul igte won cat ith gery he

‘ump set mst be netaed and arouse gos mtb lo ough he

pump one dg,

‘se annection 6 to dan the fi handed (ie ring of may cnet)

746Dismantting the pump set

1.4.1 Gane infoomation/Safety eglaons

A Unga personnel pertarming work on he pom et)

Race ry

© Awayshove ep ork and meintenance wrk palo by spall sine

{uae pessoal

A zs

sot,

+ low the pump sto cooldown to abit temperate

|

|

Inpapeidngnovng of heavy assembles or components

Pesaran and damage to property

» the stable tarpon devices iting equpment aniting tackle to move

avy asec componet

‘Oban the gene safety instucons and information (2 Seton 7 Page 4)

Fo aty work on the moto, berth rutin ofthe relevant motor

For dnaring nd reamenblyrter tthe gral sel roving.

(Secon 1.Pae 6).

Inthe event of damage you can avays contact eur sevice departments

RH ssot00

xsab,) 2 Sekine

esufent prepration of work on the pun Gt),

shot

"Propet down the pup set (© Seton 6.1.13 Page 38)

"Coe the shut of elementsin te suction ine and dchge tn,

"Oran the pup ad lez the pure ese, ( Seton 73, Page 48)

» Shut oft ny alin fed es

= Aa the pump st 10 cool downto ambient enpratire,

‘Aa Preparing the pump et

1. nterup the power supply and ser the pup aginst unitetonl artap.

2. biconec and remove al uso pipework

5. heave the coupling se

14 emovethe outing ser, 2

5. Drain he flo uric being.

7A3Removing the mar

Demons

suspen or support he moter to ravent i rom ting

1. Dianne the motor Hon the power upp

2. bat the motor rom the tpt,

5. shite the motor to separate rom

2.4 Ramoving the bck pl ut nit

7 Ae pump ses without spacer-type coupling the motor ae hen removed

cpu out uni ting

sk ching hands ad ett

© Suspend or support the beorng bracket tthe pump end

1 requ suspend er suppor bearing bracket 30 o prevent fer ping

2. temave heagor nut 92001 volte ain 102

3. Ue forcing ce 90.20% pl the bck ult unit tof voit casing 12

4: temove and dspos of jl ing 11.10.

5. Mace the ac lot ani on lean and ave ice,

snotan RH

ksab,. Seng strance

1ASRemoving the impel

745: Looerng the pst —for ening rakes B2 to 0S

“The noes andstepstated in (2 Secon 714, Page) to

(C'seton 744, Page st) have been obeeredated ou,

The back plaut nth bee plc ethan eel sty aes

1. Unico impilar t 92.01 vith reed ier ight hand trod),

For vrsins with aul impeer Ursrew ay rp 252 th te

threadedinsrt (ighthand tess) _

2.42 Losening the impller—for beating brackets and 867

“Th notes and steps stated n (2 Scion 7A, Page)

(@ sean 74 Pag a) have ben oberveiaeto

The back pl out unit hasbeen placed na eth and eve ater ae0

1, sre and remove impeller hu ap 260 gitar thea)

‘er verans wth ally ine: Use an remove rg us ap

2600 gna ead)

2 temowe and diposeof nti 1131,

or ests th usta Impater Remove and pose fol ring A158

2. end open lock water 931.2

{. emove inp sen 996 lth ad wae 931.02 a i 5508,

eeversins with aul ipl: Pl ry per 23° te shat

‘Remove ey 34003 ramshah 20. Ramave and Sapo of iting #1123

7.453 Removing he impala —fr al boring brakes

Teles andstep (0 Seton 7.1, Page 8) stated nto

(seclen'nas age 5) have been soured ou

2 Pace impllar 230093 eon ad vel aac

2 move aye 4001 from shaft 21,

4 oti sh 42.0 ted nd gra crews 99838

5. tamove hating bu 20, ian

1.46 tmoung the cies

“The notes and tps stated in 2 Seaton 7.1, Page 4) 10

(P'seaion 453: Pape 51) hovebeenobsvedaed ot

The bce pullout unt kept a dea ad vee ars

1 Casebng sate oe oe Shogo ls for tng te

ngge ust js ay, inthe groove of sat protecting sleeve 52401

nde ghten the hogan haa bate

4 se for sees 801.1 to emve eating bracket 330,

[rth same tay pul shaft rtecing leew 24.01 Gt ay) th complete

Caridge soo 3 of hat 0.

5. ake care not to damage Ons 412013, ay.

{6 Unde hexagon nut 920.02 and remove el comer 47.1 andlor he se

cenage

‘bse the sel intaitin drawing of he mechanic

PH stofe0

xsab,)

7 Senidog Maintenance

7A Diamanting the beaings

~The noes andes sated in (2 Secten 7.4.1, Page 49) to

(C'S 746, Pages have been observed ou

The beating Wace hasbeen placed dean ad eve assembly

1. Un the heragn seket hed eaten the coupling ha,

2. Put tne coupting hal of he pum 2 with ue

3. fmove key 940.02.

4 Remove fan hood on hl 5.2 or fan wheel 891.02

5 Undo hexagon nt 320.02 and remove cover 471.0 anor he eh

cme

6 Undo grb soem 04.4142 and remove throes 507.0.

7. dada eragon sok ead cap srs 94401 and remo pumped esting

{bier 30 seating 40004

1. no heagon head Hot 9037 and remove motorend besing over 3602

‘ual 3 ng 41222 reed.

8 Carafe shat 210 eget th angular contact bl earng 320.02 and

‘henner ing of rr eller bering 3201, nung a awe 080

{ny ot of te beringbrackt toad hed od

10.Removeeindril raler beating 32201 Galler cage) rom bering bracket 230

"il throner 0601 i ited, eve rb 761 90420 ond pulthe tone!

these

12. ten open lock washer 931.01 behind ote round nt 82021 on shaft 210.

1. Ure sted round nt 920.21 gh hand ted and remove lock washer

[Ste

otras due to heating of components fr esembimanting

ak at brat

Wear heat oat potetie plows

= emave fommoble substance from he danger zo,

A

|, fee ara

"eat wp angular contac bal bering 32002 andthe ne ing Finda

‘iter bearing 32201 080" and ul hem sate 3,

75 Reassembling the pump:

175.1 General iformation/safty regulations

‘prope ifting/noving of haw ase or components

Perrin and dage to prope!

* Ue stale raniport eves, ting equipment and iting take to mone

ene onemiier or component

fas

| __ —_aeeeaEnte|

Inpreper resin

Damage tothe pump!

* feasemble the pump (lin cordance wth he general ule of sound

‘ainering pice

+ te gal pare pats oy

sot

xssb,) 2 Seringntitnance

Sequence Awa rnb the np acorn wth te ceponing teal ase

Sealing laments» Gk

~ Alay se ne gaskets making sre that hey ave the same hikes at

~ Always gaskets of asbestos ree materi graphite without wing

icin (copper arene graphite paste

~ Never se Oingsthat have been made by cating an ng cord ose and

‘Sing the end tote

nat of ng with graphite sina mati

Fiicould escape!

* Do not coat ing with graphite sir mati

+ se animal fats runt based sean a PTFE

= For gia oid the ne of ese adhsis posible

~ Hasembiy aden areca te cereale cnt,

sheave "

~ Only apply ares at selected points and in hina,

~ Never se aicksetng adhesives anon hee.

~ Goat the ating surfaces often! components and steed

‘onnachon with grape sil bore eae.

Por reaseriycrew bck ay forcing ses and duting te,

Tightening torques Fer asembly,ghten allscrews and ol ede inthis manus,

1782 ting the borings

To individu pats have been placed in clean an level seb ares

~ Aldsmamie pans hve been dean ad hacked fr wea,

fay damaged or werpatshave ben rplced by rg spre parts

The seating faces have bon ceed

otrfaces duet heating of component for seemblydienanting

ako bur

Wear heat retant protective gles

*temove Rana substances rm the danger ze

"Heat up angular contact ball bering 320.02 andthe ine ng of india

taller bearing 32201 im anol att er by meas cf amino eater

‘oproximotey 80°C

2 Side angular cnt ba easing 320.02 ota shaft 2103 far asia go

2. iether ing of fn ore 32201 osha 21a ast

igo

4 tor bearing radkts an B05 ake sre that 550i psned ceri

Ru saotao

xsab, 2 seiingtinnance

‘Anuar contact bal bering stb installed in bck o-back arrangement

ht tat a ving nae pss ma ty ee ome

5 a9 Camara en te ond 39021 igh hand vend without

6 Let anguar contact bal beating 32001 col downto approximately 5% above

Srbent emerstre

1 tighten sete round ot 92021, then acres

py afer po faite Mica og Mate) othe conta eof

10 Tighten ote ound mat 20.24,

1. tend bk waser 91.0

12. roves ol tower SUD eno shaft 210.

13.5 grub sr 80420 ol owe SOR

14. Guide cinder bearing 32201 (alr cage nt bearing brake 20.

'5.Crfilly inset shaft 210 ageter wth ang contac bal eating 220.02 and

‘hetane ring fend llr beating 3220, eaing rower SOR

on it bering bracket 320 towards the pup em

16. ser Oring 41222 nto the ron of motorend esting cove 36002

17. art motar-end bearing over 360.02 with ing 122 to bring bach

"Bottom the motor end

10. srew hexagon hed ols 901.27 with eakng over 360.02 int eaing

inecet 0 nom temotar on.

19.1 puma bering cover 350.01 th jo ing 400.0%.

2. id rower 07.01 eta shat 20 fo he pumped Ieeing 2mm ge

een he tomer and pnp end beng cut 3600

22 sre grub screw 90841 to pnp ed rar 5070,

22 Sie thrower 507.02 ont shaft 210 fom the motor en, evng 92mm G60

‘een the tener an motor andbeaing coe 30.2

2 sre grub sew 90421 nto motored ror 50702.

25m fan hod 82 fan hb 85.02 and an imple 83.07, any

25 rom the motor end ret ey 940.02 it the Kyi a the shalt nd

2. ral the coupling half onto the sf

28 sow the hexagon socket heed ep sew nt the coupling hub

state RH

xsab, 2 Sangean

75.3itg the shalt el

75.31 staling he carvidge sat

‘Aas ober the following point when staling the caries:

+ Intl the caries show nthe el installaton drown

* Work clesny and aerate

+ event any damage othe seal faces or Ong

Thenoesandstepsstatedin (2 Scan 75.1 Page 2) to

(©'sertn 782, Page 33) have been sbvred a said out

‘tse cover 471 an the cate sel a ghton hexagon hen ts 2002.

Side casng cove 16 wth atid e423 ont shaft 210 ram he pap

raul de compete re assed bering bracket 320 onto sts 982.15,

‘is have Den sree nt cing cover 6

‘Oncol versions, wateh Oring 412.0121 at cas corer 16

See casing cover 16 to compete bearing athe 330 with heagon ts

sts

7.5.4 th pele

1754. ting the peer — foal beating bact ies

~The notes andstepsstatedin 2 ection 75, Page 52) to

(section 78.3.1, Page55) hae teen ouarved sd cared at

The back pleut nina plced in ean and ee! assembly aes.

~The presembly (motor sat bering bracket, ing core ha been lon

hon a eve sey ares

Aldsmante parts hoe been dane and checked for weet.

ay damage or worn pars have ben placed by rg

Tre sealing sutaes ave bee eset

* tape setting bth $4202 ent impel 230,

2, Sen rub stews 90438 trotting bush 54202.

2 Site joining 415.2, any nto shot 210

4 lace ey 940.1 nt the eyo shaft 210

7.542 stoning he impr — for bearing aa B82 0 BOS

‘The notes and sepssatedin (2 Secon 75.1, Page 52 to

(Seton 734, Page 35) have buen abr carted ou

The sealing urtaces have been deaed

1. rer neon ng 41.31 appa

3. rer newt ng 4816 apes

4. Sew inpeter ns 522.01 with vend inter ight hand teed) on satt

For versions with aul inet: cow stay npr 2-2 with heeded

ict ight hard eal one st 21, Oba th igen ards

(CSedion 7.6%, Page 3

5. tnd ve the ads

ee

RH ssotn0

xsab,) 2 Senkioghstenance

7.5.43 Fstesng the impale —for beating brackets 86a 7

‘Te notesand sep stated in ( Seton 75.1, Page 2) to

(@ Setion 75, Page) have ben sere cared out

tha sealng surtacas ave been ceed

Oni fr verstans with won inp: irr eye 94003 int shat 210 set

tne tring 131 to peer 210 Gade say peer 232 one

2. sr ds 55087 ad ok wate 931.0

5. sre impr aw 96 nto shalt 210

4 Obzovethetghteing targus (2 Scion 26, Page 57)

‘bond back ack ther 81.02

1 rsrta nee jit ing 41.3 it impaer 20,

‘or vera witha poe: Pleo re lt ing 41.59. una

Impaler 282, Scew inpelr habeap 268.1 ont ashy pel 23:2

2. sri hu cap 20 into pele 230 igh hand 099)

2.5.nstlng he back plot it

cpu out uniting

ser eushing hand and fet

Suspend or upper he bstng Eracet the pimped

‘The nees and eps stated in ( Sectian 75.1, Page 2) wo

(CSc 5, Pages have bon teed scared out

kay damaged or worn arts have bee placed by oan pep

The setng sures ate been desed

~ Forbnd plot its thou coup, te aping cordance vith he

‘nutter acon

+ Freqred suspend or upp the back pull out nit to prevent fen ting.

‘nde nto volte caning 108 wn ew gacet 1890.

2 tighten nt 520.01 at wate sng 12, Observe the tightening tres

(Sein 18, Pages)

1756 touting themator

NOTE

1. Sf he moter to connect tthe pp athe coun,

2 Ften the motor tothe beat

4 Goethe otro the power spy fete manuacurers prod

Seaton RH

ksab, sang natnane

76 Tightening torques

78.1 Tghening targus forthe pump

se torque wrench tighten the srewed connections (80201920. between the

vette ong athe sng eve

rues for dtederewed conmecont

"| A193 Grade 87/ “A183Graden7/) 109 | = | AR76 Type 316 THT |

panes cs

[ sua ‘stud 902.15 [Hexagon head | “mpelior rut 922.01

| [on aie | Sie

i | ie Fe

: q ee |

i} u Th Re

ns 25-190 | 12/6 aves | 80 |

He ae

ia a0

font (16 aie

\aozei 16 |)

fom po im

‘w03 |

| —|

a | fame) a8 [Mio | 120"

wie a+ [oars | Ow

jie) war antes] 10"

vase we) es

a 1 js 59)

| |

6 os 0"

mie 121 cts | 350%

pers

1B Aer ropere ghey the tes sn ing fo ova salle recy 151030

19 Suawbst tsar eater aes st 2

19 Wester on’ cde 7018

RH sroteo

xsab,) 2 Seinghatnne

(erat [A793 Grade [a Gade 77] Yaa "| Aare ste |

Usinond | 8167 me “rye 20

‘rmeres)_| AA Grade m4 i

Motwial | 17Tea/ie7A | sear

europey_|_onde3X)

Sto aR215 Hapa ea) Sod 9E22 | ipa at 9201

AT |

i

‘mi

Taking

wey ao

fia 7 |waads| com

88) 1 son 60%

1/7/65} 6004

snofea rw

ss

RH

xseb,) sehen

762 ghtening torques for the hat a

fe

920.21

Fig 18 Ste rt poston

Table 2: Shaft mt ttening totes

727 Spare pars stock

724 o1doing spre parts

Alay gute the llowing data when oxdesng replacment or spare pats

+ Tipe series

+ She

+ Metal variant

+ Year of construction

eter tothe mame pt fora dats.

‘Ala pct te flowing dat:

* Pai mumbe and descotion (© Sedan 9.1, age 66)

+ Quantiy of pare pts

+ Shpving adress

* Moe of aspaten erg mal expres ghar tegh)

By tsonn de tence ction

26) tholtahenng aut

oot eH

nerf ening.

xs.) 2s

‘T2aRecommended spare pas tock fr? year operation to DM 24286

‘Table 22: Gunny of spare part frrcoaneed pare pt tock

Jronio. [dessin

amber pnp Ug dy usd

[Aus inpate ——|

[2002 angular contact bl bang

ist

ating

sing ck

som cin |

Seaing emer |

‘a IMecaneaseo comple 1

= tr

stot

{TSenidngnsintenance

xsab,)

1.7.3Inerchangebity of pnp componente

Components featuring the same nomen clin ar intrchngeste

iy of pup components

ABE

ms]

faa

(esuipton

50450 | 29 23

“ole 2: terchangeab

f

RH

ote

xsab,) Senki steance

scion

iMedia sak

acing wea ng, scion se

7202) aing wen rng. decnge SE

nies pacer

xl fet | cag coves umole

oes

feloe[seaon|_fnpenernae

=

+

< l 5070%] Hwa pomp ed

aa

a Giotto

xsab,) alestetig

8 Trouble-shooting

goper work to remedy aus

stat injury

"For any work performed torneo ure the relevant information

‘denn this operating manual andor inthe protec Heatre prone by he

prt cra re not debe nthe following able, cman wth the

SB stoner sere brequte

Pn delves isi

Moti eens

ceive dicharge presse

Ines bearing temperature

‘xe leakage athe sat seal

Virations ding pump operation

Inpemisbe temperature ines nthe pun

Table 24: Trae shooting

fA] |C[D] | F [6H Ponibiecose ene aaa]

x)-|-]-)--1-[- Pump deers opin on exesively eat ody it. ]

eee

high esr {ec steno putes.

I fit ger mpi"

/-|-||= |=) -|- Simnine imps dogged tenove dea ind oo

a] |-]-]-]-)-|- [rman ficken te ina Aer iin vet.

1) |=]=]=)-/ XX Sito its tc ian Cea ie

(contenatanhes nso ital ups toneee |

Fiori da amet thesiion |

[Bane non ne he online|

‘Scgninesre ohh

[Becnyutebtedncin oping.

[Ghurvepomiti edt perk

Irate a [geet fl ct pp eel ir

‘inca rent br a

Irena

IN te _

‘Gre he earl oreo ft mater

‘athe cool tu

Wrong dct of

* Specs to ow.

+ pe ton ith egy ne | «hasan agatiouy he

+ Spat tht een {teqveny nvr te pare range,

npr

20am rear mtb lend ere tempi remedy np hae incl o ee

eT

St

Pump isk preset

speed isto hah

bra diving pump operation Creche scion conn.

{octet inte prchasconder,” ihe patent oveoaing, tun

oo sown impr.

Detect goat

Ges hing taunt

Ian re mpc.

| eae preire the pur scion nozzle

“he purpsrtisisliged. Reign

rump warped or spnpthete Check th ping connections and secure Fang

|i te ping lgpan iru, resice dances betwcch

i: _ : ton ater

rr seul Tn mre wee dre ico

Non-compliance with specie |e the dtanceaccardng vo th genera

‘eouningsstance [stangement raving, °

[> efetne being

= Motor runing on 2 phases ony. Replace the cetecive ae

store ftaance lean the impair,

[1 Flow atetootow

RH sof00

xsab,! 2 aed Docent

‘Related Documents

9.1 General assmbly drawings with tof components

9.1 ening brackets B02 to 805

|

i

ae ‘

| A ae!

f J

Fig. 18: Bearing brackets B02 to BOE, a) uncooled and) cooled

“able25 List of components, beara brackets B02 0 BIS

Liner

‘sina wer

ie (cing

on ng

casing war ig

2B) forcosed iano

ceotan RH

fart (eomoing [estion

‘erp Wexagon nt

a0 210 att

son) Sted ind nit —

ator tok war

poovier -

movin jeter wena —

sonsc.or (sub scew

fuauaae intrng

5BODSO" [ang conact bal bearing wih de 50 (ating wae)

{nda rer bearing

tearing bracket

om

f

| Bosna

|

‘a2

saat

se

sar

bioowm —aenovra2

eragonsokethead cap aew

(asin wooing

sououoe

‘soiovee™ ‘soxever

‘orev: sorovee

a

3) Faroetog waxes on sly

3) Fert aindo ron

erot%0

xsab,) hd Ds

‘Saedrond at

eter -

- impala - -

[eb sew

peg - |

a ister bp ———— —

foo gi etn wa -

fazat fae being =

iso anwing iste -

stew ae

- Bearing err — a

ST osing —|

ent aer SS

Cilentsighi gas -

hoa — Free —

berava7 Hnsagontaadba

rasa Hert - a

—— Scots

ery Hetgen Res apa 7

moire aon erg eer —

‘not eat

aor |Mexagon socket head cop screw

aoiiee — aaa csi weg -

boasiars lesen -

sexoue — smover Impetermearing -

i 7 a eb sr —|

Serovar sorover —|

90438 (sib screw ~ -

‘oa sag ie _

an a Koning -

Be forced py

33) fering of al it ony

33) Optom!

RH

Table 27 Design ovis

91.3esgn vrans

ese (tied view

eg ih cies E ee

ay G 2

[Design with thrower ci

i

If}

Or

RH

)—_snantonnee

(osign [aed view

Design wt lag

(Deg wh welded ria

|

‘nota

xseb, 101. oeratan of cntomiy

10 EU Declaration of Conformity

Manatee KH ta Kan

{5722 Pana (Germany)

“he manutaurer herewith dele that he

+ incon th he proons ofthe following Directives x amended om tne to tne

~ fap (et: Machinery Oeste 2006260

‘he manufaurer ao dearest:

+ the foaving harceived intentional standard have een opi:

= e109

INENI50 13709

Peso euthaised to cmp the tee fe

‘adres compar)

‘aes Sees No)

‘despot 2 code, cy county)

nota

xseb, cesta of bcotaninaton

11 Certificate of Decontamination

enti hr alae

rintie lot come roe

tt otanndaus yea

A A A A

eroticy Se end enter dt

We herent cere rou ire om harder hm, lg nade bane

Fermag ie pump hae roti plc con ing natin, ja beng a rt een

1 hetoening fey peas rerequted ar ang a dre

‘esoagtprntin

timation ate tect ar comple and that dpath elected acadanc wth he

ace date and gate ‘ess ‘company samp

mote0 RH

xseb, ne

Index

A

B

ac putout unit so

earng temperate

c

ortteat of decontamination 74

eaance 45

‘ommisening 31

ouping 20.45,

D

Design 1,19

Direction f rotation 30

hase 49

posal 15

E

‘Ordering spre peso

a3 44 45,47 "

F

hue ned emesis st

Fett of sppation 9

Fitee24,7

Dery a

Farce ard moments 25

Frequeng of stats38

4

Heating 36

Heating weed 36

Heating vp 35

1

Iter ype 17

istation on foundation 22

Instalation ast 24

Intercangeabtiy of pump components 6

K

Keoping warm 36

Key to safety sbolsinarhings 3

L

st of component 6,

1

entrance 4

Mechel 37

Mitring equipment 12

N

Note races

°

trusty?

‘operating its 38

Order mmber?

the appiable documents?

P

Paty completed machine 7

Preveration 1,41

Pring and venting 3

Produc devrition 16

Pam casing 17

R

Rewintosupsser ta

s

safey 9

Safety awareness 10

Seope of upp 19

PH

xsab,) nde

‘oa pat

Spocal sews 70

sarcn37

storage 4 41

T

Temperate itference 36

Tightening toraues 57

‘St

TWanspo 13

w

oranty ine?

ister colng 3438,

26000 eH

o

1964

PROCEDURE

———————

pocumeNT conTRoL |

CONTROLLED COPY ) .

+ Detunjue Kerio No]

PETUNJUK KERJA INSPEKSI lwct2 |

ROTATING EQUIPMENT issue 3

loste: 21-12-2016

age 1/6.

“MANUAL PETURIUK REA HUT |

aa

32

33

42

Tanggal

~~ aiiapian alan Disetujr ee

PURPOSE

‘To provde written instruction for rotating inspection certification and

recertification.

scope

This'procedure describes the requirements and techniques for rotating

Inspection and certification

‘RESPONSIBLITY.

Inspector: erly, Inspect, prepare report and certincate

Head of department/branch deputy/Manager Project: verify report and

cetiia

Head of S8U/branch : sign certineate

PRoceDunE

Inspector qualification

4+ Minimum Diploma Engineering;

+ Qualifed and certified Rotating Equipment Inspector Issued by

‘competency certification institute

Regulation, code, standard & specification

+ Decree of Directorate General of Ol and Gas No. 18 year 2018

+ Decree of Directorate General of EBTKE No. 387K/30/03E/2012

+ APL610, API 674, API 675, API 676, API 677

+ API 613, API617, APE 618, API 619

1+ ASME 831.1, ASME 8.31.3 ; ANSI 8.16.5

+ ASME V, ASME VII, ASME 1X

seer fant

[Petunjuk Kerja No:

PETUNIUK KERIA INSPEKST en

ROTATING EQUIPMENT wwe 3

wr lbnte: 21-12-2018

omgsctanes" | WANUAL PETUNIUK KERIA MUTU [Pons 2/6

+ APL670, APL 671, API 662, APT 68S

+ 180 10816, 150 13708, 180 2371, 1s0 4871

+ 15,10 19

+ Standar Nasional Indonesia (SMI)

4.3 Scope Of Work For Rotating Equipment Certification

4.3.1 Documen: Review

+ Quality System

Design Speciieation/Baste Design

+ Design Drawing and Calculation

+ Material Speciation

+ Walding, Botting & Connecting Spec.

+ Walding Procedure

+ Man Component Speciication

+ Ausliary and Safety Device Spec

+ Operation & Maintenance Manual

+ Test Procedure

+ Remaining Life Assessment (RLA)

4.3.2 Fabrication Inspection

+ Material Laentincaion

“+ Piping and Instrumentation verification

+ Leveling Check

+ Main Component Test

+ Balance Test

+ Algnment Test

+ Insirument and Electrical Functional Test

‘system Functional test incuded Urwer / Pnme Mover Test

+ Factory Acceptance test (for new equipment)

& PETUNJUK KERJA INSPEKSE—— |Wi-c'12

ongootesn’" | MANUAL PETUNIUK KERIA MUTU [Page : 3/6

Petunjuk Kerja No?

ROTATING EQUIPMENT issue : 2

loate.: 28-08-2018

433

434

44

44a

+ Acceptance criteria for testing referred to owner/manufacturer test

precedure

Fold Inspection

+ Kdenitcation of equipment and the components

Foundation inspection

Verification of measuring equipment

+ General inspection of installation including alignment

+ Mechanical, electrical and instrument test

+ Safety devices and Protection Equipment teat

+ Pre-commissioning

+ Performance Test (Commissioning)

‘Non Conformity Report (1f Available)

[NCR to be issued if during Inspection found parts not compliant with

standard/zode/specification, NCR to be followed up with corrective

action and closed out accordingly

Scope Of #ork For Rotating Equipment Recertification

Document Review

+ Manufacture Data Report

Inspection Procedure

+ Exiting SKPP

+ Brewing

+ Manual Book

+ Maintenance Record

+ Condition of Rotating Equipment & Driver

+ Condition of Foundation

= FPetunjuk Kerja Wo +

PETUNJUK KERJA INSPEKSE lwi.c-12 Z

ROTATING EQUIPMENT Issue : 3

m ee Date: 21-12-2018,

ssfiponesin " [MANUAL PETUNJUK KERIA MUTU [Page : 4/6 1

+ Condition of drain system,

+ Leveling Check

+ Leaking

Piping System

Instrument and Safety Device

+ lectrical (cable and junction box)

+ Incicators (Pressure, Temperature, Level and Flow).

443 MamePlate Veification

+ Rated pressure

+ Setiat Number

+ Speed

Power

Mane

+ mar

Hydrostatic test pressure

+ Rated Capacity

4.5 Reporting and Certification

‘Alter satisfactory completion of design review and site inspection, BK

vill prepare inspection report and certification to ellen. The report to

‘be submitted consist of:

45.1 Certitication

Registered certificate from government

Cortfiate of inspection

Executive summary

Conclusion & recommendation

lst nen.

$

"rhoonesin’” | MANUAL PETUNJUK KERJA MUTI

JPetunjuk Kerja No

PETUNJUK KERJA INSPEKST

ROTATING EQUIPMENT

482

483

7. Photoaraph

8. Log Book

9. Attachment

+ Data sheet

+ Design ealeulation

+ Drawing

+ Test report

+ mor

+ Be

Revertifeation

|. Registered certificate from government

Certificate of inspection

Executive summary

checklist

Conclusion & recommendation

Test Report

USE NCR,

Photograph

09 Book

10,Attachment

+ Data sheet

Design calculation

+ brawing

+ Maintenance Record

+ MD

+ ae

Related Document

+ Catatarharlan inspektur/Log book Inspektur;

PETUNJUK KERJA INSPEKST

ROTATING EQUIPMENT

‘nga | ~ MANUAL PETUNSUK KERIA HUTO

JPetunjuk Kerja No

\wr-c-12

' + Laporan ketldaksesuatan (NCR);

+ Sortittat inspeksi (FK.33.6.1)- Migas

+ Sertila inspeksi (FK.33.6.8) - BKI

+ Potunju KerlaInepeke Sertifikasi Kompresor (WI-C-12.1)

+ Potunjul Kerja Inspeksi Sertifikas ulang Kompresor

+ Petunjok Kerja Inspeksi Sertifikasi Pompa (WI-C-12,

+ Petunjuk Kerja Inspeksi Sertfias! ulang pompa (WI

(wi-c-12.2)

3)

12.4)

o

1964

CERTIFICATE PERSONIL

8d “a undo, Sueques GurT6i0 14a YO1e WW OUD;

mig)

srpnnsu siewp.00% ica Ye

nse: 2009 wn 102 soqwoNtos Oz 01 s9qUaIdOS 94 wo EurpUe u seb ofa

cue e409 37 ka py oadSu wound BuNeDe JO uEHEARIEND OH jeaKAzo| Banyo BU er

iva sey veSusp ‘e102 seqwitag oz ps -oquieices:

‘seiade3: ic? dojo ueresebGuoyesio Bush xing veieRied sT32GSu ISEHHeNY SLE] UeBNguNG LEseEaMued frmBvow [Bouse YET,

(ezeszeq) etseucpur tseytstseTy ozte Za

TueTsy [Tnzeztn nybuez

04 van

repedoy ueu9aia

¥01934SNI LNSWINOS ONLLYLOS

avLNd NVLVIvVaad YNLY3dSNI

sivoraiL3>

LvylalLyas

(wasn

svomvavovinisisnisconvruan aura vorenn QSOS

wo

1964

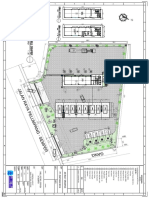

DRAWING

1964

PHOTOGRAPH

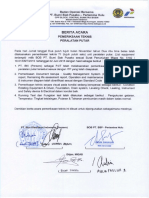

DAFTAR PERIKSA INSPEKSI PERALATAN PUTAR

Rolating Equipment Inspection

mo K.asiNAsy

lpocumentarion owner ‘ Petamina(Peer) apt Terminal Kovera Rays

Equipment < Pampa Petalio

TupfSeristNo, © Pompa.a7/49:P1707062.004

Loeaon Depat Terminal Ka Raya, an Lnksamana

aahayl in 31, Keg ay, Bande sh

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Draft Report RLA Pipeline PDFDocument47 pagesDraft Report RLA Pipeline PDFTengku Nizarul AslamiNo ratings yet

- DTP-201939-R001 Reva PDFDocument68 pagesDTP-201939-R001 Reva PDFTengku Nizarul AslamiNo ratings yet

- A1.01 Layout Spbu Shell SemperDocument1 pageA1.01 Layout Spbu Shell SemperTengku Nizarul Aslami100% (2)

- Bat Rotating Bob PT BSPDocument2 pagesBat Rotating Bob PT BSPTengku Nizarul Aslami100% (1)

- Laporan Level Tangki T 302Document12 pagesLaporan Level Tangki T 302Tengku Nizarul Aslami100% (1)

- 1776279Document82 pages1776279Tengku Nizarul AslamiNo ratings yet

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Tengku Nizarul AslamiNo ratings yet

- Pump Balancing Test Report001Document6 pagesPump Balancing Test Report001Tengku Nizarul Aslami100% (1)