Professional Documents

Culture Documents

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Uploaded by

brunizzaCopyright:

Available Formats

You might also like

- 8.2 (111 Marks) : MarkschemeDocument47 pages8.2 (111 Marks) : MarkschemeSemwezi Enock0% (1)

- Fabric Conveyor Belts Installation and Maintenance GuideDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guidejonodo89100% (2)

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Thermanit Mts-3 Gtaw enDocument1 pageThermanit Mts-3 Gtaw ensoft4gsmNo ratings yet

- Wire Thermanit CSiDocument1 pageWire Thermanit CSiviphemantNo ratings yet

- T - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFDocument1 pageT - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFnebojsa70No ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- Thermanit 13-04 Si (Boehler)Document1 pageThermanit 13-04 Si (Boehler)queno1No ratings yet

- Thermanit Chromo 9 V - SMAW PDFDocument1 pageThermanit Chromo 9 V - SMAW PDFsbktceNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Flux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelDocument14 pagesFlux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 Steelamit singhNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Flux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelDocument7 pagesFlux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelSachin SharmaNo ratings yet

- 3dprint AM P22: Material TypeDocument1 page3dprint AM P22: Material TypeKara WhiteNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Rod - Union I Crmo 910Document1 pageRod - Union I Crmo 910Rushita SolankiNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelLaboratorio CalidadNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Aisi 316L 1.4404Document2 pagesAisi 316L 1.4404Carlos Alberto Sutachán Cuevas CasNo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document3 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- B - Boehler FOX CM 9 KB - Se - en - 5Document1 pageB - Boehler FOX CM 9 KB - Se - en - 5misthahNo ratings yet

- P91 - Modified 9crmo: Alloy TypeDocument7 pagesP91 - Modified 9crmo: Alloy TypeHanLe DuyNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Sandvik Saf 31803 Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik Saf 31803 Tube and Pipe, Seamless: DatasheetPaul NeedhamNo ratings yet

- Datasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Document9 pagesDatasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Gonzalo AlarciaNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- D2 Spec Sheet V1 - 0Document1 pageD2 Spec Sheet V1 - 0NPD TEAM HosurNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelMarwan ShehataNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Sandvik WeldingDocument3 pagesSandvik WeldingRam KadamNo ratings yet

- 410 NiMo MigDocument2 pages410 NiMo MigAnonymous skBAwexNo ratings yet

- 409Document2 pages409satish04No ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Bar SolderDocument1 pageBar SolderbrunizzaNo ratings yet

- OK Grain 21.85Document1 pageOK Grain 21.85brunizzaNo ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- Oxford Alloy 625T-1 (ENiCrMo3T1-1)Document1 pageOxford Alloy 625T-1 (ENiCrMo3T1-1)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Nicrobraz Cement 680Document1 pageNicrobraz Cement 680brunizzaNo ratings yet

- AFM Bronze AlloysDocument15 pagesAFM Bronze AlloysbrunizzaNo ratings yet

- Citoflux r82 SR (T 46 6 Ni1 P M 1 h5)Document1 pageCitoflux r82 SR (T 46 6 Ni1 P M 1 h5)brunizzaNo ratings yet

- SK 322-O (MF 3-GF-55-T)Document1 pageSK 322-O (MF 3-GF-55-T)brunizzaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- SK Tool Alloy C-S (Up 23-Gf-200-Ckz)Document1 pageSK Tool Alloy C-S (Up 23-Gf-200-Ckz)brunizzaNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- NC-SMQ®90 Solder Paste: Product Data SheetDocument2 pagesNC-SMQ®90 Solder Paste: Product Data SheetbrunizzaNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- The World Specialist in Nickel Based Alloy Wire: Phyweld 82Document1 pageThe World Specialist in Nickel Based Alloy Wire: Phyweld 82brunizzaNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Properties of Water PDFDocument5 pagesProperties of Water PDFMicah VicenteNo ratings yet

- WorleeK 162 VDocument2 pagesWorleeK 162 VCamilo GuardadoNo ratings yet

- ValveWorld06 P0607 Strang-Valve Materials For Seawater NAB RivalsDocument18 pagesValveWorld06 P0607 Strang-Valve Materials For Seawater NAB RivalsYQNo ratings yet

- Alkanes: H2 Chemistry 9647 Alkanes NYJC 2014Document17 pagesAlkanes: H2 Chemistry 9647 Alkanes NYJC 2014Chen ZhihaoNo ratings yet

- Material Safety Data Sheet: 1. Product IdentificationDocument4 pagesMaterial Safety Data Sheet: 1. Product IdentificationMuhammad Wasim Shahzad0% (1)

- Qenos Alkatane GF7740F2Document1 pageQenos Alkatane GF7740F2Manoj SahuNo ratings yet

- Case Study of Occupational Mercury Exposure During Decontamination of Turnaround in Refinery PlantDocument7 pagesCase Study of Occupational Mercury Exposure During Decontamination of Turnaround in Refinery PlantDilipSinghNo ratings yet

- Bio Ch13 l02 QuizDocument3 pagesBio Ch13 l02 Quizghaidaavl443No ratings yet

- Polyester FibersDocument33 pagesPolyester FibersChaudhary Shahzad ZahoorNo ratings yet

- H2PIntro-0V02 Introduction 2Document7 pagesH2PIntro-0V02 Introduction 2Christian AmadouNo ratings yet

- Namma Kalvi 12th Chemistry Unit 1 Study Material em 215343Document28 pagesNamma Kalvi 12th Chemistry Unit 1 Study Material em 215343HarishNo ratings yet

- RefrectarioDocument2 pagesRefrectarioCristian Mena HidalgoNo ratings yet

- Hydrogels For Biomedical ApplicationsDocument10 pagesHydrogels For Biomedical ApplicationshtfhfhfyNo ratings yet

- Corrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesDocument42 pagesCorrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesrickrobbinsNo ratings yet

- CorrosionDocument25 pagesCorrosionmahmoud EissaNo ratings yet

- Flare Modeling ParametersDocument20 pagesFlare Modeling ParametersvartharajanNo ratings yet

- Dlp-Science 9 NewDocument4 pagesDlp-Science 9 NewYhan Brotamonte BoneoNo ratings yet

- Tabel VCDocument1 pageTabel VCgame downloadNo ratings yet

- Working Paper of Buffer Solutions Grade 11Document11 pagesWorking Paper of Buffer Solutions Grade 11Winston LeonardNo ratings yet

- Chemistry Assignment and Project 2Document13 pagesChemistry Assignment and Project 2Guru SrinivaasNo ratings yet

- Britishhomoeopat 00 BritialaDocument448 pagesBritishhomoeopat 00 BritialaAlbena Trifonova0% (2)

- Experiment 3. The Test For Protein: Substance Reaction With Copper Sulphate and Sodium HydroxideDocument4 pagesExperiment 3. The Test For Protein: Substance Reaction With Copper Sulphate and Sodium HydroxideAndrew PooleNo ratings yet

- Low-PAH Oils in View of Brazilian Tire LegislationDocument26 pagesLow-PAH Oils in View of Brazilian Tire LegislationlisojordanNo ratings yet

- Bahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGDocument33 pagesBahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGMahanani SubagioNo ratings yet

- Catalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Document7 pagesCatalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Nirajkumar NairNo ratings yet

- Astm B633Document5 pagesAstm B633nisha_khan100% (1)

- Infiltration Embedding ReviewerDocument4 pagesInfiltration Embedding ReviewerJoey Magno50% (4)

- Gold Ore Processing PlantDocument4 pagesGold Ore Processing Plantjafer2000No ratings yet

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Uploaded by

brunizzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Thermanit Mts 3 (G Crmo91, Er90s-B9)

Uploaded by

brunizzaCopyright:

Available Formats

08.

2009

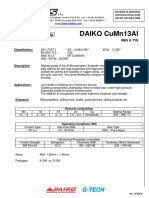

Thermanit MTS 3 Rev.: 0

GMAW solid wire

Classifications EN ISO 21952-A EN ISO 21952-B AWS A5.28 Mat. No.

G CrMo91 G 62 M 9C1MV ER90S-B9 1.4903

High temperature resistant, resistant to scaling up to 600 °C

(1112 °F). Suited for joining and surfacing applications with

Characteristics

quenched and tempered 9% Cr steels, particularly for

and field of use

matching high temperature resistant parent metal T91 / P91

according to ASTM.

1.4903 – X10CrMoVNb9-1;

ASTM A 199 Gr. T91, A213/213M Gr. T91, A355 Gr. P91 (T91)

Materials

Typical analysis C Si Mn Cr Mo Ni Nb V

in % 0.1 0.3 0.5 9.0 1.0 0.7 0.06 0.2

Creep and stress According to matching high temperature resitant parent metal

rupture properties

Mechanical proper- Heat- Yield strength Tensile Elongation Impact values

treatment 0.2% strength (L0=5d0) in J CVN

MPa MPa %

ties of the weld

to EN ISO 15792-1 760 °C / 2 h 520 620 16 50

metal according

(min. values at RT) (1400 °F / 2 h)

Structure Martensite, suitable for quenching and tempering

Welding instruction

Materials Preheating Cooling Postweld heat treatment

Matching steels/ 200 - 250 °C ≤100 °C Tempering at 760 °C

cast steel grades (392 - 482 °F) (212 °F) (1400 °F) – at least 2 h / air

Shielding gas (EN ISO 14175) M12, (M13)

Polarity = +

www.t-put.com

Packaging and Diam. (mm) Spool kg/pack

weights 0.8 B300 12.5

(Tolerances acc. EN ISO 544)

1.0 B300 15

1.2 B300 15

1.6 B300 15

Böhler Schweisstechnik Deutschland GmbH · Unionstr. 1· D-59067 Hamm · +49(0)2381-271-02

You might also like

- 8.2 (111 Marks) : MarkschemeDocument47 pages8.2 (111 Marks) : MarkschemeSemwezi Enock0% (1)

- Fabric Conveyor Belts Installation and Maintenance GuideDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guidejonodo89100% (2)

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Thermanit Mts-3 Gtaw enDocument1 pageThermanit Mts-3 Gtaw ensoft4gsmNo ratings yet

- Wire Thermanit CSiDocument1 pageWire Thermanit CSiviphemantNo ratings yet

- T - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFDocument1 pageT - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFnebojsa70No ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- Thermanit 13-04 Si (Boehler)Document1 pageThermanit 13-04 Si (Boehler)queno1No ratings yet

- Thermanit Chromo 9 V - SMAW PDFDocument1 pageThermanit Chromo 9 V - SMAW PDFsbktceNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Flux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelDocument14 pagesFlux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 Steelamit singhNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Flux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelDocument7 pagesFlux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelSachin SharmaNo ratings yet

- 3dprint AM P22: Material TypeDocument1 page3dprint AM P22: Material TypeKara WhiteNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Rod - Union I Crmo 910Document1 pageRod - Union I Crmo 910Rushita SolankiNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelLaboratorio CalidadNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Aisi 316L 1.4404Document2 pagesAisi 316L 1.4404Carlos Alberto Sutachán Cuevas CasNo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document3 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- B - Boehler FOX CM 9 KB - Se - en - 5Document1 pageB - Boehler FOX CM 9 KB - Se - en - 5misthahNo ratings yet

- P91 - Modified 9crmo: Alloy TypeDocument7 pagesP91 - Modified 9crmo: Alloy TypeHanLe DuyNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Sandvik Saf 31803 Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik Saf 31803 Tube and Pipe, Seamless: DatasheetPaul NeedhamNo ratings yet

- Datasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Document9 pagesDatasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Gonzalo AlarciaNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- D2 Spec Sheet V1 - 0Document1 pageD2 Spec Sheet V1 - 0NPD TEAM HosurNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelMarwan ShehataNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Sandvik WeldingDocument3 pagesSandvik WeldingRam KadamNo ratings yet

- 410 NiMo MigDocument2 pages410 NiMo MigAnonymous skBAwexNo ratings yet

- 409Document2 pages409satish04No ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Bar SolderDocument1 pageBar SolderbrunizzaNo ratings yet

- OK Grain 21.85Document1 pageOK Grain 21.85brunizzaNo ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- Oxford Alloy 625T-1 (ENiCrMo3T1-1)Document1 pageOxford Alloy 625T-1 (ENiCrMo3T1-1)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Nicrobraz Cement 680Document1 pageNicrobraz Cement 680brunizzaNo ratings yet

- AFM Bronze AlloysDocument15 pagesAFM Bronze AlloysbrunizzaNo ratings yet

- Citoflux r82 SR (T 46 6 Ni1 P M 1 h5)Document1 pageCitoflux r82 SR (T 46 6 Ni1 P M 1 h5)brunizzaNo ratings yet

- SK 322-O (MF 3-GF-55-T)Document1 pageSK 322-O (MF 3-GF-55-T)brunizzaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- SK Tool Alloy C-S (Up 23-Gf-200-Ckz)Document1 pageSK Tool Alloy C-S (Up 23-Gf-200-Ckz)brunizzaNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- NC-SMQ®90 Solder Paste: Product Data SheetDocument2 pagesNC-SMQ®90 Solder Paste: Product Data SheetbrunizzaNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- The World Specialist in Nickel Based Alloy Wire: Phyweld 82Document1 pageThe World Specialist in Nickel Based Alloy Wire: Phyweld 82brunizzaNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Properties of Water PDFDocument5 pagesProperties of Water PDFMicah VicenteNo ratings yet

- WorleeK 162 VDocument2 pagesWorleeK 162 VCamilo GuardadoNo ratings yet

- ValveWorld06 P0607 Strang-Valve Materials For Seawater NAB RivalsDocument18 pagesValveWorld06 P0607 Strang-Valve Materials For Seawater NAB RivalsYQNo ratings yet

- Alkanes: H2 Chemistry 9647 Alkanes NYJC 2014Document17 pagesAlkanes: H2 Chemistry 9647 Alkanes NYJC 2014Chen ZhihaoNo ratings yet

- Material Safety Data Sheet: 1. Product IdentificationDocument4 pagesMaterial Safety Data Sheet: 1. Product IdentificationMuhammad Wasim Shahzad0% (1)

- Qenos Alkatane GF7740F2Document1 pageQenos Alkatane GF7740F2Manoj SahuNo ratings yet

- Case Study of Occupational Mercury Exposure During Decontamination of Turnaround in Refinery PlantDocument7 pagesCase Study of Occupational Mercury Exposure During Decontamination of Turnaround in Refinery PlantDilipSinghNo ratings yet

- Bio Ch13 l02 QuizDocument3 pagesBio Ch13 l02 Quizghaidaavl443No ratings yet

- Polyester FibersDocument33 pagesPolyester FibersChaudhary Shahzad ZahoorNo ratings yet

- H2PIntro-0V02 Introduction 2Document7 pagesH2PIntro-0V02 Introduction 2Christian AmadouNo ratings yet

- Namma Kalvi 12th Chemistry Unit 1 Study Material em 215343Document28 pagesNamma Kalvi 12th Chemistry Unit 1 Study Material em 215343HarishNo ratings yet

- RefrectarioDocument2 pagesRefrectarioCristian Mena HidalgoNo ratings yet

- Hydrogels For Biomedical ApplicationsDocument10 pagesHydrogels For Biomedical ApplicationshtfhfhfyNo ratings yet

- Corrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesDocument42 pagesCorrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesrickrobbinsNo ratings yet

- CorrosionDocument25 pagesCorrosionmahmoud EissaNo ratings yet

- Flare Modeling ParametersDocument20 pagesFlare Modeling ParametersvartharajanNo ratings yet

- Dlp-Science 9 NewDocument4 pagesDlp-Science 9 NewYhan Brotamonte BoneoNo ratings yet

- Tabel VCDocument1 pageTabel VCgame downloadNo ratings yet

- Working Paper of Buffer Solutions Grade 11Document11 pagesWorking Paper of Buffer Solutions Grade 11Winston LeonardNo ratings yet

- Chemistry Assignment and Project 2Document13 pagesChemistry Assignment and Project 2Guru SrinivaasNo ratings yet

- Britishhomoeopat 00 BritialaDocument448 pagesBritishhomoeopat 00 BritialaAlbena Trifonova0% (2)

- Experiment 3. The Test For Protein: Substance Reaction With Copper Sulphate and Sodium HydroxideDocument4 pagesExperiment 3. The Test For Protein: Substance Reaction With Copper Sulphate and Sodium HydroxideAndrew PooleNo ratings yet

- Low-PAH Oils in View of Brazilian Tire LegislationDocument26 pagesLow-PAH Oils in View of Brazilian Tire LegislationlisojordanNo ratings yet

- Bahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGDocument33 pagesBahan-Bahan Restorasi: DRG Erma Sofiani, Sp. KGMahanani SubagioNo ratings yet

- Catalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Document7 pagesCatalytic Conversion of Plastic Waste To Fuel: ISSN: 2394-1766Nirajkumar NairNo ratings yet

- Astm B633Document5 pagesAstm B633nisha_khan100% (1)

- Infiltration Embedding ReviewerDocument4 pagesInfiltration Embedding ReviewerJoey Magno50% (4)

- Gold Ore Processing PlantDocument4 pagesGold Ore Processing Plantjafer2000No ratings yet