Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

ACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

Uploaded by

Shreyas AlagundiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsDocument9 pagesCyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsShreyas AlagundiNo ratings yet

- Capacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationDocument17 pagesCapacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationShreyas AlagundiNo ratings yet

- Cyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementDocument7 pagesCyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementShreyas AlagundiNo ratings yet

- Evaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderDocument12 pagesEvaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderShreyas AlagundiNo ratings yet

- Support 3Document15 pagesSupport 3Shreyas AlagundiNo ratings yet

- Joint StrengthDocument37 pagesJoint StrengthShreyas AlagundiNo ratings yet

- Paper With y MX 2)Document25 pagesPaper With y MX 2)Shreyas AlagundiNo ratings yet

- Support 1.1Document87 pagesSupport 1.1Shreyas AlagundiNo ratings yet

- Performance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesDocument16 pagesPerformance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesShreyas AlagundiNo ratings yet

- Doors and WindowsDocument45 pagesDoors and WindowsShreyas AlagundiNo ratings yet

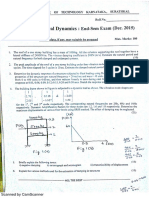

- Structural Dynamics Question PapersDocument18 pagesStructural Dynamics Question PapersShreyas AlagundiNo ratings yet

- Pes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Document26 pagesPes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Shreyas Alagundi100% (1)

- Applications of DgpsDocument11 pagesApplications of DgpsShreyas AlagundiNo ratings yet

- Nitk PG SyllabusDocument415 pagesNitk PG SyllabusShreyas AlagundiNo ratings yet

ACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

ACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

Uploaded by

Shreyas Alagundi0 ratings0% found this document useful (0 votes)

8 views11 pagesOriginal Title

ACFrOgB1Gfu51zmZFWDK5k_r0jrNPaDQZ0plu_m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7_c-apcT7WAFGQ_HuwznP5fIxVCF4g-YmML5i

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views11 pagesACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

ACFrOgB1Gfu51zmZFWDK5k r0jrNPaDQZ0plu m5rhzDtkKY9Fbe4cSTWxmCTqVOXYSe3eWXUUArnPjC9tUWKwLx79-I9qUxj8ms9PbMIenCeVg7 c-apcT7WAFGQ HuwznP5fIxVCF4g-YmML5i

Uploaded by

Shreyas AlagundiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

Construction an Building Materials 71 (2084) 510-520,

Contents lists available at ScienceDirect

Construction and Building Materials

ELSEVIER

journal homepage: www.

evier.com/locate/conbuildmat =

Mechanical properties of high performance fiber reinforced

cementitious composites

Mostafa Fakharifar“', Ahmad Dalvand, Mahdi Arezoumandi®’, Mohammad K. Sharbatdar”,

Genda Chen‘, Ali Kheyroddin”

“Departmen of Ci Arciectra end Enrmentl Ener, Misour Univers of conrad Technol, 209 Pie Bultin 1304 Xe Ste, Rolle, MO 65408,

United ees

"Dxparment of Cit Engineering Soran Univesity, Sean, ran

“Department of Gi. rctectarl and Environmental Eiri Missouri Universo cece ond Tetnaogy, 212 Butler Cron Hal, M401 Nine Str, ol, MO

(5408, United Sates

“Deponment of Cl Archetural and Enronmentl Eger, Misia Uniersy of Sence and Teel, 128 Butler Carton Hal, 1401 Nie Sire, ala, MO

own

HIGHLIGHTS

+ Compressive and flexural strength of HPFRCC follow normal dstsibution.

inear relationship exists between flexural and compressive strength of HPFRCC,

steasng iber content improves mechanical properties of HPFRCC;

‘increasing fbr content enhances Ast crack and failuce strength of HPFRCC.

ARTICLE INFO ABSTRACT

‘arc ison [Exensive experimental studies on High Performance Fiber Reinforced Cement Composites (HPFRCC)

Received 6 February 2014 ‘wing to their remarkable properties have been carried out. Statistical studios Rave Been mainly focused

Received in revised form 21 August 2014 fon Fiber Reinforced Concrete (FRC) An extensive study including an experimental/sttistcal approach

‘Accepted 24 August 2014

ae adessing key mechanical properties (compressive and flexural strength) and impact resistance of such

high performance composites with inclusion of dillerent volume of fibers has been caried ut on two-

hhundfed and forty specimens in this research

Results fom this study revealed that compressive and lexural strength as well as impact resistance of

LHPFRCC follow the normal distribution. Furthermore, statistical data analyses (both paramettc and non-

parametric) showed higher percentage of fibers led in greater values for mechanical properties and

iis Impact resistance of HPFRCC. Moreover, based on acquired test results, equations were developed

between mechanical properties and impact resistance of HPFRCC materials.

(© 2014 Elsevier Li llrightsreserved

Kepwors:

Compressive tenth

Feral stent

Inpac esistance

Probability dstabution

egy abuorpon

1. Introduction

High Performance Fiber Reinforced Cementitious Composites

(HPFRCC) is a class of fiber cement composites with fine aggre-

sates, demonstrating, remarkable properties such as improved

Y Covespnding author. Te: #1573 341 4462 fax: +1 575 3414720.

Email adareses: mihdcOnstedu (M. Fakhanar, Ahm dalend@ymail

‘om (A. Daan), ma52G@nstedu (M. Arzoumand mshaatdar@semnanccit

(ik Stata cheno (Chen) Kiyandinssrnan cr Keyra)

ek 11579 416845 on 40 S733 47,

2 Tels #1573 3416972 fu 41573341 4729,

hp:ibdiorg)10.10165conbutémat.201408.058

(50-0618) 2014 Eee Ue Al rghis reserve

resilience and sustainability. HPFRCC materials also exhibit

improved properties compared with normal concrete (NC) andfor

Fiber Reinforced Concrete (FRC) in terms of higher ductility, dura-

bility and energy dissipation capacity. This material ean be charac-

terized by a pseudo-ductile tensile strain hardening behavior with

‘multiple cracking prior to failure [1.2] Tensile behavior of NC, FRC

and HPFRCC materials are compared in Fig. ). This figure clearly

‘exhibits three distinct behavior upon cracking. When concrete,

‘mortar or FRC are subjected to tension, brittle degrading behavior

at first cracking due to inability to transfer tensile stresses across

the crack surface is observed. In contrary, HPFRCC materials

tundergo multiple cracking after first cracking, exhibiting a

M Fathanor ea Construction and uling Motels 71 (2014) 510-520

tt

“Tensile stress

Strain hardSaing esion

(Mull cracking)

sn

Single mek

and

localization

ttt

Brite failure of NC

— a.

hl

tt

a -

©

tH

7 = Crack Opening

12

Strain or Deformation Crack Opening

(Material and sreturaldoctiity) (Surface energy, material ductili)

Fig. 1. typical tens stress-strain or deformation relation upto ature of (2) normal caneete NC}: (b) Fier Reinforced Concrete (FRC): and) Migh Peformance Fiber

efrced Cements Competes (HPFRCC), adopted fo [2 10),

‘abte1

“ype mechanical apse properties of EC [8

Compresive Fist cackingsuengih_Ulimate tensile suengih Flexural strength Youngs madulis _UNimate tensile stain Density

strenath utr. ora) cate. (cra @ (ale

20-95 37 «12 10-30 1834 1 095-23

hardening behavior, ie. strength increase after frst cracking. Only

for the HPFRCC materials the post cracking strength, dpc, is higher

than the frst cracking strength,

In recent years, a new class of HPFRCC materials called

engineered cementitious composites (ECC) has emerged, offering

‘promising solutions for structures with longer service life featuring

enhanced structural performance. Developed at the University of

Michigan, ECC exhibits a typical moderate tensile strength of 4-

© MPa and ductility of 3~5% [3], Besides, other types of ECC mate-

rials including self-consolidating ECC, early high strength ECC. light

‘weight ECC and green ECC were introduced and studied by various

researchers |4~7|, Typical Mechanical and physical properties of

[ECC material is presented in Table 1 [8]. Polyvinyl alcohol (PVA)

fibers have been widely used in development of ECC materials.

However, fiber selection depends on different parameters

including: (1) fiber properties (diameter, surface roughness and

mechanical behavior), (2) characteristics of matrix (crack resis

tance and fiber-matrix interfacial bonding strength), (3) perfor-

‘mance objectives of ECC (desired properties, durability, and

sustainability), and (4) cost considerations of ECC materials in filed

applications [9

‘As set forth eatlier and illustrated in Fig. 1, adding fibers into

conerete may enhance concrete mechanical properties, including,

flexural strength, fracture toughness, thermal shock strength, fat

gue strength and impact resistance | 0-15]. Many studies revealed

the superior performance of HPFRCC materials based on its

‘observed static mechanical properties. Little research has been

‘undertaken on the loading rate effect on the mechanical behavior

‘of HPFRCC materials. Behavior of fiber, matrix and the interfacial

‘bond between them is dependent on loading (strain) rate [2 Thus,

impact tests are valuable tools to characterize completely the

behavior of HPFRCC materials under high strain rate loadings

se. IM Fao tl /Contrton and Building Matera 71 (2014) 510-520

Loading rate effect is significantly important on strength and duc-

tility of critical regions within structures, such as beam-column

joints and coupling beams |16,17) when subjected to earthquake

loading.

Existing statistical data analyses available in the literature are

‘mainly focused on mechanical properties (compression and flex-

lure) and impact strength of FRC materials. Implementation of a

reliable large set of experimental tests in addition to statistical data

analyses would be an appropriate method to further study and

‘develop the understanding of mechanical properties of these high

potential composite materials. Effect of fiber content on statistical

parameters and distribution of flexural strength, compressive

strength and impact strength of HPERCC is vital and need to be

addressed. Energy dissipation of HPFRCC has never been staisti-

‘ally studied previously. To the best of the author's knowledge. a

thorough experimentalfstatistical_ study on impact strength,

‘mechanical properties and energy dissipation of HPFRCC materials

hhas not been investigated yet. Although, HPFRCC have been studied

for their mechanical properties, but not statistically evaluated yet

based on adequately large number of compression, flexure and

impact test specimens, including different fiber contents.

2. Research significance

Research on HPFRCC materials widely indicated their enhanced,

properties featuring improved ductility, strength and durability

lunder static load condition. Impact tests characterize the perfor-

mance of HPFRCC under high strain rates. Effect of fiber content

‘on the impact strength of HPFRCC under dynamic loading is not

completely characterized yet. A thorough experimental/statistical

study would contribute to better characterization of mechanical

properties and impact strength of HPFRCC, including different fiber

‘contents. Thus, a relatively large test matrix was developed by the

authors to further investigate the mechanical properties and

impact strength of HPFRCC materials. Two hundred and forty spec-

imens total, tat is significantly larger than test matrices in similar

studies to provide a reliable baseline for statistical analyses, were

‘ast, prepared and tested to achieve this goal.

3. Experimental study and procedures

‘Three volume fraction of polypropylene (PP) fiber equal to 0.5%

0.75% and 1% were considered in this study. Considering the three

different fiber content, total specimens in this study would be cat=

‘egorized as: 60 specimens (100 x 100 « 100 mm) for compressive

strength (20 specimens per group), 60 specimens

(60 « 80 « 320 mm) for flexural strength (20 specimens per group)

‘and 120 specimens (150 x 64 mm) for impact resistance (40 spec-

mens per group). The proposed drop-weight test according to the

ACI Committee 544 [18], commonly used for impact strength of

FRC, has been used for impact resistance test of HPFRCC specimens

in the current study, Data obtained from such tests usually have a

‘coefficient of vatiation (COV) of mote than 25%. The variation in

impact strength from the drop-weight test has been reported for

the FRC materials [19-24 and not for the HPFRCC yer.

All three groups of HPFRCC specimens were cast with identical

‘water-cement ratio of 0.38 with three different volume fiber

contents of 0.5%, 0.75% and 1%, which are designated as HP-0:5,

HP-0.75 and HP-1, respectively. Numeric value represents the

percentage offers used in the corresponding group of specimens.

For example, HP-0.5 represents the group of specimens with 0.5%

fibers. Compressive strength tests were performed on twenty

100x100 100mm cubic specimens per group prepared

according to BS 1881-108:1983 [25]. Flexural strength tests were

‘conducted on twenty 60x 80x 320mm beam specimens per

‘group according to BS EN 12390-5:2009 [26 Although compres-

sive and flexural strength test procedures are almost fixed, a brief

‘explanation on drop test procedute undertaken in this research is

presented. Drop-weight tests were conducted following the ACT

544 Committee's recommendations. For each concrete mix, ten

150 x 300 mm cylindrical specimens were cast. Then each cylinder

was cut into four 64 mm thick cylindrical disks using a diamond

blade concrete saw. During impact tests, each cylindrical disk

‘was set centered on a base plate within four positioning lugs,

‘and impacted by repeated blows. Blows were applied through a

4.45 kg, hammer falling continually from a 457 mm height onto a

steel ball with the diameter of 63.5 mm, which was centered at

the top surface of the disk. The number of blows required to cause

the firs visible crack and then failure were recorded. With the aid

‘of a magnifier equipped with built-in flashlight, the number of

blows to initiate the first visible crack on the top surface was

defined as the first-crack strength, while the number of blows (0

‘generate failure of the disk was identified as the failure strength,

Al tests were performed after curing the specimens for 28 days.

4. Materials and specimens preparation

Inehis experimental study, AIM Type Prand coment, rushed sand and

fers were wed nthe mk ables 2a 3 present the cement compositions and

mechanical properties of P es respectivey high cange water reduce gent

twit the commer name of Mapet10" was used to aus the workablty of the

‘concrete mores For batching cement was mixed with aggregate for 1 min The,

thewaterandwaterredocer agent wer addedto the mix and mixed for 6-8 min The

mature proportions for hee diferent mixes are provided in Ta. Tea est eon-

fete was east Imo. cUiC_ form (100 » 100» 100mm) cylinder

(150 300mm), and prisms for (0 » RO = 320 mm) for compressive, impact

‘able?

Chemical composition and_ physical properties of

Composition Peeentge

Los a37

Myo. 156

Ko ase

GO. a3

cs 51

cs 27

cA 5

CaF na

specie wavy sn

Specie src en) 3000

Mechanical popes of polypropylene es

Tength Diameter Color Tensile Younes ‘ens

(oom) (oom) trent (MPa) mods (Pa) _ (hm)

‘abled

Mure proportions of once por cuble meter concrete)

Wate Cameat Poypropylene Fine

fement aio fiers (2) aggregates

M Fathanor ea Construction and uling Motels 71 (2014) 510-520 sis

Compressive sens of cable specimens (MPa)

Specimen no Compresive rent

30 a) Sra

a0 Stes S290

asi 4598 our

asat 5501 Sia

aah 472 so14

ast 512 4558

4575 a7 sia

a6 5029 519

4634 sun

saz 898

sais seu

683 ea

and flexural tests, respectively Allo the specimens were moist cure at a tempera

{ure rage of 3-30°C and a relative humidity range f 85-1005 forthe st 24

‘Ate demoling, he specimens were stored ina ser-contrled environment with

‘temperaturerangeof 20-25 anda ete hamid range of 35-50 for 28 day,

‘specimens were tested ater curing for 28 das om batting

5. Results and discussion

5.1. Compressive strength

‘The compressive strength tests were cartied out on sixty

100 x 100° 100mm cube specimens, using a digital standard

automatic testing machine of 2000kN capacity. Compressive

strength test results are presented in Table 5. Results indicate that

the addition of fibers into specimens improved. compressive

strength and it increases with increasing, PP fiber percentage

Fig. 2a presents the histogram of compressive strength fi for

1HP-1.00 specimens. This figure shows thatthe results are normally

distributed and fit well withthe superimposed normal distribution

curve (it will be explained in more details in Section 5). HP-1

specimen group has the highest mean compressive strength value

amongall the specimen groups while exhibiting the highest COV)

atthe same time. As itis observed, by increasing fiber percentage

in HPFRCC specimens, dispersion of compressive strength data is

increasing accordingly a5 well as COV. The COV is lower than a

limit of 15% suggested by Swamy and Stavrides [27]. Moreover

Day (28) suggested that a COV between 5% and 10% generally rep”

resents a reasonable quality contol, asthe acquited results here

fits in that range of variation,

5.2 Fleaural strength

Flexural strength test was performed on sixty

320 x 80 x 60 mm specimens. Schematic ofthe flexural test appa-

tatus is shown in Fig. 3. Flexural strength test results from 60 spec-

imens for three groups with different fiber contents are presented

in Table 6. The highest mean flexural strength values belongs to

HP-1 specimens, which is 29% and 21% more than mean flexural

strength values of HP-0.5 and HP-0.75 specimens, respectively

The frequency histograms of flexural strength, f for HP-1.00 spec-

imens are shown in Fig. 2b. This figure shows that flexural

strengths follow the normal distsibution, Interestingly enough,

the COV for all specimens with different percentages are around

10%,

5.3. Impact resistance

Drop-weight test results of 120 disk specimens including forty

specimens per group, are given in Table 7. The impact test appara-

tus and schematic details are shown in Fig. 4.

‘ :

rs Be

° nt

ss 3055-60 65 70 Ts

(af. Of,

‘ i ‘

_ Ba

17 | A

° °.

(ep FC (acu

ig. 2 Monat dstibations of MP specimens.

su IM Fao tl /Contrton and Building Matera 71 (2014) 510-520

Toaing ap

Fosural specimen

Fig. 3. Flemral et configuration under four-point ong.

ables

Fear sengts of beam specimen (MP).

Specimen po odkles of ape

P05 weave et

4 435 Sor 638

5 4a1 ait 574

6 521 an 639

4 427 351 620

8 538 559 574

10 388 494 ons

a 51 5a 633

14 403 5a 485

8 523 nz 731

cov en) 04 805 oa

5.3.1. First crack strength

‘The frequency histogram and fitted normal curve of the flst-

crack strength, FC distribution for HP-1.00 are shown in Fig. 2c.

First-crack strength of HP-1.00 specimens hardly follows a normal

distribution (lower p-values in Table 8). Results implied that with

increasing fiber percentage, first-crack strength increases. Mean

values for first-crack strength of HP-1 group with 1% fibers was

approximately 57% and 18% more than HP-0.5 and HP-0.75 groups,

respectively. The COV of first-crack strength for HP-1 group is 16%

‘and 6% more than HP-0.5 and HP-0.75 groups, respectively.

5.3.2 Failure strength

Fig. 2d depicts the histogram of failure strength, UC for HP-1.00,

impact specimens, with the fitted normal curve superimposed.

‘Similar to frst crack resistance, all three groups hardly follow the

‘normal distribution. According to Table 7, the mean value of the

failure strength of HP-1 group was approximately 66% and 19%

higher than those of HP-0.5 and HP.0.75 groups, respectively

‘The number of blows to reach the failure strength of specimens

ranges from 17 to 105 for the HP-05 group, from 18 to 139 for

the HP-0.75 group, and from 25 to 167 for the HP-1 group. Increase

of fiber content increased the number of requited blows to failure

as well. HP-1 group had the highest COV among all the three

‘groups, revealing higher scattering of data. As shown in Table 7,

adding fibers to mixture increases the mean and dispersion of

the failure strength. Fig. 5 demonstrates impact specimens at fail-

ure including different fiber content featuring radial conerete spit-

ting initiated from center and extended radially.

53.3. Bnergy absorption and post crack strength

‘The impact energy per blow was applied by a 4.45 kg hammer

‘dropped repeatedly from 457 mm height on top of a 63.5 mm steel

ball Energy absorbed by the concrete disk for frst crack and falure

‘rack strength is shown in Table 7. According to these tables the

‘maximum absorbed energy for first crack and failure strength

‘occurs in HP-1 group. Mean value of energy absorbed by HP-1

_sroup for failure strength was approximately 66% and 19% higher

than HP-0.5 and HP-0.75 groups, respectively. The Percentage

Increase in the Number of Post initial crack Blows to failure is

labeled as the “PINPB" parameter. Mean values of PINPB parameter

‘of HP-1 group is 40% and 12% greater than HP-0.5 and HP-0.75,

_groups, respectively. Adding fibers to concrete mixture causes

increasing the distance between first-crack strength and failure

strength by limiting the intial crack and delaying the ultimate fail-

ure, This however maybe regarded as the pseudo-ductility ratio.

Fibers provide three-dimensional fibrous reinforcement. which

assist a disk specimen in absorbing the impact energy of repeated

blows, thus downplaying the impetuousness of the disk specimen

‘against crack progression. Fig. 5 illustrates the efficacy of fiber

increase in altering one large single cracking at failure (HP-0.50)

to multiple cracks (HP-1,00)

5.4, Statistical data analysis

‘The following section discusses probability distributions of

‘compressive strength, flexural strength, and impact resistance of

fiber reinforced concrete. It also explains about relationship

between mechanical properties as well as prediction of impact

resistance from mechanical properties,

5.4.1. Probability distributions

‘The statistical computer program Minitab 16 [2] was

‘employed to find probability distributions of mechanical proper~

ties as well as impact resistance of fiber reinforced concrete. The

Kolmogorov-Smimnov, Ryan-Joiner, and Anderson-Darling meth-

‘ods were used to test normality of the data. The hypotheses for

the normal distribution are as follows:

Hoy. The compressive strength of fiber reinforced concrete follows

the normal distribution,

oa. The flexural strength of fiber reinforced concrete follows the

normal distribution,

1M Fathaor ea /Constraction and uling Motels 7 (2014) 510-520 sis

Impact eesistances an predicted aur tenths of specimens

Specimen no, HROS0 HPO75 P00

FO US PINT Impoctenergy FC “UCCINPR—mpacrenergy «=~=CUC INP Impact energy

(blows) (kN) (Blows) (kN) (Blows) (EN am)

7 a8 4s 9 cg ins a

5 8 108912004556 2 6116682300

0 a 2 a7 ws 75 ” 2 1567 228

" » 2 590 ost 3546 a 6 27509

2 ce so ius 2 mb ee

0 a oF 5 75) 2430 2 7 has 1729

1 ae 189 a 2m 41008

15 rer! ot 7 S158 36 8 m™m |96

16 a 66 95 15s iw oT 2068

© 5 997 19 stg 38 46 731160

20 si 3s m6 5775 a 25 488610

2 ry ms '96 8 ” 6 346 “570

2 nO so 610528 2 3951009

as Bo om 495 4a % 7 15261628

38 % a0 1216285980 3 7107861

36 B67 118013635075 2 % S16 1008

” % 105 126 216 HB io 302035 28

8 no ot 89535 6 a8

30 aa as 50965175100 8 2» 9161099

oe 0 2 8 oo 4 oe s

~ Nunber of blows for ist rack strat

numberof blows for fare strength

«Percentage increase in number of post-frst-crck blows

Ha. The first crack impact resistance of fiber reinforced concrete

follows the normal distribution

Hag The ultimate impact resistance of fiber reinforced concrete

follows the normal distribution

Hy Not Hos 2

“Table 8 shows that p-values for all of the above tests are greater

than 0.05. This confirms the null hypothesis atthe 0.5 significance

level. In other words, the compressive strength, flexural strength,

first crack impact resistance, and ultimate impact resistance of

fiber reinforced concrete follow the normal distribution. Iris worth

‘noting that the compressive strength and flexural strength of the

LHPFRCC specimens fit better to the normal distribution compared

with the first crack impact resistance and ultimate impact resis-

tance of the HPERCC specimens (it is more clear in Fig. 2)

5.42. Relationship between mechanical properties and impact

resistance

It is useful to derive equations to predict the HPFRCC flexural

strength from compressive strength test results. Fig. 6 shows that

there is linear relationship between flexural and compressive

strength of HPFRCC for all of the fiber percentages. Eqs. (1)-(3)

show these relationships. Interestingly, the HP-0.75 and HP-1.00,

showed the same slope, but for HP-0.50 it was around 45% steeper

than both the HP-0.75 and HP-1.00 mixes. In other words, adding

(050% fiber was more effective than both 0.75% and 1.00% in terms

of improving flexural strength (Fig. 6)

J.=0A19f, ~3.75. (HP-0.50) a

J.=0.3f,-1.57 (HP-0.75) @

J, =0.13f, 0.99 (HP-1.00) 3)

Stee! pipe with 64 mm

Sts ap

Base fre

200 mi

Stool with 6

(Matha onstrctin and Bing Mater 71 (2014) 510-520

©)

Fig 4. Fling hammer test etal for impact strength (a) Impact test configuration: schematic (let) and apparatus (ight) an (b) details f impact Bll and tel cap:

schematic (het and aparates gh

where fs the compressive strength of concrete (MPa) and fis the

flexural strength of concrete (MPa).

Both the first crack and ultimate impact resistance of specimens,

can be predicted by using the compressive strength of specimens.

‘The linear relationship (Eqs. (4)-(9)) observed between first crack)

tltimate impact resistance and compressive strength for HPFRCC

specimens are included as well. As it can be seen from Fig. 7, in

terms of first crack resistance, HP-1.00 and HP-0.75 specimens

had the highest and lowest slope, respectively: however, the

ultimate impact resistance of HP-0.50 had the highest slope that

followed by HP-0.75 and HP-1.00. The higher slope means more

effectiveness of percentage of fiber to resist impact force.

FC-6.77f,-27333 (HP-050) @

UC=8:77f,-36042 (HP-0.50) o

FC 647f,- 272.51 (HP-0.75) 6

UC=8.66f,—36655 (HP-0.75) o

FC 7.69f, 344.90. (HP-1.00) ®

UC-6.08f,-274.86 (HP-1.00) ®

Where FC is the First crack resistance and UC i the ultimate impact

resistance.

Values forthe normality eto at

Tet HPS Hem Hoo

“ompresve senate

a 0705 0986 oon

ws ais,

>ao

Fesuralserath

» 0959 0960 955

5 ato

rst crock restance

8 pao

timate impect resistance

is sas

8 ato

‘adeson- Dating

* Koimagorov-Smirov

«yan

Another valuable result can be predicting the ultimate impact

resistance from the first crack resistance of specimens. Similar to

the aforementioned equations, the ultimate impact resistance

M Fathanor ea Construction and uling Motels 71 (2014) 510-520 si

(a) HP-OS

(b) HP-0.75

(©) HP-1.00

Fg 5. Fllre mode of impact disk specimens foal groups.

8

fa) [FC = 6.77f, -273.33 (-090)]

. = [Ucar 042 e090)

g 0

5 wl 2 7

é yet ae

g 3 mes 2 7

ae © rum F.(tPay

- ‘ —-nras| (a) HP-0.50

vm

40 a0 30 60 70 80 [FC = 6.47f, - 272.51 w'-09]

cay [c= Nsar, 36655 0-009)

© i

Fe 6 Fowl rent. conpresve sent of pce. 8 & —

: 3

= 4 --K

and the fst crack resistance ate related to each other linearly by e

Eqs. (10)-(12). "SD 0 0.

uc—1.27FC- 101 (HP.050) (ao) fare)

uc=1.27FC +168 (HP-075) ay () HP-0.75

Uc 1.23FC +527 (HP-1.00) 02) “Ee

Fig. 8 shows that HP-0.50 and HP-.75 specimens have identical = 160 = =

slope, whereas HP-1.00 specimen shows the lowest slope. That ©“ [FC=Gonr,-27486 0] A

means adding 1% fiber, decreased the gap between first crack S120

and ultimate impact resistance compared to 050% and 0.75% fiber Egg

cantent.

E 4

543. Parametric and nonparametric tests

Statistical tests (bath parametric and nonparametric) were used 0 o

to evaluate whether there is any statistically significant difference Fora)

between the mechanical properties of HPFRCC materials with df= iourine

ferent fiber contents. .

5.43.1. Parametric test. The paired t-test is a statistical technique

used fo compare two population means. This test assumes that

the differences between pairs are normally distributed. If this

assumption is violated, the paired t-test may not be the most pow-

erful test. The hypothesis for the paited t-test is as Follows:

‘The compressive strength of the HP-0.75 mix is higher than

the HP-0.50 mix [f(HP-0.75) > f.(HP-0:50)|

aa The compressive strength ofthe HP-.00 mix is higher than

the HP-0.75 mi [f(HP-100) > f.(HP-0.75)

Fig 7. The fst crackultinate impact resistance vs. compressive strength of

specimens.

Hy. The compressive strength of the HP-1.00 mix is higher than.

the HP-050 mix f,(HP-1.00) ~ f,(HP-0:50)).

Hq. The flexural strength of the HP-0.75 mix is higher than the

HP“0.50 mix if HP-0.75) > f,{HP-0:50)

Hs. The flexural strength of the HP-1.00 mix is higher than the

HP-0.75 mix [f,(HP-1.00) > f,(HP-0.75),

sis (Matha onstrctin and Bing Materia 71 (2014) 510-520

2a

1s0

& 100

so] a

i [uC= ITC LOTR O95)

a 30 To 150 2

Few

(a) HP-050

210

& ww

so]

« TCT TRE ODA)

‘ w 100 150 200

FCW)

() HP-075

209

1s

= 1m

s0|

| TRC STROH)

» o 100 150 210

Fo@

(©) HP-1.00

Fie BT imate impact esac it rack esa.

Statistical data analysis esas pale)

Number of replications requ to hep the ero under specified init at 90% and

95t evel of confidence.

bor) HPOSO HRO7S Poo

CE one Ce

Level af conden

20 od en oa

25 a5 58 os

0 oa a 1

3s yo Bd 53

<0 2 3 2 2 eo

So 1 1 1 1 1 1

95% Lee of comience

“0 Ce

He. The flexural strength of the HP-1.00 mix is higher than the

HP-0:50 mix Jf HP-1.00) > f,(HP-0.50),

Hox. The frst crack resistance of the HP-0.75 mixis higher than the

HP-0.50 mix [FC(HP-0.75) > FC(HP-0.50))

Hg. The first crack resistance of the HP-1.00 mix is higher than the

HP-0.75 mix [FC(HP-1.00) > FC\HP-0.75))

Ho. The first crack resistance of the HP-1,00 mix is higher than the

HP-0:50 mix [FC(HP-1.00) > FC\HP-0.50))

Horo. The ultimate impact resistance of the HP-0.75 mix is higher

than the HP-0.50 mix [UC(HP-0.75) > UC\HP-0.50))

Hon. The ultimate impact resistance of the HP-1,00 mix is higher

than the HP-0.75 mix [UC(HP-1.00) > UC(HP-0.75))

Fav 075)» POS)

av) > OTS) Tar)» F030)

‘Neal 7s oss oa

Nonparametric 1000 1.00 1000

900.075)» J,04-.050) 0.90)» f44.075) 0.00)» f-050)

oralty 0210 oa “029

Parametric 1.00 | 1.000 3

Nonpramete 100 1.000 .

Fo(HP-075) >» FeHP.050) Fc(HP-1.00)-FeHe-075) FciHP-100) -FEHP-0.50)

oraliy 052s one

Nonparametric 007 ‘00

oraliy 038 0525

Nonparametric 000 ‘000

~ Sine p-value ses thn 005, te pareve and nonparametric tts cannot be performed

M Fathanor ea Construction and uling Motels 71 (2014) 510-520 sig

Hoja. The ultimate impact resistance of the HP-1.00 mix is higher

than the HP-0.50 mix [UC{HP-1.00) > UC\HP-0.50))

He. Not Hes:

‘The statistical computer program SAS 9.2 [30] was employed to

perform these statistical tests. The Anderson-Darling test showed

the data ~ the differences between the mechanical properties of

specimens with different percentage of fiber ~ follows a normal

distribution (see Table 9). Therefore, the paired t-tests could be

performed, The result of the paired ¢-test presented in Table 9 that

shows the p-values were greater than 0.05 forall of the hypothe-

ses. This confirms the null hypotheses atthe 0.05 significance level.

Inother words, increasing the fiber content improved the mechan-

ical properties of HPFRCC,

5.43.2. Nonparametric test. Unlike the parametric tests, nonpara-

metric tests are referred to as distribution-free tests. These tests

have the advantage of requiring no assumption of normality, and

they usually compare medians rather than means. The Wilcoxon

signed-rank test is usually identified as a nonparametric alterna-

tive to the paired t-test. The hypothesis for this test is the same

a those for the paired test. The Wilcoxon signed rank test

assumes that the distribution of the difference of pairs is syramet-

‘cal. This assumption can be checked; ifthe distribution is normal,

it is also symmetrical. As mentioned earlier, the data follows the

normal distribution and the Wilcoxon signed ranks test can be

used, As i can be seen in Table 9, similar to the parametric study

all the p-values for the Wilcoxon signed rank were greater than

(0.05. Like the parametric test, the nonparametric test confirms

the null hypotheses at the 0.05 significance level. interestingly,

the p-values for both the parametric and nonparametric tests are

very close to each other. Overall, results of the statistical data anal-

yyses showed that the HPFRCC mix with higher fiber content pos-

sesses higher mechanical properties,

5.44, Number of replications

‘The COV ofthe test results, presented in Table 7 ean be used 10

determine the minimum number of tests “n*, required for guaran-

‘teeing that the percentage error “e” in the measured average value

is below a specified limit. This number of tests can be calculated

using Eq, (13) (27|

(cove

e

‘where COVis the coefficient of vatiation and ris the value of Student

‘distribution fo the specified level of confidence. The value of Stu-

dent distribution “r" not only depends on the level of confidence,

bbut also itis dependent on the degree of freedom, which is related

{to the numberof samples. For degrees of freedom of more than 120,

the value of "" approaches 1.645 and 1.282 at 95% and 90% level of

confidence, respectively (31,32), Table 10 presents the minimum

‘number of replications required to keep the error under specified

limits at the 90% level of confidence. Table 10 shows that, if the

error is retained lower than 10% for first-crack strength, the mini-

‘mum number of requited replications would be 26, 32 and 36 at

LHP-0.50, HP-0.75 and HP-1,00 groups, respectively, at 90% level of

confidence. Also, for HP-0.50, HP-0.75 and HP-1 groups for failure

strength at 90% level of confidence, i the error is retained lower

than 10%, the minimum number of replications required are 30,

32 and 33, respectively. Table 10 also demonstrates the number

of tests required to keep the error under a specific limit at the

95% level of confidence. According to this table, ifthe etror is

retained lower than 10% the minimum numbers of replications

for HP-0.50, HP-0.75 and HP-1.00 group are 43, 52 and 59 for the

(13)

first-crack strength and 49, 53 and 95 for the failure strength,

respectively. It is clear in Table 10 that adding fibers to concrete

‘mixture increases the umber of tests Fequired at each level of

6, Conclusions and findings

In this study, effects of polypropylene fibers on mechanical

properties of HPFRCC specimens with fine aggregates were investi-

gated experimentally and statistically, based on 240 implemented

tests. Based on the acquired test data of 240 specimens divided in

tree groups (60 cubic specimens for compressive strength, 60

bbeam specimens for flexural strength, and 120 disk specimens

{or impact resistance), the following conclusions can be drawn:

‘The compressive and flexural strength, first crack and ultimate

impact resistance follow the normal distributions.

+ In all cases, the mean and the COV both increase with the

Increase in percentage of fibers. The more data dispersion in

concrete specimens with higher percentage fibers is likely

attributed to the pronounced effect of fiber-concrete interfacial

bond.

‘The COV for the impact resistance from drop-weight tests is

highest among the three mechanical properties. Ths is likely

attributed to additional uncertainties involved in impact test-

ing. such as specimen surface roughness and loading position

+ Linear relationship was observed between flexural and com-

pressive strength of HPFRCC.

+ The HP-0.50 specimens have the highest rate of gaining flexural

strength.

+ The first crack and ultimate impact resistance can be predicted

by using compressive strength with high coefficient of determi-

nation (F)

+ HP-1,00 and HP-0.50 specimens showed the best performance

in terms of the fist crack and the ultimate impact resistance,

respectively.

‘©The first crack and ultimate impact resistance are related to

each other linearly.

+ HP-1.00 specimen showed inferior performance after first crack

compared to both HP-0:50 and HP-0.75 specimens that per-

formed almost identical

+ Statistical data analysis (both parametric and nonparametric)

showed that increasing fiber content improves the mechanical

properties of HPFRCC,

‘Adding fibers into concrete increases the number of blow

Counts required to cause both the first visible crack and the fail-

ture of test specimens, and the number of blow counts from the

first crack to failuc.

+ The mean energy absorption ofthe specimens with 1% fibers is,

666% and 19% higher than that ofthe specimens with 0.5% and

0.75% fibers, respectively. The mean post-crack blow count of

the specimens with 1% fibers is 40% and 12% greater than that

of the specimens with 0.5% and 0.75%, respectively.

Acknowledgements

Financial support for this study was partly provided by the

Department of Civil, Architectural, and Environmental Engineering,

at Missouri University of Science and Technology, US. and by the

US. National Science Foundation under Award No. CMMI-1030399,

The results, discussion, and opinions reflected in this paper are

‘those ofthe authors only and do not necessarily reflect the official

views or policies of the funding institutions

20 (Matha onstrctin and Bing Mater 71 (2014) 510-520

References.

11) ive. wu ie Constons for pscdo strain-hardening in fiber reinforce brite

Imax composts] Ap ech Rey 192438) 390-8

[2] Naaman AE, Reinhard MW. Choratterization of igh performance fb

Fenfrce cement cmposites, HPFRCC-2 1986. p. 1-28

|p) seer G. Wang, LC. Design of engineered Eementtions composes for

Processing and wertabltyrequlements ne Seventh Internacional

‘Shmpostum on brite matrx Composites 2003. 29-36.

141 Kong Hike 5. UVC. Development of a slfcompactng engineered

cementitious composite employing eletosteie dispersion sabzation J

{Cem Coner compos 2003:250);301-8.

1) WeSC Heh ens nice cementws compote Ac

fo} Wang 5 I Ve. Maes design of lighewelght FVA-EC. In; Naaman AE,

Reinhardt HW. editors, Proc HPFRCC. Rl: 2003. 379-90,

171 Lepech MD, L Ve. Roberson RE. Reottan GA. Desian of tle engineered

‘ements composts for improved sustainably. AC Mater] 207

Is) LV Engineered cemenciious composts (Ecc) matena, struct, 20d

‘uralty performance An Abr Mt 48109: Univesity of Michigan: 2007

Ip) Ize kien kt YW Predicion of EC tensile strss-stain curves based 03

mated ber bing relations considering fiber dstibution characteristics.

{Comput Cone Int} 201071.

Wo] seer 6, Vc. structura composts with EC. Xl Y, Mabin SA ets

Proceedings othe ASCES USC 2000p. 1001-8,

Inn] Yan Sun Chen The elect sca fame apd steel ber on the dye

Imechanieal perfomance of bighstreth “concrete. Cem Cone Res

Ion.a423 6

[12] Bana’ N, Sappakitipakorn M. Toughness enhancement in steel Aer

‘Solace content Aer hydration Cot es

na] Altezainy A, Sroushian Mira F Mechaicl properties of palypropylene

fiber reinforced concrete and the eet of pozzalanc materials Com Coner

(Comps 1996:182)35-92,

[na] estsy FS Harwich K. Compressive strength and deformation of ste! re

vnlored concrete under high rate of sein ne Cer Campos Lighight

oner 1885:71)21-8.

[n5}Toahim 8 he kar MB. fects om mechanical properties of ndusrasnd

Steal iees aan tO normal weight concrete. Proc ERg.2011:18

116] Para: Montesinos G) High-performance Aber enforced cement composites:

Sh aternative for sami design of stestures ACI ret] 20051023)

107) Fakhantor Mt sharbatdar MK LinZDalvand A ivand-Pour A Chen G Seismic

performance and gota ductility of KC tame rehabiated wie retoted

Joins by CF Laminates. arin Eng Eng Vib 2014:131 59-73,

[ne] AC Commitee 544 Measurement of properties of tibrreitored concrete,

‘AC Mater | 1988:85(6 583-99,

luo) Song Ps Wa J, Hwang. Shew BC. Asesment of stats vations in

Impact resistance of gh stengrh concrete and high strength steel Ae

Fefrced concrete} Com Concr Res 2005135:395-2

(20) Barat shou Atal F tens Andree Ktastcal variations in mpoet

resisanee of polypronvine “bre-reinreed concrete} Impact ng

‘ovw:s 1907-20.

[2t) Songs, uJ: Hvangs, shew Bc. Satis analysis of impact strength and

strength celal of see-polypropyene hb fbe-enfrced concrete}

Constr Bul Mater 2005;19°1-3

[22] Nataraja MC Daan N: Gupta AP. Statistical varlatons a impact estance of

steel fber-cinforced conerete subjected to drop wea test Cem Cone Res

1900,25089-95,

(2s) fanman T Kan shekarch MSA A Statistical and experimental analysis

fon the bevior of ber relafrced concretessubeced to drop weight fet

nat ld Mater 201257360.

[241 Swany RN Jj AH Impact resistance of stelle enforced lightweight

concrete Int} Cem Compo Uihtwegt Cone 1982.4) 200-20,

125) Bris standaras nsittion, 6 1861-108:1985. Method fr making test

cubes rom fea cancet: 1985

(26) Bits Staaas, Isto, BS. EN 12390-52009, Testing, tardened

oncete-fexual stegth est specimens. Min Keyes, UK: 2008

[271 Swamy RN. Savides,H. Some staustcal considerations of steel Are

Fefrced composites Cem Concr es 1975:92):201-15

{2s} Day HOW. Concrete mi design, quity contol and speciation. 2nd

‘Landon! ERFM Spon 1985

(29) Minitab 17 Stas! Sofware. [Compute sofware, State Calls, Pa:

Minitab In. sr mina cons, 2010"

30) Sao" 91. Procedures gulde Copy 2011. Cary. NC USA: SAS nstut ne

[31] Bo CEP, Hunter WG, Hunter J. Statistics for experimenters. USA: Wiley:

378,

132] Moore DS, McCabe GP. intrdetion to the practice of statisti. New

"York WH. Freeman 8 Company: 1589.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsDocument9 pagesCyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsShreyas AlagundiNo ratings yet

- Capacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationDocument17 pagesCapacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationShreyas AlagundiNo ratings yet

- Cyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementDocument7 pagesCyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementShreyas AlagundiNo ratings yet

- Evaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderDocument12 pagesEvaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderShreyas AlagundiNo ratings yet

- Support 3Document15 pagesSupport 3Shreyas AlagundiNo ratings yet

- Joint StrengthDocument37 pagesJoint StrengthShreyas AlagundiNo ratings yet

- Paper With y MX 2)Document25 pagesPaper With y MX 2)Shreyas AlagundiNo ratings yet

- Support 1.1Document87 pagesSupport 1.1Shreyas AlagundiNo ratings yet

- Performance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesDocument16 pagesPerformance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesShreyas AlagundiNo ratings yet

- Doors and WindowsDocument45 pagesDoors and WindowsShreyas AlagundiNo ratings yet

- Structural Dynamics Question PapersDocument18 pagesStructural Dynamics Question PapersShreyas AlagundiNo ratings yet

- Pes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Document26 pagesPes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Shreyas Alagundi100% (1)

- Applications of DgpsDocument11 pagesApplications of DgpsShreyas AlagundiNo ratings yet

- Nitk PG SyllabusDocument415 pagesNitk PG SyllabusShreyas AlagundiNo ratings yet