Professional Documents

Culture Documents

Acfrogc G Koejumwubtafydapfifhfud7v3tsqr Oaytcvrpg9rasyehcdmftzc7c0pxj Acrhvtnmdtssb8p6kp K4hy7wajoy2ablpb0odluz Ryxc6yln1ytevfjqi Rluzgdlih570xa2e

Acfrogc G Koejumwubtafydapfifhfud7v3tsqr Oaytcvrpg9rasyehcdmftzc7c0pxj Acrhvtnmdtssb8p6kp K4hy7wajoy2ablpb0odluz Ryxc6yln1ytevfjqi Rluzgdlih570xa2e

Uploaded by

Shreyas Alagundi0 ratings0% found this document useful (0 votes)

5 views16 pagesOriginal Title

Acfrogc g Koejumwubtafydapfifhfud7v3tsqr Oaytcvrpg9rasyehcdmftzc7c0pxj Acrhvtnmdtssb8p6kp k4hy7wajoy2ablpb0odluz Ryxc6yln1ytevfjqi Rluzgdlih570xa2e

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

5 views16 pagesAcfrogc G Koejumwubtafydapfifhfud7v3tsqr Oaytcvrpg9rasyehcdmftzc7c0pxj Acrhvtnmdtssb8p6kp K4hy7wajoy2ablpb0odluz Ryxc6yln1ytevfjqi Rluzgdlih570xa2e

Acfrogc G Koejumwubtafydapfifhfud7v3tsqr Oaytcvrpg9rasyehcdmftzc7c0pxj Acrhvtnmdtssb8p6kp K4hy7wajoy2ablpb0odluz Ryxc6yln1ytevfjqi Rluzgdlih570xa2e

Uploaded by

Shreyas AlagundiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 16

Consrtion a Building Matra 180 (2018) 65-680

Contonts lists available at ScionooDiroct

Construction and Building Materials

journal homepage: www.elsevier.com/locate/conbuildmat =

Enhancement of seismic performance of beam-column joint connections ®

using high performance fiber reinforced cementitious composites ax

Mohammad hossein Saghafi, Hashem Shariatmadar*

Departmen of Cl Enginceing, Fedo Unversity of Mashd, #0, Box 9175-1111, Mashhad, tan

+ Sx hall-scale exterior beam-column connections are cested under cyeic loads

‘The effective parameters ofthe test ae a) stirrup details in joint b) patern and type of concrete materials

{The absence of stiup at column in joint zane caused shear failure of NC connection.

¢ Substitution of NC with HPFRCC in the joint zone enkanced shear and flexural capacity.

+ Flexural failure was observed at failure stage of HPFRCC beam-column joint

ARTICLE INFO AuSTRACT

‘re Naony

feceved 20 gos 2007

Received in ese form 26 Apel 2018

‘Accepted 26 May 2018

‘vable ontne 20 June 2018,

In this paper, six hall-scale exterior beam-columan joint connections are casted and tested under cyclic

Toads to investigate and evaluate the possibilty of using high performance fiber reinforced cementitious

‘composites (HPFRCC) o remove the necessity of confining (transverse) reinforcements an solve the con

‘struction problems in beam-column joints under seismic loads. ber reinforced cementitious materials,

used in this study comprises 2% volume faction of hybrid fiber, hooked end steel fiber and hybrid macro

synthetic fibers. The basic mechanical properties of HPFRCC are determined by uniaxial tension and com

Se pression tests. The hysteretic Deavir, dutty, shes, nergy dsspation, damping characterises

Saeed cenit fn raking patterns of HPERCebeam-£)) 17). The cumulative energy

dissipation by the specimens versus diferent drift and the compat-

isons are shown in Fig. 20.

According to Fig. 20, the cumulative dissipated energy for nor-

‘mal conerete and HPFRCC connections are approximately the same

in initial stages until achieving the drift of 2.0%, due to nearly sim-

ilar modulus of elasticity of normal concrete and HPFRCC spe

mens. At the drifts higher than 2.0%, the tensile strength, shear

strength, ductility and energy dissipation capacity are enhanced

and the pinching of hysteretic loops in beam-column joint connec-

tions are minimized, due to bridging of cracks and preventing the

propagation and opening of the cracks. The HPFRCC specimens

showed better energy dissipation performance compared to nor-

‘mal concrete connection specimens. The dissipated energy from

initiation of the test until the drift of 46.0% for J1-NC, 2-NC, J1-

CCI-HPFRCC and J1-C2-HPFRCC are 50.75, 19.71, 68.81 and 78.38

kN-m, respectively and for J2-C2-HPFRCC and J2°C1-HPFRCC spec-

imens is obtained as 62.60 kN-m. By increasing the drift, 1-C2-

LHPFRCC connection specimen is capable of providing more energy

dissipation compared to that of other specimens after yielding.

According. to Fig. 21, the cumulative dissipated energy ratio of

specimens at the drift of 60% is compared with J1-NC and J2-NC

specimens. While the average cumulative dissipated energy ratio

Hystress oop

Dis.

\EEnctay disipation per

Fe eles ae)

Fig. 19, Cumulative dissipated energy and scat stihess for ey response (2)

aE

She

3m | LSB

brine)

Fle. 20, Cumulative hysteretic energy dissipation of specimens.

‘of the HPFRCC specimens at the drift of 6.0% is 1.33 and 3.45 com-

pared to J1-NC and J2-NC specimens, respectively.

3.26. Suffness degradation

Alternate stifiness of beam-column joint connection is approx-

‘mately equal to the line slope of maximum point to maximum

point in each cycle. The alternate stiffness in alternate cycles is cal-

culated by Eq. (1) (See Fig. 19}. Only the first load cycle is consid-

ered in this calculation,

VFL + IF

(ail lar]

‘The stifiness degradation due to increase in drift of each test

specimen is shown in Fig. 22. This degradation is developed by

inelastic performances due to shear and flexural cracking, warping,

a

ig. 21. comparison of cumulative

that of NC and 2 NC species

ed energy of specimens in comparison to

om Mhosin Sahai Shriatmadar/Constucton and Buding Mater 180 (2018) 665-680

of joint, nonlinear deformations of concrete, deterioration of con-

{rete cover and slip of reinforcing bars in connection specimens.

‘The lower stiffness degradation fate represents the more ductile

behavior and the higher degradation rate indicates the more brittle

response ofthe structural elements. According to Fig. 22, tifness

degradation rate of the specimens ate observed up to the drift of

3.5% due to initial damages and no identical local damages was

‘observed. However, at the drifts higher than 40%, due to uncon-

fined concrete of joint and development of shear cracks in J2-NC

specimen, the local damages in joint caused severe degradation

‘compared to HPFRCC and normal concrete specimens with seismic

details. Moreover, the removal of transverse reinforcements in

HPFRCC joint specimens has lower effects on stiffness degradation.

In J2-C2-HPFRCC specimen, mote reduction in stiffness is observed

‘due to the failure of top beam reinforcing bars atthe drift of 6.0%

3.27. Equivalent hysteretic damping ratio

‘The most common damping in structures is due to hysteretic

load-tisplacement response [32]. The equivalent damping

coefficient based on parameters from hysteretic behavior of

bbeam-column joint connection specimens are obtained by Eq. (2)

Equivalent hysteretic damping ratio represents the ratio between

the value of hysteretic energy dissipation in each cycle to energy

dissipation of a normal elastic equivalent cycle and is one of the

best criteria to minimize the pinching effect (32). According to

Fig. 19, & is the energy dissipation in each cycle and is equal to

total area under load-lisplacement hysteretic loop and Ae repre-

sents the potential elastic strain energy in equivalent linear elastic

system under static condition,

1 areaof loop

n= ag (srenor tang) 2

E& E

ZPD AAA, °

In Eq, (3), Py and Dy represent the average maximum load and,

displacement for cycle | and the effective stiffness is calculated by

Bq. (4).

Pos

Du

Equivalent hysteretic damping versus drift curve for each spec~

imen is shown in Fig. 23

For the drifts lower than 1.5%, the equivalent hysteretic damp-

ing ratio is about 5 due to similarity of cracks and limitation of

‘damages in all specimens. The damping ratio is increased by

increasing the displacement, concentrated growth of cracks and

Ker @

i

a

q

Ee

i

i

i

«wo

Fig. 22. Comparison ofstiiness in each yee up fo the di of 60% and ste of

pa

Fons

tere esas ae

ig. 25, equlalent hysteretic damping ati vorsus dit cue.

yielding of reinforcing bars. In J2-NC specimen, after the drift of

3.5%, the equivalent hysteretic damping ratio is not increased

‘due to pinching effect and strength reduction due to shea failure

‘of joint. in normal concrete specimen with seismic details and

HPFRCC, the damping ratio is increased due to plastic hinge mech-

anism, no pinching effect and inereasing of hysteretic loops. The

‘equivalent damping ratio in normal concrete connection with seis

mic details atthe drift of 6.0% is limited to 18% and this value in

HPFRCC connection specimens is increased to 20% to 30%. In

Fig. 24, the compatison between equivalent hysteretic damping

ratio of specimens compared to that of J2-NC and JI-NC specimens

at the drift of 6.0% is shown. While the average equivalent hys-

teretic damping ratio of HPFRCC specimens compared to that of

JI-NC and J2-NC specimens at the drift of 6.0% is obtained to

bel.35 and 3.38, respectively.

3.28, Damage index

‘The damage index model by Park and Ang [33] has been widely

used because of its simplicity and the fact that it has been cali-

brated using various experimental tests [34], According. to

Fig. 25, Park and Ang damage index is used for the comparison of

relative performance of beam-column joint connection specimens.

‘The damage index is expressed as follows:

ow, B

a Feb

6)

where, y isthe maximum displacement demand under cyclic load-

ing: 4. is the ultimate displacement capacity under one-directional

load. The integral partis the amount of energy dissipation under

‘eyclic loading and F, is the yield strength ofthe structure and fis

the strength degradation parameter, and its value for well rein-

forced concrete structure is 0.1 [35]

Spesiment

Fig. 28. Comparison of equivalent hysteretic daring ratio f specimens compared

toh f JUNC and 2-NC specimens athe dito GU

Missin Saha H,Shratmadar Construction and Buldig Matra 180 (2018) 665-80 on

“Drit (76)

Fig 25, Dame index versus dit in al specimens.

The damage index (D1) values vary from 0 to 1. Where, "0" rep-

resents no damage and "1" represents complete damage. In this

research, itis assumed that the DI in the range of 0< DI <0. indi

«ates elastic behavior or no damage, 0.2 < Dl«< 0.4 represents slight

damage, 0.4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsDocument9 pagesCyclic Behavior of HPFRC-repaired Reinforced Concrete Interior Beam-Column JointsShreyas AlagundiNo ratings yet

- Capacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationDocument17 pagesCapacity Models For Shear Strength of Exterior Joints in RC Frames: State-Of-The-Art and Synoptic ExaminationShreyas AlagundiNo ratings yet

- Cyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementDocument7 pagesCyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementShreyas AlagundiNo ratings yet

- Evaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderDocument12 pagesEvaluation of Beam-Column Joints Made of HPFRCC Composites To Reduce Transverse Reinforcements - Elsevier Enhanced ReaderShreyas AlagundiNo ratings yet

- Support 3Document15 pagesSupport 3Shreyas AlagundiNo ratings yet

- Joint StrengthDocument37 pagesJoint StrengthShreyas AlagundiNo ratings yet

- Paper With y MX 2)Document25 pagesPaper With y MX 2)Shreyas AlagundiNo ratings yet

- Support 1.1Document87 pagesSupport 1.1Shreyas AlagundiNo ratings yet

- Performance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesDocument16 pagesPerformance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesShreyas AlagundiNo ratings yet

- Doors and WindowsDocument45 pagesDoors and WindowsShreyas AlagundiNo ratings yet

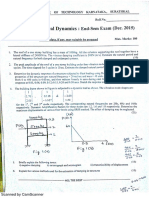

- Structural Dynamics Question PapersDocument18 pagesStructural Dynamics Question PapersShreyas AlagundiNo ratings yet

- Pes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Document26 pagesPes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Shreyas Alagundi100% (1)

- Applications of DgpsDocument11 pagesApplications of DgpsShreyas AlagundiNo ratings yet

- Nitk PG SyllabusDocument415 pagesNitk PG SyllabusShreyas AlagundiNo ratings yet