Professional Documents

Culture Documents

Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Section

Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Section

Uploaded by

nishat529Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Section

Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Section

Uploaded by

nishat529Copyright:

Available Formats

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

**ON A/C ALL Air Conditioning Pack (21–51–00)

21−50−00−001 The main functions of the air conditioning packs are:

COOLING − Condition the bleed air from the engines (or APU) and

supply it to the air distribution system

Introduction − Protect the Air Cycle Machines (ACMs) from excessively

high temperatures

The air conditioning system supplies the desired flow of conditioned

− Recirculate cool air to the pack inlet to counteract high

air to the aircraft air distribution system. The air is conditioned to the

bleed air temperatures

proper temperature and humidity required to maintain a comfortable

environment for the crew and passengers. − Remove condensed water from the conditioned air.

General Description Refer to Figures 1 , 2 and 3.

The ECS Electronic Control Unit (ECU) monitors and controls the

The air conditioning pack is part of the Environmental Control operation of the air conditioning packs. The ECU has input from the

System (ECS). It uses bleed air from the engines or Auxiliary Power selector switches on the AIR CONDITIONING control panel and from

Unit (APU) to supply conditioned air to the cabin and flight the sensors and switches located throughout the packs. The ECU

compartment. The system responds to flight crew commands and uses these inputs to monitor and control the temperature and flow

compartment temperature controls to supply a comfortable rate of the conditioned air leaving the air conditioning packs.

temperature environment for passengers and crew.

Two air cycle machines (ACMs), with one dual heat exchanger, cool

The flow control system uses pressure and temperature data to the bleed air coming from the two engines. This configuration has the

control the flow of the bleed air that enters the air conditioning pack. redundancy of two ACMs while allowing access to a much larger

The Electronic Control Unit (ECU) opens and closes the pack flow dual heat exchanger during single ACM operation.

control and shutoff valve to regulate the flow of bleed air.

The dual heat exchanger receives warm air from the pack flow

Detailed Description control and shutoff valve. The primary section of the dual heat

exchanger cools the air which then goes through two compressor

The cooling system has the sub−systems that follow: inlet check valves. These valves prevent any back flow from the

downstream ACM compressor into the primary section of the dual

− Air Conditioning Pack (21–51–00)

heat exchanger during single ACM operation.

− Flow Control System (21–52–00)

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 2

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

The ACM compresses the air and sends the warm compressed air to used only for Built In Test (BIT) purposes to monitor the efficiency of

the secondary circuit of the dual heat exchanger for cooling. The air the heat exchanger.

then goes through the condenser section of the

condenser/reheater/mixer, where water in the air is condensed into Flow Control System (21–52–00)

droplets. The cooled air then goes through the water collector where

the water droplets are collected to flow out through a drain. The drain Refer to Figure 4.

water then goes to a nozzle where it is sprayed against the ram inlet The flow control system uses pressure and temperature data to

face of the dual heat exchanger for evaporative cooling. control the flow rate of the bleed air that enters the air conditioning

The air continues on through the reheater, where it is warmed. This pack. The flow control system has three components:

relatively warm, compressed air is then expanded in the turbine − Valve, Pack Flow Control and Shutoff (21–52–01)

section of the ACM, where it is cooled. The temperature at the pack

outlet is modulated by the pack bypass valves, that introduce warm − Sensor, Absolute Pressure (21–52–06)

bleed air into the turbine outlet. The signals that control the positions − Sensor, Pack Inlet Temperature (21–52–11)

of these valves come from the Electronic Control Unit (ECU).

These components are installed in the ducting that supplies bleed air

When necessary, the temperature of the bleed air at the pack inlet is to the air conditioning pack. The two sensors supply the pressure

lowered by opening the temperature reduction valve. This valve and temperature data of the bleed air to the Electronic Control Unit

allows cooler air downstream of the secondary heat exchanger to (ECU). The ECU uses this data to open and close the pack flow

flow into the pack inlet. The temperature switch of the temperature control and shutoff valve to regulate the flow of bleed air to the air

reduction valve sends a signal to the ECU that is compared with the conditioning pack.

signal from the pack inlet temperature sensor. The ECU then

determines if the temperature reduction valve is operating correctly.

The compressor outlet overtemperature sensor supplies a signal to

reduce the pack flow if the temperature in the compressor is too high.

The compressor outlet overtemperature switch turns the ACM off if

the compressor temperature is too high. This switch supplies backup

protection in case the compressor outlet overtemperature sensor

fails.

The secondary heat exchanger outlet temperature sensor senses the

temperature at the secondary heat exchanger outlet. This signal is

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 3

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

D

FW

NOTE

Left ACM removed for clarity.

A

fs586a01.cgm

AIR CONDITIONING PACK LOCATOR

Figure 1

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 4

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

4 OW

AIR

5 FL

AIR

AIRFLOW

FL

3 6

OW

AIRFLOW

2

OW

FL

AIR

OW

FL

AIR

4

NOTE

Left ACM removed for clarity.

LEGEND

1. Conditioned Air Supply.

2. Engine Bleed Air.

3. Ram Air.

1 4. Ram Air Exhaust.

5. Emergency Ram Air.

6. APU Bleed Air.

7. Recirculated Air.

OW

FL 7

AIR

W

F LO

AIR

fsb52a01.cgm

AIR CONDITIONING PACK AIRFLOW

Figure 2

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 5

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

SECONDARY

HEAT EXCHANGER

TEMPERATURE TEMPERATURE SENSOR

REDUCTION

VALVE

AIR

S CYCLE

MACHINE TURBINE

P

SHUTOFF

T VALVE

FAN BYPASS F GROUND AIR (21−23−00)

CHECK VALVE C T

REHEATER

COMPRESSOR T

INLET CHECK

VALVES

DUAL HEAT

SECONDARY

SPRAY TURBINE

EXCHANGER

PRIMARY

NOZZLE RAM SHUTOFF TO CABIN

MIXER

RAM INLET VALVE AND FLIGHT (21−21−00)

AIR P T COMPARTMENT (21−22−00)

OUT DISTRIBUTION

COMPRESSOR

OUTLET

TEMPERATURE

SWITCH CONDENSOR

WATER

T COLLECTOR

LEGEND

FAN BYPASS C WATER

CHECK VALVE

T

F C ACM COMPRESSOR

F ACM FAN

T ACM TURBINE

BLEED(36−11−00) AIR S

PACK SOLENOID VALVE

AIR IN CYCLE P

MACHINE BYPASS

T VALVE P T PNEUMATIC TORQUE MOTOR VALVE

RECIRCULATION

M FAN TEMPERATURE SWITCH

PACK

ABSOLUTE PACK INLET P

BYPASS FROM CABIN COMPRESSOR OUTLET

PRESSURE TEMPERATURE T VALVE

SENSOR SWITCH T TEMPERATURE SENSOR

TEMPERATURE

P REDUCTION VALVE

SWITCH DUAL ELEMENT TEMPERATURE SENSOR

EMEREGENCY (21−24−00)

PACK FLOW P P PRESSURE SENSOR

RAM AIR

CONTROL T

VALVE F POSITION SWITCH

F

FLOW CONTROL (21−52−00) CHECK VALVE

SYSTEM

fsb47a01.cgm

AIR CONDITIONING PACK SCHEMATIC

Figure 3

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 6

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

LEGEND

TO AIR P T PNEUMATIC TORQUE MOTOR VALVE

CONDITIONING F POSITION SWITCH

PACK

DUAL ELEMENT TEMPERATURE SENSOR

P PRESSURE SENSOR

P T F

TORQUE MOTOR OUTPUT

SENSOR INPUT PACK FLOW CONTROL

AND SHUTOFF VALVE

P

SENSOR INPUT

PACK INLET

TEMPERATURE

SENSOR

ECS ELECTRONIC CONTROL UNIT

ABSOLUTE

PRESSURE SENSOR

BLEED AIR

FROM ENGINES

OR APU

fsb48a01.cgm

FLOW CONTROL SYSTEM

Figure 4

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 7

Aug 05/2008

E

AIRCRAFT MAINTENANCE MANUAL − SYSTEM DESCRIPTION SECTION

THIS PAGE INTENTIONALLY LEFT BLANK

PSM 1−84−2A − MASTER

EFFECTIVITY:

See first effectivity on page 2 of 21−50−00 Config 001

Config 001

21−50−00 Page 8

Aug 05/2008

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- A320 21 Air Conditioning SystemDocument41 pagesA320 21 Air Conditioning SystemBernard Xavier95% (22)

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- A320 ApuDocument11 pagesA320 ApuEdwar ZulmiNo ratings yet

- A380-LEVEL I - ATA 21 Air ConditioningDocument62 pagesA380-LEVEL I - ATA 21 Air ConditioningAbolfazl Mazloomi100% (10)

- 01-CPD-8, Civil Aviation Procedure Document On Airworthiness-MinDocument884 pages01-CPD-8, Civil Aviation Procedure Document On Airworthiness-Minnishat529100% (1)

- Powerplant Q400Document282 pagesPowerplant Q400nishat529100% (2)

- Hyosung GV650Document223 pagesHyosung GV650panpols1100% (3)

- GE Gas Turbine Generator Frame 6 Spare PartsDocument2 pagesGE Gas Turbine Generator Frame 6 Spare PartsAxelrose04100% (1)

- Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description SectionDocument23 pagesCooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- 21 AIR CONDITIONING RDocument84 pages21 AIR CONDITIONING Rescobaragustin161No ratings yet

- Aero Technology Dgca Easa Module 15 Part 6 EngineDocument32 pagesAero Technology Dgca Easa Module 15 Part 6 EnginemarshallNo ratings yet

- Q400-Air Cond and PressDocument38 pagesQ400-Air Cond and PressMoshiurRahman100% (2)

- Ata 21aircond l1Document42 pagesAta 21aircond l1svyat_kNo ratings yet

- Ata 21 Air ConditioningDocument82 pagesAta 21 Air ConditioningSohaib Aslam ChaudharyNo ratings yet

- B737-6 21 Jar B1 e (Jun2004 CMP)Document198 pagesB737-6 21 Jar B1 e (Jun2004 CMP)Belisario Sergio Llacchas rodasNo ratings yet

- 21 Air ConditioningDocument88 pages21 Air ConditioningmvchithranganiNo ratings yet

- ATA 21 Air Conditioning SJI-MT-RRJ95B / T1-T2 Rev 3.0 January 2013Document203 pagesATA 21 Air Conditioning SJI-MT-RRJ95B / T1-T2 Rev 3.0 January 2013ErichCastrejónRodriguezNo ratings yet

- 21 Air ConditioningDocument232 pages21 Air ConditioningAle Torrico TamayoNo ratings yet

- B 737-6/7/8/900 Boeing: ATA 21 Air ConditioningDocument20 pagesB 737-6/7/8/900 Boeing: ATA 21 Air ConditioningBelisario Sergio Llacchas rodasNo ratings yet

- Level II - Ata 36-21-30 Air SystemsDocument88 pagesLevel II - Ata 36-21-30 Air SystemswagdiNo ratings yet

- A319 A320 A321 21z Sistema Aire AcondicionadoDocument330 pagesA319 A320 A321 21z Sistema Aire Acondicionadomarcelojm7No ratings yet

- A330Document79 pagesA330Dipendra Sen100% (1)

- Single Aisle Technical Training Manual T2 (IAE V2500) (LVL 2&3) Air ConditioningDocument90 pagesSingle Aisle Technical Training Manual T2 (IAE V2500) (LVL 2&3) Air ConditioningNavin TiwaryNo ratings yet

- 1 2seDocument7 pages1 2sePapitos TodoparabebesNo ratings yet

- System AND: Maintenance ManualDocument14 pagesSystem AND: Maintenance ManualBeka KarumidzeNo ratings yet

- Amta 329 - MedallaDocument8 pagesAmta 329 - MedallaBENoNo ratings yet

- SECTION 2-09 Auxiliary Power Unit: Airplane Operations ManualDocument14 pagesSECTION 2-09 Auxiliary Power Unit: Airplane Operations ManualAnish ShakyaNo ratings yet

- CH21Document15 pagesCH21ranjit prasadNo ratings yet

- SDS1230 21 51 00Document30 pagesSDS1230 21 51 00นาถวัฒน์ ฉลาดแย้มNo ratings yet

- ML B 200 b200mm145Document12 pagesML B 200 b200mm145robson lopes bezerraNo ratings yet

- Cessna Citation X-Pressurization and Environmental SystemDocument18 pagesCessna Citation X-Pressurization and Environmental SystemDVSNo ratings yet

- McDonnell Douglas DC-10-40-Air Cond and Press PDFDocument15 pagesMcDonnell Douglas DC-10-40-Air Cond and Press PDFFMMServicesNo ratings yet

- # Air Conditioning - General:: Note For CPC Manual ModeDocument30 pages# Air Conditioning - General:: Note For CPC Manual Modejontis jasoliyaNo ratings yet

- A330-200 PneumaticDocument42 pagesA330-200 PneumaticTarik BenzinebNo ratings yet

- B Ata 21Document175 pagesB Ata 21Horacio Quispe FernandezNo ratings yet

- 787故障快速处理参考手册R2Document211 pages787故障快速处理参考手册R2Chen AndyNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Air ConditioningDocument130 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Air ConditioningРоман ДяченкоNo ratings yet

- 36 PneumaticDocument50 pages36 PneumaticduythienddtNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) PneumaticDocument32 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) PneumaticjuanNo ratings yet

- SDS1230 21 50 00Document6 pagesSDS1230 21 50 00นาถวัฒน์ ฉลาดแย้มNo ratings yet

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticDocument50 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticAnh NguyenXuanNo ratings yet

- Electronic Control Unit CoolingDocument2 pagesElectronic Control Unit CoolingPédro GONZALEZNo ratings yet

- Training Manual A 318: ATA 21 Air ConditionDocument17 pagesTraining Manual A 318: ATA 21 Air ConditionbnolascoNo ratings yet

- Ata 36 PneumaticDocument30 pagesAta 36 PneumaticSohaib Aslam ChaudharyNo ratings yet

- 36 Pneumatic RDocument56 pages36 Pneumatic Rescobaragustin161No ratings yet

- AMTA 329 - Abay-AbayDocument2 pagesAMTA 329 - Abay-AbayBENoNo ratings yet

- Airbus 21 A300 A310 Air ConditioningDocument146 pagesAirbus 21 A300 A310 Air ConditioningElijah Paul Merto100% (3)

- Amta 329-Cabin Atmosphere Control System Dornier 328-JetDocument2 pagesAmta 329-Cabin Atmosphere Control System Dornier 328-JetBENoNo ratings yet

- Atomizing Air SysDocument6 pagesAtomizing Air SysMoses TanNo ratings yet

- Eec - Pcu - FadecDocument9 pagesEec - Pcu - FadecWilliam XavierNo ratings yet

- 47 Fuel InertingDocument28 pages47 Fuel InertingTamara AntonyNo ratings yet

- Sfi SystemDocument96 pagesSfi SystemWawan SatiawanNo ratings yet

- 21 Air ConditioningDocument196 pages21 Air Conditioningfourj74780% (5)

- Ata 21 Air Conditioning PDFDocument38 pagesAta 21 Air Conditioning PDFEDUARDO RAFAEL GRANJA RIVERA100% (1)

- Ata70 320Document130 pagesAta70 320Kais Graidia100% (4)

- Air Conditioning SystemDocument2 pagesAir Conditioning SystemMelvin MateoNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Battery System Adjustment and Test: Aircraft Maintenance ManualDocument3 pagesBattery System Adjustment and Test: Aircraft Maintenance Manualnishat529No ratings yet

- Department of Transport Master Minimum Equipment List Ministere Des Transports List Principale DDocument2 pagesDepartment of Transport Master Minimum Equipment List Ministere Des Transports List Principale Dnishat529No ratings yet

- Aircraft Maintenance Manual: TASK 24 00 00 861 801Document9 pagesAircraft Maintenance Manual: TASK 24 00 00 861 801nishat529No ratings yet

- Temporary Revision 21 043: Filing InstructionsDocument16 pagesTemporary Revision 21 043: Filing Instructionsnishat529No ratings yet

- Aircraft Maintenance Manual: TASK 24 00 00 861 801Document6 pagesAircraft Maintenance Manual: TASK 24 00 00 861 801nishat529No ratings yet

- Battery System: Aircraft Maintenance Manual System Description SectionDocument30 pagesBattery System: Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- Battery System: Aircraft Maintenance Manual System Description SectionDocument23 pagesBattery System: Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- 02-CPD-8-02, Civil Aviation Procedure Document On Airworthiness Inspector Training System-MinDocument142 pages02-CPD-8-02, Civil Aviation Procedure Document On Airworthiness Inspector Training System-Minnishat529No ratings yet

- Battery System: Aircraft Maintenance Manual System Description SectionDocument33 pagesBattery System: Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description SectionDocument23 pagesCooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- 14-ANO (Airworthiness) Part-147, Approved Maintenance Training Organization-MinDocument57 pages14-ANO (Airworthiness) Part-147, Approved Maintenance Training Organization-Minnishat529No ratings yet

- Dgca Module 15 Part 6Document3 pagesDgca Module 15 Part 6nishat529No ratings yet

- 15a. CH 61 - Props q400Document66 pages15a. CH 61 - Props q400nishat529100% (1)

- Dgca Module 15 Part 5Document14 pagesDgca Module 15 Part 5nishat529100% (1)

- Dgca Module 15 Part 2Document24 pagesDgca Module 15 Part 2nishat529100% (1)

- Dgca Module 15 Part 4Document19 pagesDgca Module 15 Part 4nishat529No ratings yet

- Methodology For Setting Up Questions For Examination (AME)Document21 pagesMethodology For Setting Up Questions For Examination (AME)nishat529No ratings yet

- Pareto Analysis of Aircraft DefectsDocument1 pagePareto Analysis of Aircraft Defectsnishat529No ratings yet

- JS200 - Electrics ErrorDocument4 pagesJS200 - Electrics ErrorMarcelo Lana100% (1)

- Daily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1Document12 pagesDaily Progress Report: Engineering, Procurement and Construction of Sarqala-3 Well Connection To CPF at Sarqala-1rashid kNo ratings yet

- Friction and Wear Testing MachineDocument7 pagesFriction and Wear Testing MachineElkallati FettahNo ratings yet

- Automobile EngineeringDocument3 pagesAutomobile EngineeringSourabh SumanNo ratings yet

- Steyr Marine Engines: Spare Parts CatalogueDocument151 pagesSteyr Marine Engines: Spare Parts CatalogueMartin FrancoNo ratings yet

- Assignment 4 Reciprocating Air CompressorsDocument8 pagesAssignment 4 Reciprocating Air CompressorsAkshay A KumarNo ratings yet

- Aria Electronic Multiprocessor ControllerDocument60 pagesAria Electronic Multiprocessor Controllerelshan_asgarov100% (1)

- Lathe ReportDocument11 pagesLathe ReportWan Syafiq Wan Syamsulbahri100% (2)

- Pneumatic Air GunDocument14 pagesPneumatic Air GunsivaramkumarNo ratings yet

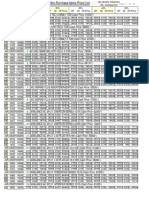

- HP CurrentPriceListZero NormalDocument46 pagesHP CurrentPriceListZero NormalMuneeba AttiqueNo ratings yet

- QSB3.3 CM2250 B137 5411062Document1 pageQSB3.3 CM2250 B137 5411062Cristobal HenriquezNo ratings yet

- Broad X Non-Electric Chiller: Model Selection & Design ManualDocument27 pagesBroad X Non-Electric Chiller: Model Selection & Design ManualdokundotNo ratings yet

- Over Hauling of 125 KVA DG SetDocument6 pagesOver Hauling of 125 KVA DG SetmukelectNo ratings yet

- Sendzimir MillDocument11 pagesSendzimir Millanil khuntiaNo ratings yet

- Hydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuDocument42 pagesHydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuCarlos Alberto BaptistaNo ratings yet

- DC Compound MotorsDocument5 pagesDC Compound MotorsDionimar DiscionNo ratings yet

- Detailed Notes - Section 06 Thermal Physics - AQA Physics A-LevelDocument9 pagesDetailed Notes - Section 06 Thermal Physics - AQA Physics A-LevelDeepesh SureshNo ratings yet

- Worm GearsDocument31 pagesWorm Gearsmohammad khoraminiaNo ratings yet

- MS 01 54Document6 pagesMS 01 54fagundds2No ratings yet

- API 2C (2004) Specification For Offshore Pedestal Mounted CranesDocument51 pagesAPI 2C (2004) Specification For Offshore Pedestal Mounted CranesDenisNo ratings yet

- Nissan Livina L11 - Engine Control SystemDocument629 pagesNissan Livina L11 - Engine Control SystemH. Yusmira (Kang Otto)No ratings yet

- NPTEL Course Developer For Fluid Mechanics Dr. Niranjan Sahoo Module 04 Lecture 33 IIT-GuwahatiDocument4 pagesNPTEL Course Developer For Fluid Mechanics Dr. Niranjan Sahoo Module 04 Lecture 33 IIT-GuwahatilawanNo ratings yet

- Evaluation of Engine Oils For Roller Follower Wear in Light-Duty Diesel EngineDocument19 pagesEvaluation of Engine Oils For Roller Follower Wear in Light-Duty Diesel Enginemohammed karasnehNo ratings yet

- Steel Design - Tradeoff On Structural System, Excel ProgramDocument299 pagesSteel Design - Tradeoff On Structural System, Excel ProgramEmmanuel Lazo100% (1)

- Separation of Multiphase Multicomponent SystemDocument812 pagesSeparation of Multiphase Multicomponent Systemkrit_kasem100% (1)

- Structural Design of g+4 Mixeduse Building and Software DevelopmentDocument343 pagesStructural Design of g+4 Mixeduse Building and Software DevelopmentyimamNo ratings yet

- Relativistic Dynamics: Notes OnDocument53 pagesRelativistic Dynamics: Notes OnMuhammad YounasNo ratings yet

- Friction Loss Charts 2008Document36 pagesFriction Loss Charts 2008idiayNo ratings yet