Professional Documents

Culture Documents

Instructions For The Safe Use Of: Shackles

Instructions For The Safe Use Of: Shackles

Uploaded by

reda mesbahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instructions For The Safe Use Of: Shackles

Instructions For The Safe Use Of: Shackles

Uploaded by

reda mesbahCopyright:

Available Formats

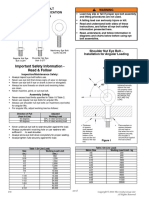

Instructions for the safe use of:

Shackles

The information in this leaflet should be passed to the user of the equipment

This document is issued in accordance with the requirements of Never galvanise or subject a shackle to other plating processes

Section 6 of the Health and Safety at Work etc Act 1974, without the approval of the supplier.

amended March 1988. It outlines the care and safe use of

SHACKLES and is based on Section 18 of the LEEA Code of Using Shackles Safely

Practice for the Safe Use of Lifting Equipment. It should be read Do not attempt lifting operations unless you understand the use

in conjunction with the requirements for general purpose of the equipment, the slinging procedures and the mode factors

slinging practice given overleaf, the principles of which may be to be applied.

applied to the use of shackles with or without slings.

Do not use defective shackles or unidentified pins.

This information is of a general nature only covering the main

points for the safe use of shackles. It may be necessary to Shackles should be fitted so that the body takes the load along

supplement this information for specific applications. its centre line and is not subjected to side bending loads. When

connecting a number of sling legs, and similar applications,

position them so that they do not impose a side load on the

ALWAYS: shackle jaws. Use spacers to position them if necessary.

Ensure the pin is correctly screwed into the shackle eye.

• Store and handle shackles correctly. Tighten by hand, use a small bar to lock the collar to the

• Inspect shackles before use and before placing into storage. shackle eye. Check that the thread is fully engaged with the

• Select the correct pattern of shackle and pin for the body but is not too long so that tightening causes the body to

application. deform.

• Allow for the full resultant imposed load. With bolt and nut pins ensure the nut jams on the inner end of

the thread and not on the eye of the shackle. The bolt should be

• Fully tighten the pin. free to rotate with minimal side float. The split cotter pin must be

• Ensure the load acts through the centre line of the shackle fitted before making a lift.

using spacers if necessary to meet this requirement. When using shackles with slings in choke hitch, or in other

applications where there may be movement, place the pin

NEVER: through the eye or link of the sling and never in contact with the

• Use shackles with bent pins or deformed bodies. bight of the choke or moving parts which may cause the pin to

unscrew.

• Force, hammer or wedge shackles into position.

• Eccentrically load shackles. In-service Inspection and Maintenance

• Replace the pin with a bolt. Maintenance requirements are minimal. Keep shackles clean,

the threads free of debris and protect from corrosion.

• Fit pins in contact with moving parts which may loosen or

unscrew them. Regularly inspect shackles and, in the event of the following

defects, refer the shackle to a Competent Person for thorough

• Shock load shackles. examination: illegible markings; distorted, worn, stretched or

bent body; bent pin; damaged or incomplete thread forms;

nicks, gouges, cracks or corrosion; incorrect pin; any other

Selecting the Correct Shackle defect.

Shackles are available in a range of material grades, sizes and

designs. Select the shackle to be used and plan the lift taking © Lifting Equipment Engineers Association 2011 SI No. 6.3

the following into account:

Type of shackle to be used - dee or bow, British Standard or Further information is given in:

other design. The Code of Practice for the Safe Use of Lifting Equipment,

published by:

Type of pin - screwed with collar and eye are suitable for

general purposes; with countersunk head for where clearance

is limited; bolt and nut for where the pin may be out of sight or LIFTING EQUIPMENT ENGINEERS ASSOCIATION

subject to movement. 3 Osprey Court, Kingfisher Way,

Full resultant imposed load - when using shackles with multi-leg Hinchingbrooke business Park, Huntingdon,

slings remember that as the included angle increases and so Cambridgeshire. PE29 6FN.United Kingdom

does the load in the leg and any attachment to the leg. When Tel: + 44 (0) 1480 432801

used to suspend pulley blocks account must be taken of the Fax: + 44 (0) 1480 436314

imposed load due to operating effort.

E-mail: mail@leea.co.uk

CAUTION: BS and ISO Standard shackles are designed and Website: www.leeaint.com

rated for the pin to accept a central point load. Other, commonly

available, types are designed and rated for the load to be

evenly distributed over the full width of the pin. Unless the basis

for rating is clearly stated it should be assumed that the jaw

must be fully filled and the load evenly spread across the

shackle pin width.

Storing and Handling Shackles

Never return damaged shackles to storage. They should be dry,

clean and protected from corrosion.

Do not alter, modify or repair shackles and never replace

missing pins with unidentified pins, bolts etc, but refer such

matters to a Competent Person.

GENERAL PURPOSE SLINGING PRACTICE

The following information is based on Section 1 - Appendix 1.5

Operative Training

of the LEEA Code of Practice for the Safe Use of Lifting Slings should only be used by trained operatives who

Equipment. It should be read in conjunction with the instructions understand the methods of rating and application of mode

for the safe use, given overleaf, of which it forms an integral factors.

part and with any specific instructions issued by the supplier.

Safe use of Slings

This information is of a general nature only covering the main

points for the safe use of various types of slings for general o Good slinging practice must ensure that the load is as safe

lifting purposes. and secure in the air as it was on the ground and that no

harm is done to the load, lifting equipment, other property or

persons.

ALWAYS: o Establish the weight of the load, ensure the lifting method is

• Plan the lift, establish the weight of the load and prepare the suitable and inspect the sling and attachments for obvious

landing area ensuring that it will take the weight. defects. Prepare the landing area making sure the floor is

strong enough to take the load. Follow any specific

• Check slings and equipment are free of damage, use instructions from the supplier.

slings/slinging methods suitable for the load and protect

slings from sharp edges and corners. o Ensure the lifting point is over the centre of gravity. Any loose

parts of the load should be removed or secured. Secure the

• Attach the sling securely to the load and appliance and sling firmly to the load by hooks onto lifting points or shackles

position hooks to face outwards. etc. The sling must not be twisted, knotted or kinked in any

• Ensure the load is balanced and will not tilt or fall. way.

• Keep fingers, toes etc clear when tensioning slings and when o Use packing to prevent damage to the sling from corners or

landing loads. edges and to protect the load.

• Ensure that the load is free to be lifted. o Do not exceed the SWL or rated angle. Any choke angle

must not exceed 120° and any basket 90°.

• Make a trial lift and trial lower.

o Do not hammer, force or wedge slings or accessories into

NEVER: position; they must fit freely.

• Use damaged slings or accessories. o When attaching more than one sling to the hook of the

• Twist, knot or tie slings. appliance use a shackle to join the slings and avoid

overcrowding the hook.

• Hammer slings into position.

o Use an established code of signals to instruct the crane

• Overload slings due to the weight of the load or the mode of driver.

use.

o Ensure the load is free to be lifted and not, for example,

• Trap slings when landing the load. bolted down.

• Drag slings over floors etc or attempt to pull trapped slings o Check that there are no overhead obstacles such as power

from under loads. lines.

• Allow personnel to ride on loads. o Keep fingers, toes etc clear ensuring they do not become

trapped when lifting, lowering or controlling loads.

Sling Configurations and Rating o Make a trial lift by raising the load a little to ensure it is

balanced, stable and secure and if not lower it and adjust the

Slings are available in single, two, three and four leg or endless slinging arrangement.

form. In practice it will be found that chain, wire rope and fibre

o Where appropriate use tag lines to control the load.

rope slings are available in any of these configurations but that

flat woven webbing is limited to single leg and endless whilst o Except where special provision is made, do not allow anyone

roundslings are only supplied in endless form. The maximum to pass under or ride upon the load. The area should be kept

load that a sling may lift in use will be governed by the slinging clear.

arrangement (mode of use) and may vary from the marked o Make a trial set down, ensure the sling will not become

SWL. In the case of textile slings the SWL for the various trapped and the load will not tip when the slings are released.

modes of use is usually given on the information label. In other Use supports which are strong enough to sustain the load

cases it is necessary to multiply the marked SWL by a mode without crushing.

factor.

o Never drag slings over floors etc or attempt to drag a trapped

The following three simple rules will ensure that the sling is not sling from under a load.

overloaded. In some cases this will mean that the sling will be

under utilised although this is unlikely to hinder the user unduly. o Never use a sling to drag a load.

Where the maximum utilisation is required reference should be o Place the hooks of free legs back onto the master link and

made to a Competent Person who understands the factors take care to ensure that empty hooks do not become

involved and who can perform the necessary calculations. accidentally engaged.

(1) For straight lift never exceed the marked SWL and in the o Never use slings in contact with chemicals or heat without the

case of multi-leg slings the specified angle or range of manufacturers approval.

angles.

o Never use damaged or contaminated slings.

(2) When using slings in choke hitch multiply the marked SWL

o On completion of the lift return all equipment to proper

by 0.8 to obtain the reduced maximum load the sling may

storage.

lift ie reduce the safe working load by 20%.

(3) With multi-leg slings, when using less than the full number

of legs, reduce the maximum load in proportion to the Further information is given in:

number of legs in use. Simply multiply the marked SWL by LEEA Code of Practice for the Safe Use of Lifting Equipment.

the number of legs in use expressed as a fraction of the Various British Standards covering individual products.

total thus: one leg of a two leg sling = ½ marked SWL,

three legs of a four leg sling = ¾ marked SWL and so on.

SI GSP 1.2 (2011)

You might also like

- 03 AGT Written Exam With AnswersDocument2 pages03 AGT Written Exam With Answersreda mesbah67% (3)

- SOP Gantry Crane or HoistDocument5 pagesSOP Gantry Crane or Hoistrizki hsb100% (2)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNo ratings yet

- Catalogo Llave de VarillaDocument38 pagesCatalogo Llave de VarillaWilson Cendales100% (1)

- Current Trends in Public Health: Global and National: - Rona Grace "Ging" Tabujara, RN, MMDocument15 pagesCurrent Trends in Public Health: Global and National: - Rona Grace "Ging" Tabujara, RN, MMCzarina Dawn BelargaNo ratings yet

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: ShacklesAmeerUlHaqNo ratings yet

- Instructions For Safe Use ShacklesDocument2 pagesInstructions For Safe Use ShacklesNickNo ratings yet

- Wire Rope Slings SI 2.3Document2 pagesWire Rope Slings SI 2.3reda mesbahNo ratings yet

- QMF 123 Instructions For The Use of Wedge SocketsDocument2 pagesQMF 123 Instructions For The Use of Wedge Socketsmanglesh1No ratings yet

- Eyebolts SI 7.4Document2 pagesEyebolts SI 7.4reda mesbahNo ratings yet

- Chain Slings SI 1.3Document2 pagesChain Slings SI 1.3reda mesbahNo ratings yet

- Instructions For The Safe Use Of: Chain SlingsDocument2 pagesInstructions For The Safe Use Of: Chain SlingsMontadhar SaeedNo ratings yet

- Instructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentDocument2 pagesInstructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentMontadhar SaeedNo ratings yet

- Safe Use of Eyeblts Dlhonline PDFDocument2 pagesSafe Use of Eyeblts Dlhonline PDFMoetaz MohamedNo ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- Instructions For The Safe Use Of: Fibre Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Fibre Rope SlingsMontadhar SaeedNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- Instructions For The Safe Use Of: Flat Woven Webbing SlingsDocument2 pagesInstructions For The Safe Use Of: Flat Woven Webbing SlingsMontadhar SaeedNo ratings yet

- Lifting Beams and Spreaders SI 8.3Document2 pagesLifting Beams and Spreaders SI 8.3reda mesbahNo ratings yet

- Instructions For The Safe Use Of: Beam ClampsDocument2 pagesInstructions For The Safe Use Of: Beam ClampsMontadhar SaeedNo ratings yet

- Instructions For The Safe Use Of: EyeboltsDocument2 pagesInstructions For The Safe Use Of: Eyeboltsdsn_sarmaNo ratings yet

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

- Instructions For The Safe Use of Flat Woven Webbing SlingsDocument4 pagesInstructions For The Safe Use of Flat Woven Webbing SlingsavisheklochunNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- Hand Operated Chain Lever Hoists SI 12.3Document2 pagesHand Operated Chain Lever Hoists SI 12.3reda mesbahNo ratings yet

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNo ratings yet

- Windows-1256 - Hand Operated Chain Lever HoistsDocument2 pagesWindows-1256 - Hand Operated Chain Lever HoistsFenner ElectromechanicalNo ratings yet

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- Instructions For The Safe Use Of: Hand Operated Chain Lever HoistsDocument2 pagesInstructions For The Safe Use Of: Hand Operated Chain Lever HoistsMontadhar SaeedNo ratings yet

- Instructions For The Safe Use of Vertical Plate ClampsDocument1 pageInstructions For The Safe Use of Vertical Plate ClampsrewmarineNo ratings yet

- Instructions For The Safe Use Of: RunwaysDocument2 pagesInstructions For The Safe Use Of: Runwaysreda mesbahNo ratings yet

- Efogen Rigging SlingingDocument52 pagesEfogen Rigging SlingingBalasuperamaniam RamanNo ratings yet

- Quantum SkillUp Work Instruction Manual For Spreader BeamsDocument2 pagesQuantum SkillUp Work Instruction Manual For Spreader BeamsbeshoyNo ratings yet

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocument2 pagesLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979No ratings yet

- Shackles PDFDocument1 pageShackles PDFPrimelift Safety Resources LimitedNo ratings yet

- Handbook Lifting Load SafelyDocument17 pagesHandbook Lifting Load SafelyAlok SinghNo ratings yet

- Instructions For The Safe Use Of: Beam ClampsDocument2 pagesInstructions For The Safe Use Of: Beam ClampsRonny AndalasNo ratings yet

- Instructions For The Safe Use Of: Travelling Girder TrolleysDocument2 pagesInstructions For The Safe Use Of: Travelling Girder TrolleysMuhammad Umair RasheedNo ratings yet

- Dos and Donts in Metallic Expansion Joints InstallationDocument1 pageDos and Donts in Metallic Expansion Joints InstallationoconcheiroNo ratings yet

- Safe Rigging PracticesDocument86 pagesSafe Rigging Practicesmagantiramudu94% (34)

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- Instructions For The Safe Use Of: Jacks: AlwaysDocument1 pageInstructions For The Safe Use Of: Jacks: Alwaysreda mesbahNo ratings yet

- Rigging HardwareDocument18 pagesRigging HardwareARULSELVAN MURUGESANNo ratings yet

- Lay-Out or Assemble Scaffolds and BracesDocument37 pagesLay-Out or Assemble Scaffolds and BracesagtwtcNo ratings yet

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsDocument2 pagesImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsiLLeno 23No ratings yet

- Milwaukee HoistDocument40 pagesMilwaukee HoistenkelectricalttNo ratings yet

- Mooring and UnmooringDocument7 pagesMooring and UnmooringDnv Bailey0% (1)

- EN - Polea Con FrenoDocument16 pagesEN - Polea Con FrenoEmmanuel CardosoNo ratings yet

- Chain Installation: Safety PrecautionsDocument16 pagesChain Installation: Safety PrecautionsAlejandro RodriguezNo ratings yet

- Care in Use Pipe HooksDocument2 pagesCare in Use Pipe Hooksdsn_sarmaNo ratings yet

- Safe Rigging/proper Rigging/safety in Rigging/rigging/safetyDocument49 pagesSafe Rigging/proper Rigging/safety in Rigging/rigging/safetyJun Kho100% (1)

- Illustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringFrom EverandIllustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringNo ratings yet

- Cs Shipping HazardsDocument28 pagesCs Shipping Hazardsreda mesbahNo ratings yet

- Appointed Person (Lifting Operations)Document2 pagesAppointed Person (Lifting Operations)reda mesbah100% (1)

- Confined Space Pre-Entry Checklist: Mark The Appropriate Column: X Yes, X No, or X N/A Not ApplicableDocument4 pagesConfined Space Pre-Entry Checklist: Mark The Appropriate Column: X Yes, X No, or X N/A Not Applicablereda mesbahNo ratings yet

- Library Leader: A Lonely Rider or A Team Inspirator? The X Factor" Antonia ArahovaDocument103 pagesLibrary Leader: A Lonely Rider or A Team Inspirator? The X Factor" Antonia Arahovareda mesbahNo ratings yet

- AGT Exam With AnswersDocument4 pagesAGT Exam With Answersreda mesbahNo ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry Permitreda mesbahNo ratings yet

- C-41 Aramco Man-Riding OperationsDocument3 pagesC-41 Aramco Man-Riding Operationsreda mesbahNo ratings yet

- Presenter Tip: To Demonstrate The Difference Between Supplying Air Into A Confined Space (Called "Pushing Air")Document2 pagesPresenter Tip: To Demonstrate The Difference Between Supplying Air Into A Confined Space (Called "Pushing Air")reda mesbahNo ratings yet

- Building & Sustaining Teams: 2005 Talent Development High Schools Polytechnic High School, Sun Valley, CaDocument40 pagesBuilding & Sustaining Teams: 2005 Talent Development High Schools Polytechnic High School, Sun Valley, Careda mesbahNo ratings yet

- Air Winch Man Riding Safe Operating Procedure Safe Man Riding OperationDocument2 pagesAir Winch Man Riding Safe Operating Procedure Safe Man Riding Operationreda mesbahNo ratings yet

- Gasalert Extreme Quick Reference Operations Key: IecexDocument1 pageGasalert Extreme Quick Reference Operations Key: Iecexreda mesbahNo ratings yet

- Ventilation in Confined SpaceDocument2 pagesVentilation in Confined Spacereda mesbahNo ratings yet

- 2021 VW Maintenance Schedule - All Models Except E-Golf: Service Intervals in MilesDocument2 pages2021 VW Maintenance Schedule - All Models Except E-Golf: Service Intervals in Milesreda mesbahNo ratings yet

- Hydrogen - Sulphide - EN MSDSDocument8 pagesHydrogen - Sulphide - EN MSDSreda mesbahNo ratings yet

- Tank ConfigurationsDocument2 pagesTank Configurationsreda mesbahNo ratings yet

- Portable Detector Overview: FeaturesDocument1 pagePortable Detector Overview: Featuresreda mesbahNo ratings yet

- Majlis MagazineDocument58 pagesMajlis Magazinereda mesbahNo ratings yet

- 2019 VW Maintenance Schedule - All Models Except E-Golf: Service Intervals in MilesDocument2 pages2019 VW Maintenance Schedule - All Models Except E-Golf: Service Intervals in Milesreda mesbahNo ratings yet

- Volkswagen CC FL BrochureDocument27 pagesVolkswagen CC FL Brochurereda mesbahNo ratings yet

- OCO Stage 1 Training Revision 1 January 2021Document30 pagesOCO Stage 1 Training Revision 1 January 2021reda mesbahNo ratings yet

- NQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceDocument3 pagesNQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceNGUYỄN THẾ VIỆT QUANGNo ratings yet

- Project ReportDocument10 pagesProject ReportPranoti nagesh SolapureNo ratings yet

- Qud 0014 R1 PDFDocument1 pageQud 0014 R1 PDFcdnaveenNo ratings yet

- CLCTD Date PCT Code OriginDocument35 pagesCLCTD Date PCT Code OriginMuhammad YousufNo ratings yet

- Safety in Materials Science LabDocument3 pagesSafety in Materials Science Labmohammad majeedNo ratings yet

- Kadapa of Regular and Contract DoctorsDocument12 pagesKadapa of Regular and Contract DoctorsJash InfraNo ratings yet

- Henderson CombinedDocument28 pagesHenderson CombinedjonsokolowNo ratings yet

- Pranayama and Meditation: Unit - 2Document25 pagesPranayama and Meditation: Unit - 2anitha sNo ratings yet

- Checklist - Turning Client To Lateral or Prone PositionDocument3 pagesChecklist - Turning Client To Lateral or Prone PositionNorhaina AminNo ratings yet

- Realisasi Rencana Strategis Kepala Bidang Keperawatan Dalam Menerapkan Sistem Informasi Manajemen KeperawatanDocument6 pagesRealisasi Rencana Strategis Kepala Bidang Keperawatan Dalam Menerapkan Sistem Informasi Manajemen KeperawatanRia WahidahNo ratings yet

- Questionnaire Template 08Document7 pagesQuestionnaire Template 08Just KPOPNo ratings yet

- 001 JHA On Batching Plant Ice Plant ErectionDocument11 pages001 JHA On Batching Plant Ice Plant ErectionBhupinder khindaNo ratings yet

- Activity-2 - PF - EXCERSICE ESTEVEN GUETADocument4 pagesActivity-2 - PF - EXCERSICE ESTEVEN GUETASheryl BartolayNo ratings yet

- Intentions Worksheet PDFDocument3 pagesIntentions Worksheet PDFhuracanrojo94100% (1)

- TPA025 - Sehteq - Network List - Dec'2020Document772 pagesTPA025 - Sehteq - Network List - Dec'2020Fadi AlabdullahNo ratings yet

- Fresh Rally Notfn of Aro BelgaumDocument14 pagesFresh Rally Notfn of Aro BelgaumManjunathNo ratings yet

- Tata 1mg Return & Refund Policy: 1. DefinitionDocument5 pagesTata 1mg Return & Refund Policy: 1. Definitions m sufiyanNo ratings yet

- BP Debating: Structure & Role Fulfilment: Speaker's Development, Week 2Document12 pagesBP Debating: Structure & Role Fulfilment: Speaker's Development, Week 2Chantola BoeurtNo ratings yet

- Telehealth: Health Care Is Only A Website AwayDocument3 pagesTelehealth: Health Care Is Only A Website AwayDonna MarburyNo ratings yet

- How We Survived Covid-19: in This IssueDocument40 pagesHow We Survived Covid-19: in This Issuedara o riordainNo ratings yet

- ST No. 4 - Q1 - M.A.P.E.H. 6Document3 pagesST No. 4 - Q1 - M.A.P.E.H. 6Gia Rose R. RafolNo ratings yet

- Muhammad Safeer Ahmed RescumeDocument3 pagesMuhammad Safeer Ahmed RescumeEngr Safeer AhmedNo ratings yet

- PPAR Q StandardDocument2 pagesPPAR Q Standardkyungiebae kkiechanNo ratings yet

- Kiosk Earthing CircularDocument1 pageKiosk Earthing CircularsunilgvoraNo ratings yet

- ارزیابی مقالات کارآزمایی بالینی دارای گروه کنترل تصادفی شده مجله دانشکده دندانپزشکی دانشگاه علوم پزشکی مشهد منتشره از سال 2831 الی2814Document10 pagesارزیابی مقالات کارآزمایی بالینی دارای گروه کنترل تصادفی شده مجله دانشکده دندانپزشکی دانشگاه علوم پزشکی مشهد منتشره از سال 2831 الی2814Majid KarimiNo ratings yet

- Kushal A, Gupta SK, Mehta M, Singh MMDocument3 pagesKushal A, Gupta SK, Mehta M, Singh MMJohnnel Acosido PrietosNo ratings yet

- Bowen EHS, Inc.: ASP/CSP 08 PPE Respiratory Protection Study SolutionsDocument2 pagesBowen EHS, Inc.: ASP/CSP 08 PPE Respiratory Protection Study SolutionssahiyNo ratings yet

- Smile S M I L E: Haring Agic N Ove VerywhereDocument16 pagesSmile S M I L E: Haring Agic N Ove VerywhereSteffanie OlivarNo ratings yet

- LOLER Inspection Checklist - SafetyCultureDocument25 pagesLOLER Inspection Checklist - SafetyCultureTatak Bay AhmedNo ratings yet