Professional Documents

Culture Documents

FPC of Procces Making Crumb Rubber

FPC of Procces Making Crumb Rubber

Uploaded by

Amanda MelialaCopyright:

Available Formats

You might also like

- RAB Rumah Subsidi Type 30 Isi PANDAWADocument2 pagesRAB Rumah Subsidi Type 30 Isi PANDAWASoerja Soengoehta75% (4)

- CONS - BOX CULVERT (2x2) EARTH FILL-R2Document1 pageCONS - BOX CULVERT (2x2) EARTH FILL-R2Saddam LoneNo ratings yet

- Outline Spek Series 7x9 20191021Document83 pagesOutline Spek Series 7x9 20191021frans sianiparNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Description: Polypropylene 8573Document1 pageDescription: Polypropylene 8573ChivuAlexandruNo ratings yet

- Review of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesDocument24 pagesReview of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesAnbasNo ratings yet

- Microbiology Available Equipments Data As Per NABL FormatDocument8 pagesMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaNo ratings yet

- Aquaduct TreatmentDocument1 pageAquaduct TreatmentKetaki HallurNo ratings yet

- 6.1 PMP 2012Document6 pages6.1 PMP 2012Safrin SangiaNo ratings yet

- Phenolic Resins Specification: Condition ConditionDocument1 pagePhenolic Resins Specification: Condition Condition8612106535No ratings yet

- Night Shift Plan 17-12-22Document1 pageNight Shift Plan 17-12-22Mohammed Rafeek SNo ratings yet

- Indicador de Paso de ChanchoDocument12 pagesIndicador de Paso de ChanchoPedro Luis Choque MamaniNo ratings yet

- Project: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017Document1 pageProject: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017JeanmuelEstolonioNo ratings yet

- RENCANA ANGGARAN BIAYA ISOLASI, SOOTBLOWER, DESUPERHEATER, STACK Rev 04 - 220614-15.19 FIXDocument21 pagesRENCANA ANGGARAN BIAYA ISOLASI, SOOTBLOWER, DESUPERHEATER, STACK Rev 04 - 220614-15.19 FIXEky Aditya PutraNo ratings yet

- Lavon-Swan City: Proposed Material Specification (Option)Document29 pagesLavon-Swan City: Proposed Material Specification (Option)frans sianiparNo ratings yet

- ASummarySAMPLE 1Document2 pagesASummarySAMPLE 1Christelle JoyNo ratings yet

- Flowchart Inco ProcessingDocument3 pagesFlowchart Inco ProcessingWilly ApryantoNo ratings yet

- FORM 4.5. Material Plan - Unit Rate Analysis: DieselDocument10 pagesFORM 4.5. Material Plan - Unit Rate Analysis: DieselUTTAMNo ratings yet

- Cross CROSS SECTION ETO TALAGA YUNDocument1 pageCross CROSS SECTION ETO TALAGA YUNFermin NaragNo ratings yet

- Acronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDocument1 pageAcronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDuodo NguyenNo ratings yet

- CostingDocument51 pagesCostingCharlton CabagingNo ratings yet

- Manual de Grabado y Corte A5 Pro 40W GRBLDocument3 pagesManual de Grabado y Corte A5 Pro 40W GRBLgalindobrendabNo ratings yet

- Block Diagram Pulp PT TELDocument1 pageBlock Diagram Pulp PT TELEra MileniaNo ratings yet

- Drilling Fluid Programs Flow Chart HDD GuideDocument1 pageDrilling Fluid Programs Flow Chart HDD GuideIndra SUdirmanNo ratings yet

- POLISHing Sequence PDFDocument8 pagesPOLISHing Sequence PDFrobin parmarNo ratings yet

- Product Category Specchem Euclid/Tamms Basf Sika W.R. Meadows Dayton Misc. Misc. MiscDocument2 pagesProduct Category Specchem Euclid/Tamms Basf Sika W.R. Meadows Dayton Misc. Misc. MiscMNo ratings yet

- 1002KWDocument2 pages1002KWPhuoc TranNo ratings yet

- K-8501 Compressor Lifting PlanDocument4 pagesK-8501 Compressor Lifting Planciba.o.cibaoNo ratings yet

- Overview STG-BB Untuk KPDocument56 pagesOverview STG-BB Untuk KPJibraltar Amin SyamNo ratings yet

- Ic2024 - 17 - 1Document26 pagesIc2024 - 17 - 1sk tripathiNo ratings yet

- Type of Foam Pigs For Cross Country PipelinesDocument13 pagesType of Foam Pigs For Cross Country PipelinesHamad AhmadNo ratings yet

- SBR and Natural Rubber LatexDocument33 pagesSBR and Natural Rubber Latexain kamarudinNo ratings yet

- Rekap PR 2020-2021Document750 pagesRekap PR 2020-2021ika yuniNo ratings yet

- Sample Gen Cargo Stowage PlanDocument1 pageSample Gen Cargo Stowage PlanVictor CarlosNo ratings yet

- Ppi CL PDFDocument3 pagesPpi CL PDFMaxflowNo ratings yet

- Final Drawings For FirozabadDocument12 pagesFinal Drawings For FirozabadApoorva AgrawalNo ratings yet

- F10 09 Ref Eng Macropoxy FTDocument2 pagesF10 09 Ref Eng Macropoxy FTsaul xool mayNo ratings yet

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- FormworkPropSupport ILP FRAMEDocument13 pagesFormworkPropSupport ILP FRAMEINTAN FARHANA MOHD ROSLANNo ratings yet

- Roof Framing Plan A Roof Framing Plan B Roof Framing Plan CDocument1 pageRoof Framing Plan A Roof Framing Plan B Roof Framing Plan Cleland macasinagNo ratings yet

- Material SORDocument2 pagesMaterial SORKrishna RaiNo ratings yet

- KHRI - Webinar (11-04-2020) - Sustainable Solutions For Flexible Pavements-Er. T K Subhaash - KHRI - Assistant Director KHRIDocument41 pagesKHRI - Webinar (11-04-2020) - Sustainable Solutions For Flexible Pavements-Er. T K Subhaash - KHRI - Assistant Director KHRIAmit Rajendra PhadatareNo ratings yet

- Hsub 2021Document149 pagesHsub 2021ded kurniawaNo ratings yet

- HIRENOL BrochureDocument1 pageHIRENOL BrochureTasos PapadopoulosNo ratings yet

- BQ Nissan Pramuka-JakartaDocument18 pagesBQ Nissan Pramuka-JakartaHermanto STNo ratings yet

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- Softening Cation Exchange Resins: Go To MenuDocument4 pagesSoftening Cation Exchange Resins: Go To Menuedal_108No ratings yet

- GSR 2014 - Roads (Highway Sector)Document88 pagesGSR 2014 - Roads (Highway Sector)NileshNo ratings yet

- West Elevation: Contract DocumentationDocument1 pageWest Elevation: Contract DocumentationMário CarreiraNo ratings yet

- Bro CPD SikaWrap Us PDFDocument4 pagesBro CPD SikaWrap Us PDFjohanes b mudaNo ratings yet

- Cognis Copper Update F - Cobre Las Cruces PresentationDocument15 pagesCognis Copper Update F - Cobre Las Cruces PresentationHelen HuancaNo ratings yet

- Cooling Water ME Test Bulan JanuariDocument4 pagesCooling Water ME Test Bulan JanuariAnto AriNo ratings yet

- PB SN Phase Diagram 22x28 AADocument1 pagePB SN Phase Diagram 22x28 AAalonso_matias88No ratings yet

- Rainbow - 3720 - R1 (3KL - R1)Document1 pageRainbow - 3720 - R1 (3KL - R1)TKT ConsultantNo ratings yet

- Tank Comparision SheetDocument8 pagesTank Comparision SheetEr Amit SolankiNo ratings yet

- Breathability PDFDocument3 pagesBreathability PDFCatalin VelcsovNo ratings yet

- Raft Filling Methodology With Weep Holes 2Document1 pageRaft Filling Methodology With Weep Holes 2Abilaash VNo ratings yet

- Cement Modifier (Primer) : Areas of Application IncludeDocument3 pagesCement Modifier (Primer) : Areas of Application IncludeChiara JayneNo ratings yet

- PP Woven NewDocument3 pagesPP Woven Newabhimanyu.xplastNo ratings yet

- Keyword Tool Export - Keyword Suggestions - Pipa PVCDocument11 pagesKeyword Tool Export - Keyword Suggestions - Pipa PVCJumadil AwalNo ratings yet

- Pipe PVC Sni Air Minum - 01 April 2022Document4 pagesPipe PVC Sni Air Minum - 01 April 2022onshopNo ratings yet

- Design Studio: Shin Yang Development SDN BHDDocument1 pageDesign Studio: Shin Yang Development SDN BHDcRi SocietyNo ratings yet

- Company Name City Meeting/Flast SamplDocument5 pagesCompany Name City Meeting/Flast Sampljhakundan555No ratings yet

- Bangladesh Tanners AssociationDocument48 pagesBangladesh Tanners AssociationAmiruzzaman PalashNo ratings yet

- 10th May 2020: Standard GroupDocument167 pages10th May 2020: Standard GroupAlinda Gupta Abhro0% (1)

- Eastern Region Voters ListDocument21 pagesEastern Region Voters ListAman DubeyNo ratings yet

- NEW Quotation For Paintball Bunkers-Funworld2022Document5 pagesNEW Quotation For Paintball Bunkers-Funworld2022Ricardo DiazNo ratings yet

- Cable B2B QuoteDocument23 pagesCable B2B Quote5pd5bt4spnNo ratings yet

- RPEDocument1,033 pagesRPERoxana TudosieNo ratings yet

- Export Headers 2017Document49 pagesExport Headers 2017Shahid NadeemNo ratings yet

- Ethiopian TANNERIESDocument15 pagesEthiopian TANNERIESNahomaBek100% (1)

- Tubo Pvc-U para Conduccion de Fluidos A Presion Con Empalme Union Flexible (U F) Especificaciones Tecnicas Ntp-Iso 4422Document1 pageTubo Pvc-U para Conduccion de Fluidos A Presion Con Empalme Union Flexible (U F) Especificaciones Tecnicas Ntp-Iso 4422Luigi OttoNo ratings yet

- BQ Auditorium Fem PDF FinalDocument48 pagesBQ Auditorium Fem PDF FinalivanNo ratings yet

- Pilot DMA For Debre BirhanDocument2 pagesPilot DMA For Debre BirhanStc MumbaiNo ratings yet

- Indicator Norme Deviz Sanitare SDocument484 pagesIndicator Norme Deviz Sanitare SPavel SergiuNo ratings yet

- 664 Bang Gia Vat TuDocument12 pages664 Bang Gia Vat Tuhoptacxa31No ratings yet

- Nike Material Tracking List: STT Lab No Buyer Name Material NameDocument24 pagesNike Material Tracking List: STT Lab No Buyer Name Material Namedan quangNo ratings yet

- CRR ValromDocument5 pagesCRR ValromIrinel AfteneNo ratings yet

- PVC & CPVC PipeDocument4 pagesPVC & CPVC PipeHeiNo ratings yet

- Sustainable Material Guide LeatherDocument15 pagesSustainable Material Guide LeatherVictor RamosNo ratings yet

- Mangrovite Belting Limited, Tanners and Manufacturers of Leather and Raw Hide, Belting, Belt Laces, Mechanical, Leathers: Price ListDocument30 pagesMangrovite Belting Limited, Tanners and Manufacturers of Leather and Raw Hide, Belting, Belt Laces, Mechanical, Leathers: Price ListAndrea GrazioliNo ratings yet

- List of Industries Inspected On 24-12-2018Document2 pagesList of Industries Inspected On 24-12-2018Jiva SharmaNo ratings yet

- WINDOWSTEIN As Per Po CertifiedDocument9 pagesWINDOWSTEIN As Per Po CertifiedKarthikNo ratings yet

- Dissertation of RishabhDocument72 pagesDissertation of RishabhRishabh DubeyNo ratings yet

- Leather (Crust & Finished)Document4 pagesLeather (Crust & Finished)Simom Hasan100% (1)

- UPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductDocument7 pagesUPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductRavi ShankarNo ratings yet

- Labwork 2 (1) - Nur Azizatul Aisyah Binti Mohd Sanif (f1064)Document3 pagesLabwork 2 (1) - Nur Azizatul Aisyah Binti Mohd Sanif (f1064)ajis sNo ratings yet

FPC of Procces Making Crumb Rubber

FPC of Procces Making Crumb Rubber

Uploaded by

Amanda MelialaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FPC of Procces Making Crumb Rubber

FPC of Procces Making Crumb Rubber

Uploaded by

Amanda MelialaCopyright:

Available Formats

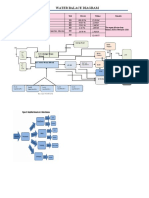

FLOW PROCESS CHART OF CRUMB RUBBER

Latex Water

900 s 691.200 s

O-1 harvest latex Maturity

3600 s from rubber tree O-4 Blend Slab and Cup lamb M-1

with ratio 1:3

Transfer latex 2m T-11 Move to Storage

T-1 to Weighing Bridge 2m T-5 Move to Prebreaker

1000 m

Grind the raw material S-2 Save the Crumb Rubber

O-5

I-1 weighing latex 900 s into smaller pieces

360 s

2m T-6 Move to Blending tub 2

S-1 Save latex

Transfer Latex Blend until the material

900 s O-6

2m to Factory is homogen

T-2

freeze latex that 2m T-7 Move to Blending tub 3

clot naturally (Cup Lump)

10.800 s O-2 Dry Rubber Containt (DRC)

60%-90%

Blend and wash to

900 s O-7

reduce contamination

2m T-3 Move to Blending tub 1

Move to crumb grinding

2m T-8 by Hammer MIll

mixing the material

900 s O-8

freeze latex that clot intentionally (macro blending)

O-3

+ Formic Acid ( Slab)

900 s DRC 30%-60%

homogenize material with

with size 40x30x10 cm micro process and make

900 s O-9 it to be sheet

( micro blending)

2m T-4 Move to Blending tub 1

water O-10 Grinding the crumb rubber

dirt

2m T-9 Move to operator Crepper

Symbol Information Qty Time Distance

Storage 2

900 s O-11 Fold the sheet

of crumb rubber

Operation 12 21.960 s

900 s O-12 Rolled up the sheet

Transportation 11 1020 m of crumb rubber

1 roll is 24 kg( Blangket)

DRC 70%

Maturity 1 691.200 s 2m T-10

Chart No.1

Transfer to Maturity Storage

Subject Charted : Crumb Rubber

Activity: Making of Crumb Rubber

I-1 Inspection 1 Method: Process of Making Crumb Rubber

Charted by : Amanda Reihan Sembiring Meliala

NIM : 180403066

Total 27 713.160 s 1020 m Date :Monday, 19 November 2018

You might also like

- RAB Rumah Subsidi Type 30 Isi PANDAWADocument2 pagesRAB Rumah Subsidi Type 30 Isi PANDAWASoerja Soengoehta75% (4)

- CONS - BOX CULVERT (2x2) EARTH FILL-R2Document1 pageCONS - BOX CULVERT (2x2) EARTH FILL-R2Saddam LoneNo ratings yet

- Outline Spek Series 7x9 20191021Document83 pagesOutline Spek Series 7x9 20191021frans sianiparNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Description: Polypropylene 8573Document1 pageDescription: Polypropylene 8573ChivuAlexandruNo ratings yet

- Review of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesDocument24 pagesReview of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesAnbasNo ratings yet

- Microbiology Available Equipments Data As Per NABL FormatDocument8 pagesMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaNo ratings yet

- Aquaduct TreatmentDocument1 pageAquaduct TreatmentKetaki HallurNo ratings yet

- 6.1 PMP 2012Document6 pages6.1 PMP 2012Safrin SangiaNo ratings yet

- Phenolic Resins Specification: Condition ConditionDocument1 pagePhenolic Resins Specification: Condition Condition8612106535No ratings yet

- Night Shift Plan 17-12-22Document1 pageNight Shift Plan 17-12-22Mohammed Rafeek SNo ratings yet

- Indicador de Paso de ChanchoDocument12 pagesIndicador de Paso de ChanchoPedro Luis Choque MamaniNo ratings yet

- Project: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017Document1 pageProject: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017JeanmuelEstolonioNo ratings yet

- RENCANA ANGGARAN BIAYA ISOLASI, SOOTBLOWER, DESUPERHEATER, STACK Rev 04 - 220614-15.19 FIXDocument21 pagesRENCANA ANGGARAN BIAYA ISOLASI, SOOTBLOWER, DESUPERHEATER, STACK Rev 04 - 220614-15.19 FIXEky Aditya PutraNo ratings yet

- Lavon-Swan City: Proposed Material Specification (Option)Document29 pagesLavon-Swan City: Proposed Material Specification (Option)frans sianiparNo ratings yet

- ASummarySAMPLE 1Document2 pagesASummarySAMPLE 1Christelle JoyNo ratings yet

- Flowchart Inco ProcessingDocument3 pagesFlowchart Inco ProcessingWilly ApryantoNo ratings yet

- FORM 4.5. Material Plan - Unit Rate Analysis: DieselDocument10 pagesFORM 4.5. Material Plan - Unit Rate Analysis: DieselUTTAMNo ratings yet

- Cross CROSS SECTION ETO TALAGA YUNDocument1 pageCross CROSS SECTION ETO TALAGA YUNFermin NaragNo ratings yet

- Acronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDocument1 pageAcronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDuodo NguyenNo ratings yet

- CostingDocument51 pagesCostingCharlton CabagingNo ratings yet

- Manual de Grabado y Corte A5 Pro 40W GRBLDocument3 pagesManual de Grabado y Corte A5 Pro 40W GRBLgalindobrendabNo ratings yet

- Block Diagram Pulp PT TELDocument1 pageBlock Diagram Pulp PT TELEra MileniaNo ratings yet

- Drilling Fluid Programs Flow Chart HDD GuideDocument1 pageDrilling Fluid Programs Flow Chart HDD GuideIndra SUdirmanNo ratings yet

- POLISHing Sequence PDFDocument8 pagesPOLISHing Sequence PDFrobin parmarNo ratings yet

- Product Category Specchem Euclid/Tamms Basf Sika W.R. Meadows Dayton Misc. Misc. MiscDocument2 pagesProduct Category Specchem Euclid/Tamms Basf Sika W.R. Meadows Dayton Misc. Misc. MiscMNo ratings yet

- 1002KWDocument2 pages1002KWPhuoc TranNo ratings yet

- K-8501 Compressor Lifting PlanDocument4 pagesK-8501 Compressor Lifting Planciba.o.cibaoNo ratings yet

- Overview STG-BB Untuk KPDocument56 pagesOverview STG-BB Untuk KPJibraltar Amin SyamNo ratings yet

- Ic2024 - 17 - 1Document26 pagesIc2024 - 17 - 1sk tripathiNo ratings yet

- Type of Foam Pigs For Cross Country PipelinesDocument13 pagesType of Foam Pigs For Cross Country PipelinesHamad AhmadNo ratings yet

- SBR and Natural Rubber LatexDocument33 pagesSBR and Natural Rubber Latexain kamarudinNo ratings yet

- Rekap PR 2020-2021Document750 pagesRekap PR 2020-2021ika yuniNo ratings yet

- Sample Gen Cargo Stowage PlanDocument1 pageSample Gen Cargo Stowage PlanVictor CarlosNo ratings yet

- Ppi CL PDFDocument3 pagesPpi CL PDFMaxflowNo ratings yet

- Final Drawings For FirozabadDocument12 pagesFinal Drawings For FirozabadApoorva AgrawalNo ratings yet

- F10 09 Ref Eng Macropoxy FTDocument2 pagesF10 09 Ref Eng Macropoxy FTsaul xool mayNo ratings yet

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- FormworkPropSupport ILP FRAMEDocument13 pagesFormworkPropSupport ILP FRAMEINTAN FARHANA MOHD ROSLANNo ratings yet

- Roof Framing Plan A Roof Framing Plan B Roof Framing Plan CDocument1 pageRoof Framing Plan A Roof Framing Plan B Roof Framing Plan Cleland macasinagNo ratings yet

- Material SORDocument2 pagesMaterial SORKrishna RaiNo ratings yet

- KHRI - Webinar (11-04-2020) - Sustainable Solutions For Flexible Pavements-Er. T K Subhaash - KHRI - Assistant Director KHRIDocument41 pagesKHRI - Webinar (11-04-2020) - Sustainable Solutions For Flexible Pavements-Er. T K Subhaash - KHRI - Assistant Director KHRIAmit Rajendra PhadatareNo ratings yet

- Hsub 2021Document149 pagesHsub 2021ded kurniawaNo ratings yet

- HIRENOL BrochureDocument1 pageHIRENOL BrochureTasos PapadopoulosNo ratings yet

- BQ Nissan Pramuka-JakartaDocument18 pagesBQ Nissan Pramuka-JakartaHermanto STNo ratings yet

- Water Balance Diagram PDFFDocument2 pagesWater Balance Diagram PDFFEMS 4AYDNo ratings yet

- Softening Cation Exchange Resins: Go To MenuDocument4 pagesSoftening Cation Exchange Resins: Go To Menuedal_108No ratings yet

- GSR 2014 - Roads (Highway Sector)Document88 pagesGSR 2014 - Roads (Highway Sector)NileshNo ratings yet

- West Elevation: Contract DocumentationDocument1 pageWest Elevation: Contract DocumentationMário CarreiraNo ratings yet

- Bro CPD SikaWrap Us PDFDocument4 pagesBro CPD SikaWrap Us PDFjohanes b mudaNo ratings yet

- Cognis Copper Update F - Cobre Las Cruces PresentationDocument15 pagesCognis Copper Update F - Cobre Las Cruces PresentationHelen HuancaNo ratings yet

- Cooling Water ME Test Bulan JanuariDocument4 pagesCooling Water ME Test Bulan JanuariAnto AriNo ratings yet

- PB SN Phase Diagram 22x28 AADocument1 pagePB SN Phase Diagram 22x28 AAalonso_matias88No ratings yet

- Rainbow - 3720 - R1 (3KL - R1)Document1 pageRainbow - 3720 - R1 (3KL - R1)TKT ConsultantNo ratings yet

- Tank Comparision SheetDocument8 pagesTank Comparision SheetEr Amit SolankiNo ratings yet

- Breathability PDFDocument3 pagesBreathability PDFCatalin VelcsovNo ratings yet

- Raft Filling Methodology With Weep Holes 2Document1 pageRaft Filling Methodology With Weep Holes 2Abilaash VNo ratings yet

- Cement Modifier (Primer) : Areas of Application IncludeDocument3 pagesCement Modifier (Primer) : Areas of Application IncludeChiara JayneNo ratings yet

- PP Woven NewDocument3 pagesPP Woven Newabhimanyu.xplastNo ratings yet

- Keyword Tool Export - Keyword Suggestions - Pipa PVCDocument11 pagesKeyword Tool Export - Keyword Suggestions - Pipa PVCJumadil AwalNo ratings yet

- Pipe PVC Sni Air Minum - 01 April 2022Document4 pagesPipe PVC Sni Air Minum - 01 April 2022onshopNo ratings yet

- Design Studio: Shin Yang Development SDN BHDDocument1 pageDesign Studio: Shin Yang Development SDN BHDcRi SocietyNo ratings yet

- Company Name City Meeting/Flast SamplDocument5 pagesCompany Name City Meeting/Flast Sampljhakundan555No ratings yet

- Bangladesh Tanners AssociationDocument48 pagesBangladesh Tanners AssociationAmiruzzaman PalashNo ratings yet

- 10th May 2020: Standard GroupDocument167 pages10th May 2020: Standard GroupAlinda Gupta Abhro0% (1)

- Eastern Region Voters ListDocument21 pagesEastern Region Voters ListAman DubeyNo ratings yet

- NEW Quotation For Paintball Bunkers-Funworld2022Document5 pagesNEW Quotation For Paintball Bunkers-Funworld2022Ricardo DiazNo ratings yet

- Cable B2B QuoteDocument23 pagesCable B2B Quote5pd5bt4spnNo ratings yet

- RPEDocument1,033 pagesRPERoxana TudosieNo ratings yet

- Export Headers 2017Document49 pagesExport Headers 2017Shahid NadeemNo ratings yet

- Ethiopian TANNERIESDocument15 pagesEthiopian TANNERIESNahomaBek100% (1)

- Tubo Pvc-U para Conduccion de Fluidos A Presion Con Empalme Union Flexible (U F) Especificaciones Tecnicas Ntp-Iso 4422Document1 pageTubo Pvc-U para Conduccion de Fluidos A Presion Con Empalme Union Flexible (U F) Especificaciones Tecnicas Ntp-Iso 4422Luigi OttoNo ratings yet

- BQ Auditorium Fem PDF FinalDocument48 pagesBQ Auditorium Fem PDF FinalivanNo ratings yet

- Pilot DMA For Debre BirhanDocument2 pagesPilot DMA For Debre BirhanStc MumbaiNo ratings yet

- Indicator Norme Deviz Sanitare SDocument484 pagesIndicator Norme Deviz Sanitare SPavel SergiuNo ratings yet

- 664 Bang Gia Vat TuDocument12 pages664 Bang Gia Vat Tuhoptacxa31No ratings yet

- Nike Material Tracking List: STT Lab No Buyer Name Material NameDocument24 pagesNike Material Tracking List: STT Lab No Buyer Name Material Namedan quangNo ratings yet

- CRR ValromDocument5 pagesCRR ValromIrinel AfteneNo ratings yet

- PVC & CPVC PipeDocument4 pagesPVC & CPVC PipeHeiNo ratings yet

- Sustainable Material Guide LeatherDocument15 pagesSustainable Material Guide LeatherVictor RamosNo ratings yet

- Mangrovite Belting Limited, Tanners and Manufacturers of Leather and Raw Hide, Belting, Belt Laces, Mechanical, Leathers: Price ListDocument30 pagesMangrovite Belting Limited, Tanners and Manufacturers of Leather and Raw Hide, Belting, Belt Laces, Mechanical, Leathers: Price ListAndrea GrazioliNo ratings yet

- List of Industries Inspected On 24-12-2018Document2 pagesList of Industries Inspected On 24-12-2018Jiva SharmaNo ratings yet

- WINDOWSTEIN As Per Po CertifiedDocument9 pagesWINDOWSTEIN As Per Po CertifiedKarthikNo ratings yet

- Dissertation of RishabhDocument72 pagesDissertation of RishabhRishabh DubeyNo ratings yet

- Leather (Crust & Finished)Document4 pagesLeather (Crust & Finished)Simom Hasan100% (1)

- UPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductDocument7 pagesUPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductRavi ShankarNo ratings yet

- Labwork 2 (1) - Nur Azizatul Aisyah Binti Mohd Sanif (f1064)Document3 pagesLabwork 2 (1) - Nur Azizatul Aisyah Binti Mohd Sanif (f1064)ajis sNo ratings yet