Professional Documents

Culture Documents

Aisc Weld Built Up Section FW

Aisc Weld Built Up Section FW

Uploaded by

Jeff cadavaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisc Weld Built Up Section FW

Aisc Weld Built Up Section FW

Uploaded by

Jeff cadavaCopyright:

Available Formats

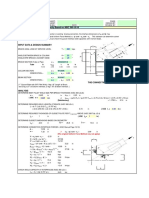

Project LOGO COMPANY NAME

ADDRESS

Client Made by Date Page

MSB 4-10-10

Title BUILT BEAM-WELD DESIGN Drawing No Checked by Date Job No.

W12x252 lbs/ft REV 0 - 4-10-10

Input ( This spread sheet is useful find out the weld size required for a built up sections by AISC-LRFD)

330

Over all depth of Built up section d= 391 mm 58

Breadth of top flange btf = 330 mm 36 166.5

275

Thickness of top flange ttf = 58 mm X X 195.5

Breadth of bottom flange bbf = 330 mm 58 15

330

Thickness of bottom flange tbf = 58 mm

thickness of web tw = 36 mm Built upsection

Min Tensile stress of Built-up plates Fy = 345 N/mm2

Proposed weld b/w web to flange w= 15 mm

Weld electrode classification number Fexx = 483 N/mm2

Properties of Built up sections

mm mm2 mm mm2 mm mm2 mm mm mm mm mm

h= A1 = y1 = A2 = y2 = A3 = y3 = ŷ= h1 = h2 = h3 =

275 19140 362 9900 195.5 19140 29 195.5 166.5 0 166.5

D-ttf-tbf btf ttf d-ttf/2 htw d-tf-h/2 bbf tbf bf/2 Ref. Eq.1 |ŷ-y1| |ŷ-y2| |ŷ-y3|

CG of section from base about xx axis ŷ= 196 mm = (A1 * y1 + A2 * y2 + A3 * y3 ) / (A1 + A2 + A3 ) Eq.1

=(19140×362+9900×195.5+19140×29

19140+9900+19140)

Second moment of Area about XX axis Ixx = 1.1.E+09 mm4 bndn3 +Anhn2

=330×58^3/12+19140×166.5^2+36×275^3/12+

9900×0^2+330×58^3/12+19140×166.5^2

Check for Weld b/w Web plate with flange plates

mm mm N/mm2 mm2

h= tw = fy = Af = y= Ixx = Fexx = w ϕ= ϕ= ϑ=

275 36 345 19140 166.5 1.1.E+09 483 ϕ15 1 0.75 0

Shear capacity of the section Pv = 2049 KN = * (0.6 * h * tw * fy) / 1000

=1×(0.6×275×36×345)/1000

Equivalent horizontal shear Ph = 5757 KN = P v * 1000 * Af * y / I xx

ϑ

=2049×1000×19140×166.5/1.1.E+09

= 0.6 * Fexx * (1 + sin[radians{ }]1.5 )

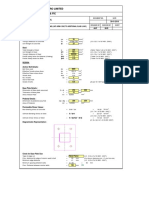

Project LOGO COMPANY NAME

ADDRESS

Client Made by Date Page

MSB 4-10-10

Title BUILT BEAM-WELD DESIGN Drawing No Checked by Date Job No.

ϑ

W12x252 lbs/ft REV 0 - 4-10-10

1.5

Fw = 290 N/mm2 = 0.6 * Fexx * (1 + sin[radians{ }] )

ϕ

=0.6×483×(1+sin(radians(0))^1.5

ϕRn = 217 N/mm2 = * Fw ϕ =0.75×290

Size of Weld required 18.73 mm = Ph / (2 * 0.707 * Rn) =5757/(2×0.707×217)

< w= 15 mm Un safe U.R=

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Tech RiderDocument9 pagesTech RiderDaniel BernardesNo ratings yet

- Simple End Plate Connection Design (Bolted End Plate Connection)Document6 pagesSimple End Plate Connection Design (Bolted End Plate Connection)Nitesh SinghNo ratings yet

- Pinned Base Plate - 03SF01Document15 pagesPinned Base Plate - 03SF01vivekNo ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- End Plate Conn 01 - Finite ElementDocument4 pagesEnd Plate Conn 01 - Finite Elementrodriguez.gaytanNo ratings yet

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocument2 pagesSheet1 A-B Bay CM: Properties of Gantry SectionadihindNo ratings yet

- Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)Document13 pagesDesign of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)rohitnrg0% (1)

- Result Summary - Overall: Pass Pass Pass PassDocument17 pagesResult Summary - Overall: Pass Pass Pass PassmaheshbandhamNo ratings yet

- UC Bracing Gusset - ASDDocument14 pagesUC Bracing Gusset - ASDFunny & InformativeNo ratings yet

- 1.SHEAR (Or) MOMENT CONNE-GENERALDocument272 pages1.SHEAR (Or) MOMENT CONNE-GENERALbalaNo ratings yet

- Joist Girder DesignDocument42 pagesJoist Girder DesignsravanNo ratings yet

- Calculation Sheet: Yb For UB BeamDocument2 pagesCalculation Sheet: Yb For UB BeamrammohanNo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Ridge Connection Design RSP-1.Document121 pagesRidge Connection Design RSP-1.Asaru DeenNo ratings yet

- Design - Calculation - For - Bracing - Connection 1 PDFDocument10 pagesDesign - Calculation - For - Bracing - Connection 1 PDFLian Jia JieNo ratings yet

- Beam Column Connection-Design2Document16 pagesBeam Column Connection-Design2abdul kareeNo ratings yet

- Indes Enginnering: Design Code - IS800:2007Document2 pagesIndes Enginnering: Design Code - IS800:2007KARTHIK SGNo ratings yet

- Shear Connections (Steel-Steel)Document14 pagesShear Connections (Steel-Steel)Izzan SabelloNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Aisc - LRFD Punch Plate Connection For HSSDocument14 pagesAisc - LRFD Punch Plate Connection For HSSJeff cadava0% (1)

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- Wind Load For Main Frame RustaqDocument2 pagesWind Load For Main Frame RustaqWilfredoEnghoyNo ratings yet

- Steel ConnectionDocument34 pagesSteel ConnectionDiana100% (1)

- Shear Key DesignDocument2 pagesShear Key DesignmaheshbandhamNo ratings yet

- Corner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HDocument2 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HKaren Esther Acuña VelasquezNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- RCC Column Calc Good MahfuzDocument1 pageRCC Column Calc Good Mahfuzkim lokNo ratings yet

- Epmc Extended LRFD Asd Aisc New 28-10-2013Document10 pagesEpmc Extended LRFD Asd Aisc New 28-10-2013tamerragaaNo ratings yet

- Beam Design With Crackwidth CalculationDocument16 pagesBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer Singh100% (1)

- Base Plate DesignDocument61 pagesBase Plate DesignWanda BeasleyNo ratings yet

- Design of Purlins Revised-2005Document45 pagesDesign of Purlins Revised-2005Nguyen Duc CuongNo ratings yet

- Rigid Connection DesignDocument215 pagesRigid Connection DesignUmer AziqNo ratings yet

- 1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedDocument120 pages1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedbalaNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- BracingDocument7 pagesBracingjatin kalraNo ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Light Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PDocument7 pagesLight Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PShan Adrias100% (1)

- Purlin Design-R00Document48 pagesPurlin Design-R00arjunNo ratings yet

- Shear Conn - Inside Fin PlateDocument30 pagesShear Conn - Inside Fin PlatekalpanaadhiNo ratings yet

- Brace TR W6X25Document6 pagesBrace TR W6X25mihai_serban13No ratings yet

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 pagesDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaNo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- LRFD Beam Column DesignDocument242 pagesLRFD Beam Column DesignChristian FTNo ratings yet

- Rolled - MomentDocument5 pagesRolled - MomentAdekimi EmmanuelNo ratings yet

- Ext Finplate ConnecDocument78 pagesExt Finplate Connechary9100No ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- Calculation For Base Plate ConnectionDocument85 pagesCalculation For Base Plate ConnectionpriantomoNo ratings yet

- Embeddedplate With StudsDocument78 pagesEmbeddedplate With StudsAkhil VNNo ratings yet

- He800b PDFDocument5 pagesHe800b PDFUday UdmaleNo ratings yet

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Document11 pagesWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNo ratings yet

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- UB406X178X85Document5 pagesUB406X178X85Uday UdmaleNo ratings yet

- Aisc-Weld-Built Up Section-FwDocument5 pagesAisc-Weld-Built Up Section-FwMohanNo ratings yet

- Aisc Weld Built Up Section FWDocument4 pagesAisc Weld Built Up Section FWmdelacua2No ratings yet

- Design Calculation For Bolted Splice For NPB SectionsDocument9 pagesDesign Calculation For Bolted Splice For NPB SectionsAtul WanodeNo ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- AISC-Weld Calculation For Built Up BeamsDocument1 pageAISC-Weld Calculation For Built Up BeamsJeff cadavaNo ratings yet

- Analysis and Design of Steel Columns - BeamsDocument2 pagesAnalysis and Design of Steel Columns - BeamsJeff cadavaNo ratings yet

- Aisc - LRFD Punch Plate Connection For HSSDocument14 pagesAisc - LRFD Punch Plate Connection For HSSJeff cadava0% (1)

- AISC-LRFD HSS Bracing Punch Plate ConnectionDocument1 pageAISC-LRFD HSS Bracing Punch Plate ConnectionJeff cadavaNo ratings yet

- Statistical Tables On CMRPI For February 2021Document2 pagesStatistical Tables On CMRPI For February 2021Jeff cadavaNo ratings yet

- Rapid Cost For Small Rise BuildingsDocument11 pagesRapid Cost For Small Rise BuildingsJeff cadavaNo ratings yet

- Hospital MDF Doors and Windows EstimateDocument8 pagesHospital MDF Doors and Windows EstimateJeff cadavaNo ratings yet

- Strategies For Managing The Wave of Retiring Workers SourcesDocument9 pagesStrategies For Managing The Wave of Retiring Workers SourcesJeff cadavaNo ratings yet

- 7 Plumbing Max Fajardo PDFDocument175 pages7 Plumbing Max Fajardo PDFJeff cadavaNo ratings yet

- Introduction To FEX and Cisco Nexus CommandsDocument29 pagesIntroduction To FEX and Cisco Nexus CommandsNagarajanNo ratings yet

- Lesson 3. The Relationship of Percent Composition and Chemical FormulaDocument4 pagesLesson 3. The Relationship of Percent Composition and Chemical FormulaRandel MontielNo ratings yet

- Demontare Oglinda InterioaraDocument9 pagesDemontare Oglinda InterioaraabutufeiNo ratings yet

- Langkah Ke 7-Cegah Cedera Melalui Implementasi Keselamatan PasienDocument79 pagesLangkah Ke 7-Cegah Cedera Melalui Implementasi Keselamatan PasienSepti MayandariNo ratings yet

- Vann Air ValveDocument4 pagesVann Air ValveDedeLesmanaNo ratings yet

- D4 InfanciaDocument3 pagesD4 InfanciaPedroPocasNo ratings yet

- UNIT - 2 - Radio Link Features in GSM SystemsDocument18 pagesUNIT - 2 - Radio Link Features in GSM SystemsPrakhar ParasharNo ratings yet

- Half Value Layer CalculationsDocument52 pagesHalf Value Layer Calculationsshabbir62675% (4)

- SLG Chem2 LG 4.9 BuffersDocument6 pagesSLG Chem2 LG 4.9 BuffersIman SontousidadNo ratings yet

- Project Report On Indian OilDocument80 pagesProject Report On Indian OilPayal PatidarNo ratings yet

- Ultimate Goals of LifeDocument11 pagesUltimate Goals of LifeDaniel C. DequiñaNo ratings yet

- A320 Standardization FLOWSDocument24 pagesA320 Standardization FLOWSAlex SilvestreNo ratings yet

- Project 89 May 2012 UpdateDocument73 pagesProject 89 May 2012 UpdategonflynnNo ratings yet

- Faiic 2016-05 Alpha Coy AssignmentDocument4 pagesFaiic 2016-05 Alpha Coy AssignmentVincent De VeraNo ratings yet

- 86 Iron and Steel Industry Final Report 29may12 VFDocument212 pages86 Iron and Steel Industry Final Report 29may12 VFAnonymous jLZ2f5tB100% (2)

- Offshore Wind FarmDocument32 pagesOffshore Wind FarmKonstantinos Papadopoulos100% (1)

- TM25RDocument2 pagesTM25Rphong nguyễn bá0% (1)

- Machiavelli'S Critique of Christianity: Paul-Erik KorvelaDocument31 pagesMachiavelli'S Critique of Christianity: Paul-Erik KorvelaMichael MungaiNo ratings yet

- EWMA Lower Leg Ulcer Diagnosis SuppDocument76 pagesEWMA Lower Leg Ulcer Diagnosis SuppAna CayumilNo ratings yet

- Signals and Systems: BITS PilaniDocument21 pagesSignals and Systems: BITS Pilanirajeevdutt_1215No ratings yet

- Msds Hydrogen PeroxideDocument2 pagesMsds Hydrogen PeroxideSlamet Ar100% (1)

- Paradip Brouchure 2010Document28 pagesParadip Brouchure 2010behera2001No ratings yet

- Fixture For Centering Connecting RodDocument2 pagesFixture For Centering Connecting Rodarie prasetyaNo ratings yet

- PDF A Century of Fluid Mechanics in The Netherlands Fons Alkemade Ebook Full ChapterDocument53 pagesPDF A Century of Fluid Mechanics in The Netherlands Fons Alkemade Ebook Full Chaptershelby.manns438100% (6)

- ICT 1105 Assignment 2Document23 pagesICT 1105 Assignment 2Rachel NgNo ratings yet

- Pre-Excavation ChecklistDocument2 pagesPre-Excavation ChecklistminimeezyNo ratings yet

- 1250 Red MSDSDocument4 pages1250 Red MSDSkwerwaNo ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- GRSS - FINAL LIST - 1 June 2011 - 2Document26 pagesGRSS - FINAL LIST - 1 June 2011 - 2Robel TadesseNo ratings yet