Professional Documents

Culture Documents

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

Uploaded by

andri putrantoCopyright:

Available Formats

You might also like

- HDFC Ergo Policy Renewal 2023 SelfDocument5 pagesHDFC Ergo Policy Renewal 2023 SelfGopivishnu KanchiNo ratings yet

- BS 4254Document19 pagesBS 4254gugaruban100% (4)

- Computer System Validation Risk Assessment ToolDocument3 pagesComputer System Validation Risk Assessment Toolcpkakope100% (1)

- OSTEORADIONECROSISDocument38 pagesOSTEORADIONECROSISAbel AbrahamNo ratings yet

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- Hoja Técnica Roto FoodGrade FluidDocument2 pagesHoja Técnica Roto FoodGrade FluidFederico Liaudat100% (1)

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- O & M of Sub StationDocument94 pagesO & M of Sub StationAlbert Sekar100% (2)

- JBT Foodtech H1 Food Grade Air Line OilDocument5 pagesJBT Foodtech H1 Food Grade Air Line Oilandri putrantoNo ratings yet

- Omega 585Document12 pagesOmega 585Vikz 4gameNo ratings yet

- JBT Foodtech H1 Food Grade 320 Gear OilDocument5 pagesJBT Foodtech H1 Food Grade 320 Gear Oilandri putrantoNo ratings yet

- 238 FG Machinery Oil: DescriptionDocument2 pages238 FG Machinery Oil: DescriptionFraz AhmadNo ratings yet

- Data Sheet Omega58Document11 pagesData Sheet Omega58GUECHI NADIRNo ratings yet

- 99454032&4046 QuinplexDocument4 pages99454032&4046 QuinplexDeltalube TangerangNo ratings yet

- Molykote G 4000 FMDocument2 pagesMolykote G 4000 FMRicardo ZuimNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- CASTROL BIO TAC OG - Pds - Rev. 17.08.2022Document2 pagesCASTROL BIO TAC OG - Pds - Rev. 17.08.2022Massimiliano VolaNo ratings yet

- Bpxe 9TQS2KDocument3 pagesBpxe 9TQS2KJayson VegillaNo ratings yet

- Cosmolubric HF-122 Data SheetDocument1 pageCosmolubric HF-122 Data Sheetsiddharth srinivasanNo ratings yet

- Description: Surface Protection:: Test Astm Test Method Test ResultDocument13 pagesDescription: Surface Protection:: Test Astm Test Method Test ResultizantuxNo ratings yet

- Aceite G A Atlascopco 1630-0542-00 20L 1630-0833-00 5LDocument2 pagesAceite G A Atlascopco 1630-0542-00 20L 1630-0833-00 5LAndres Felipe TorresNo ratings yet

- Jet-Lube Jacking Grease ECF - TDS - EnglishDocument1 pageJet-Lube Jacking Grease ECF - TDS - EnglishDon HowardNo ratings yet

- Prolube® High Temp H1 Food Grade Machinery Grease #1 & #2Document1 pageProlube® High Temp H1 Food Grade Machinery Grease #1 & #2Jhonathan AlejandroNo ratings yet

- Caltex Regal Ro 46Document3 pagesCaltex Regal Ro 46HyungTae JangNo ratings yet

- Castrol 2T: DescriptionDocument2 pagesCastrol 2T: Descriptionhoussem houssemNo ratings yet

- No Tox Food Grade Seamer OilDocument2 pagesNo Tox Food Grade Seamer OilDon HowardNo ratings yet

- Bioadd 770 DS (2007) PDFDocument2 pagesBioadd 770 DS (2007) PDFSabrina RiveraNo ratings yet

- Product Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseDocument2 pagesProduct Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseHewa PCNo ratings yet

- Omega 58 Pim en 20190102R2Document2 pagesOmega 58 Pim en 20190102R2ckpangNo ratings yet

- Pds Lm2000 Co enDocument2 pagesPds Lm2000 Co enmanojNo ratings yet

- TDS - 57006 AddNox Anti Block MBDocument1 pageTDS - 57006 AddNox Anti Block MBRajiv DubeyNo ratings yet

- Castrol BiostatDocument3 pagesCastrol BiostatjshkaNo ratings yet

- Roto ZDocument3 pagesRoto Zjayakumar rajanNo ratings yet

- React Performance Dot4Document2 pagesReact Performance Dot4jamie.crassNo ratings yet

- 4406 Synthetic HD Industrial Gear OilDocument2 pages4406 Synthetic HD Industrial Gear OilYoong TanNo ratings yet

- DANA ATF DEX III - by DANA LUBRICANTS ENGINE OIL MANUFACTURERDocument2 pagesDANA ATF DEX III - by DANA LUBRICANTS ENGINE OIL MANUFACTURERankurdanaNo ratings yet

- Gear OilDocument2 pagesGear OilQuy CocanhNo ratings yet

- Biosolve Spill RX: Technical Data SheetDocument2 pagesBiosolve Spill RX: Technical Data SheetJackNo ratings yet

- Cassida WGDocument3 pagesCassida WGRaghavendra MurthyNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Product Data: Castrol Alpha SP 150Document2 pagesProduct Data: Castrol Alpha SP 150Jagadeesh SharanNo ratings yet

- Sae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFDocument2 pagesSae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFChemilomNo ratings yet

- Advantages of Ester Over Mineral OilDocument8 pagesAdvantages of Ester Over Mineral OilMenoddin shaikhNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- PDS CALTEX Turbine OilDocument3 pagesPDS CALTEX Turbine OilAndaru Gunawan0% (1)

- Super Outboard 2TDocument2 pagesSuper Outboard 2TArvin BadruzamanNo ratings yet

- CircularDocument2 pagesCircularQuy CocanhNo ratings yet

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- Sinopec Crystal GreaseDocument2 pagesSinopec Crystal GreaseImran ImranNo ratings yet

- Molykote® G-1502FM Data SheetDocument2 pagesMolykote® G-1502FM Data SheetlorenzoNo ratings yet

- XIAMETER™ Q1-6083 Antifreeze Additive: Features & BenefitsDocument2 pagesXIAMETER™ Q1-6083 Antifreeze Additive: Features & BenefitsAlex CamposNo ratings yet

- Mobil DTE FM 32Document3 pagesMobil DTE FM 32UtkarshNo ratings yet

- CASTROL Bpxe-98rlqaDocument2 pagesCASTROL Bpxe-98rlqarexNo ratings yet

- Product Information: Valvoline™ HD Nitrite Free Coolant RTUDocument2 pagesProduct Information: Valvoline™ HD Nitrite Free Coolant RTUmcalidonio5656No ratings yet

- ISO Grade 68: Performance in MotionDocument2 pagesISO Grade 68: Performance in MotionJose Angel GonzalezNo ratings yet

- Product Data Sheet: No-Tox HD Food Grade GreaseDocument3 pagesProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- MAK Hydrol HVLPDocument3 pagesMAK Hydrol HVLPadheesNo ratings yet

- PDS CST820 CO enDocument2 pagesPDS CST820 CO enm.onderolaganNo ratings yet

- Roto Z Foodgrade: For Oil-Free Z Rotary Screw and Tooth CompressorsDocument2 pagesRoto Z Foodgrade: For Oil-Free Z Rotary Screw and Tooth CompressorsMario MullerNo ratings yet

- Rando HD: Premium Anti-Wear Hydraulic FluidDocument2 pagesRando HD: Premium Anti-Wear Hydraulic FluidbdsisiraNo ratings yet

- 1543995316221-P4BA-4.00549 - (Waves - Rubber) 160X110Document1 page1543995316221-P4BA-4.00549 - (Waves - Rubber) 160X110andri putrantoNo ratings yet

- Pds Shell Gadus S2 V220-0Document2 pagesPds Shell Gadus S2 V220-0andri putrantoNo ratings yet

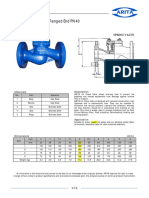

- LiftCheck CS PN40 SSTrimDocument1 pageLiftCheck CS PN40 SSTrimandri putrantoNo ratings yet

- STMCS Laser Cleaning MoldDocument7 pagesSTMCS Laser Cleaning Moldandri putrantoNo ratings yet

- QJ-8-105-20-consumable Bu Putri-SignedDocument1 pageQJ-8-105-20-consumable Bu Putri-Signedandri putrantoNo ratings yet

- O Ring Data SheetDocument3 pagesO Ring Data Sheetandri putrantoNo ratings yet

- Permintaan Disc SPK 04915Document1 pagePermintaan Disc SPK 04915andri putrantoNo ratings yet

- Specification STMCS 3 0 - FreigegebenDocument10 pagesSpecification STMCS 3 0 - Freigegebenandri putrantoNo ratings yet

- FT-H40K DatasheetDocument2 pagesFT-H40K Datasheetandri putrantoNo ratings yet

- Capacitor Bank 70kvarDocument1 pageCapacitor Bank 70kvarandri putrantoNo ratings yet

- Nu 313 Ecm - 20230125212Document5 pagesNu 313 Ecm - 20230125212andri putrantoNo ratings yet

- PT. Airlock Service BrochureDocument5 pagesPT. Airlock Service Brochureandri putrantoNo ratings yet

- Push Botton DrawingDocument1 pagePush Botton Drawingandri putrantoNo ratings yet

- Ultra Coolant LubricantDocument3 pagesUltra Coolant Lubricantandri putrantoNo ratings yet

- SMC VP7Document24 pagesSMC VP7andri putrantoNo ratings yet

- Spec Bias CuttingDocument4 pagesSpec Bias Cuttingandri putrantoNo ratings yet

- Frangklin Pump Data SheetDocument1 pageFrangklin Pump Data Sheetandri putrantoNo ratings yet

- Oil-Flooded Rotary Screw Compressed Air Systems: 4-37 KW (5.5-50 HP)Document3 pagesOil-Flooded Rotary Screw Compressed Air Systems: 4-37 KW (5.5-50 HP)andri putrantoNo ratings yet

- CL-M685 I-Type 2/3/4/5 Pins IP68 Waterproof Connector: Features and BenefitsDocument1 pageCL-M685 I-Type 2/3/4/5 Pins IP68 Waterproof Connector: Features and Benefitsandri putrantoNo ratings yet

- 3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 BarDocument2 pages3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 Barandri putrantoNo ratings yet

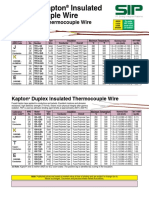

- TFE Insulated Thermocouple Wire: Iron - ConstantanDocument1 pageTFE Insulated Thermocouple Wire: Iron - Constantanandri putrantoNo ratings yet

- JBT Foodtech H1 Food Grade 320 Gear OilDocument5 pagesJBT Foodtech H1 Food Grade 320 Gear Oilandri putrantoNo ratings yet

- T30 2-Stage Lubricated Air CompressorDocument1 pageT30 2-Stage Lubricated Air Compressorandri putrantoNo ratings yet

- 1.5 Tons Per Hours Wood PelletDocument4 pages1.5 Tons Per Hours Wood Pelletandri putrantoNo ratings yet

- JBT Foodtech H1 Food Grade Air Line OilDocument5 pagesJBT Foodtech H1 Food Grade Air Line Oilandri putrantoNo ratings yet

- Toptherm Wall-Mounted Cooling Unit Blue E Total Cooling Output 0.50 - 0.75 KW - SK 3361.500Document4 pagesToptherm Wall-Mounted Cooling Unit Blue E Total Cooling Output 0.50 - 0.75 KW - SK 3361.500andri putrantoNo ratings yet

- pH/ORP/Temperature Datalogger: Records Data On An SD Card in Excel FormatDocument1 pagepH/ORP/Temperature Datalogger: Records Data On An SD Card in Excel Formatandri putrantoNo ratings yet

- ABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFDocument3 pagesABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFandri putrantoNo ratings yet

- Electrical Data General Data: Order NumberDocument1 pageElectrical Data General Data: Order Numberandri putrantoNo ratings yet

- 1 jISHADocument5 pages1 jISHAFirman MufidNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (25)

- Mbarang 10102022Document3 pagesMbarang 10102022zeta chenkNo ratings yet

- Activated Carbon MSDS PDFDocument6 pagesActivated Carbon MSDS PDFRIANG TRIANDONONo ratings yet

- Environmental Crisis Causes and ManifestationsDocument26 pagesEnvironmental Crisis Causes and Manifestationsबाजीराव सिंघम0% (1)

- CSF PDFDocument58 pagesCSF PDFVas KannanNo ratings yet

- Material Sub Group Item CodeDocument2,818 pagesMaterial Sub Group Item Codegouri gouriNo ratings yet

- Ramsay Health Care - BudgetDocument13 pagesRamsay Health Care - BudgetTatiana Garcia MendozaNo ratings yet

- Stilboestrol Tablets MSDSDocument6 pagesStilboestrol Tablets MSDSIsaac lauricNo ratings yet

- Discard ManagementDocument9 pagesDiscard ManagementDevvrath SinghNo ratings yet

- Capinew Account June13Document7 pagesCapinew Account June13ashwinNo ratings yet

- Re 51400Document14 pagesRe 51400Jamin Smtpng0% (1)

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- Silvestres Grupo 5Document39 pagesSilvestres Grupo 5Juliana DiazNo ratings yet

- Over The Counter MedicinesDocument3 pagesOver The Counter MedicinesJhun Echipare100% (3)

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- ws3-1 R B Carating PDFDocument7 pagesws3-1 R B Carating PDFJuliet AbalosNo ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- Dan Sof TG 0122Document30 pagesDan Sof TG 0122Erick Trujillo100% (1)

- 00000102Document108 pages00000102Scary CreaturesNo ratings yet

- Thesis Van Ende FinalDocument277 pagesThesis Van Ende FinalArtem KravchenkoNo ratings yet

- Problem Sets For Solutions AnalysisDocument2 pagesProblem Sets For Solutions AnalysisKamil Guillergan100% (1)

- Blue Bead McqsDocument11 pagesBlue Bead Mcqsanu minochaNo ratings yet

- Physics Answers Electric and MagnetismDocument8 pagesPhysics Answers Electric and MagnetismGeethanjali SivakumarNo ratings yet

- Inorganic Chemistry HomeworkDocument3 pagesInorganic Chemistry HomeworkAlpNo ratings yet

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

Uploaded by

andri putrantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

JBT Foodtech H1 Food Grade Seamer Oil Synthetic Demulsifying

Uploaded by

andri putrantoCopyright:

Available Formats

Madera, California: +1-559-661-3200

Australia: +61-3-9756-2908*

Sint-Niklaas, Belgium: +32-3-780-1211

Parma, Italy: +39-0521-908-411

Thailand: +66-2261-4261-3

Nonfood Compounds

www.jbtfoodtech.com Program Listed H1

e-mail: madera.fpsd@jbtc.com NSF Reg. No.139946

JBT FoodTech H1 Food Grade Seamer Oil

Synthetic Demulsifying

For use in Seamer Recycled Oil Systems

• Outstanding Antiwear Protection

• Custom Formulations for Product Compatibility

• FDA / NSF Food Grade Compliant

• Excellent Filterability Characteristics

• Excellent High Temperature Oxidation Stability

• High Level Rust & Corrosion Protection

• Includes Micronox® Technology

APPLICATION

High speed beverage can seamer systems for the protection of internal

components. In newer higher speed models, typically 10, 12, 14, 16 or 18

station units, the majority utilize a sophisticated recirculating system

involving an oil lubricated advanced coalescing filter system. Unlike older

models which utilized the lubricating fluid in a one-pass mode, these require

a high-performance fluid that will provide enhanced wear protection and

long fluid life. In addition, the fluids must be NSF H1 food-grade level

acceptable and be able to handle issues involved with various packaged

products from beer to soda water to fruit juices to mineral waters. Typical Property Seamer Oil Synthetic

Experience has dictated different performance requirements based upon Demulsifying

the products being packaged.

Viscosity, 100°C, cSt 12 -14

PERFORMANCE Viscosity, 40°C, cSt 135 -150

JBT FoodTech Seamer Fluid is a fully synthetic, food grade, antiwear fluid. Viscosity Index 120 min.

They are compounded to provide the ultimate in wear and corrosion

protection as shown in industry standard tests as well as extensive field trials. ISO Viscosity Grade 100

SAE Viscosity Grade 30

JBT FoodTech Demulsifying D-Seamer Fluid is a demulsifying lubricant Pounds per Gallon 7.2

intended for can closers processing low fructose or corn syrup products where

minimal migration of processed product to the lubricating fluid is present. It Pour Point, °F (°C) -42 (-41)

provides optimum water and contamination separation characteristics for Flash Point, °F (°C) 464 (240)

easier filtration and lower filter pressures. Making the fluid more compatible Fire Point, °F (°C) 543 (284)

with the filter system and easing the water separation characteristics assure

the oil system of optimum wear protection and filtration performance. This Copper Strip Corrosion 1b

results in optimum seaming equipment performance and longevity. RBOT @ 150°C, min. 750 -1000

Emulsion Characteristics @ 54°C) 40-38-2 (10)

BENEFITS Oil-Water-Cuff (Minutes)

What does all of this mean to the beverage packager and the performance

of their JBT FoodTech or Angelus can closers? In a nutshell: greatly Foaming Characteristics Initial / 0 / 0 (8 sec.)

extended intervals between major overhauls or routine replacement of wear Final Volume (Time) Sequence I 8 / 0 (4 sec.)

parts, greater compatibility with the online oil filtration systems, reduced Sequence II Sequence III 0 / 0 (8 sec.)

concerns over product or water migration into the lubrication system and

confidence knowing that all of this performance is accomplished with NSF / Rust Test Method A - Distilled Water Pass

FDA compliant food grade lubricants. Method B - Synthetic Sea Water Pass

JBT FoodTech Part Numbers Noack Volatility, % Weight Loss 6.2%

Demulsifying Shell Four-Ball Wear, Scar Diameter, mm 0.43

575087 5 Gal. (18.9 L) Pail NSF Reg. No. / Category Code 139946 / H1

575088 55 Gal. (208 L) Drum

ORDER PARTS ONLINE

or call 1-800-3230 24/7 for

www.myjbtfoodtech.com questions, ordering or help

with online registration. * To contact agent

JBT FoodTech, whose policy is to continuously improve its products, reserves the right to discontinue

© Copyright by John Bean Technologies Corporation. Printed in USA 0808 or change specifications, models or design without notice and without incurring obligation.

Approval Date 7/1/2008

Material Safety Data Sheet Supersedes Date 12/7/2007

Section I. Chemical Product and Company Identification

Product Name/ JBT FOODTECH H1 SYNTHETIC SEAMER OIL - Product 575087; 575088

Trade Name DEMULSIFYING ID No.

CAS # COMPLEX MIXTURE

Supplier JBT FoodTech

CAS Number Not Applicable

2300 Industrial Avenue

In Case of Emergency

Box A

In the event of a chemical spill, release,

Madera, CA 93639 USA poisoning or exposure, Call 3E Company, Inc.:

800-514-1746 (North America)

Synonym(s) None 001 760-602-8897 (International)

Chemical Name Synthetic lubricating oil For JBT PHONE: 800-835-3230

Information JBT FAX: 559-661-3140

Chemical Family Synthetic hydrocarbon

Chemical Formula Mixture

Material Uses Lubricant

Section II. Composition and Information on Ingredients

Name PEL/TLV, Source CAS # % by Weight

PROPRIETARY FORMULA. This material is essentially a synthetic lubricating oil. 5 mg/m3 (oil mist), OSHA Mixture 100.0

LC50, LD50 of Ingredients Not available

Section III. Hazards Identification

Emergency Overview Potential health risks vary from person to person. As a precaution, exposure to liquids, vapors, mists or fumes should be

minimized. In an accident involving high-pressure equipment, this product may be injected under the skin, resulting in a small,

sometimes bloodless puncture wound. Immediate treatment at a surgical emergency center is recommended.

Potential Health Effects:

Eye Contact May cause slight irritation and redness.

Skin Contact Prolonged or repeated skin contact may cause mild irritation. Not expected to be harmful to internal organs if absorbed

through the skin. High-Pressure Equipment information: Accidental high-velocity injection under the skin of materials

of this type may result in serious injury. Seek medical attention at once should an accident like this occur. The initial wound at

the injection site may not appear to be serious at first, but if left untreated, could result in disfigurement or amputation of the

affected part.

Ingestion Ingestion may cause irritation of the digestive tract. Aspiration into lungs can cause pneumonitis, which can be fatal.

Inhalation Vapor inhalation under ambient temperature conditions is not normally a problem. May cause respiratory irritation or other

pulmonary effects following prolonged or repeated inhalation of oil mist at airborne levels above the recommended oil mist

exposure limit.

Continued on Next Page

JBT FOODTECH H1 SYNTHETIC SEAMER OIL - DEMULSIFYING

PAGE 2 OF 4

Section III. Hazards Identification (cont'd)

HAZARD RATINGS

0 Minimal Hazard 3 Serious Hazard

HMIS Code Health: 1 Fire: 1 Physical Hazard: 0 1 Slight Hazard 4 Severe Hazard

2 Moderate Hazard

Section IV. First Aid Measures

Eye Contact Remove contact lenses, if worn, and and flush eyes with water. If irritation persists, consult a physician.

Skin Contact Remove clothing and shoes if contaminated. Wash skin with soap and water. Wash or clean contaminated clothing before reuse

and discard oil-soaked shoes. If irritation persists, consult a physician.

Ingestion If swallowed, DO NOT induce vomiting. As a precaution, give the person a glass of water to drink and seek medical attention.

Never give anything by mouth to an unconscious person. Consult a physician.

Inhalation If exposed to excessive levels of material in the air, move the exposed person to fresh air. Seek medical attention if coughing or

respiratory discomfort occurs.

Section V. Fire and Explosion Data

Autoignition Temperature Not available

Flash Point 464°F (240°C), ASTM D 92

Flammable Limits (Approx.) LOWER Flammable Limit: Not available UPPER Flammable Limit: Not available

Explosion Hazards See Lower and Upper Flammable Limits

Products of Combustion Carbon monoxide, carbon dioxide, smoke and irritating vapors as products of incomplete combustion.

Fire Fighting Media Dry chemical, alcohol foam, and carbon dioxide type extinguishing agents may all be suitable for extinguishing fires involving this

and Instructions type of product, depending on the size or potential size of fire and circumstances related to the situation. Plan fire protection and

response strategy through consultation with local fire protection authorities or appropriate specialists. The following procedures

for this type of product are based on the recommendations in the National Fire Protection Association's Fire Protection Guide on

Hazardous Materials. Use water to keep fire-exposed containers cool. If a leak or spill has not ignited, use water spray to

disperse the vapors and to provide protection for men attempting to stop a leak. Water spray may be used to flush spills away

from explosives. Firefighters should wear full protective gear, including helmet. Use supplied-air breathing equipment for

enclosed or confined spaces or as otherwise needed.

Special Remarks - For fires involving this material, do not enter any enclosed or confined fire space without proper protective equipment, including

Fire and Explosion self-contained breathing apparatus. Leaks/ruptures in high-pressure systems using materials of this type can create a fire hazard

Hazards when in the vicinity of ignition sources (open flame, pilot lights, sparks or electric arcs).

Section VI. Accidental Release Measures

Release or Spill Ventilate area, especially low places where heavy vapors might collect. Extinguish all ignition sources. For small spills/leaks,

mop, wipe or soak up on an inorganic material immediately. Remove to vent hood or outside. For large spills/leaks, evacuate

area, contain spill (dike area), and transfer contained liquid to a DOT-approved container for disposal. Keep out of water supply.

Refer to other sections of this MSDS for information regarding physical and health hazards, respiratory protection, ventilation, and

personal protective equipment. When disposing of unused contents, the preferred options are to send to licensed reclaimers or to

permitted incinerators. Any disposal practice must be in compliance with federal, state, and local laws and regulations. Do not

dump into sewers, on the ground, or into any body of water.

Environmental Impact Report spills as required to the appropriate authorities. U.S Coast Guard Regulations require immediate reporting of spills that

could reach any waterway including intermittent dry creeks. Report spill to the Coast Guard toll-free number 800-424-8802.

Section VII. Handling and Storage

Handling Container is not designed to contain pressure. Do not use pressure to empty container or it may rupture with explosive force.

"Empty" containers retain product residue and can be dangerous. Do not pressurize, cut, weld, braze, solder, drill, grind, or

expose such containers to heat, flame, sparks, static electricity, or other sources of ignition as they may explode and can cause

injury or death. Empty container should be promptly returned to a drum reconditioner.

Storage Do not use in high-pressure systems in the vicinity of flames, sparks and hot surfaces. Keep container closed. Do not store near

heat, sparks, open flame, pilot lights, static electricty, or where temperature may exceed 120°F (49°C).

Continued on Next Page

JBT FOODTECH H1 SYNTHETIC SEAMER OIL - DEMULSIFYING

PAGE 3 OF 4

Section VIII. Exposure Controls and Personal Protection

Respiratory Protection Use respiratory protection if needed to keep airborne levels below recommended mineral oil mist exposure limits.

Ventilation Use in a well-ventilated area. See Engineering Controls.

Protective Gloves Any lined non-permeable rubber gloves.

Eye Protection Chemical splash goggles or face shield in compliance with OSHA regulations are advised when eye contact may occur.

Personal Hygiene Wash skin thoroughly after contact, before breaks and meals and at end of work period. Product is readily removed from skin by

waterless hand cleaners followed by washing thoroughly with soap and water.

Engineering Controls If user operations generate an oil mist, use process enclosures, local exhaust ventilation, or other engineering controls to control

airborne levels below the recommended mineral oil mist exposure limits.

Exposure Limit See Section II.

Section IX. Physical and Chemical Properties

Appearance/Odor Orange-colored lube oil with little or no odor Vapor Pressure Nil

Vapor Density Not available

Odor Threshold Not available Percent Volatile 0.0

Specific Gravity 0.8654 Evaporation Rate Nil

Density Not available Viscosity Not available

Molecular Weight Not available Solubility in Water Nil

pH Not available Coefficient of Water/Oil Not available

Distribution

Boiling Point Not available

Physical State Liquid

Freezing/Melting Point Not available

Section X. Stability and Reactivity Data

Stability Stable under normal temperatures and pressures.

Conditions of Reactivity Not available

Conditions and Materials Avoid heat, sparks, open flames and oxidizing materials.

to Avoid

Hazardous Polymerization Hazardous polymerization will not occur.

Hazardous Decomposition Carbon monoxide, carbon dioxide, smoke and irritating vapors as products of incomplete combustion.

Products

Section XI. Toxicological Information

Routes of Entry Dermal contact, eye contact, inhalation, ingestion.

Toxicity to Animals Not available

Effects of Acute Exposure Not available

Acute Effects of Not available

Sensitization

Ingestion Not available

Inhalation Not available

Toxically Synergistic Not available

Products

Chronic Effects on Humans:

Carcinogenic Effects This product does not contain a carcinogen or potential carcinogen as listed by NTP, IARC, or OSHA [29 CFR 1910.1200(D)#4].

Mutagenic Effects No data available to indicate any components present at greater than 0.1% may present a mutagenic hazard.

Continued on Next Page

JBT FOODTECH H1 SYNTHETIC SEAMER OIL - DEMULSIFYING PAGE 4 OF 4

Section XI. Toxicological Information (cont'd)

Teratogenic Effects No data available to indicate any components present at greater than 0.1% may present a teratogenic hazard.

Reproductive Effects No data available to indicate any components present at greater than 0.1% may present a reproductive hazard.

Section XII. Ecological Information

Ecotoxicity There is no data available on the adverse effects of this material on the environment.

Section XIII. Disposal Considerations

Waste Disposal Consult federal, state or local authorities for proper disposal and reporting procedures. All disposals must comply wtih federal,

state and local regulations.

Section XIV. Transportation Information

I.A.T.A. Air Transportation: U.S. D.O.T. Ground Transportation:

Shipping Name Not regulated Shipping Name Not regulated

Hazard Class None

UN Number None

Packing Group None U.S. D.O.T. Remarks The above U.S. D.O.T. information applies to

I.A.T.A. Remarks None shipping BY GROUND ONLY.

Section XV. Regulatory Information

U.S. Federal Regulations:

CERCLA Release of the following chemical(s) at quantities equal to or greater than the reportable quantities (RQ), is regulated by

40 CFR 302.4 :

None

SARA (Section 313) This product contains the following chemical(s) listed in Section 313 at or above the de minimis concentrations:

None

SARA Extremely This product contains greater than 1.0% of the following chemical(s) on the SARA Extremely Hazardous Substances List:

Hazardous List

None

TSCA Inventory All components of this material are on the U.S. TSCA Inventory.

California Prop. 65 This product contains the following chemical(s) known to the State of California to cause birth defects or other reproductive

harm:

None

International Regulations:

Canada All components are in compliance with the Canadian Environmental Protection Act. This product has been classified in

accordance with the hazard criteria of the CPR and this MSDS contains all the information required by CPR.

Japan MITI Not available

Australia Not available

Switzerland Not available

Section XVI. Other Information

Approval Date 7/1/2008

Supersedes Date 12/7/2007

Prepared by Technical Services 800-835-3230

Sections Revised Section I

Since Last Version

The information and recommendations contained herein are, to the best of JBT FoodTech's knowledge and belief, accurate and reliable as of the date issued.

JBT FoodTech makes no warranty or guarantee, expressed or implied, of their accuracy or reliability, and JBT FoodTech shall not be liable for any loss or

damage based upon the criteria supplied by the developers of these rating systems, together with JBT FoodTech's interpretation of the available data.

You might also like

- HDFC Ergo Policy Renewal 2023 SelfDocument5 pagesHDFC Ergo Policy Renewal 2023 SelfGopivishnu KanchiNo ratings yet

- BS 4254Document19 pagesBS 4254gugaruban100% (4)

- Computer System Validation Risk Assessment ToolDocument3 pagesComputer System Validation Risk Assessment Toolcpkakope100% (1)

- OSTEORADIONECROSISDocument38 pagesOSTEORADIONECROSISAbel AbrahamNo ratings yet

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- Hoja Técnica Roto FoodGrade FluidDocument2 pagesHoja Técnica Roto FoodGrade FluidFederico Liaudat100% (1)

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- O & M of Sub StationDocument94 pagesO & M of Sub StationAlbert Sekar100% (2)

- JBT Foodtech H1 Food Grade Air Line OilDocument5 pagesJBT Foodtech H1 Food Grade Air Line Oilandri putrantoNo ratings yet

- Omega 585Document12 pagesOmega 585Vikz 4gameNo ratings yet

- JBT Foodtech H1 Food Grade 320 Gear OilDocument5 pagesJBT Foodtech H1 Food Grade 320 Gear Oilandri putrantoNo ratings yet

- 238 FG Machinery Oil: DescriptionDocument2 pages238 FG Machinery Oil: DescriptionFraz AhmadNo ratings yet

- Data Sheet Omega58Document11 pagesData Sheet Omega58GUECHI NADIRNo ratings yet

- 99454032&4046 QuinplexDocument4 pages99454032&4046 QuinplexDeltalube TangerangNo ratings yet

- Molykote G 4000 FMDocument2 pagesMolykote G 4000 FMRicardo ZuimNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- CASTROL BIO TAC OG - Pds - Rev. 17.08.2022Document2 pagesCASTROL BIO TAC OG - Pds - Rev. 17.08.2022Massimiliano VolaNo ratings yet

- Bpxe 9TQS2KDocument3 pagesBpxe 9TQS2KJayson VegillaNo ratings yet

- Cosmolubric HF-122 Data SheetDocument1 pageCosmolubric HF-122 Data Sheetsiddharth srinivasanNo ratings yet

- Description: Surface Protection:: Test Astm Test Method Test ResultDocument13 pagesDescription: Surface Protection:: Test Astm Test Method Test ResultizantuxNo ratings yet

- Aceite G A Atlascopco 1630-0542-00 20L 1630-0833-00 5LDocument2 pagesAceite G A Atlascopco 1630-0542-00 20L 1630-0833-00 5LAndres Felipe TorresNo ratings yet

- Jet-Lube Jacking Grease ECF - TDS - EnglishDocument1 pageJet-Lube Jacking Grease ECF - TDS - EnglishDon HowardNo ratings yet

- Prolube® High Temp H1 Food Grade Machinery Grease #1 & #2Document1 pageProlube® High Temp H1 Food Grade Machinery Grease #1 & #2Jhonathan AlejandroNo ratings yet

- Caltex Regal Ro 46Document3 pagesCaltex Regal Ro 46HyungTae JangNo ratings yet

- Castrol 2T: DescriptionDocument2 pagesCastrol 2T: Descriptionhoussem houssemNo ratings yet

- No Tox Food Grade Seamer OilDocument2 pagesNo Tox Food Grade Seamer OilDon HowardNo ratings yet

- Bioadd 770 DS (2007) PDFDocument2 pagesBioadd 770 DS (2007) PDFSabrina RiveraNo ratings yet

- Product Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseDocument2 pagesProduct Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseHewa PCNo ratings yet

- Omega 58 Pim en 20190102R2Document2 pagesOmega 58 Pim en 20190102R2ckpangNo ratings yet

- Pds Lm2000 Co enDocument2 pagesPds Lm2000 Co enmanojNo ratings yet

- TDS - 57006 AddNox Anti Block MBDocument1 pageTDS - 57006 AddNox Anti Block MBRajiv DubeyNo ratings yet

- Castrol BiostatDocument3 pagesCastrol BiostatjshkaNo ratings yet

- Roto ZDocument3 pagesRoto Zjayakumar rajanNo ratings yet

- React Performance Dot4Document2 pagesReact Performance Dot4jamie.crassNo ratings yet

- 4406 Synthetic HD Industrial Gear OilDocument2 pages4406 Synthetic HD Industrial Gear OilYoong TanNo ratings yet

- DANA ATF DEX III - by DANA LUBRICANTS ENGINE OIL MANUFACTURERDocument2 pagesDANA ATF DEX III - by DANA LUBRICANTS ENGINE OIL MANUFACTURERankurdanaNo ratings yet

- Gear OilDocument2 pagesGear OilQuy CocanhNo ratings yet

- Biosolve Spill RX: Technical Data SheetDocument2 pagesBiosolve Spill RX: Technical Data SheetJackNo ratings yet

- Cassida WGDocument3 pagesCassida WGRaghavendra MurthyNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Product Data: Castrol Alpha SP 150Document2 pagesProduct Data: Castrol Alpha SP 150Jagadeesh SharanNo ratings yet

- Sae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFDocument2 pagesSae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFChemilomNo ratings yet

- Advantages of Ester Over Mineral OilDocument8 pagesAdvantages of Ester Over Mineral OilMenoddin shaikhNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- PDS CALTEX Turbine OilDocument3 pagesPDS CALTEX Turbine OilAndaru Gunawan0% (1)

- Super Outboard 2TDocument2 pagesSuper Outboard 2TArvin BadruzamanNo ratings yet

- CircularDocument2 pagesCircularQuy CocanhNo ratings yet

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- Sinopec Crystal GreaseDocument2 pagesSinopec Crystal GreaseImran ImranNo ratings yet

- Molykote® G-1502FM Data SheetDocument2 pagesMolykote® G-1502FM Data SheetlorenzoNo ratings yet

- XIAMETER™ Q1-6083 Antifreeze Additive: Features & BenefitsDocument2 pagesXIAMETER™ Q1-6083 Antifreeze Additive: Features & BenefitsAlex CamposNo ratings yet

- Mobil DTE FM 32Document3 pagesMobil DTE FM 32UtkarshNo ratings yet

- CASTROL Bpxe-98rlqaDocument2 pagesCASTROL Bpxe-98rlqarexNo ratings yet

- Product Information: Valvoline™ HD Nitrite Free Coolant RTUDocument2 pagesProduct Information: Valvoline™ HD Nitrite Free Coolant RTUmcalidonio5656No ratings yet

- ISO Grade 68: Performance in MotionDocument2 pagesISO Grade 68: Performance in MotionJose Angel GonzalezNo ratings yet

- Product Data Sheet: No-Tox HD Food Grade GreaseDocument3 pagesProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- MAK Hydrol HVLPDocument3 pagesMAK Hydrol HVLPadheesNo ratings yet

- PDS CST820 CO enDocument2 pagesPDS CST820 CO enm.onderolaganNo ratings yet

- Roto Z Foodgrade: For Oil-Free Z Rotary Screw and Tooth CompressorsDocument2 pagesRoto Z Foodgrade: For Oil-Free Z Rotary Screw and Tooth CompressorsMario MullerNo ratings yet

- Rando HD: Premium Anti-Wear Hydraulic FluidDocument2 pagesRando HD: Premium Anti-Wear Hydraulic FluidbdsisiraNo ratings yet

- 1543995316221-P4BA-4.00549 - (Waves - Rubber) 160X110Document1 page1543995316221-P4BA-4.00549 - (Waves - Rubber) 160X110andri putrantoNo ratings yet

- Pds Shell Gadus S2 V220-0Document2 pagesPds Shell Gadus S2 V220-0andri putrantoNo ratings yet

- LiftCheck CS PN40 SSTrimDocument1 pageLiftCheck CS PN40 SSTrimandri putrantoNo ratings yet

- STMCS Laser Cleaning MoldDocument7 pagesSTMCS Laser Cleaning Moldandri putrantoNo ratings yet

- QJ-8-105-20-consumable Bu Putri-SignedDocument1 pageQJ-8-105-20-consumable Bu Putri-Signedandri putrantoNo ratings yet

- O Ring Data SheetDocument3 pagesO Ring Data Sheetandri putrantoNo ratings yet

- Permintaan Disc SPK 04915Document1 pagePermintaan Disc SPK 04915andri putrantoNo ratings yet

- Specification STMCS 3 0 - FreigegebenDocument10 pagesSpecification STMCS 3 0 - Freigegebenandri putrantoNo ratings yet

- FT-H40K DatasheetDocument2 pagesFT-H40K Datasheetandri putrantoNo ratings yet

- Capacitor Bank 70kvarDocument1 pageCapacitor Bank 70kvarandri putrantoNo ratings yet

- Nu 313 Ecm - 20230125212Document5 pagesNu 313 Ecm - 20230125212andri putrantoNo ratings yet

- PT. Airlock Service BrochureDocument5 pagesPT. Airlock Service Brochureandri putrantoNo ratings yet

- Push Botton DrawingDocument1 pagePush Botton Drawingandri putrantoNo ratings yet

- Ultra Coolant LubricantDocument3 pagesUltra Coolant Lubricantandri putrantoNo ratings yet

- SMC VP7Document24 pagesSMC VP7andri putrantoNo ratings yet

- Spec Bias CuttingDocument4 pagesSpec Bias Cuttingandri putrantoNo ratings yet

- Frangklin Pump Data SheetDocument1 pageFrangklin Pump Data Sheetandri putrantoNo ratings yet

- Oil-Flooded Rotary Screw Compressed Air Systems: 4-37 KW (5.5-50 HP)Document3 pagesOil-Flooded Rotary Screw Compressed Air Systems: 4-37 KW (5.5-50 HP)andri putrantoNo ratings yet

- CL-M685 I-Type 2/3/4/5 Pins IP68 Waterproof Connector: Features and BenefitsDocument1 pageCL-M685 I-Type 2/3/4/5 Pins IP68 Waterproof Connector: Features and Benefitsandri putrantoNo ratings yet

- 3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 BarDocument2 pages3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 Barandri putrantoNo ratings yet

- TFE Insulated Thermocouple Wire: Iron - ConstantanDocument1 pageTFE Insulated Thermocouple Wire: Iron - Constantanandri putrantoNo ratings yet

- JBT Foodtech H1 Food Grade 320 Gear OilDocument5 pagesJBT Foodtech H1 Food Grade 320 Gear Oilandri putrantoNo ratings yet

- T30 2-Stage Lubricated Air CompressorDocument1 pageT30 2-Stage Lubricated Air Compressorandri putrantoNo ratings yet

- 1.5 Tons Per Hours Wood PelletDocument4 pages1.5 Tons Per Hours Wood Pelletandri putrantoNo ratings yet

- JBT Foodtech H1 Food Grade Air Line OilDocument5 pagesJBT Foodtech H1 Food Grade Air Line Oilandri putrantoNo ratings yet

- Toptherm Wall-Mounted Cooling Unit Blue E Total Cooling Output 0.50 - 0.75 KW - SK 3361.500Document4 pagesToptherm Wall-Mounted Cooling Unit Blue E Total Cooling Output 0.50 - 0.75 KW - SK 3361.500andri putrantoNo ratings yet

- pH/ORP/Temperature Datalogger: Records Data On An SD Card in Excel FormatDocument1 pagepH/ORP/Temperature Datalogger: Records Data On An SD Card in Excel Formatandri putrantoNo ratings yet

- ABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFDocument3 pagesABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFandri putrantoNo ratings yet

- Electrical Data General Data: Order NumberDocument1 pageElectrical Data General Data: Order Numberandri putrantoNo ratings yet

- 1 jISHADocument5 pages1 jISHAFirman MufidNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (25)

- Mbarang 10102022Document3 pagesMbarang 10102022zeta chenkNo ratings yet

- Activated Carbon MSDS PDFDocument6 pagesActivated Carbon MSDS PDFRIANG TRIANDONONo ratings yet

- Environmental Crisis Causes and ManifestationsDocument26 pagesEnvironmental Crisis Causes and Manifestationsबाजीराव सिंघम0% (1)

- CSF PDFDocument58 pagesCSF PDFVas KannanNo ratings yet

- Material Sub Group Item CodeDocument2,818 pagesMaterial Sub Group Item Codegouri gouriNo ratings yet

- Ramsay Health Care - BudgetDocument13 pagesRamsay Health Care - BudgetTatiana Garcia MendozaNo ratings yet

- Stilboestrol Tablets MSDSDocument6 pagesStilboestrol Tablets MSDSIsaac lauricNo ratings yet

- Discard ManagementDocument9 pagesDiscard ManagementDevvrath SinghNo ratings yet

- Capinew Account June13Document7 pagesCapinew Account June13ashwinNo ratings yet

- Re 51400Document14 pagesRe 51400Jamin Smtpng0% (1)

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- Silvestres Grupo 5Document39 pagesSilvestres Grupo 5Juliana DiazNo ratings yet

- Over The Counter MedicinesDocument3 pagesOver The Counter MedicinesJhun Echipare100% (3)

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- ws3-1 R B Carating PDFDocument7 pagesws3-1 R B Carating PDFJuliet AbalosNo ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- Dan Sof TG 0122Document30 pagesDan Sof TG 0122Erick Trujillo100% (1)

- 00000102Document108 pages00000102Scary CreaturesNo ratings yet

- Thesis Van Ende FinalDocument277 pagesThesis Van Ende FinalArtem KravchenkoNo ratings yet

- Problem Sets For Solutions AnalysisDocument2 pagesProblem Sets For Solutions AnalysisKamil Guillergan100% (1)

- Blue Bead McqsDocument11 pagesBlue Bead Mcqsanu minochaNo ratings yet

- Physics Answers Electric and MagnetismDocument8 pagesPhysics Answers Electric and MagnetismGeethanjali SivakumarNo ratings yet

- Inorganic Chemistry HomeworkDocument3 pagesInorganic Chemistry HomeworkAlpNo ratings yet