Professional Documents

Culture Documents

Technical Note: What Is A VFD?

Technical Note: What Is A VFD?

Uploaded by

mdkhandaveOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Note: What Is A VFD?

Technical Note: What Is A VFD?

Uploaded by

mdkhandaveCopyright:

Available Formats

—

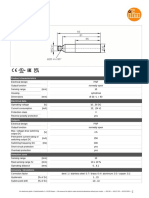

Technical note

What is A VFD?

You can divide the world of electronic motor drives

into two categories: AC and DC. A motor drive

controls the speed, torque, direction and resulting

horsepower of a motor. A DC drive typically controls a

shunt wound DC motor, which has separate armature

and field circuits. AC drives control AC induction

motors, and-like their DC counterparts-control speed,

torque, and horsepower.

Application As An Example

Figure 2, Basic Induction Motor Construction

Let’s take a brief look at a drive application. In Fig. 1,

you can see a simple application with a fixed speed

fan using a motor starter. You could replace the

3-phase motor starter with Variable Frequency Drive

(VFD) to operate the fan at variable speed. Since you

can operate the fan at any speed below its maximum,

you can vary airflow by controlling the motor speed

instead of the air outlet damper.

Figure 3, Operating Principles of Induction Motor

With one pole pair isolated in a motor, the rotor

Figure 1, Fixed Speed Fan Application (shaft) rotates at a specific speed: the base speed.

The number of poles and the frequency applied

A drive can control two main elements of a 3-phase determine this speed (Fig. 4). This formula includes an

induction motor: speed and torque. To understand effect called “slip.” Slip is the difference between the

how a drive controls these two elements, we will take rotor speed and the rotating magnetic field in the

a short review of AC induction motors. Fig. 2 shows stator. When a magnetic field passes through the

the construction of an induction motor. The two basic conductors of the rotor, the rotor takes on magnetic

parts of the motor, the rotor and stator, work through fields of its own. These rotor magnetic fields will try

magnetic interaction. A motor contains pole pairs. to catch up to the rotating fields of the stator.

These are iron pieces in the stator, wound in a specific However, it never does -- this difference is slip. Think

pattern to provide a north to south magnetic field. of slip as the distance between the greyhounds and

the hare they are chasing around the track. As long as

they don’t catch up to the hare, they will continue to

revolve around the track. Slip is what allows a motor

to turn.

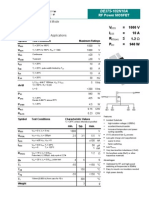

Figure 6, Basic PWM Drive Components

Although some drives accept single-phase input

power, we’ll focus on the 3-phase drive. But to

Figure 4, Induction Motor Slip Calculation

simplify illustrations, the waveforms in the following

drive figures show only one phase of input and

output.

We can conveniently adjust the speed of a motor by

changing the frequency applied to the motor. You

The input section of the drive is the converter. It

could adjust motor speed by adjusting the number of

contains six diodes, arranged in an electrical bridge.

poles, but this is a physical change to the motor. It

These diodes convert AC power to DC power. The next

would require rewinding, and result in a step change

section-the DC bus section-sees a fixed DC voltage.

to the speed. So, for convenience, cost-efficiency, and

The DC Bus section filters and smooths out the

precision, we change the frequency. Fig. 5 shows the

waveform. The diodes actually reconstruct the

torque developing characteristic of every motor: the

negative halves of the waveform onto the positive

Volts per Hertz ratio (V/Hz). We change this ratio to

half. In a 460V unit, you’d measure an average DC bus

change motor torque. An induction motor connected

voltage of about 650V to 680V. You can calculate this

to a 460V, 60 Hz source has a ratio of 7.67. As long as

as line voltage times 1.414. The inductor (L) and the

this ratio stays in proportion, the motor will develop

capacitor (C) work together to filter out any AC

rated torque. A drive provides many different

component of the DC waveform. The smoother the DC

frequency outputs. At any given frequency output of

waveform, the cleaner the output waveform from the

the drive, you get a new torque curve.

drive.

The DC bus feeds the final section of the drive: the

inverter. As the name implies, this section inverts the

DC voltage back to AC. But, it does so in a variable

voltage and frequency output. How does it do this?

That depends on what kind of power devices your

drive uses. If you have many SCR-based drives in your

facility, see the Sidebar. Bipolar Transistor technology

began superseding SCRs in drives in the mid-1970s. In

the early 1990s, those gave way to using Insulated

Gate Bipolar Transistor (IGBT) technology, which will

Figure 5, Volts/Hertz Ratio form the basis for our discussion.

Switching Bus With IGBTs

How Drive Changes Motor Speed

Today’s inverters use Insulated Gate Bipolar

Just how does a drive provide the frequency and

Transistors (IGBTs) to switch the DC bus on and off at

voltage output necessary to change the speed of a

specific intervals. In doing so, the inverter actually

motor? That’s what we’ll look at next. Fig. 6 shows a

creates a variable AC voltage and frequency output.

basic PWM drive. All PWM drives contain these main

As shown in Fig. 7, the output of the drive doesn’t

parts, with subtle differences in hardware and

provide an exact replica of the AC input sine

software components.

waveform. Instead, it provides voltage pulses that are

at a constant magnitude.

Sidebar: What if you have SCRs?

One item is noteworthy. In the beginning of this

article, DC Drives are referenced, and SCRs are

indicated in relation to AC Drives and DC Drives.

Currently, SCRs primarily find themselves as the

power conversion component mainly in DC Drives.

The use of SCRs in AC Drives has been overtaken by

Diodes and IGBTs for many years.

Figure 7, Drive Output Waveform

With that in mind, there is a large installed base of

SCRs and you might want to know how these

The drive’s control board signals the power device’s

operate. An SCR (originally referred to as a

control circuits to turn “on” the waveform positive half

thyristor) contains a control element called a gate.

or negative half of the power device. This alternating

The gate acts as the “turn-on” switch that allows

of positive and negative switches recreates the 3

the device to fully conduct voltage. The device

phase output. The longer the power device remains

conducts voltage until the polarity of the device

on, the higher the output voltage. The less time the

reverses-and then it automatically ‘turns off.”

power device is on, the lower the output voltage

Special circuitry, usually requiring another circuit

(shown in Fig.8). Conversely, the longer the power

board and associated wiring, controls this

device is off, the lower the output frequency.

switching.

The speed at which power devices switch on and off is

the carrier frequency, also known as the switch

The SCR’s output depends on how soon in the

frequency. The higher the switch frequency, the more

control cycle that gate turns on. The IGBT output

resolution each PWM pulse contains. Typical switch

also depends the length of time the gate is on.

frequencies are 3,000 to 4,000 times per second

However, it can turn off anytime in the control

(3KHz to 4KHz). (With an older, SCR-based drive,

cycle, providing a more precise output waveform.

switch frequencies are 250 to 500 times per second).

IGBTs also require a control circuit connected to

As you can imagine, the higher the switch frequency,

the gate, but this circuitry is less complex and

the smoother the output waveform and the higher the

doesn’t require a reversal of polarity. Thus, you

resolution. However, higher switch frequencies

would approach troubleshooting differently if you

decrease the efficiency of the drive because of

have an SCR-based drive.

increased heat in the power devices.

Shrinking cost and size

Drives vary in the complexity of their designs, but the

designs continue to improve. Drives come in smaller

packages with each generation. The trend is similar to

that of the personal computer. More features, better

performance, and lower cost with successive

generations. Unlike computers, however, drives have

dramatically improved in their reliability and ease of

use. And also unlike computers, the typical drive of

today doesn’t spew gratuitous harmonics into your

distribution system-nor does it affect your power

factor. Drives are increasingly becoming “plug and

play.” As electronic power components improve in

reliability and decrease in size, the cost and size of

VFDs will continue to decrease. While all that is going

on, their performance and ease of use will only get

better.

LVD-EOTN01U-EN REVB 01/31/2018

— —

ABB Inc. We reserve the right to make technical We reserve all rights in this document and in

Robotics and Motion changes or modify the contents of this the subject matter and illustrations

Drives and Controls document without prior notice. With regard contained therein. Any reproduction,

16250 W. Glendale Drive to purchase orders, the agreed particulars disclosure to third parties or utilization of

New Berlin, WI 53151 shall prevail. ABB does not accept any its contents – in whole or in parts – is

responsibility whatsoever for potential forbidden without prior written consent of

errors or possible lack of information in this ABB. Copyright© 2018 ABB

document. All rights reserved

abb.com/drives

You might also like

- Chapter 15Document71 pagesChapter 15Mogaka LucasNo ratings yet

- Proton Arena Jumbuck Engine Electrical 1.5 1.8 Service ManualDocument50 pagesProton Arena Jumbuck Engine Electrical 1.5 1.8 Service ManualEddie Jai0% (1)

- Siemens VCBDocument64 pagesSiemens VCBInayat HathiariNo ratings yet

- What Is A DriveDocument4 pagesWhat Is A DriveJibjab7No ratings yet

- What Is A Variable Frequency Drive? How Does A VFD Work?Document6 pagesWhat Is A Variable Frequency Drive? How Does A VFD Work?S.M.Touhidur RahmanNo ratings yet

- Figure 1. Simple VFD / Fan ApplicationDocument7 pagesFigure 1. Simple VFD / Fan ApplicationTapas PalNo ratings yet

- VFD Rebate Dsire: What Is A VFD?Document35 pagesVFD Rebate Dsire: What Is A VFD?Stephen Rey CaldeaNo ratings yet

- Variable Frequency DriveDocument12 pagesVariable Frequency Drive-Danielle Dimitrova100% (1)

- Electric Drives: Drive BasicsDocument5 pagesElectric Drives: Drive BasicsJisha KuruvillaNo ratings yet

- Ac Drive (Simple Theory To Understand) By: Nitish DhawanDocument10 pagesAc Drive (Simple Theory To Understand) By: Nitish DhawanNitish DhawanNo ratings yet

- AC Drives and Soft Starter Application GuideDocument5 pagesAC Drives and Soft Starter Application GuideMinh TranNo ratings yet

- Ac MotorsDocument17 pagesAc MotorsPineappleJamNo ratings yet

- Ramesh 2011Document6 pagesRamesh 2011Hoang Hoang LeNo ratings yet

- Chap2 Fyp Report NewDocument9 pagesChap2 Fyp Report NewAsad AzharNo ratings yet

- Permanent Magnet Brushless DC MotorDocument7 pagesPermanent Magnet Brushless DC MotoratultiwarihinduNo ratings yet

- Answer: Control System (Unit 1)Document18 pagesAnswer: Control System (Unit 1)Ajeet Kumar shuklaNo ratings yet

- BLDC PDFDocument36 pagesBLDC PDFZariz ZakianNo ratings yet

- IDC Unit-4Document9 pagesIDC Unit-4Gaurav SinghNo ratings yet

- 10-Tutorial of Induction MotorDocument48 pages10-Tutorial of Induction Motorrida.hamza.muhammadNo ratings yet

- VVVF - Working Principle & Its OperationDocument18 pagesVVVF - Working Principle & Its Operationdownload4sumitNo ratings yet

- PE 13 EnhDocument45 pagesPE 13 EnhSanthosh Kumar JNo ratings yet

- Shaded Pole Induction MotorDocument7 pagesShaded Pole Induction MotorRahul BhumkarNo ratings yet

- Diode Clamped Multilevel Inverter Fed BLDC Motor Using SEPIC ConverterDocument5 pagesDiode Clamped Multilevel Inverter Fed BLDC Motor Using SEPIC Convertermanoj kumarNo ratings yet

- Motors and DrivesDocument23 pagesMotors and DrivesharishkumarsinghNo ratings yet

- Power Analysis of PWM Motor Drives PDFDocument22 pagesPower Analysis of PWM Motor Drives PDFJaime Vanegas IriarteNo ratings yet

- Brushless DC MotorsDocument21 pagesBrushless DC MotorsSRL MECHNo ratings yet

- Four Quadrant OperationDocument9 pagesFour Quadrant OperationMOTILAL SUTHAR215291No ratings yet

- Be3251 Beee QBDocument3 pagesBe3251 Beee QBMr MovieNo ratings yet

- EES (Lec20)Document16 pagesEES (Lec20)Muhammad SagheerNo ratings yet

- Four Quadrant Speed Control of DC Motor Using ChopperDocument5 pagesFour Quadrant Speed Control of DC Motor Using ChopperismayilcNo ratings yet

- Variable Frecuency Drives For Fans PDFDocument15 pagesVariable Frecuency Drives For Fans PDFReyes SanchezNo ratings yet

- AC Drives and Soft Starter Application Guide - AllenBradleyCoDocument5 pagesAC Drives and Soft Starter Application Guide - AllenBradleyCojoyama100% (1)

- DC Shunt Motor - Speed Control & Characteristics - Electrical4U PDFDocument4 pagesDC Shunt Motor - Speed Control & Characteristics - Electrical4U PDFIvica IndjinNo ratings yet

- Chapter 7Document36 pagesChapter 7meeedooo.abo.elenenNo ratings yet

- Alternating Current Machines NotesDocument16 pagesAlternating Current Machines Notesbhenguluyanda97No ratings yet

- Embedded BLCDDocument24 pagesEmbedded BLCDDhananjay PatilNo ratings yet

- Advanced Power Electronics and Microcontrollers For Renewable Energy SystemsDocument39 pagesAdvanced Power Electronics and Microcontrollers For Renewable Energy Systemsbisrat yeshidagnaNo ratings yet

- TP2-Satya PrakashDocument13 pagesTP2-Satya Prakashm_azhagarNo ratings yet

- Servicing Schneider Altivar 66Document118 pagesServicing Schneider Altivar 66znim04No ratings yet

- Introduction: The Induction Motor Is A Three Phase AC Motor and Is The MostDocument3 pagesIntroduction: The Induction Motor Is A Three Phase AC Motor and Is The MostAnil KumarNo ratings yet

- What Are The Speed Control Method of Induction MotorsDocument12 pagesWhat Are The Speed Control Method of Induction MotorsRajeev ValunjkarNo ratings yet

- Module 3 - Shunt DC MotorDocument12 pagesModule 3 - Shunt DC MotorMARY JOY MAGAWAYNo ratings yet

- 098STUT8489034-002Document94 pages098STUT8489034-002bijalmehtaNo ratings yet

- CNC Feed DrivesDocument26 pagesCNC Feed DrivesAndrejNo ratings yet

- Electric MotorsDocument10 pagesElectric Motorsmgongo88No ratings yet

- AC MotorDocument18 pagesAC MotorCathy IsraelNo ratings yet

- AC Motors PCIDocument30 pagesAC Motors PCIThomas DuNo ratings yet

- Electrical Machines Lab March 16 UpdateDocument53 pagesElectrical Machines Lab March 16 Updatepeter vanderNo ratings yet

- 1-Phase Induction MotorDocument20 pages1-Phase Induction MotorNure AlamNo ratings yet

- Ac Machines ModuleDocument42 pagesAc Machines ModuleFranzon MelecioNo ratings yet

- Brushless MotorsDocument3 pagesBrushless MotorsHossam DawoodNo ratings yet

- DocumentDocument7 pagesDocumentakhilnandanNo ratings yet

- Implementing Embedded Speed Control For Brushless DC Motors Part1Document8 pagesImplementing Embedded Speed Control For Brushless DC Motors Part1charliesteven100% (2)

- Difference Between Slip Ring Motor With Conventional Drive and Squirrel Cage Motor With Variable Speed DriveDocument4 pagesDifference Between Slip Ring Motor With Conventional Drive and Squirrel Cage Motor With Variable Speed DriveMohamed Ayman Hefny MohamedNo ratings yet

- EEE 321 Marking SchemeDocument8 pagesEEE 321 Marking Schemefaisal sbennaNo ratings yet

- Stepper and Servo MotorDocument5 pagesStepper and Servo Motorகோகுல்நாத் ஸ்ரீ கிNo ratings yet

- BLDC Motor Application Techniques 1701585005Document50 pagesBLDC Motor Application Techniques 1701585005qn27kkbf4hNo ratings yet

- Brushless DC MotorsDocument14 pagesBrushless DC MotorsNeroGetsu100% (1)

- Brushless DC (BLDC) Motor FundamentalsDocument20 pagesBrushless DC (BLDC) Motor FundamentalsEdo007100% (1)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Autonomous Maintenance Part 1Document40 pagesAutonomous Maintenance Part 1mdkhandaveNo ratings yet

- Press Machine 1Document6 pagesPress Machine 1mdkhandaveNo ratings yet

- Application For Migration CertificateDocument1 pageApplication For Migration CertificatemdkhandaveNo ratings yet

- Lean 2Document12 pagesLean 2mdkhandaveNo ratings yet

- PRINTDocument1 pagePRINTmdkhandaveNo ratings yet

- 1 s2.0 S2351978917305036 MainDocument8 pages1 s2.0 S2351978917305036 MainmdkhandaveNo ratings yet

- JH QDocument2 pagesJH QmdkhandaveNo ratings yet

- Lean 1 2Document1 pageLean 1 2mdkhandaveNo ratings yet

- Presentation On Lean ManufacturingDocument11 pagesPresentation On Lean ManufacturingmdkhandaveNo ratings yet

- Press SizingDocument1 pagePress SizingmdkhandaveNo ratings yet

- QDocument2 pagesQmdkhandaveNo ratings yet

- Why Kobetsu Kaizen Called As Focused Improvement?Document3 pagesWhy Kobetsu Kaizen Called As Focused Improvement?mdkhandaveNo ratings yet

- Kan Ban 3Document1 pageKan Ban 3mdkhandaveNo ratings yet

- SummaryDocument1 pageSummarymdkhandaveNo ratings yet

- Lean 5Document1 pageLean 5mdkhandaveNo ratings yet

- Kanban 4Document1 pageKanban 4mdkhandaveNo ratings yet

- Maintenancetypes of Main.6815851.PowerpointDocument17 pagesMaintenancetypes of Main.6815851.PowerpointmdkhandaveNo ratings yet

- QDocument1 pageQmdkhandaveNo ratings yet

- TPI ListDocument1 pageTPI ListmdkhandaveNo ratings yet

- K 7Document1 pageK 7mdkhandaveNo ratings yet

- Integrated Management Systems - Three Different Levels of IntegrationDocument11 pagesIntegrated Management Systems - Three Different Levels of IntegrationmdkhandaveNo ratings yet

- Kanban 5Document1 pageKanban 5mdkhandaveNo ratings yet

- Kan Ban 1Document3 pagesKan Ban 1mdkhandaveNo ratings yet

- Technical Information: Tonnage CalculationDocument2 pagesTechnical Information: Tonnage CalculationmdkhandaveNo ratings yet

- MDK I PDFDocument1 pageMDK I PDFmdkhandaveNo ratings yet

- A Project Based Lab Report On STREET LIGHTDocument7 pagesA Project Based Lab Report On STREET LIGHTManish KumarNo ratings yet

- D Q1159bu 0 Emelec Q1159bu Cable PDFDocument1 pageD Q1159bu 0 Emelec Q1159bu Cable PDFYineth Lorena Garcia MolinaNo ratings yet

- Pulse Counters: With and Without Manual Zero ResetDocument2 pagesPulse Counters: With and Without Manual Zero ResetonglichNo ratings yet

- Laboratory Report N.01 Diodes PDFDocument5 pagesLaboratory Report N.01 Diodes PDFCristian Camilo Díaz PiñerosNo ratings yet

- Trihal TRI0400245298IP210Document2 pagesTrihal TRI0400245298IP210Eka Hospital BekasiNo ratings yet

- Combined Instrument Transformers Ivokt TMCDocument8 pagesCombined Instrument Transformers Ivokt TMCRamzan100% (1)

- Testing Electrical and Electronics: Component / Devices With MultimeterDocument17 pagesTesting Electrical and Electronics: Component / Devices With MultimeterIra CervoNo ratings yet

- Ia5127 00 - en GBDocument3 pagesIa5127 00 - en GBSales support TechnicalNo ratings yet

- LEM-435 - 15 - 430 - 20 - 30 - EN نسخة انجليزيةDocument12 pagesLEM-435 - 15 - 430 - 20 - 30 - EN نسخة انجليزيةfararNo ratings yet

- ECS Korry QS 389 6pin D41861Document4 pagesECS Korry QS 389 6pin D41861Peter BirdNo ratings yet

- Build Your Own Transistor Based Mobile Line Follower RobotDocument7 pagesBuild Your Own Transistor Based Mobile Line Follower Robotiky77No ratings yet

- SIGMA JT Products PDFDocument64 pagesSIGMA JT Products PDFAurel DeduNo ratings yet

- Modern Circuit Breakers and Reclosers Free Electrical Engineering Xyz Whitepaper PDFDocument24 pagesModern Circuit Breakers and Reclosers Free Electrical Engineering Xyz Whitepaper PDFm khNo ratings yet

- De375 102n10aDocument5 pagesDe375 102n10akleephNo ratings yet

- Eaton Guide Specification Notes and Instructions To SpecwriterDocument10 pagesEaton Guide Specification Notes and Instructions To Specwriterhung nguyenNo ratings yet

- DrivDocument11 pagesDrivRobert Berry100% (1)

- SIEPC71061737Document1,026 pagesSIEPC71061737Alberto MolinaNo ratings yet

- P.E - 16MDocument16 pagesP.E - 16M20EUEE053- MADHUBALAN.SNo ratings yet

- Close and Trip Relay - Electric Power & Transmission & Distribution - Eng-Ti PDFDocument11 pagesClose and Trip Relay - Electric Power & Transmission & Distribution - Eng-Ti PDFalimaghamiNo ratings yet

- Analysis of Commutation in DC MachinesDocument57 pagesAnalysis of Commutation in DC Machinesagnostic07No ratings yet

- Check List Tray ListDocument9 pagesCheck List Tray ListAldeline SungahidNo ratings yet

- Purchase Plan Electrical Consumable Material, Stationery 2022Document11 pagesPurchase Plan Electrical Consumable Material, Stationery 2022Muhammad AsifNo ratings yet

- ElectrationDocument5 pagesElectrationVaronika KourNo ratings yet

- SUN2000L 2 3 3,68 4 4,6 5 KTL Data SheetDocument2 pagesSUN2000L 2 3 3,68 4 4,6 5 KTL Data SheetAdrian Ioan POPNo ratings yet

- Unit - I Synchronous GeneratorDocument25 pagesUnit - I Synchronous GeneratorVenkatesan SwamyNo ratings yet

- Benshaw Low Voltage Starters PDFDocument16 pagesBenshaw Low Voltage Starters PDFRollyDuqueCampoverdeNo ratings yet

- Table of Specification: Republic of The PhilippinesDocument1 pageTable of Specification: Republic of The PhilippinesRosel DumlaoNo ratings yet

- Silicon Epitaxial Planar Transistor SS8550Document4 pagesSilicon Epitaxial Planar Transistor SS8550OreolNo ratings yet