Professional Documents

Culture Documents

Discussion Experiment 3

Discussion Experiment 3

Uploaded by

Jojnojie DannyzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discussion Experiment 3

Discussion Experiment 3

Uploaded by

Jojnojie DannyzCopyright:

Available Formats

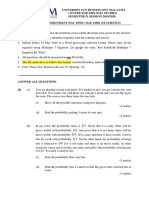

6.

0 DISCUSSION

The Flakiness Index is the mass of particles in that aggregate expressed as a

percentage of the total mass of that aggregate which will pass the slot or slots of specified

width for the appropriate size fraction. While elongation index test is used to determine the

quantity of aggregate particles that are elongated instead of cubicle in shape. The particles

are classified as flaky or elongated particles according to the rather arbitrary assumption that

are particles is flaky if its flaky is loss than 0.6 times the sieve size and that a particle is

elongated if its long is greater than 1.8 times the sieve size. In this experiment, flakiness

index was used as independent variables and other properties such as gradation are kept

constant as far as their properties met the specification required for the asphalt mixture.

According to British Standard Institution (BSI-812, 1975) classifies aggregate into six classes

that are rounded, irregular, angular, flaky and elongated and elongated. The rounded,

irregular and angular for special purpose are group into the category an equidimensional or

cuboidal. The aggregate are flaky, elongated, flaky and elongated or equal dimension are

determined by the ratio of the shortest, the largest and average diameter of the particles.

From the experiment, firstly we separate aggregate sample by sieving into different

size fraction, each falling within a narrow size function is essentially a single-size aggregate.

The sieve size rage are (20 ± 40) mm, (14 ± 10) mm and (10 ± 6.3) mm. From the data

experiment, we made the calculation and discussed by the all group member. When this

experiment is doing, we make some experimental error such as when sieving process is

being take place. For examples, the aggregate may not trough sieve by machine and some

of aggregate we shake manually by hand. Besides, the error do occur when the weighing the

amount of aggregate that we need. The careless attitudes that we gauge the particles

separating by hand. Maybe we pass the particles to the wrong gauge. It is because we have

separate too many particles in the short time.

References:

https://www.slideshare.net/yasminehaslann/determination-of-elongation-index-

test#:~:text=Page%20%7C%207%20DISCUSSION%20The%20Flakiness,for%20the

%20appropriate%20size%20fraction.

-British Standards Methods of determination of particle shape BS 812, Part 105, 1989.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tutorial 1 Topic: Vibration BNJ 20303 Mechanic of Machine SEMESTER 1 SESI 2020/2021Document6 pagesTutorial 1 Topic: Vibration BNJ 20303 Mechanic of Machine SEMESTER 1 SESI 2020/2021Jojnojie DannyzNo ratings yet

- Question 4 (A) at y 3.2, The Value of Table For X and y 0 2 4 6 80 53.5 38.4 3 30.39Document2 pagesQuestion 4 (A) at y 3.2, The Value of Table For X and y 0 2 4 6 80 53.5 38.4 3 30.39Jojnojie DannyzNo ratings yet

- Order and Linearity: Faculty of Applied Sciences and Technology Universiti Tun Hussein Onn Malaysia BWM12303 Tutorial 1Document1 pageOrder and Linearity: Faculty of Applied Sciences and Technology Universiti Tun Hussein Onn Malaysia BWM12303 Tutorial 1Jojnojie DannyzNo ratings yet

- Separable Equations: Faculty of Applied Sciences and Technology Universiti Tun Hussein Onn Malaysia BWM12303 Tutorial 2Document2 pagesSeparable Equations: Faculty of Applied Sciences and Technology Universiti Tun Hussein Onn Malaysia BWM12303 Tutorial 2Jojnojie DannyzNo ratings yet

- Centre For Diploma Studies SEMESTER II, SESSION 2019/2020 Individual Assignment Dac 10702 / Dae 23602 (Statistics)Document2 pagesCentre For Diploma Studies SEMESTER II, SESSION 2019/2020 Individual Assignment Dac 10702 / Dae 23602 (Statistics)Jojnojie DannyzNo ratings yet

- Free Chegg Answer From Techlacarte: 1 MessageDocument4 pagesFree Chegg Answer From Techlacarte: 1 MessageJojnojie DannyzNo ratings yet

- Unit 6 Deformation of Statically Determinate Beam 2 Double IntegrationDocument37 pagesUnit 6 Deformation of Statically Determinate Beam 2 Double IntegrationJojnojie DannyzNo ratings yet

- Gmail - Free Chegg Answer From TechLaCarteDocument3 pagesGmail - Free Chegg Answer From TechLaCarteJojnojie DannyzNo ratings yet

- B6439.01 113.11 FabriTRAK Acoustical Test 1 Inch FabriTACK No FabricDocument10 pagesB6439.01 113.11 FabriTRAK Acoustical Test 1 Inch FabriTACK No FabricJojnojie DannyzNo ratings yet

- IndividualassignmentDocument4 pagesIndividualassignmentJojnojie DannyzNo ratings yet

- Tutorial 7B: Tutorial Tahap Clo-PloDocument12 pagesTutorial 7B: Tutorial Tahap Clo-PloJojnojie DannyzNo ratings yet

- Expert Answer: Free Chegg Answer From TechlacarteDocument9 pagesExpert Answer: Free Chegg Answer From TechlacarteJojnojie DannyzNo ratings yet

- Title: Sound Absorption Test Results Product: 2" Echo Eliminator (3lb. PCF)Document5 pagesTitle: Sound Absorption Test Results Product: 2" Echo Eliminator (3lb. PCF)Jojnojie DannyzNo ratings yet

- Tutorial7 7d KinematicsRigidBodyDocument12 pagesTutorial7 7d KinematicsRigidBodyJojnojie DannyzNo ratings yet

- Please Find Your Answer Below (Or) in The Attached Image / Document!Document4 pagesPlease Find Your Answer Below (Or) in The Attached Image / Document!Jojnojie DannyzNo ratings yet

- Tutorial 7C: Tutorial Tahap Clo-PloDocument14 pagesTutorial 7C: Tutorial Tahap Clo-PloJojnojie DannyzNo ratings yet

- S A S A: Exercise 10 & SolutionDocument5 pagesS A S A: Exercise 10 & SolutionJojnojie DannyzNo ratings yet

- Mind Map Websinar - Jienovicco Winner Jaibin AA191820Document1 pageMind Map Websinar - Jienovicco Winner Jaibin AA191820Jojnojie DannyzNo ratings yet

- Free Chegg Answer From Techlacarte: 1 MessageDocument4 pagesFree Chegg Answer From Techlacarte: 1 MessageJojnojie DannyzNo ratings yet

- Free Chegg Answer From Techlacarte: 1 MessageDocument4 pagesFree Chegg Answer From Techlacarte: 1 MessageJojnojie DannyzNo ratings yet

- Gmail - Free Chegg Answer From TechCrachi #CH-19943Document2 pagesGmail - Free Chegg Answer From TechCrachi #CH-19943Jojnojie DannyzNo ratings yet

- Expert Answer: Free Chegg Answer From TechlacarteDocument9 pagesExpert Answer: Free Chegg Answer From TechlacarteJojnojie DannyzNo ratings yet

- Dac 20502 Hydrology SEMESTER 1 SESSION 2020/2021: NO. Name Matrics NODocument27 pagesDac 20502 Hydrology SEMESTER 1 SESSION 2020/2021: NO. Name Matrics NOJojnojie DannyzNo ratings yet

- Schedules Q&A FYP1 - Sem1 - 2020 - 2021 - 26&27 - 1 - 2021.v1Document13 pagesSchedules Q&A FYP1 - Sem1 - 2020 - 2021 - 26&27 - 1 - 2021.v1Jojnojie DannyzNo ratings yet

- Extra Tutorial1b Vibration DampedDocument3 pagesExtra Tutorial1b Vibration DampedJojnojie DannyzNo ratings yet

- Centre For Diploma Studies Principle of ProgrammingDocument6 pagesCentre For Diploma Studies Principle of ProgrammingJojnojie DannyzNo ratings yet

- Lab2a 28anintroductiontoc 29Document5 pagesLab2a 28anintroductiontoc 29Jojnojie DannyzNo ratings yet