Professional Documents

Culture Documents

26 41 00 Surge Protective Device

26 41 00 Surge Protective Device

Uploaded by

Langzkie NalipaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26 41 00 Surge Protective Device

26 41 00 Surge Protective Device

Uploaded by

Langzkie NalipaCopyright:

Available Formats

<<Project Title>> SURGE PROTECTIVE DEVICE

<<Project Title>> Section 26 41 00

<< Project Number>> Page 1 of 4

PART 1 - GENERAL

1.1 SUMMARY

.1 This section includes:

.1 Materials and installation for Surge Protective Devices.

1.2 REFERENCES

.1 Canadian Standards Association (CSA International)

1.3 SUBMITTALS

.1 SHOP DRAWINGS

.1 Submit shop drawings for product specified in this section.

.1 Provide verification that the SPD’s device complies with the

required UL 1449 SVRs.

.2 Provide actual let through voltage test data in the form of

oscillo-graph results for both the ANSI/IEEE C62.41 Category C3

(combination wave) and B3 (ring wave) tested in accordance with

ANSI/IEEE C62.45.

.3 Provide spectrum analysis of each unit based on MIL-STD-

220A test procedures between 50 kHz and 200 kHz verifying the

device's noise attenuation exceeds 50 dB at 100 kHz.

.4 Electrical/mechanical drawings showing unit dimensions,

weights, installation instruction details, and wiring configuration.

PART 2 - PRODUCTS

PART 3 - Surge protective device (spd)

PART 4 - Surge protective device is to be installed on the main distribution panel servicing outlets for electronic equipment and

the panel servicing the ABM with its associated equipment.

PART 5 - The SPD application covered under this Section include distribution and branch panel locations. The branch panel

located SPD shall be tested to demonstrate they are suitable for ANSI/IEEE C62.41 Category C1 environments.

PART 6 - The individual units shall be UL Listed under UL 1449 complimentary listed under UL 1283 and CSA Standards.

PART 7 - The UL 1449 surge ratings and CSA label shall be permanently affixed to the SPD unit.

.1 All surge protection devices in the switchboard and subpanels shall be from the same

manufacturer.

.2 Electrical requirements:

.1 Unit Operating Voltage: Refer to drawings for operating voltage and unit

configuration.

.2 Maximum Continuous Operating Voltage (MCOV). The MCOV shall be

greater than 115% of the nominal system operating voltage.

.3 Protection Modes. For a wye configured system, the device must have

directly connected suppression elements between line-neutral (L-N), line-ground

(L-G), and neutral-ground (N-G). For a delta configured system, the device

must have suppression elements between line to line (L-L) and line to ground

(L-G).

.4 Surge Current Capacity. Total surge current per phase (based on an

8x20 microsecond waveform) that the device is capable of surviving shall not be

less than 120 kA per phase, or 60 kA per mode on L-G, L-N and N-G modes

(Wye system); L-L and N-G (Delta system).

.5 UL 1449 SVRs. The manufacturer must provide certified UL 1449 SVRs

on all protected modes. The maximum UL 1449 SVR for the device must not

exceed the following:

Scotiabank September 2015

<<Project Title>> SURGE PROTECTIVE DEVICE

<<Project Title>> Section 26 41 00

<< Project Number>> Page 2 of 4

Modes 208Y/120 480Y/277 600Y/347

L-N; L-G; N-G 400 V 800 V 1200 V

L-L 800 V 1500V 2000 V

.6 (SVR must be for complete device; modular only SVR are not

acceptable)

.7 ANSI/IEEE Cat C3 Let Through Voltage. The let through voltage based

on IEEE C62.41 and C62.45 recommended procedures for Category C3 surges

(20 kV, 10kA) must be included in the submittal package and shall be less than:

Modes 208Y/120 480Y/277 600Y/347

L-N 500 V 900 V 1300 V

.8 ANSI/IEEE Cat. B3 Let Through Voltage. Let Through voltage based on

IEEE C62.41 and C62.45 recommended procedures for the ANSI/IEEE Cat. B3

ringwave (6 kV, 500 amps) shall be included in the submittal package and shall

be less than:

Modes

208Y/120 480Y/277 600Y/347

L-N 130 V 200 V 300 V

.9 Lifecycle. Each unit must be capable of surviving more than 2500

Category C transients without failure or degradation of UL 1449 clamp voltage.

.10 Balanced suppression Platform

.1 The surge current shall be equally distributed to all MOV

components to ensure equal stressing and maximum performance. The

surge suppression platform must be rated to 400 kA per phase and

provide equal impedance paths to each matched MOV. Designs

incorporating multiple SPD modules or printed circuit boards do not

provide a balanced impedance path to each MOV and shall not be

acceptable. Suppression system shall not utilize gas tubes, silicon

avalanche diodes, or other components which may crowbar the system

leading to the system upset.

.11 Electrical Noise Filter

.1 Each unit shall include a high performance EMI/RFI noise

rejection filter. Noise attenuation for electric line noise shall be 55 dB at

100 kHz using the MIL-STD-220A insertion loss test method. The unit

shall be complimentary listed to UL 1283. Products not able to

demonstrate noise attenuation of 55 dB @ 100 kHz shall be rejected.

.12 Internal Connections.

.1 No plug-in component modules or printed circuit boards shall

be used as surge current conductors. All internal components shall be

hardwired with connections utilizing low impedance conductors and

compression fittings.

.13 Safety and Diagnostic Monitoring.

.1 Each unit shall provide the following three levels of monitoring:

.1 Continuous monitoring of 200 kAIC internal fuses.

.2 Internal infrared sensor system for monitoring of

individual MOVs (including neutral to ground). The system

must be capable of identifying open circuit failures not

monitored by conventional fusing systems.

.3 A thermal detection circuit shall monitor for

overheating in all modes due to thermal runaway.

Scotiabank September 2015

<<Project Title>> SURGE PROTECTIVE DEVICE

<<Project Title>> Section 26 41 00

<< Project Number>> Page 3 of 4

.4 A green/red solid state indicator light shall be

provided on each phase. The absence of a green light and the

presence of a red light, shall indicate which phase(s) have

been damaged.

.5 Fault detection will activate a flashing trouble, form C

contacts and audible alarm (if specified).

.6 Units which cannot detect open circuit damage,

thermal conditions, and over current will not be accepted.

.7 Remote Status Monitor. The SPD device must

include Form C dry contacts (one N.O. and one N. C.) for

remote annunciation of unit status. The remote alarm shall

change state if any of the three monitoring systems described

detect a fault condition.

.8 Monitor Test Point. Each suppression unit shall

incorporate an integral monitor test point which verifies the

operational integrity of the unit's monitoring system.

.14 Warranty. The manufacturer shall provide a full five year warranty from

the date of shipment against any part failure when installed in compliance with

manufacturer's written instructions and any applicable national or local electric

code.

PART 8 - Accetable Manufacturers:

.1 General Electric Tranquell Series

.2 Innovative Technologies ST Series

PART 9 - EXECUTION

PART 10 - installation

.1 Wiring Requirements. The device shall be installed according to manufacturer

recommended practices. Conductor lead length to the SPD device is to be as short and

straight as possible. Conductors shall be twisted and tightly bound together to reduce

impedance. Refer to manufacturer’s instructions for required size of conductor wires.

.2 Integrated Panel board Applications.

.1 Distribution and Panel suppressors shall be installed inside the panel

boards at the manufacturer's factory.

.2 Locate suppressor close to the panel board bus bar. Maximum

allowable conductor lead length shall be 12 inches.

.3 Motor Control Centres

.1 To minimize impedance of the suppression path, the suppressor shall

be mounted within an available MCC compartment.

.2 The suppressor shall be mounted in a standard 12 inch NEMA 1

compartment. Conductor length between the suppressor and the stab shall be

less than 5 inches. All units shall be internally fused with 200 kAIC. All status

indicators and monitors shall be mounted on the front of the MCC compartment

for easy visibility.

.4 Bus plug Applications.

.1 The suppressor shall be mounted within a standard bus plug enclosure

(approximately 12 x 23.5 x 62 inch). Conductor length between the suppressor

and the stab connections shall be less than 5 inches.

.2 All units shall be internally fused with 200 kAIC. All status indicators

shall be mounted on the front of the enclosure for easy visibility.

.3 The Bus plug shall include a disconnect switch.

.5 Optional Installation (externally mounted SPD)

Scotiabank September 2015

<<Project Title>> SURGE PROTECTIVE DEVICE

<<Project Title>> Section 26 41 00

<< Project Number>> Page 4 of 4

.1 Provide 30 amp breaker for panel applications.

.2 Maximum conductor lead length between breaker and suppressor shall

not exceed 14 inches. Comply with manufacturer's recommended installation

and wiring practises.

END OF SECTION

Scotiabank September 2015

You might also like

- Instruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENDocument79 pagesInstruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENКонстантин Гетьман100% (1)

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerDocument88 pages01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- Samsung HT Z120Document76 pagesSamsung HT Z120Marcos OficinaNo ratings yet

- Catalog SurgelogicDocument14 pagesCatalog SurgelogicLuizNo ratings yet

- LG 60pa6500-Tm Chassis Pa23aDocument49 pagesLG 60pa6500-Tm Chassis Pa23aJ Fernando GarciaNo ratings yet

- 2014 Animal Feeds Formulation Training - 18-03-2014Document1 page2014 Animal Feeds Formulation Training - 18-03-2014Eddy Mwachenje100% (1)

- Labor Relations Cheat SheetDocument8 pagesLabor Relations Cheat SheetThea MagallanesNo ratings yet

- Eries: Model 510, Surge Protective DeviceDocument4 pagesEries: Model 510, Surge Protective Deviceoperaciones1 sesaNo ratings yet

- Vanjen SPD TrainingDocument52 pagesVanjen SPD TrainingRebekah PowellNo ratings yet

- Liebert Accuvar (Acv Series) Surge Protective Device (SPD) (With Noise Filtering) Guide Specifications For A Parallel Surge Suppression SystemDocument7 pagesLiebert Accuvar (Acv Series) Surge Protective Device (SPD) (With Noise Filtering) Guide Specifications For A Parallel Surge Suppression SystemX5companyNo ratings yet

- Service Manuals LG TV PLASMA 42PB4D 42PB4D Service ManualDocument59 pagesService Manuals LG TV PLASMA 42PB4D 42PB4D Service Manual邱政鋒100% (1)

- Plasma TV: Service ManualDocument54 pagesPlasma TV: Service ManualMARTIN ROJASNo ratings yet

- Service Manual 2t C42bd1iDocument53 pagesService Manual 2t C42bd1iservis tvNo ratings yet

- Plasma TV: Service ManualDocument51 pagesPlasma TV: Service ManualJosias MangueiraNo ratings yet

- Page 1 of 6: Effective Date 7/2007 PS01005002EDocument4 pagesPage 1 of 6: Effective Date 7/2007 PS01005002EkrcdewanewNo ratings yet

- Transient Voltage Surge Suppression PDFDocument7 pagesTransient Voltage Surge Suppression PDFwafikmh4No ratings yet

- Plasma TV: Service ManualDocument48 pagesPlasma TV: Service ManualSuperlano JoséNo ratings yet

- LG 42pc55 (ET)Document53 pagesLG 42pc55 (ET)Andy CoyneNo ratings yet

- SN65HVD1050Document19 pagesSN65HVD1050ZaegorNo ratings yet

- Plasma TV: Service ManualDocument49 pagesPlasma TV: Service ManualВиталий МорозовNo ratings yet

- Service Manual 21GIII-08 SLIMDocument33 pagesService Manual 21GIII-08 SLIMAlexandra BarzaianuNo ratings yet

- 2-Installation and Maintenance ManualDocument14 pages2-Installation and Maintenance ManualEric ChienNo ratings yet

- AC Combiner Box Specification 400vac)Document7 pagesAC Combiner Box Specification 400vac)emilNo ratings yet

- LG 50pg20r CH Pp81aDocument28 pagesLG 50pg20r CH Pp81aAdao AraujoNo ratings yet

- 02.power Transformer-160 &63mvaDocument138 pages02.power Transformer-160 &63mvaraj_stuff006100% (1)

- TeSys Ultra - LUCM32BLDocument4 pagesTeSys Ultra - LUCM32BLNur Awwaluddin ZNo ratings yet

- Videocon - Chassis Nano3 CST - Nano4 CSTDocument29 pagesVideocon - Chassis Nano3 CST - Nano4 CSTchanchaldatta0% (1)

- LT26C31BJEDocument46 pagesLT26C31BJEchipblownNo ratings yet

- Delta VFD c200 User ManualDocument363 pagesDelta VFD c200 User ManualFreund MachinesNo ratings yet

- Haier Model - 21F7A-P TVDocument26 pagesHaier Model - 21F7A-P TVGiovanny Enrique Gonzalez CastroNo ratings yet

- KR21N7N Service ManualDocument16 pagesKR21N7N Service ManualBogdan DorofteyNo ratings yet

- LG 50PB560B Chassis PU41A PDFDocument47 pagesLG 50PB560B Chassis PU41A PDFCesar Guzman100% (1)

- Samsung Sv5000W-1 PDFDocument103 pagesSamsung Sv5000W-1 PDFsigi_204No ratings yet

- Service Manual: Colour TelevisionDocument21 pagesService Manual: Colour TelevisionTecnico GenioNo ratings yet

- Power Supply EmersonDocument20 pagesPower Supply Emersonindra gunawanNo ratings yet

- 5560A Speng0100 0Document30 pages5560A Speng0100 0Juan RomeroNo ratings yet

- Videocon - Nano 1bstpf Vpt21uv TzaDocument37 pagesVideocon - Nano 1bstpf Vpt21uv Tzaparthiban parthiNo ratings yet

- Single Phase Recloser CatalogDocument8 pagesSingle Phase Recloser CatalogCesar VenturoNo ratings yet

- LCD TV Service Manual: Konka Group Co, LTDDocument20 pagesLCD TV Service Manual: Konka Group Co, LTDsolomon mekonnenNo ratings yet

- Installation Guide: SMC8150L2Document57 pagesInstallation Guide: SMC8150L2denisNo ratings yet

- ATS22D88S6U: Product Data SheetDocument12 pagesATS22D88S6U: Product Data SheetRene AlfaroNo ratings yet

- CRT Monitor KT2914F 2914DF Service ManualDocument38 pagesCRT Monitor KT2914F 2914DF Service Manualfpanci100% (1)

- Segg Specs - LT PartDocument2 pagesSegg Specs - LT PartRohit GoelNo ratings yet

- 3 4D Recloser G2801041Document11 pages3 4D Recloser G2801041Rehan KhalilNo ratings yet

- S7-200 Technical SpecificationsDocument78 pagesS7-200 Technical SpecificationsThuy Nguyen Xuan0% (1)

- Allen Bradly Safty Interlock SwitchDocument6 pagesAllen Bradly Safty Interlock SwitchDilip KumarNo ratings yet

- Led LCD TV: Service ManualDocument70 pagesLed LCD TV: Service Manualsonak1971No ratings yet

- 4 15 2 LFAA 102 SMDocument161 pages4 15 2 LFAA 102 SMĐỗ Xuân BằngNo ratings yet

- General: Clause No. Variable Frequency DrivesDocument15 pagesGeneral: Clause No. Variable Frequency Drivesrahul patraNo ratings yet

- 02 40058 02 enDocument4 pages02 40058 02 enShirin AzadiNo ratings yet

- SAKO SKI780 ManualDocument74 pagesSAKO SKI780 ManualJordi Garcia100% (1)

- Sds A 11753650 SURGE ARRESTER PROTECTION DEVICESDocument16 pagesSds A 11753650 SURGE ARRESTER PROTECTION DEVICESMarilou GaralNo ratings yet

- Product Bulletin Fisher Fieldvue dvc2000 Digital Valve Controller en 123326Document8 pagesProduct Bulletin Fisher Fieldvue dvc2000 Digital Valve Controller en 123326László LósNo ratings yet

- Technical Specification: Section-Series Reactor (400 KV CLASS)Document15 pagesTechnical Specification: Section-Series Reactor (400 KV CLASS)byjuvcNo ratings yet

- Ongc 2mw BomDocument39 pagesOngc 2mw BomPrince MittalNo ratings yet

- 75 W Single Output, Power-Factor Corrected LED Driver Using TOP250YNDocument36 pages75 W Single Output, Power-Factor Corrected LED Driver Using TOP250YNvladimir_p80No ratings yet

- Av 29fh1sug JVC, 100hzDocument48 pagesAv 29fh1sug JVC, 100hzQ-EntityNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 22 42 01 Plumbing Specialties and AccessoriesDocument5 pages22 42 01 Plumbing Specialties and AccessoriesLangzkie NalipaNo ratings yet

- 23 05 93 Testing Adjusting and BalancingDocument7 pages23 05 93 Testing Adjusting and BalancingLangzkie NalipaNo ratings yet

- 21 13 13 - Wet Pipe Sprinkler SystemsDocument7 pages21 13 13 - Wet Pipe Sprinkler SystemsLangzkie NalipaNo ratings yet

- 23 05 00 - Common Work Results For HVACDocument7 pages23 05 00 - Common Work Results For HVACLangzkie NalipaNo ratings yet

- 22 42 00 Commercial Plumbing FixturesDocument5 pages22 42 00 Commercial Plumbing FixturesLangzkie NalipaNo ratings yet

- 00 01 10 - MEP List of ContentsDocument2 pages00 01 10 - MEP List of ContentsLangzkie NalipaNo ratings yet

- 23 07 13 - Duct InsulationDocument3 pages23 07 13 - Duct InsulationLangzkie NalipaNo ratings yet

- 22 33 00 - Instantaneous Electric Domestic Water HeatersDocument2 pages22 33 00 - Instantaneous Electric Domestic Water HeatersLangzkie NalipaNo ratings yet

- 22 11 16 Domestic Water Supply Piping CopperDocument3 pages22 11 16 Domestic Water Supply Piping CopperLangzkie NalipaNo ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- 26 53 00 Exit LightsDocument2 pages26 53 00 Exit LightsLangzkie NalipaNo ratings yet

- 26 20 00 Electrical SErvice and DistributionDocument3 pages26 20 00 Electrical SErvice and DistributionLangzkie NalipaNo ratings yet

- 23 11 23 - Facility Natural Gas PipingDocument3 pages23 11 23 - Facility Natural Gas PipingLangzkie NalipaNo ratings yet

- 26 24 17 Panelboards Breaker TypeDocument1 page26 24 17 Panelboards Breaker TypeLangzkie NalipaNo ratings yet

- 26 50 00 LightingDocument14 pages26 50 00 LightingLangzkie NalipaNo ratings yet

- Infloorboard Ii: Installation GuideDocument6 pagesInfloorboard Ii: Installation GuideLangzkie NalipaNo ratings yet

- 23 72 23 Air-to-Air Energy-Recovery UnitsDocument2 pages23 72 23 Air-to-Air Energy-Recovery UnitsLangzkie NalipaNo ratings yet

- 23 31 13 DuctworkDocument4 pages23 31 13 DuctworkLangzkie NalipaNo ratings yet

- 23 33 13 Dampers BalancingDocument2 pages23 33 13 Dampers BalancingLangzkie NalipaNo ratings yet

- Warehouse Heating and Ventilating: Equipment Selection FactorsDocument8 pagesWarehouse Heating and Ventilating: Equipment Selection FactorsLangzkie NalipaNo ratings yet

- Tle 10 q1 Mod3 Agri-Crop Production - Farm ToolsDocument16 pagesTle 10 q1 Mod3 Agri-Crop Production - Farm ToolsChristle Angelu CristobalNo ratings yet

- G 128 - G 128M - 15Document15 pagesG 128 - G 128M - 15ruben carcamoNo ratings yet

- Evening Street Review Number 36Document306 pagesEvening Street Review Number 36Barbara BergmannNo ratings yet

- IMECE2018-87738: Thermal Behavior of Soils Under Tidal Effect: A Case Study in Guayaquil, EcuadorDocument7 pagesIMECE2018-87738: Thermal Behavior of Soils Under Tidal Effect: A Case Study in Guayaquil, EcuadorRemigio VasconezNo ratings yet

- MASE lABDocument3 pagesMASE lABAli Aslam100% (1)

- Physics Student Safety ContractDocument3 pagesPhysics Student Safety ContractJdeen FajardoNo ratings yet

- Equate EGDA 6888Document2 pagesEquate EGDA 6888akshayNo ratings yet

- Meaning-Centered Couples Therapy: Logotherapy and Intimate RelationshipsDocument9 pagesMeaning-Centered Couples Therapy: Logotherapy and Intimate RelationshipsLaith AtakNo ratings yet

- Cap DependentDocument6 pagesCap DependentKAIST이박터No ratings yet

- Director Manager Payroll CPP in Seattle WA Resume Michael HoernerDocument1 pageDirector Manager Payroll CPP in Seattle WA Resume Michael HoernerMichaelHoerner2No ratings yet

- Globular ProteinDocument4 pagesGlobular ProteinArvin O-CaféNo ratings yet

- Furuno Installation ManualDocument35 pagesFuruno Installation ManualZakaria Chowdhury71% (7)

- A 26 V 14 N 02Document6 pagesA 26 V 14 N 02faustinopateiro3497No ratings yet

- Case 1Document3 pagesCase 1nikunjrnanavatiNo ratings yet

- Understand Behaviours Better 001 The Barnum Forer EffectDocument1 pageUnderstand Behaviours Better 001 The Barnum Forer EffectJithesh AnandNo ratings yet

- Crime Fighting and Crime Prevention (Criminal Justice)Document127 pagesCrime Fighting and Crime Prevention (Criminal Justice)Dimitrije Živković100% (1)

- Stressors and Stress Management Amongst Undergraduates in The University of BeninDocument18 pagesStressors and Stress Management Amongst Undergraduates in The University of BeninGlad DysNo ratings yet

- Clinical Nutrition: Colin R. Paterson, David AyoubDocument6 pagesClinical Nutrition: Colin R. Paterson, David AyoubruthchristinawibowoNo ratings yet

- 10 Skills You Need To Succeed As A StewardessDocument2 pages10 Skills You Need To Succeed As A StewardessStartdoNo ratings yet

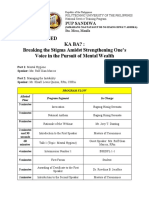

- Open-Minded Ka Ba?: Breaking The Stigma Amidst Strengthening One's Voice in The Pursuit of Mental WealthDocument3 pagesOpen-Minded Ka Ba?: Breaking The Stigma Amidst Strengthening One's Voice in The Pursuit of Mental WealthEstrada JulianeNo ratings yet

- Foreva - Seismic Repair and Strengthening of Existing BuildingsDocument12 pagesForeva - Seismic Repair and Strengthening of Existing BuildingsHuy Nguyen VanNo ratings yet

- Darah Dan Fungsi DarahDocument14 pagesDarah Dan Fungsi DarahdelisNo ratings yet

- Diploma in Palm Oil Milling Technology & Management Semester 1Document15 pagesDiploma in Palm Oil Milling Technology & Management Semester 1Mohd Irham IdrisNo ratings yet

- Olierook - Mechanisms For Permeability Modification in The Damage Zone of A Normal FaultDocument19 pagesOlierook - Mechanisms For Permeability Modification in The Damage Zone of A Normal FaultUgik GeoNo ratings yet

- Unit 77: Plan & Co-Ordinate Vehicle MaintenanceDocument12 pagesUnit 77: Plan & Co-Ordinate Vehicle MaintenanceNurul AduraNo ratings yet

- Unit Test - 4 Class-Xii Sub.-Chemistry Time:01:30 Hrs Mm:40Document2 pagesUnit Test - 4 Class-Xii Sub.-Chemistry Time:01:30 Hrs Mm:40Nihar Ranjan NikuNo ratings yet

- Advanced Stat. ResearchDocument6 pagesAdvanced Stat. ResearchYen YenNo ratings yet

- Platts Nucleonics Week 19 July2012Document15 pagesPlatts Nucleonics Week 19 July2012Jovi Savitri Eka PutriNo ratings yet