Professional Documents

Culture Documents

Food Process Eng - Intro

Food Process Eng - Intro

Uploaded by

snabil0 ratings0% found this document useful (0 votes)

134 views22 pagesThe document discusses the course Food Process Engineering, which covers the scientific principles and applications of engineering in developing and refining food products, and includes topics like materials science, engineering design, and working in food processing industry. The aims are for students to understand theoretical foundations of engineering applied to food and be able to improve food processes, apply new technologies, and work professionally in food engineering.

Original Description:

Original Title

Food Process Eng_Intro

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the course Food Process Engineering, which covers the scientific principles and applications of engineering in developing and refining food products, and includes topics like materials science, engineering design, and working in food processing industry. The aims are for students to understand theoretical foundations of engineering applied to food and be able to improve food processes, apply new technologies, and work professionally in food engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

134 views22 pagesFood Process Eng - Intro

Food Process Eng - Intro

Uploaded by

snabilThe document discusses the course Food Process Engineering, which covers the scientific principles and applications of engineering in developing and refining food products, and includes topics like materials science, engineering design, and working in food processing industry. The aims are for students to understand theoretical foundations of engineering applied to food and be able to improve food processes, apply new technologies, and work professionally in food engineering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 22

Food Process Engineering

Credit Hr 3 (2-1) Course Code FST-25405

Dr. Muhammad Shahbaz

Assistant Professor

Post-doc (South Korea)

Ph.D. (South Korea)

Department of Food Science and Human Nutrition

Introduction Of The Course

Food Engineering

“Food engineering is a scientific, academic, and professional field that

interprets and applies principles of engineering, science, and mathematics

to food manufacturing and operations, including the processing, production,

handling, storage, conservation, control, packaging and distribution

of food products”

Food Process Engineering

• Food Process Engineering is a scientific multidisciplinary field dealing with the

development and refinement of food products for human and animal consumption

• As a scientific discipline, Food Process Engineering encompasses the practical

applications of science to develop efficient industrial production, packaging, storage,

and marketing of wholesome and convenient foods

• Education in Food Process Engineering includes training in materials science

[rheology, mass transfer properties, and thermal and electrical food properties] applied

mathematics, quality control, engineering design of food process, and microbiological

applications in food processing

• Experts in Food Process Engineering work in academia, the public sector and industry

with the primary role of assessing the problems concerning food production, food

quality, process and plant design and food regulation

Aims and Objectives

At the end of the programme, students are expected to:

• Demonstrate a detailed understanding of the relevant theoretical foundations and

concepts of mathematics, chemistry, biology, physics and engineering as applied to

Food Process Engineering

• Be able to conduct, analyse and interpret experiments and apply experimental results

to improve processes

• Be able to apply new technology, design, plan, control and manage food process

engineering systems

• Be able to differentiate and select efficient technology in the development of agro-

industry processing to achieve profitable and environmentally safe outcomes

• Be able to apply new technology, design, plan, control and manage food process

engineering systems

• Demonstrate an appreciation for professional, ethical and social responsibilities

What are the Industry/Global Trends that

we can achieve through Food Process Eng

• In recent times, the food process industry has been characterized by efficient mass

production and transportation of food supplies

• This development has been dictated by increasing concentration of people in

urban areas, where large segment of the population depend on large quantities of

pre-treated, pre-processed, or ready-to-eat foodstuffs. Driven by this need, food

process engineers are at the forefront of developing and refining food products that

are uniform in quality and safe

• Another emerging trend is the preferences for non-thermal processed foods. Food

engineers are thus applying techniques such as highly hydrostatic pressure (HPP),

pulsed electric fields, light pulses, ultrasound, magnetic fields to satisfy this demand

Trends in modern food processing

Health

• Reduction of fat content in final product e.g. by using baking instead of deep-frying

in the production of potato chips

• Maintaining the natural taste of the product e.g. by using less artificial sweetener

Hygiene

• The introduction of HACCP standards during production and distribution reduce the

risk of contamination of the products

Trends in modern food processing

Efficiency

• Rising energy costs lead to increasing usage of energy-saving technologies, e.g.

heat insulation of factory buildings, heated vessels, and energy recovery

systems

• Factory automation systems (often distributed control systems) reduce

personnel costs and may lead to more stable production results

Reference Book for Our Course is shared with you in My Google Drive: Check your Email

Introduction:

Fundamentals of Food Process Engineering

Food Process and Unit Operations

What is a process?

• A ‘process’ is defined as a set of actions in a specific sequence, to a specific end

• A manufacturing process starts with raw materials and ends with products and by-

products

• The number of actually existing and theoretically possible processes in any

manufacturing industry is enormous

• The ‘actions ’ that constitute a process may be grouped in a relatively small number of

operations – called Unit Operations

• Early in the 20th century, these operations, called unit operations , became the

backbone of chemical engineering

• Since the 1950s, the unit operation approach has also been extensively applied by

teachers and researchers in food

Unit Operations Of The Food Processing Industry By Principal Groups

Unit Operations Of The Food Processing Industry By Principal Groups

Unit Operations Of The Food Processing Industry By Principal Groups

Types of Processes

Batch and Continuous Processes

Processes may be carried-out in

• Batch

• Continuous

• Mixed Fashion

A Batch Process

• In batch processing , a portion of the materials to be processed is separated

from the bulk and treated separately

• The conditions such as temperature, pressure, composition etc. usually vary

during the process

• The batch process has a definite duration and, after its completion, a new

cycle begins, with a new portion of material

• The batch process is usually less capital intensive but may be more costly to

operate and involves costly equipment dead-time for loading and unloading

between batches

• It is easier to control and lends itself to intervention during the process

A Batch Process

• Small-scale production and to frequent

changes in product composition and

process conditions

• A typical example of a batch process

would be the mixing of flour, water,

yeast and other ingredients in a bowl

mixer to make a bread dough

• After having produced one batch of

dough for white bread, the same mixer

can be cleaned and used to make a

batch of dark dough

A Continuous Process

• In continuous processing , the materials pass through the system continuously,

without separation of a part of the material from the bulk

• The conditions at a given point of the system may vary for a while at the beginning

of the process, but ideally they remain constant during the best part of the process

• In engineering terms, a continuous process is ideally run at steady state for most of

its duration

• Continuous processes are more difficult to control, require higher capital

investment, but provide better utilization of production capacity, at lower

operational cost

A Continuous Process

• They are particularly suitable for

lines producing large quantities of

one type of product for a relatively

long duration

• A typical example of a continuous

process would be the continuous

pasteurization of milk

A Mixed Process

• Mixed processes are composed of a sequence of continuous and batch

processes

• An example of a mixed process would be the production of strained infant food.

• In this example, the raw materials are first subjected to a continuous stage

consisting of washing, sorting, continuous blanching or cooking, mashing and

finishing (screening).

• Batches of the mashed ingredients are then collected in formulation tanks

where they are mixed according to formulation

• Usually, at this stage, a sample is sent to the quality assurance laboratory for

evaluation

A Mixed Process

• After approval, the batches are pumped, one after the other, to the continuous

homogenization, heat treatment and packaging line

• Thus, this mixed process is composed of one batch phase between two

continuous phases

• To run smoothly, mixed processes require that buffer storage capacity be

provided between the batch and continuous phases.

You might also like

- ABE 27 Physical Factors Which Make Up The EnvironmentDocument23 pagesABE 27 Physical Factors Which Make Up The EnvironmentRJ LlorenNo ratings yet

- II-6 Agronomy 1-23Document24 pagesII-6 Agronomy 1-23SannyBombeoJomocNo ratings yet

- Corn ThresherDocument3 pagesCorn ThresherAnonymous 1P2S4tbMNo ratings yet

- Handbook For Common Calculations in Finfish AquacultureDocument60 pagesHandbook For Common Calculations in Finfish Aquaculturegladys galantoNo ratings yet

- PART 3 ElectrificationDocument20 pagesPART 3 ElectrificationglymayNo ratings yet

- III-2 Thermo 1-3Document3 pagesIII-2 Thermo 1-3SannyBombeoJomocNo ratings yet

- Axelum Resources Corp Preliminary ProspectusDocument198 pagesAxelum Resources Corp Preliminary ProspectusEmil Victor Medina MasaNo ratings yet

- III 6 RicePostProd 1 8Document9 pagesIII 6 RicePostProd 1 8SannyBombeoJomocNo ratings yet

- Citrus CommercializationDocument23 pagesCitrus Commercializationannacarmelaaa100% (1)

- III 7 CornPostPro 1 4Document4 pagesIII 7 CornPostPro 1 4SannyBombeoJomocNo ratings yet

- 1 AE 44 Syllabus 2019Document12 pages1 AE 44 Syllabus 2019stephene larim100% (1)

- PublishedPaper Automatic Onion Peeling and Cutting MachineDocument5 pagesPublishedPaper Automatic Onion Peeling and Cutting Machineዘረአዳም ዘመንቆረርNo ratings yet

- Estimating Field Capacity PDFDocument4 pagesEstimating Field Capacity PDFMatthester100% (1)

- Introduction To Agricultural Processing and Food EngineeringDocument5 pagesIntroduction To Agricultural Processing and Food EngineeringMay Deguia100% (1)

- Abe 424 Farm Structures and Environmental ControlDocument42 pagesAbe 424 Farm Structures and Environmental ControlAmabi SilasNo ratings yet

- Area 1Document7 pagesArea 1Krisher DhayNo ratings yet

- Development of A Solar Powered Knapsack Sprayer: K Singh, D Padhee, AK Parmar and BL SinhaDocument4 pagesDevelopment of A Solar Powered Knapsack Sprayer: K Singh, D Padhee, AK Parmar and BL SinhasubyNo ratings yet

- Rheological Properties of Food and Agricultural ProductsDocument7 pagesRheological Properties of Food and Agricultural ProductsRizki AhmadNo ratings yet

- PAES 410-Lairage For Swine, Small & Large Animals PDFDocument15 pagesPAES 410-Lairage For Swine, Small & Large Animals PDFMissyCentenoNo ratings yet

- Agri Engineering Profession Roadmap PresentationDocument24 pagesAgri Engineering Profession Roadmap PresentationKaren Joy BabidaNo ratings yet

- Centrifugal ExtractorDocument5 pagesCentrifugal ExtractorShivaniNo ratings yet

- Rice Post Production ProcessingDocument7 pagesRice Post Production ProcessingMenard SoniNo ratings yet

- ABE2 Exercise 2 Lab ReportDocument5 pagesABE2 Exercise 2 Lab ReportRica APEXNo ratings yet

- Module (Fluid Mechanics)Document3 pagesModule (Fluid Mechanics)Kenneth Roy MatuguinaNo ratings yet

- CPU Part3Document122 pagesCPU Part3Quel LeNo ratings yet

- ThesisDocument64 pagesThesisHamdi ShaarNo ratings yet

- ABE30 Laboratory Exercise 4Document5 pagesABE30 Laboratory Exercise 4MARK LOUIE SUGANOBNo ratings yet

- Board Exam: Math: Science ofDocument9 pagesBoard Exam: Math: Science ofJP Taccad RomeroNo ratings yet

- III 3 HeatTransfer 1 3Document3 pagesIII 3 HeatTransfer 1 3SannyBombeoJomocNo ratings yet

- Agricultural Processing EquipmentsDocument42 pagesAgricultural Processing EquipmentsSachinNo ratings yet

- Agricultural Engineering Formula 1 - 2006 EditionDocument195 pagesAgricultural Engineering Formula 1 - 2006 EditionRaymarck PatricioNo ratings yet

- ELECTRICAL PROPERTIES-smart2Document31 pagesELECTRICAL PROPERTIES-smart2Erika LeeNo ratings yet

- Design and Development of Automatic Operated Seeds Sowing MachineDocument3 pagesDesign and Development of Automatic Operated Seeds Sowing MachineEditor IJRITCC100% (3)

- Philippine Agricultural Engineering StandardsDocument5 pagesPhilippine Agricultural Engineering StandardsYsmael Alongan B. Mangorsi100% (1)

- Microclimatic Modification PartsDocument12 pagesMicroclimatic Modification PartsJermaine Aceremo De CastroNo ratings yet

- Paes 204 Mechanical Rice Thresher SpecificationsDocument8 pagesPaes 204 Mechanical Rice Thresher SpecificationsEdsel Jay RaperNo ratings yet

- Recalled QuestionsDocument5 pagesRecalled QuestionsEspeeNo ratings yet

- Psychrometry: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerDocument15 pagesPsychrometry: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerBilly AgustinNo ratings yet

- Gravity-Fed Drip Irrigation Design ProcedureDocument12 pagesGravity-Fed Drip Irrigation Design ProcedureHector QuezadaNo ratings yet

- Irrigation LecturesDocument18 pagesIrrigation Lecturesfaizankhan23No ratings yet

- MmmmmmmmwordDocument69 pagesMmmmmmmmwordMariaNo ratings yet

- Chapter 15 Grain StorageDocument77 pagesChapter 15 Grain StorageRyza MartizanoNo ratings yet

- Performance Evaluation of A PhotovoltaicDocument6 pagesPerformance Evaluation of A PhotovoltaicJasem AbdurahmanNo ratings yet

- Esci 116N - Differential Equations First Long Examination Instructions: Handwrite Your Answers in Separate Sheets of Paper. After Answering All TheDocument10 pagesEsci 116N - Differential Equations First Long Examination Instructions: Handwrite Your Answers in Separate Sheets of Paper. After Answering All TheBienvenida Ycoy MontenegroNo ratings yet

- 6b. Rice and Other Crop Processing MachineryDocument130 pages6b. Rice and Other Crop Processing MachineryNiño Evangelista FranciscoNo ratings yet

- 5-6. General Management Practices and Animal Health Program - PDFDocument61 pages5-6. General Management Practices and Animal Health Program - PDFRoxan Mae AmplayoNo ratings yet

- Section 3 - Flat Bed DryerDocument27 pagesSection 3 - Flat Bed DryerRea Sarmiento0% (1)

- Rural ElectrificationDocument7 pagesRural ElectrificationAlfredo CondeNo ratings yet

- Machinery and MechanizationDocument2 pagesMachinery and MechanizationJezrael Kim SaquingNo ratings yet

- Law. QuestionDocument3 pagesLaw. QuestionGener Habala NavarroNo ratings yet

- ABE2 Exercise 7 Lab ReportDocument6 pagesABE2 Exercise 7 Lab ReportRica APEXNo ratings yet

- ABE Review 2022 Irrigation and Drainage Engineering Weirs, Orifice, and Other Flow Measurements Problem 1Document8 pagesABE Review 2022 Irrigation and Drainage Engineering Weirs, Orifice, and Other Flow Measurements Problem 1Niel Crizza Chloe JandaNo ratings yet

- Practical Radiation Heat TransferDocument4 pagesPractical Radiation Heat TransfertskNo ratings yet

- Abme 103 LectureDocument12 pagesAbme 103 LectureAlexa CuevasNo ratings yet

- Grain Drying in Asia Part 7 20158Document41 pagesGrain Drying in Asia Part 7 20158francisdimeNo ratings yet

- Design and Testing of A Natural Convection Solar Fish Dryer PDFDocument114 pagesDesign and Testing of A Natural Convection Solar Fish Dryer PDFMeryL AngNo ratings yet

- Abe Related Laws Review 2023bDocument41 pagesAbe Related Laws Review 2023bPeter ian AutenticoNo ratings yet

- ABE Review 2022 - AMEDocument23 pagesABE Review 2022 - AMEJirah Mae T. CATALU�ANo ratings yet

- Food and Crop Storage TechnologyDocument23 pagesFood and Crop Storage TechnologyElenduJuniorOgbonna100% (2)

- Lec#6 How To Write A ProposalDocument9 pagesLec#6 How To Write A ProposalsnabilNo ratings yet

- Lec#7 How To Present A Proposal For A Research PaperDocument27 pagesLec#7 How To Present A Proposal For A Research PapersnabilNo ratings yet

- Lec# 5 Aims of Proposals: Abdul RahmanDocument9 pagesLec# 5 Aims of Proposals: Abdul RahmansnabilNo ratings yet

- Process Flow Chart or Process Flow DiagramDocument12 pagesProcess Flow Chart or Process Flow DiagramsnabilNo ratings yet

- Reading Skill: Abdul RahmanDocument18 pagesReading Skill: Abdul RahmansnabilNo ratings yet

- Lec#4 Intensive Reading Test 1Document17 pagesLec#4 Intensive Reading Test 1snabilNo ratings yet

- Lec#2 Intensive Reading Practice 1Document12 pagesLec#2 Intensive Reading Practice 1snabilNo ratings yet

- Process Flow Diagram of Carrot and RiceDocument2 pagesProcess Flow Diagram of Carrot and RicesnabilNo ratings yet

- Lec#3 Intensive Reading Practice 2Document17 pagesLec#3 Intensive Reading Practice 2snabilNo ratings yet

- Food Preparation EquipmentDocument17 pagesFood Preparation EquipmentsnabilNo ratings yet

- Mechanical Processing EquipmentDocument8 pagesMechanical Processing EquipmentsnabilNo ratings yet

- Feature of Food ProcessesDocument22 pagesFeature of Food ProcessessnabilNo ratings yet

- Mosfet Gate DriveDocument6 pagesMosfet Gate DrivegubiliNo ratings yet

- RTOS TrainingDocument34 pagesRTOS Trainingमेनसन लाखेमरूNo ratings yet

- Br. No. 276-1 97919Document1 pageBr. No. 276-1 97919Krushana GiteNo ratings yet

- Compaines All MailDocument4 pagesCompaines All MailInfo Sanko SteelNo ratings yet

- Method of Statement (MOS) PDFDocument2 pagesMethod of Statement (MOS) PDF林诗倩100% (1)

- Presentation - Java - Basics - and Thread (Session 1 and Session 2)Document112 pagesPresentation - Java - Basics - and Thread (Session 1 and Session 2)hari chandanNo ratings yet

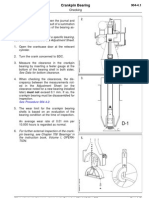

- Bottem End Bearing RemovalDocument8 pagesBottem End Bearing RemovalRohit Mishra100% (2)

- Vinayak Vaish: Job ProfileDocument1 pageVinayak Vaish: Job ProfileVinayak VaishNo ratings yet

- Construction EstimatorDocument2 pagesConstruction Estimatorapi-76938856No ratings yet

- in CE-1Document18 pagesin CE-1olive banielNo ratings yet

- A Study of Consumer Behavior Towards E-Banking Services in Faridabad CityDocument9 pagesA Study of Consumer Behavior Towards E-Banking Services in Faridabad CityNguyễn Ngọc Đoan DuyênNo ratings yet

- CMDBuild AdministratorManual ENG V240Document134 pagesCMDBuild AdministratorManual ENG V240jesusferre2No ratings yet

- Toro 151Document2 pagesToro 151jualt_velazugNo ratings yet

- LAXMICOINDocument13 pagesLAXMICOINDevanshu ShroffNo ratings yet

- NTC-PTC/ P R V-I I-V/ Pt100 TC: Double Stage Electronic ControllerDocument4 pagesNTC-PTC/ P R V-I I-V/ Pt100 TC: Double Stage Electronic ControllerJaime DiazNo ratings yet

- Electrical Spare Parts Catalog: PROJECT CODE: I-P21004-1 (BB1500)Document15 pagesElectrical Spare Parts Catalog: PROJECT CODE: I-P21004-1 (BB1500)NidDou100% (1)

- Ats 2 F04Document3 pagesAts 2 F04Mark MarasiganNo ratings yet

- SYS600 Status CodesDocument232 pagesSYS600 Status CodesPhuong LaiMinh100% (1)

- WRCEDocument1 pageWRCERichmark MacuhaNo ratings yet

- CCB Optional Products Installation Guide v2 4 0 3Document36 pagesCCB Optional Products Installation Guide v2 4 0 3Job LeftNo ratings yet

- Aids To NavigationDocument20 pagesAids To NavigationCraigChristopherLobo100% (2)

- DBB - SS-V3NBM8-F8-11421Document1 pageDBB - SS-V3NBM8-F8-11421ns_cempedakNo ratings yet

- # Consensus and Agreement Algorithms: Distributed ComputingDocument9 pages# Consensus and Agreement Algorithms: Distributed ComputingTrending MediaNo ratings yet

- F.Port Protocol (Without Phyid) V2.1: 1. Physical DefinitionDocument3 pagesF.Port Protocol (Without Phyid) V2.1: 1. Physical DefinitionhelioapmarquesNo ratings yet

- 11-0.433kV, 3500kVA Oil TX PDFDocument1 page11-0.433kV, 3500kVA Oil TX PDFEzany EzNo ratings yet

- Log Analysis 2018Document35 pagesLog Analysis 2018Ricardo MeloNo ratings yet

- Time and Frequency Dissemination: Advances in GPS Transfer TechniquesDocument7 pagesTime and Frequency Dissemination: Advances in GPS Transfer Techniquesa amuhaNo ratings yet

- Bit 2317 (Naks) Fundamentals of Computer SecurityDocument3 pagesBit 2317 (Naks) Fundamentals of Computer Securityroot parrotNo ratings yet

- FDocument94 pagesFFilipe Luis Teixeira 6CNo ratings yet

- Introduction To Data Communication: Dept. of Computer Engineering Faculty of EngineeringDocument29 pagesIntroduction To Data Communication: Dept. of Computer Engineering Faculty of Engineeringআসিফ রেজাNo ratings yet