Professional Documents

Culture Documents

PORPLASTICET Soft / Solid: Elastic Wearing Layer For PORPLASTICGREEN Systems

PORPLASTICET Soft / Solid: Elastic Wearing Layer For PORPLASTICGREEN Systems

Uploaded by

Youssef AribiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PORPLASTICET Soft / Solid: Elastic Wearing Layer For PORPLASTICGREEN Systems

PORPLASTICET Soft / Solid: Elastic Wearing Layer For PORPLASTICGREEN Systems

Uploaded by

Youssef AribiCopyright:

Available Formats

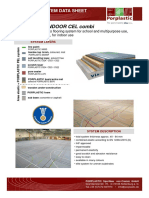

SYSTEM DATA SHEET

PORPLASTICET soft / solid

Elastic wearing layer for PORPLASTICGREEN systems

SYSTEM with ET

PORPLASTICGREEN

Filling with

PORPLASTICEPDM

and sand

PORPLASTICET

Unbound wearing layer

(rough and fine gravel)

Total elasticity of the system depends on

1. elasticity of PORPLASTICGREEN artificial turf

pile height

amount and quality of filling material

2.elasticity of PORPLASTICET soft or solid

layer thickness

sub-base

MODULAR SYSTEM ADVANTAGES

• increased elasticity of artificial turf fields

Artificial

PORPLASTICGREEN artificial turf

• less stress on muscoskeletal system of athletes

turf

Pile height 35 – 50 mm

Filled with PORPLASTICEPDM granules and sand • no deformations in goal

• high quality materials and still economic price

• high elasticity included automatically in the PU-

PORPLASTICEL elastic layer Elastic wearing layer

binder

Elastic

(approx. 15-30 mm) PORPLASTICET35

layer

OR

soft / solid or • good shock absorption

Bound wearing layer (asphalt) • weather-stable

PORPLASTICEL 25 /30

(approx. 25-50 mm) • water-permeable constructions for all climates

• long lifetime

Unbound layer (0/32 mm, > 200 mm)

Sub-base

Filter layer (> 60 mm)

Sub-base

PORPLASTIC Sportbau v. C. GmbH & Co. KG

Graf-Bentzel-Str. 78, D-72108 Rottenburg a. N

Tel.+49 (0)7472-937970 • info@porplastic.de

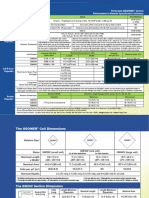

SYSTEM DATA SHEET

PORPLASTICET

APPLICATION AND CONSUMPTION

Layer Product consumption (kg/m²)

Thickness [mm]

Elastic layer Application with paver

PORPLASTICET35 soft binder: PORPLASTIC T775 approx. 6 - 7 % Mixture : 40 kg/m²

SBR/quartz mixture:

PORPLASTIC SBR (2 – 7 mm) 50 parts by weight

(up to ¼ of the SBR granules can be replaced by SBR fibre)

filling material (chippings, dry, 2-8 mm) 50 parts by weight

PORPLASTICET35 solid binder: PORPLASTIC T775 approx. 6 - 7 % Mixture : 44 kg/m²

SBR/quartz mixture:

PORPLASTIC SBR (2 – 7 mm) 13 parts by weight

(up to ¼ of the SBR granules can be replaced by SBR fibre)

filling material (chippings, dry, 2-8 mm) 87 parts by weight

WORKING CONDITIONS SUBBASE

Relative humidity: between 40-90 % (according to DIN V 18035-7: 2002-06)

Temperature: between 10-35°C Minimum thickness:

unbound wearing layer: 200 mm

Thickness: +/- 15% Water permeability: > 0,02 cm/s

Evenness: as sub-base (see underneath) Slope: max. 0,8%

Nominal height tolerance: +/- 15 mm

Height tolerance at edges: +/- 15 mm

Evenness:

Deflection limit at a measuring point interval of

1 m ≤ 4 mm 2 m ≤ 6 mm

3 m ≤ 8 mm 4 m ≤ 10 mm

TECHNICAL DATA

Layer / Water Tensile Shock Shock

thickness permea- strength absorp- absorption

bility transverse tion system

[cm/s] [N/mm²] [%] [%]

requirement only EL with turf

DIN V18035-7 > 0,002 > 0,08 (without 45-70%

turf)

FIFA 1 star 55-70%

FIFA 2 star 60-70%

PORPLASTIC 65%

0,24 0,09 55

ET35 (EL+42 MS reflex)

Remark: for further information please refer to the product data sheets or contact our technical service. All data are approximate values. Therefore no liability claims can be derived

from the system data sheet. As all PORPLASTIC data sheets are updated on a regular basis it is the users responsibility to obtain the most recent issue (see www.porplastic.com or

contact us directly). Date of issue: Feb. 2016– all technical information is subject to change without prior notice

PORPLASTIC Sportbau v. C. GmbH & Co. KG

Graf-Bentzel-Str. 78, D-72108 Rottenburg a. N

Tel.+49 (0)7472-937970 • info@porplastic.de

You might also like

- LECTURE No. 11. ADVANCED MATERIALS-SMART MATERIALS-BIOMATERIALS-NANOMATERIALSDocument13 pagesLECTURE No. 11. ADVANCED MATERIALS-SMART MATERIALS-BIOMATERIALS-NANOMATERIALSBizuayehu Tadesse AzeneNo ratings yet

- Porplasticfun 120 - : The Ultimate Protection: Jointless and DecorativeDocument2 pagesPorplasticfun 120 - : The Ultimate Protection: Jointless and DecorativeYoussef AribiNo ratings yet

- Sysds Porplastic Fun 120Document2 pagesSysds Porplastic Fun 120Youssef AribiNo ratings yet

- Porplasticfun 100 - : Jointless and Decorative Protection For Very Big Fall HeightsDocument2 pagesPorplasticfun 100 - : Jointless and Decorative Protection For Very Big Fall HeightsYoussef AribiNo ratings yet

- Sysds Porplastic Fun 100Document2 pagesSysds Porplastic Fun 100Youssef AribiNo ratings yet

- Porplasticfun 40 - : System Data SheetDocument2 pagesPorplasticfun 40 - : System Data SheetYoussef AribiNo ratings yet

- Sysds Porplastic Fun 60Document2 pagesSysds Porplastic Fun 60Youssef AribiNo ratings yet

- Porplasticfun 80 - : Safe and Attractive Play Zones Without Stumbling or TrippingDocument2 pagesPorplasticfun 80 - : Safe and Attractive Play Zones Without Stumbling or TrippingYoussef AribiNo ratings yet

- Porplasticindoor Cel Combi: System Data SheetDocument2 pagesPorplasticindoor Cel Combi: System Data SheetYoussef AribiNo ratings yet

- Matex Product Catalog - 2017Document13 pagesMatex Product Catalog - 2017DecoSports infraNo ratings yet

- Densolen - System AS39P / R20HT: Product InformationDocument2 pagesDensolen - System AS39P / R20HT: Product InformationCarlos PazNo ratings yet

- Item 200-201 & 310Document19 pagesItem 200-201 & 310KaJong JaclaNo ratings yet

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezNo ratings yet

- WCD Viscotaq PE Outerwrap TDSDocument3 pagesWCD Viscotaq PE Outerwrap TDSvissupleNo ratings yet

- Porplastic Ms Tender: System Data SheetDocument2 pagesPorplastic Ms Tender: System Data SheetYoussef AribiNo ratings yet

- PORPLASTIC M+F Evolution: System Data SheetDocument2 pagesPORPLASTIC M+F Evolution: System Data SheetYoussef AribiNo ratings yet

- Neo Backer RodDocument2 pagesNeo Backer RodhazelNo ratings yet

- Sigma 36Document2 pagesSigma 36EngTamerNo ratings yet

- Certoplast 514 TD EnglischDocument1 pageCertoplast 514 TD Englischgutman98No ratings yet

- Presto: Property Value Test MethodDocument2 pagesPresto: Property Value Test MethodledagoNo ratings yet

- DPF 390 FlexDocument3 pagesDPF 390 FlexCESAR GUERRERONo ratings yet

- Passive Corrosion Prevention For Flanges and Valves: Product InformationDocument3 pagesPassive Corrosion Prevention For Flanges and Valves: Product InformationAnant RubadeNo ratings yet

- Aerofoam Acoustic LinerDocument4 pagesAerofoam Acoustic LinerGovindarajanNo ratings yet

- Yiheng Specifications 2020Document6 pagesYiheng Specifications 2020SAWERA TEXTILES PVT LTDNo ratings yet

- Vetotop CL530: Premixed 2 To 10 MM Thick Cementitious Self Leveling UnderlaymentDocument2 pagesVetotop CL530: Premixed 2 To 10 MM Thick Cementitious Self Leveling UnderlaymentMahmoud AliNo ratings yet

- TL-Sikafloor-400 N ElasticDocument7 pagesTL-Sikafloor-400 N ElasticDraganNo ratings yet

- Neo Backer RodDocument2 pagesNeo Backer RodShibin PoulNo ratings yet

- Resin Transfer Molding (RTM) Feb2020.6310.1587310684.4315Document18 pagesResin Transfer Molding (RTM) Feb2020.6310.1587310684.4315EudoNo ratings yet

- Fiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDocument2 pagesFiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDifa LiuNo ratings yet

- Strongcoat TerrazzoDocument4 pagesStrongcoat Terrazzovincent NavarceNo ratings yet

- Pall Poly Fine ARD L PDFDocument3 pagesPall Poly Fine ARD L PDFMod KaewdaengNo ratings yet

- Sikaflex - 11 FC: 1-Part Moisture Curing, Polyurethane Adhesive SealantDocument4 pagesSikaflex - 11 FC: 1-Part Moisture Curing, Polyurethane Adhesive SealantGi GoNo ratings yet

- Toray NHP210-150S (MBR) BrochureDocument2 pagesToray NHP210-150S (MBR) Brochurenatalia sagredoNo ratings yet

- Premier Coatings Premtape TropicalDocument2 pagesPremier Coatings Premtape TropicalIm ChinithNo ratings yet

- Brochure Radyarn Stretch-YarnDocument4 pagesBrochure Radyarn Stretch-Yarnnivej17295No ratings yet

- Jontsil EjtDocument2 pagesJontsil EjtAnkita Baban GavadeNo ratings yet

- Trelleborg ATP Ballast Mat BrochureDocument8 pagesTrelleborg ATP Ballast Mat BrochureÜmit KukulaNo ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- Loctite 3090: Large-Gap Filling 2-Component Instant AdhesiveDocument2 pagesLoctite 3090: Large-Gap Filling 2-Component Instant Adhesivenice guyNo ratings yet

- Artfoam Foamboard TechdataDocument1 pageArtfoam Foamboard TechdataMohammed OmerNo ratings yet

- Cinta EnterradaDocument4 pagesCinta EnterradaDaniel Garces DavilaNo ratings yet

- BOPP Sintered Wire Cloth PDFDocument12 pagesBOPP Sintered Wire Cloth PDFdiego100% (1)

- Bitumastic 50 PDSDocument2 pagesBitumastic 50 PDSscriptd_ozd3nNo ratings yet

- Pre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDocument2 pagesPre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDaniel PratamaNo ratings yet

- Cast Film Lines ReifenhauserDocument2 pagesCast Film Lines ReifenhauserJuan Carlos Ortiz PimientaNo ratings yet

- Denso FB 30 TapeDocument2 pagesDenso FB 30 TapefoamtrailerNo ratings yet

- Flexi ConnectorDocument1 pageFlexi Connectorarsya_agasNo ratings yet

- Cico Poxy Sba Thixotropic Epoxy Resin AdhesiveDocument3 pagesCico Poxy Sba Thixotropic Epoxy Resin Adhesiveharish GiriNo ratings yet

- HP100 Technical Data SheetDocument1 pageHP100 Technical Data SheetventasNo ratings yet

- GW Geoweb GW30v6 SummaryDocument1 pageGW Geoweb GW30v6 SummaryChowdhury PriodeepNo ratings yet

- Sikabit Pro P 30 0mgDocument3 pagesSikabit Pro P 30 0mgSlamet Tri UsadhaNo ratings yet

- Document 4Document1 pageDocument 4leoNo ratings yet

- Tekaflex Pu 40 For Use in ConstructionDocument2 pagesTekaflex Pu 40 For Use in ConstructionEzeval GráficaNo ratings yet

- Denso Glass Outerwrap TDSDocument3 pagesDenso Glass Outerwrap TDSIwan AgusNo ratings yet

- (Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Document1 page(Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Erickzelaya2014No ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- Fisa Tehnica PVC Krystal Nou1Document3 pagesFisa Tehnica PVC Krystal Nou1Ioan CovaliovNo ratings yet

- Sikabit Pro P 30 0peDocument3 pagesSikabit Pro P 30 0peSlamet Tri UsadhaNo ratings yet

- TDS en DesmopolDocument9 pagesTDS en Desmopolzana connorNo ratings yet

- Tputty 506 Series: Gap Filler MaterialDocument1 pageTputty 506 Series: Gap Filler MaterialSergio FernandesNo ratings yet

- Porplasticindoor Cel Combi: System Data SheetDocument2 pagesPorplasticindoor Cel Combi: System Data SheetYoussef AribiNo ratings yet

- Porplastic Ms Tender: System Data SheetDocument2 pagesPorplastic Ms Tender: System Data SheetYoussef AribiNo ratings yet

- PORPLASTIC M+F Evolution: System Data SheetDocument2 pagesPORPLASTIC M+F Evolution: System Data SheetYoussef AribiNo ratings yet

- Sysds Porplastic Fun 120Document2 pagesSysds Porplastic Fun 120Youssef AribiNo ratings yet

- Porplasticfun 120 - : The Ultimate Protection: Jointless and DecorativeDocument2 pagesPorplasticfun 120 - : The Ultimate Protection: Jointless and DecorativeYoussef AribiNo ratings yet

- Porplasticfun 40 - : System Data SheetDocument2 pagesPorplasticfun 40 - : System Data SheetYoussef AribiNo ratings yet

- Porplasticfun 100 - : Jointless and Decorative Protection For Very Big Fall HeightsDocument2 pagesPorplasticfun 100 - : Jointless and Decorative Protection For Very Big Fall HeightsYoussef AribiNo ratings yet

- Porplasticfun 80 - : Safe and Attractive Play Zones Without Stumbling or TrippingDocument2 pagesPorplasticfun 80 - : Safe and Attractive Play Zones Without Stumbling or TrippingYoussef AribiNo ratings yet

- Sysds Porplastic Fun 100Document2 pagesSysds Porplastic Fun 100Youssef AribiNo ratings yet

- Sysds Porplastic Fun 60Document2 pagesSysds Porplastic Fun 60Youssef AribiNo ratings yet

- FP100 Fire Resistant CableDocument9 pagesFP100 Fire Resistant Cableapi-3803155No ratings yet

- Ptfe Slide PlateDocument2 pagesPtfe Slide PlateLovebinNo ratings yet

- Technical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableDocument1 pageTechnical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableRasel AhmedNo ratings yet

- Solidification of MaterialDocument28 pagesSolidification of MaterialNaman DaveNo ratings yet

- Lab Hardness MemoDocument4 pagesLab Hardness MemoJan YsNo ratings yet

- Cryogenic (Imperial)Document28 pagesCryogenic (Imperial)Rahul LavandNo ratings yet

- Nivelco NivofloatDocument4 pagesNivelco NivofloatKareem RMGNo ratings yet

- TC Salboni - Comp-Wk-37Document1 pageTC Salboni - Comp-Wk-37Biplab RoyNo ratings yet

- Ducab Medium Voltage Cables Lead SheathDocument27 pagesDucab Medium Voltage Cables Lead Sheathdeodorant88No ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Influence of Eggshell Particulate On TheDocument10 pagesInfluence of Eggshell Particulate On Thesindula sai srinivasNo ratings yet

- ASTEC GFRP Permanent Technical Data SheetDocument1 pageASTEC GFRP Permanent Technical Data SheetMysara MohsenNo ratings yet

- RIPSTAR Saturant-V3Document3 pagesRIPSTAR Saturant-V3Ankita Baban GavadeNo ratings yet

- Materials Today: Proceedings: R.O. Akaluzia, F.O. Edoziuno, A.A. Adediran, B.U. Odoni, S. Edibo, T.M.A. OlayanjuDocument8 pagesMaterials Today: Proceedings: R.O. Akaluzia, F.O. Edoziuno, A.A. Adediran, B.U. Odoni, S. Edibo, T.M.A. OlayanjufebrianiNo ratings yet

- Common TSDFDocument5 pagesCommon TSDFaroramituNo ratings yet

- Setting:-: Concrete Technology (I) Lecture 5Document10 pagesSetting:-: Concrete Technology (I) Lecture 5Mahmoud HosnyNo ratings yet

- Details at "A": Sealing Details of Contraction Joint GrooveDocument3 pagesDetails at "A": Sealing Details of Contraction Joint GrooveSoodi Nagendra PrasadNo ratings yet

- Core & Shell BOQ - ArchDocument58 pagesCore & Shell BOQ - ArchashokNo ratings yet

- SMP SDocument23 pagesSMP Salireza198No ratings yet

- AVIS-FFS Approach & MethodologyDocument7 pagesAVIS-FFS Approach & MethodologymksharmaNo ratings yet

- Prediksi Masa Guna Elemen Struktur Beton - 2009 PDFDocument10 pagesPrediksi Masa Guna Elemen Struktur Beton - 2009 PDFMirna KristiyantoNo ratings yet

- Color Codes of Receptacles: Food WasteDocument1 pageColor Codes of Receptacles: Food WasteNMHaNo ratings yet

- Concrete Mix Design C 30 For KamoaDocument9 pagesConcrete Mix Design C 30 For Kamoamitendra singhNo ratings yet

- Kraton D1101 BTDocument2 pagesKraton D1101 BTosvaldo gutierrezNo ratings yet

- Dry WallDocument5 pagesDry WallNakul NayanNo ratings yet

- High Strength Concrete SC G2Document36 pagesHigh Strength Concrete SC G2Simranjit Singh MarwahNo ratings yet

- Parameter Calculation and Verification of Concrete Plastic Damage Model of AbaqusDocument9 pagesParameter Calculation and Verification of Concrete Plastic Damage Model of AbaqusAdnan NajemNo ratings yet

- Styrene Butadiene RubberDocument27 pagesStyrene Butadiene RubberabdulqadirNo ratings yet

- Concrete Is one-WPS OfficeDocument2 pagesConcrete Is one-WPS OfficeAbiodun AmusatNo ratings yet