Professional Documents

Culture Documents

A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 218

A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 218

Uploaded by

Vivek MishraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 218

A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 218

Uploaded by

Vivek MishraCopyright:

Available Formats

Contents

Variable Stresses in Machine Parts 205

Shells for Loader Engine

main gun

Sighting equipment

Commander

Driving

sprocket

Gunner

Driver

Main gun

Machine gun

Rubber tyres

Layout of a military tank.

Note : This picture is given as additional information and is not a direct example of the current chapter.

Example 6.8. A circular bar of 500 mm length is supported freely at its two ends. It is acted

upon by a central concentrated cyclic load having a minimum value of 20 kN and a maximum value

of 50 kN. Determine the diameter of bar by taking a factor of safety of 1.5, size effect of 0.85, surface

finish factor of 0.9. The material properties of bar are given by : ultimate strength of 650 MPa, yield

strength of 500 MPa and endurance strength of 350 MPa.

Solution. Given : l = 500 mm ; Wmin = 20 kN = 20 × 103 N ; Wmax = 50 kN = 50 × 103 N ;

F.S. = 1.5 ; Ksz = 0.85 ; Ksur = 0.9 ; σu = 650 MPa = 650 N/mm2 ; σy = 500 MPa = 500 N/mm2 ;

σe = 350 MPa = 350 N/mm2

Let d = Diameter of the bar in mm.

We know that the maximum bending moment,

W × l 50 × 103 × 500

Mmax = max = = 6250 × 103 N - mm

4 4

and minimum bending moment,

W × l 20 × 103 × 500

Mmin = min = = 2550 × 103 N - mm

4 4

∴ Mean or average bending moment,

M + M min 6250 × 103 + 2500 × 103

Mm = max = = 4375 × 103 N - mm

2 2

and variable bending moment,

M − M min 6250 × 103 − 2500 × 103

Mv = max = = 1875 × 103 N - mm

2 2

Section modulus of the bar,

π

Z = × d 3 = 0.0982 d 3 mm3

32

∴ Mean or average bending stress,

M m 4375 × 103 44.5 × 106

σm = Z = = N/mm 2

0.0982 d 3 d3

Top

You might also like

- Drain Design CalculationDocument10 pagesDrain Design Calculationaselabambarandage100% (2)

- 265 HcsDocument3 pages265 HcsNaveen NunnaNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityPn EkanayakaNo ratings yet

- bs8110- cantilever rc beamsDocument1 pagebs8110- cantilever rc beamsRishav ChaudharyNo ratings yet

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (2)

- Student Manual of BendingDocument6 pagesStudent Manual of BendingHannan AyubNo ratings yet

- Wood Working VisesDocument20 pagesWood Working Viseschand7777777No ratings yet

- Design of Bearing Replacement SchemeDocument10 pagesDesign of Bearing Replacement SchemeShivendra KumarNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNo ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Bird Mesh Frame Main Beam Local Capacity CheckDocument7 pagesBird Mesh Frame Main Beam Local Capacity CheckChandru MohanNo ratings yet

- Design of TurnbuckleDocument9 pagesDesign of Turnbucklejaykyu75% (4)

- Beam Design RusselDocument155 pagesBeam Design RusselRonald CostalesNo ratings yet

- Test On Close - Coiled Helical Spring: Ex. No.: 9 / Sahil Choudhury (19Bcl1028)Document6 pagesTest On Close - Coiled Helical Spring: Ex. No.: 9 / Sahil Choudhury (19Bcl1028)sahilNo ratings yet

- Beams: (Frame 2)Document54 pagesBeams: (Frame 2)John Rafael R. CanoosNo ratings yet

- 8b.design of Control Room BuildingDocument49 pages8b.design of Control Room BuildingNuru TwahaNo ratings yet

- AKASH InputDocument3 pagesAKASH InputJitendra PatelNo ratings yet

- Page 6Document1 pagePage 6Edward Albert BañagaNo ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Title: Tensile TestDocument5 pagesTitle: Tensile TestAbdulrahmanNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 219Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 219Vivek MishraNo ratings yet

- Design As Per IS 800-2007 (Jindal) (20131011)Document11 pagesDesign As Per IS 800-2007 (Jindal) (20131011)Pruthviraj JuniNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- Detale 2Document8 pagesDetale 2MuhamedNo ratings yet

- Ume 1312 Som Lab Ese QP - A2 Batch PDFDocument19 pagesUme 1312 Som Lab Ese QP - A2 Batch PDFDhanush NatesanNo ratings yet

- Design of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Document3 pagesDesign of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Ayush GargNo ratings yet

- Solucion Parcial: 303,6 KN 396,4 KN 153,6 200 50Document2 pagesSolucion Parcial: 303,6 KN 396,4 KN 153,6 200 50MELISSA VEGANo ratings yet

- University of Dar Es SalaamDocument10 pagesUniversity of Dar Es SalaamChris AdaminovicNo ratings yet

- Base Plate MCCDocument7 pagesBase Plate MCCabbasamuNo ratings yet

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Experiment Lab Sheet j2020Document8 pagesExperiment Lab Sheet j2020nur nazatul najwaNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Elastomeric Bearing 21.6mDocument8 pagesElastomeric Bearing 21.6mnaresh KUMARNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007soumyaNo ratings yet

- Design Calculations For Primary Beam Connections As Moment ConnectionDocument3 pagesDesign Calculations For Primary Beam Connections As Moment ConnectionRajesh PoreNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Calculation Sheet: B F F A A ADocument1 pageCalculation Sheet: B F F A A Aiwanguna71No ratings yet

- Davit Design and Support CalculationDocument22 pagesDavit Design and Support CalculationJagdish KotadiyaNo ratings yet

- Beam Design DraftDocument5 pagesBeam Design DraftJohn Christopher BaquingNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument2 pagesTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Test On Close - Coiled Helical SpringDocument4 pagesTest On Close - Coiled Helical SpringKartikeya ThadaniNo ratings yet

- 3PB Pilecap DesignDocument3 pages3PB Pilecap DesignJONAS NGNo ratings yet

- Hollow Core Slab DesignDocument3 pagesHollow Core Slab DesignNaveen Nunna0% (1)

- Steel Column CheckDocument8 pagesSteel Column CheckJunnoKaiserNo ratings yet

- Example NR 2Document5 pagesExample NR 2Meseret ShimelisNo ratings yet

- Chapter 4 Shear ReinforcementDocument17 pagesChapter 4 Shear ReinforcementAnis SyafiqahNo ratings yet

- 5.0 Connection 4Document3 pages5.0 Connection 4Gaurav BhabadNo ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- Fasfki L MDocument12 pagesFasfki L MmaulanaNo ratings yet

- Page 5Document1 pagePage 5Edward Albert BañagaNo ratings yet

- Design of Diaphragm Word FileDocument3 pagesDesign of Diaphragm Word Fileparas rahangdaleNo ratings yet

- SkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXDocument7 pagesSkyCiv Beam Summary Report - QnNAa8jdrnyXqvzc2dpxdNapwURwnLnXBastian David Castro BastiasNo ratings yet

- Design of Elastomeric Bearing: (For Effective Span of 20.95M)Document8 pagesDesign of Elastomeric Bearing: (For Effective Span of 20.95M)vivek100% (1)

- 4.3 Design Values of Bending Moments and Shear ForcesDocument7 pages4.3 Design Values of Bending Moments and Shear Forcesmn4webNo ratings yet

- Rectangular Beam 1VB27-300x650mm - Sagging: InputDocument4 pagesRectangular Beam 1VB27-300x650mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- 4PB Pilecap DesignDocument2 pages4PB Pilecap DesignJONAS NGNo ratings yet

- Appendix - 4ADocument15 pagesAppendix - 4Amoumita mukherjeeNo ratings yet

- T0-2 Propun Cornier 100x100x10 Otel S235 JR Caracteristici GeometriceDocument11 pagesT0-2 Propun Cornier 100x100x10 Otel S235 JR Caracteristici GeometriceCristian RusuNo ratings yet

- 5.3 Design of Crash BarrierDocument3 pages5.3 Design of Crash BarrierMd BIN HASANNo ratings yet

- Plate 2Document3 pagesPlate 2snoariNo ratings yet

- BT-206 Sessional-II 20210813145653Document8 pagesBT-206 Sessional-II 20210813145653Vivek MishraNo ratings yet

- BT-206 Sessional-II 20210813145653Document5 pagesBT-206 Sessional-II 20210813145653Vivek MishraNo ratings yet

- BT-206 Assignment-I 20210813145725Document2 pagesBT-206 Assignment-I 20210813145725Vivek MishraNo ratings yet

- Quiz 2Document2 pagesQuiz 2Vivek MishraNo ratings yet

- 2.5.3 Any Additional InformationDocument1 page2.5.3 Any Additional InformationVivek MishraNo ratings yet

- Sessional 2Document1 pageSessional 2Vivek MishraNo ratings yet

- SSR 17.10.2022Document116 pagesSSR 17.10.2022Vivek MishraNo ratings yet

- Scriet (Agriculture Depatment), Ccsu Meerut Machine Design (Unit 1, Keys Lecture 2)Document3 pagesScriet (Agriculture Depatment), Ccsu Meerut Machine Design (Unit 1, Keys Lecture 2)Vivek MishraNo ratings yet

- Chaudhary Charan Singh University, MeerutDocument2 pagesChaudhary Charan Singh University, MeerutVivek MishraNo ratings yet

- National Institute of Technology RourkelaDocument4 pagesNational Institute of Technology RourkelaVivek MishraNo ratings yet

- Scriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Document2 pagesScriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Vivek MishraNo ratings yet

- 2.5.3 Any Additional InformationDocument12 pages2.5.3 Any Additional InformationVivek MishraNo ratings yet

- RTI PerformaDocument8 pagesRTI PerformaVivek MishraNo ratings yet

- Scriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 3)Document7 pagesScriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 3)Vivek MishraNo ratings yet

- Scriet Agriculture Engg. 5Th Sem. Machine Design (Ag-503) QuizDocument1 pageScriet Agriculture Engg. 5Th Sem. Machine Design (Ag-503) QuizVivek MishraNo ratings yet

- $ $ VS W Fik M$/: M.S. Regional Ayurveda Research Institute For Endocrine DisordersDocument2 pages$ $ VS W Fik M$/: M.S. Regional Ayurveda Research Institute For Endocrine DisordersVivek MishraNo ratings yet

- Index For Naac Criteria 2Document1 pageIndex For Naac Criteria 2Vivek MishraNo ratings yet

- Scriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 4)Document8 pagesScriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 4)Vivek MishraNo ratings yet

- Track Shipment Status - Consignment Status - DTDC IndiaDocument1 pageTrack Shipment Status - Consignment Status - DTDC IndiaVivek MishraNo ratings yet

- Scriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 6)Document8 pagesScriet (Mechanical Depatment), Ccsu Meerut Strength of Material (Unit 2 Lecture 6)Vivek MishraNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 217Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 217Vivek MishraNo ratings yet

- Fatigue Design ProblemsDocument7 pagesFatigue Design ProblemsVivek MishraNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 219Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 219Vivek MishraNo ratings yet

- Index: B.Tech ME 5 SemDocument6 pagesIndex: B.Tech ME 5 SemVivek MishraNo ratings yet

- Index: B.Tech ME 5 SemDocument5 pagesIndex: B.Tech ME 5 SemVivek MishraNo ratings yet

- Index: B.Tech ME 5 SemDocument4 pagesIndex: B.Tech ME 5 SemVivek MishraNo ratings yet

- Index: B.Tech ME 5 SemDocument4 pagesIndex: B.Tech ME 5 SemVivek MishraNo ratings yet

- Index: B.Tech ME 5 SemDocument3 pagesIndex: B.Tech ME 5 SemVivek MishraNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNo ratings yet

- Scriet (Agriculure Engineering), Ccsu Meerut Machine Desgn (Unit 3 Helical Gears, Lecture 5)Document21 pagesScriet (Agriculure Engineering), Ccsu Meerut Machine Desgn (Unit 3 Helical Gears, Lecture 5)Vivek MishraNo ratings yet

- 3 MoS PRSDocument50 pages3 MoS PRSAmritNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityJaineshNo ratings yet

- Wu 2001Document15 pagesWu 2001Alejandro Gancedo ToralNo ratings yet

- Modelling of The Hysteretic Behaviour of Buckling Restrained BracesDocument8 pagesModelling of The Hysteretic Behaviour of Buckling Restrained BracesCristian Camilo Martinez JimenezNo ratings yet

- Construction and Building Materials: Martin Schäfers, Werner SeimDocument11 pagesConstruction and Building Materials: Martin Schäfers, Werner SeimKarrar MonarchNo ratings yet

- Bearing Design Design NoteDocument4 pagesBearing Design Design Notearepelli madhuNo ratings yet

- ATENA - Theory Nonlinear RCDocument282 pagesATENA - Theory Nonlinear RCPreloxNo ratings yet

- Chapter 3Document35 pagesChapter 3Girma Fikre100% (1)

- Connection - IDEA StatiCa PDFDocument18 pagesConnection - IDEA StatiCa PDFDaniel TuerosNo ratings yet

- Plate Buckling NotesDocument0 pagesPlate Buckling NotesSharyn PolleyNo ratings yet

- ADA307702Document234 pagesADA307702Andres Rodriguez HerreraNo ratings yet

- Strain Life ApproachDocument65 pagesStrain Life Approachsjdjd ddjdjfNo ratings yet

- CompressorDocument6 pagesCompressor吳晨維No ratings yet

- Metal Forming Lecture 4 Yield ConditionsDocument42 pagesMetal Forming Lecture 4 Yield ConditionsYashwant YadavNo ratings yet

- 1 Tensile TestDocument10 pages1 Tensile TestAsadullahSafiNo ratings yet

- Past Test & Exam Papers (STRMIA3)Document32 pagesPast Test & Exam Papers (STRMIA3)Tivani MphiniNo ratings yet

- 08 VibrationDocument10 pages08 VibrationAisha Zaheer50% (2)

- Simplified Guide To Lorry Types and WeightsDocument24 pagesSimplified Guide To Lorry Types and WeightspetruNo ratings yet

- BARUS METROPOL Type-2 Uygunluk 9nov2021Document8 pagesBARUS METROPOL Type-2 Uygunluk 9nov2021Ali KayaNo ratings yet

- In The Name of God: Time Dependent Behavior of RocksDocument48 pagesIn The Name of God: Time Dependent Behavior of RocksDiego Palomino GasteluNo ratings yet

- Som & DmeDocument2 pagesSom & DmeSurulivelrajantNo ratings yet

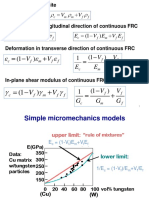

- Micromechanics-Lecture 14Document10 pagesMicromechanics-Lecture 14Steve LinkingNo ratings yet

- MSC Maths-1Document24 pagesMSC Maths-1deveshagNo ratings yet

- Handout 3 12Document15 pagesHandout 3 12Raphael FreitasNo ratings yet

- Design of Glued Laminated Timber ColumnsDocument6 pagesDesign of Glued Laminated Timber ColumnsLucas DouradoNo ratings yet

- Assignment: Name-Manansh Ram Thakur Roll No-19135055 Branch - MechDocument3 pagesAssignment: Name-Manansh Ram Thakur Roll No-19135055 Branch - MechManansh ThakurNo ratings yet

- Civil Engineering SyllabusDocument69 pagesCivil Engineering SyllabusAmit PaliwalNo ratings yet

- CE6306 Strength of Materials (SOM)Document127 pagesCE6306 Strength of Materials (SOM)goldencometNo ratings yet

- Heidarpour, (2010) - FSJDocument10 pagesHeidarpour, (2010) - FSJluisalvesqueirozNo ratings yet