Professional Documents

Culture Documents

Homework 5 Metal Drawing

Homework 5 Metal Drawing

Uploaded by

Ful RazzCopyright:

Available Formats

You might also like

- MCQ-Metal Forming ProcessDocument16 pagesMCQ-Metal Forming ProcessKunal Wagh67% (9)

- 3 End of Chapter3 Problems BULKDocument6 pages3 End of Chapter3 Problems BULKqusayNo ratings yet

- Tutorial 3 Bulk DeformationDocument2 pagesTutorial 3 Bulk DeformationSawai PariharNo ratings yet

- MA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Document4 pagesMA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Kok Keat TanNo ratings yet

- Mark Scored:: M M M M MDocument5 pagesMark Scored:: M M M M MRamesh ShresthaNo ratings yet

- Assignment One (Metal Forming Processes)Document2 pagesAssignment One (Metal Forming Processes)Anonymous XybLZfNo ratings yet

- Solving Session 1 Mech422Document2 pagesSolving Session 1 Mech422Ismail Abou ZeidNo ratings yet

- Assignment 1Document1 pageAssignment 1Abdul RafayNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Sheet Metal Operation Figures and Q A For StudentsDocument15 pagesSheet Metal Operation Figures and Q A For StudentsRavinder Antil75% (4)

- Assosa University College of Engineering Department of Mechanical EngineeringDocument2 pagesAssosa University College of Engineering Department of Mechanical EngineeringKedir AddisuNo ratings yet

- Forming E BookDocument22 pagesForming E BookunitybeginsathomeNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- Lec 3 Sheet MetalDocument11 pagesLec 3 Sheet Metalahmedbrekaa888No ratings yet

- 27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical CupDocument10 pages27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical Cupiaset123No ratings yet

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- Assignment 3Document20 pagesAssignment 3عمر صرانNo ratings yet

- Contoh Soal ForgingDocument3 pagesContoh Soal ForgingAzka ZafranNo ratings yet

- Assignment 1 ENG 173 METAL FORMINGDocument2 pagesAssignment 1 ENG 173 METAL FORMINGtoursena44No ratings yet

- Example Questions Module1Document4 pagesExample Questions Module1Kaan OkkalıNo ratings yet

- Problems: Problem 1 Problem 2Document2 pagesProblems: Problem 1 Problem 2Lily Margareth ArrietaNo ratings yet

- Tugas Drawing - 1803811 - Rivansyah P.ADocument6 pagesTugas Drawing - 1803811 - Rivansyah P.Avansyah 01No ratings yet

- 114 PDFDocument73 pages114 PDFMonu SharmaNo ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- Metal Forming Lect 4Document36 pagesMetal Forming Lect 4e22mecu0009No ratings yet

- Drawing DieDocument7 pagesDrawing Diethanhhn_1210No ratings yet

- Bulk Deformation Processes Solved ProblemsDocument15 pagesBulk Deformation Processes Solved ProblemsOloyede RidwanNo ratings yet

- TYPE A - Real Time Quiz End Semester Examination - ME331Document7 pagesTYPE A - Real Time Quiz End Semester Examination - ME331Selvi RNo ratings yet

- Metal Forming Lect 7Document22 pagesMetal Forming Lect 7e22mecu0009No ratings yet

- PunchDocument4 pagesPunchDebaprasanna PuhanNo ratings yet

- Tutorial 4 Sheet Metal WorkingDocument2 pagesTutorial 4 Sheet Metal WorkingSawai PariharNo ratings yet

- Phase 1 Quiz QP WITH ANSWERDocument5 pagesPhase 1 Quiz QP WITH ANSWERsureshkumarNo ratings yet

- Production Test PaperDocument9 pagesProduction Test Paperfaheemhaider21No ratings yet

- Gate Solved Paper - Me: Manufacturing EngineeringDocument72 pagesGate Solved Paper - Me: Manufacturing EngineeringVHemendra NaiduNo ratings yet

- HW 4Document6 pagesHW 4mustafa aliNo ratings yet

- 0910sem1 Me3162 PDFDocument10 pages0910sem1 Me3162 PDFChun Ping OngNo ratings yet

- MMCV312 Final Exam Paper - 2022Document7 pagesMMCV312 Final Exam Paper - 2022Praveet ChandNo ratings yet

- IPE 203 Fall 2020 Mist (Sec A)Document2 pagesIPE 203 Fall 2020 Mist (Sec A)Ayesha MalihaNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- ME Manufacturing-Engineering PDFDocument73 pagesME Manufacturing-Engineering PDFpankajNo ratings yet

- Objective QuestionsDocument73 pagesObjective QuestionsRajesh ShahNo ratings yet

- Machining Principles & Machine ToolsDocument16 pagesMachining Principles & Machine Toolssantosh sivarNo ratings yet

- Objective ProductionDocument6 pagesObjective ProductionM.ThirunavukkarasuNo ratings yet

- Unit 1: Special Forming ProcessesDocument21 pagesUnit 1: Special Forming ProcessesIncredible Indian StarsNo ratings yet

- Kumpulan Soal Uas Teknik PembentukanDocument25 pagesKumpulan Soal Uas Teknik PembentukanNur'aini Virani PutriNo ratings yet

- Chapter 6 Die DesignDocument55 pagesChapter 6 Die Designmulugeta assefaNo ratings yet

- 103 Manufacturing Engineering PDFDocument73 pages103 Manufacturing Engineering PDFSushil Kumar Singh100% (1)

- ForgingDocument56 pagesForgingZulfikarUdenNo ratings yet

- Design of Machine Members Mid Question PaperDocument4 pagesDesign of Machine Members Mid Question PaperSRES MECHNo ratings yet

- SMW Lect 2Document48 pagesSMW Lect 2e22mecu0009No ratings yet

- PR Pembentukan 2-DikonversiDocument2 pagesPR Pembentukan 2-Dikonversivansyah 01No ratings yet

- METALWORKINGDocument23 pagesMETALWORKINGDr Rajamani R - PSGCTNo ratings yet

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- Review Questions - 2 Group of Review QuestionsDocument3 pagesReview Questions - 2 Group of Review QuestionsVenkata DineshNo ratings yet

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

Homework 5 Metal Drawing

Homework 5 Metal Drawing

Uploaded by

Ful RazzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homework 5 Metal Drawing

Homework 5 Metal Drawing

Uploaded by

Ful RazzCopyright:

Available Formats

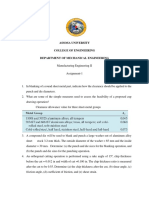

Homework 5

Metal Drawing

Problem 1

a) What are wire drawing and bar drawing?

b) Although the workpiece in a wire drawing operation is obviously subjected to tensile

stresses, how do compressive stresses also play a role in the process?

c) In a wire drawing operation, why must the drawing stress never exceed the yield strength

of the work metal?

d) What are some of the simple measures used to assess the feasibility of a proposed cup-

drawing operation?

Problem 2

A spool of wire has a starting diameter of 2.5 mm. It is drawn through a die with an opening that

is 2.1 mm. The entrance angel of the die is 18° degrees. Coefficient of friction at the work-die

interface is 0.08. The work metal has a strength coefficient of 450 MPa and a strain hardening

coefficient of 0.26. The drawing is performed at room temperature. Determine (a) area reduction,

(b) draw stress, and (c) draw force required for the operation.

Problem 3

Bar stock of initial diameter = 90 mm is drawn with a draft = 15 mm. The draw die has an

entrance angle = 18°, and the coefficient of friction at the work-die interface = 0.08. The metal

behaves as a perfectly plastic material with yield stress = 105 MPa. Determine (a) area reduction,

(b) draw stress, (c) draw force required for the operation, and (d) power to perform the operation

if exit velocity = 1.0 m/min.

Problem 4

A cup is to be drawn in a deep drawing operation. The height of the cup is 75 mm and its inside

diameter = 100 mm. Sheet-metal thickness = 2 mm. If the blank diameter = 225 mm, determine

(a) drawing ratio, (b) reduction, and (c) thickness-to-diameter ratio. (d) Does the operation seem

feasible?

You might also like

- MCQ-Metal Forming ProcessDocument16 pagesMCQ-Metal Forming ProcessKunal Wagh67% (9)

- 3 End of Chapter3 Problems BULKDocument6 pages3 End of Chapter3 Problems BULKqusayNo ratings yet

- Tutorial 3 Bulk DeformationDocument2 pagesTutorial 3 Bulk DeformationSawai PariharNo ratings yet

- MA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Document4 pagesMA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Kok Keat TanNo ratings yet

- Mark Scored:: M M M M MDocument5 pagesMark Scored:: M M M M MRamesh ShresthaNo ratings yet

- Assignment One (Metal Forming Processes)Document2 pagesAssignment One (Metal Forming Processes)Anonymous XybLZfNo ratings yet

- Solving Session 1 Mech422Document2 pagesSolving Session 1 Mech422Ismail Abou ZeidNo ratings yet

- Assignment 1Document1 pageAssignment 1Abdul RafayNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Sheet Metal Operation Figures and Q A For StudentsDocument15 pagesSheet Metal Operation Figures and Q A For StudentsRavinder Antil75% (4)

- Assosa University College of Engineering Department of Mechanical EngineeringDocument2 pagesAssosa University College of Engineering Department of Mechanical EngineeringKedir AddisuNo ratings yet

- Forming E BookDocument22 pagesForming E BookunitybeginsathomeNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- Lec 3 Sheet MetalDocument11 pagesLec 3 Sheet Metalahmedbrekaa888No ratings yet

- 27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical CupDocument10 pages27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical Cupiaset123No ratings yet

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- Assignment 3Document20 pagesAssignment 3عمر صرانNo ratings yet

- Contoh Soal ForgingDocument3 pagesContoh Soal ForgingAzka ZafranNo ratings yet

- Assignment 1 ENG 173 METAL FORMINGDocument2 pagesAssignment 1 ENG 173 METAL FORMINGtoursena44No ratings yet

- Example Questions Module1Document4 pagesExample Questions Module1Kaan OkkalıNo ratings yet

- Problems: Problem 1 Problem 2Document2 pagesProblems: Problem 1 Problem 2Lily Margareth ArrietaNo ratings yet

- Tugas Drawing - 1803811 - Rivansyah P.ADocument6 pagesTugas Drawing - 1803811 - Rivansyah P.Avansyah 01No ratings yet

- 114 PDFDocument73 pages114 PDFMonu SharmaNo ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- Metal Forming Lect 4Document36 pagesMetal Forming Lect 4e22mecu0009No ratings yet

- Drawing DieDocument7 pagesDrawing Diethanhhn_1210No ratings yet

- Bulk Deformation Processes Solved ProblemsDocument15 pagesBulk Deformation Processes Solved ProblemsOloyede RidwanNo ratings yet

- TYPE A - Real Time Quiz End Semester Examination - ME331Document7 pagesTYPE A - Real Time Quiz End Semester Examination - ME331Selvi RNo ratings yet

- Metal Forming Lect 7Document22 pagesMetal Forming Lect 7e22mecu0009No ratings yet

- PunchDocument4 pagesPunchDebaprasanna PuhanNo ratings yet

- Tutorial 4 Sheet Metal WorkingDocument2 pagesTutorial 4 Sheet Metal WorkingSawai PariharNo ratings yet

- Phase 1 Quiz QP WITH ANSWERDocument5 pagesPhase 1 Quiz QP WITH ANSWERsureshkumarNo ratings yet

- Production Test PaperDocument9 pagesProduction Test Paperfaheemhaider21No ratings yet

- Gate Solved Paper - Me: Manufacturing EngineeringDocument72 pagesGate Solved Paper - Me: Manufacturing EngineeringVHemendra NaiduNo ratings yet

- HW 4Document6 pagesHW 4mustafa aliNo ratings yet

- 0910sem1 Me3162 PDFDocument10 pages0910sem1 Me3162 PDFChun Ping OngNo ratings yet

- MMCV312 Final Exam Paper - 2022Document7 pagesMMCV312 Final Exam Paper - 2022Praveet ChandNo ratings yet

- IPE 203 Fall 2020 Mist (Sec A)Document2 pagesIPE 203 Fall 2020 Mist (Sec A)Ayesha MalihaNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- ME Manufacturing-Engineering PDFDocument73 pagesME Manufacturing-Engineering PDFpankajNo ratings yet

- Objective QuestionsDocument73 pagesObjective QuestionsRajesh ShahNo ratings yet

- Machining Principles & Machine ToolsDocument16 pagesMachining Principles & Machine Toolssantosh sivarNo ratings yet

- Objective ProductionDocument6 pagesObjective ProductionM.ThirunavukkarasuNo ratings yet

- Unit 1: Special Forming ProcessesDocument21 pagesUnit 1: Special Forming ProcessesIncredible Indian StarsNo ratings yet

- Kumpulan Soal Uas Teknik PembentukanDocument25 pagesKumpulan Soal Uas Teknik PembentukanNur'aini Virani PutriNo ratings yet

- Chapter 6 Die DesignDocument55 pagesChapter 6 Die Designmulugeta assefaNo ratings yet

- 103 Manufacturing Engineering PDFDocument73 pages103 Manufacturing Engineering PDFSushil Kumar Singh100% (1)

- ForgingDocument56 pagesForgingZulfikarUdenNo ratings yet

- Design of Machine Members Mid Question PaperDocument4 pagesDesign of Machine Members Mid Question PaperSRES MECHNo ratings yet

- SMW Lect 2Document48 pagesSMW Lect 2e22mecu0009No ratings yet

- PR Pembentukan 2-DikonversiDocument2 pagesPR Pembentukan 2-Dikonversivansyah 01No ratings yet

- METALWORKINGDocument23 pagesMETALWORKINGDr Rajamani R - PSGCTNo ratings yet

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- Review Questions - 2 Group of Review QuestionsDocument3 pagesReview Questions - 2 Group of Review QuestionsVenkata DineshNo ratings yet

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet