Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

49 viewsBlinding and Mortar Specifications

Blinding and Mortar Specifications

Uploaded by

ahmed sleemThis document discusses the construction of urban roads and sidewalks in Umm Alqura Project, Makkah. It outlines the specifications for constructing subbase and concrete base layers under the sidewalks with minimum thicknesses and compaction requirements. It also details the installation process for interlocking brick tiles on top of the concrete base, including use of cement mortar, embedding, joints, and curing. Specifications are provided for the interlocking bricks to be used, including dimensions, colors, cement content, and compressive strength testing methods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- 32 12 16 - Asphalt PavingDocument4 pages32 12 16 - Asphalt PavingSteve LezamaNo ratings yet

- 02525Document3 pages02525uddinnadeem0% (1)

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- Pothole - Method StatementDocument5 pagesPothole - Method Statementmemekenya100% (3)

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- EASA Part-66 Exam Questions of Module 01 - Part IIDocument24 pagesEASA Part-66 Exam Questions of Module 01 - Part IISteven J. Selcuk100% (2)

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Boq - Civil - For ShedDocument8 pagesBoq - Civil - For ShedMariNo ratings yet

- BOQ - External Development WorksDocument5 pagesBOQ - External Development WorksAmit RuhilNo ratings yet

- 809.2.2. Concrete Barriers Shall Be Constructed With M 40 Grade Concrete and With TMT Fe 500 D Reinforcement Conforming To IRC: 21Document2 pages809.2.2. Concrete Barriers Shall Be Constructed With M 40 Grade Concrete and With TMT Fe 500 D Reinforcement Conforming To IRC: 21sat palNo ratings yet

- MS- FLEXIBLE PAVEMENTDocument14 pagesMS- FLEXIBLE PAVEMENTMoganadass RKNo ratings yet

- Raw Material ModificationDocument4 pagesRaw Material ModificationreddyrabadaNo ratings yet

- Reference Standard Materials and Mix Proportion Batching & MixingDocument3 pagesReference Standard Materials and Mix Proportion Batching & MixingMital DamaniNo ratings yet

- Boq 212405Document10 pagesBoq 212405Paladi RaviNo ratings yet

- ITEM 600 To Be UsedDocument14 pagesITEM 600 To Be UsedMj RequillosNo ratings yet

- 2287 Technical SpecificationDocument9 pages2287 Technical SpecificationBasava NNo ratings yet

- 3. Technical SpecificationsDocument50 pages3. Technical SpecificationsrotisnoNo ratings yet

- Method of Statement - Road Works For Katibas (Pavement Work) (18.5.2020)Document9 pagesMethod of Statement - Road Works For Katibas (Pavement Work) (18.5.2020)Dominic Chupong Joss BawingNo ratings yet

- BOQ For Misc. ItemsDocument2 pagesBOQ For Misc. Itemspiyush1266No ratings yet

- Estimate of PQCDocument6 pagesEstimate of PQCMital DamaniNo ratings yet

- S-1 (2104) Remove and Replace Bituminous Pavement (Ada)Document7 pagesS-1 (2104) Remove and Replace Bituminous Pavement (Ada)George ClooneyNo ratings yet

- Technical Specifications Proposed Two Storey ResidentialDocument9 pagesTechnical Specifications Proposed Two Storey ResidentialZara DesignNo ratings yet

- Cost of ProjectDocument31 pagesCost of ProjectHayman Ahmed100% (1)

- Specification Jila Seva Sadan - 3Document176 pagesSpecification Jila Seva Sadan - 3Jignesh P KoratNo ratings yet

- Guidelines From MSRDC PDFDocument15 pagesGuidelines From MSRDC PDFSreekanth SattirajuNo ratings yet

- Pavement RoadDocument6 pagesPavement Roadkartick adhikaryNo ratings yet

- Road Works PDFDocument13 pagesRoad Works PDFSasidhar ReddyNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Compound Wall OfferDocument4 pagesCompound Wall OfferMd AbidNo ratings yet

- Specifications Section 1 GeneralDocument4 pagesSpecifications Section 1 GeneralAgia Dela VegaNo ratings yet

- 150920211801boq Sbirb Road WorksDocument4 pages150920211801boq Sbirb Road WorksMohomo AlrrahalNo ratings yet

- Method Statement - Structural ConcreteDocument7 pagesMethod Statement - Structural Concretearif_rubinNo ratings yet

- New Carparking BOQ - Gate2Document3 pagesNew Carparking BOQ - Gate2Siva SankarNo ratings yet

- 02515Document5 pages02515uddinnadeemNo ratings yet

- RA For CopingDocument26 pagesRA For CopingkunalNo ratings yet

- AbstractDocument8 pagesAbstractcivilNo ratings yet

- Sub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7Document6 pagesSub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7alfaza3No ratings yet

- General Premix Road DesignDocument6 pagesGeneral Premix Road DesignAyie Khairi100% (3)

- General Specifications - Imus SiteDocument5 pagesGeneral Specifications - Imus SitelesterjohnmolinoNo ratings yet

- MOS -ROADWORKSDocument8 pagesMOS -ROADWORKSMoganadass RKNo ratings yet

- Abstract of CostDocument4 pagesAbstract of Costcomedy INSHAAN. 12.2MNo ratings yet

- Specification WarehouseDocument18 pagesSpecification Warehousemohd sumerNo ratings yet

- RD Segm PavingDocument4 pagesRD Segm PavingAurelius GoraNo ratings yet

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- ITB# 01-17 WRF Vacuum Truck Disposal Site Concrete SpecificationDocument4 pagesITB# 01-17 WRF Vacuum Truck Disposal Site Concrete SpecificationMarco TitorNo ratings yet

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Schedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDocument2 pagesSchedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDada Chandan Das A&R DevelopersNo ratings yet

- Section 20 Deck Overlay and Concrete RehabilitationDocument20 pagesSection 20 Deck Overlay and Concrete RehabilitationSolomon AhimbisibweNo ratings yet

- SECTION 8 (Incidental Construction) (FINAL) PDFDocument119 pagesSECTION 8 (Incidental Construction) (FINAL) PDFMohammad SahmoudNo ratings yet

- 7c2de2dd-8148-44ca-a2d6-5dc6ecf36b44 (9)Document10 pages7c2de2dd-8148-44ca-a2d6-5dc6ecf36b44 (9)Jugal upadhyayNo ratings yet

- 17.02.2024-BSCPL Boq Vibhutipura Civil R00Document24 pages17.02.2024-BSCPL Boq Vibhutipura Civil R00Darshit VyasNo ratings yet

- Re Civil BOQ Format For Electrical Works - Manfo - BengaluruDocument25 pagesRe Civil BOQ Format For Electrical Works - Manfo - BengaluruDarshit VyasNo ratings yet

- 6SecIX IX.2.03 Masonry&Allied WorksDocument12 pages6SecIX IX.2.03 Masonry&Allied WorksAnonymous 7ZYHilDNo ratings yet

- WPROOFING Falcon ViewDocument11 pagesWPROOFING Falcon ViewDevinder ChawlaNo ratings yet

- Concrete PathwayDocument1 pageConcrete PathwaymrameshceNo ratings yet

- MS - Masonary Block WorkDocument14 pagesMS - Masonary Block WorkZaheer HussainNo ratings yet

- Vehicle Crossings DrawingsDocument13 pagesVehicle Crossings DrawingsfedajxzcfampflohwvNo ratings yet

- Dado Rate Analysis and Approximate Estimation of BridgeDocument14 pagesDado Rate Analysis and Approximate Estimation of BridgeNikhil RathiNo ratings yet

- Precast Concrete CurbsDocument3 pagesPrecast Concrete Curbsgskodikara2000No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- LEED CC ScorecardDocument1 pageLEED CC Scorecardahmed sleemNo ratings yet

- Inverted SiphonDocument3 pagesInverted Siphonahmed sleemNo ratings yet

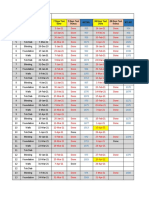

- Seg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test StatusDocument3 pagesSeg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test Statusahmed sleemNo ratings yet

- MOBILE CRANE Grove RT58D CLPDocument9 pagesMOBILE CRANE Grove RT58D CLPahmed sleemNo ratings yet

- Unit I-Cloud ComputingDocument29 pagesUnit I-Cloud ComputingAR OFFICIALNo ratings yet

- HwyconstDocument23 pagesHwyconstAmulie JarjuseyNo ratings yet

- CD Dye RD0005Document7 pagesCD Dye RD0005Juan CarlosNo ratings yet

- Neisseria Gonorrhoeae and Neisseria MeningitidesDocument3 pagesNeisseria Gonorrhoeae and Neisseria MeningitidesAmador Gielas0% (1)

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- Mec R2018Document227 pagesMec R2018Kishore Kumar RNo ratings yet

- SOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.Document20 pagesSOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.arfaoui salimNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

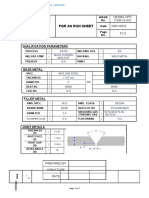

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Carbohydrates Lecture Bio024Document17 pagesCarbohydrates Lecture Bio024mike angelo albacieteNo ratings yet

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Environmental Science For AP Second EditionDocument61 pagesEnvironmental Science For AP Second Editionjoshua.little480100% (50)

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Al55 66 Technical Manual v11 EngDocument60 pagesAl55 66 Technical Manual v11 EngProblem VelikiNo ratings yet

- Intensifying AdjectivesDocument2 pagesIntensifying AdjectivesReena JimmyNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- Edible Oil - Case StudyDocument8 pagesEdible Oil - Case StudyVansh Raj GautamNo ratings yet

- Understanding Your Electricity Bill in PakistanDocument13 pagesUnderstanding Your Electricity Bill in PakistanGhayas Ud-din DarNo ratings yet

Blinding and Mortar Specifications

Blinding and Mortar Specifications

Uploaded by

ahmed sleem0 ratings0% found this document useful (0 votes)

49 views1 pageThis document discusses the construction of urban roads and sidewalks in Umm Alqura Project, Makkah. It outlines the specifications for constructing subbase and concrete base layers under the sidewalks with minimum thicknesses and compaction requirements. It also details the installation process for interlocking brick tiles on top of the concrete base, including use of cement mortar, embedding, joints, and curing. Specifications are provided for the interlocking bricks to be used, including dimensions, colors, cement content, and compressive strength testing methods.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the construction of urban roads and sidewalks in Umm Alqura Project, Makkah. It outlines the specifications for constructing subbase and concrete base layers under the sidewalks with minimum thicknesses and compaction requirements. It also details the installation process for interlocking brick tiles on top of the concrete base, including use of cement mortar, embedding, joints, and curing. Specifications are provided for the interlocking bricks to be used, including dimensions, colors, cement content, and compressive strength testing methods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views1 pageBlinding and Mortar Specifications

Blinding and Mortar Specifications

Uploaded by

ahmed sleemThis document discusses the construction of urban roads and sidewalks in Umm Alqura Project, Makkah. It outlines the specifications for constructing subbase and concrete base layers under the sidewalks with minimum thicknesses and compaction requirements. It also details the installation process for interlocking brick tiles on top of the concrete base, including use of cement mortar, embedding, joints, and curing. Specifications are provided for the interlocking bricks to be used, including dimensions, colors, cement content, and compressive strength testing methods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

UMM ALQURA PROJECT

RETAJ MAKKAH

Part (4): Urban Roads Construction

general specifications or better or according to special specifications and drawings. The

thickness of Subbase layer shall not be less than 10 cm. Subbase shall be leveled and

compacted to a compaction degree not less than 95 % of the maximum dry density at

moisture content not differ by more than 2 % from the optimum moisture content determined

by moisture/density relationship test according to AASHTO T-180 method. The compaction

processes shall be performed by the method which achieves the required smoothness and

slope to forms a stable foundation on which the sidewalks may be laid.

When Subbase is finished and accepted by the Engineer, Contractor shall wet its surface and

construct not less than 8 cm thick cement concrete layer having cement content 200 kg/m3

and 15 Mpa strength after 28 days according to ASTM C-39 method, before installing the

tiles. Contractor shall cure cement concrete layer using water and it shall be covered when

necessary, to prevent evaporation for a period not less than 3 days before constructing the

subsequent layers. The produced surface of cement concrete layer shall be leveled to

allow the installation of tiles and the constructed side walks shall gave a surface conforming

to approved longitudinal and cross slopes and compatible with the upper surface of the curbs

as approved in the drawings or specifications or according to the Engineer's instructions.

At the end of concrete Base curing period, sidewalks tiles shall be installed on cement mortar

layer having a thickness not more than 5 cm, composed of sand and cement mixture of

proportional 1cement, 2 sand (1:2), on seats of brick pieces, to achieve the required levels

and slopes. Joints between the bricks for full depth shall be filled with same cement mortar

used in installation and a groove shall be formed at the top of the mortar material to form the

joint.

The constructed sidewalk surface shall conform to slopes shown on the drawings and all tiles

shall be embedded and fully stuck on cement mortar.

Level tiles shall be used at crossing areas and ramps designated for handicapped wheel chairs

traffic at locations and according to dimensions and slopes shown on the drawings,

special specifications or according to the Engineer's instructions.

Contractor shall preserve, maintain and sprinkle with water the tile surfaces until final setting

of cement mortar.

After not less than 48 hours, Contractor shall sweep sidewalk surface with the method

accepted by the engineer and construct a layer from water, cement and sand mortar while

applying the approved colored dyeing materials as required.

B-3 Interlocking brick:

This work includes surface preparation and supply of interlocking brick to construct and

finish the sidewalks according to levels and slopes shown on the drawings, special

specifications and these general specifications or as specified by the Engineer within the

approved tolerance limits.

B-3-1 Fabrication:

The interlocking brick shall conform to dimensions, shapes and colors shown on drawings,

special specifications, requirements of specification ASTM C-936, or SASO1246

specification. And interlocking brick shall chose conform to SASO1247.

Bricks thickness shall not be less than 6 cm and not more than 10 cm, and it shall achieve the

following basic requirements:

• Cement content in the mix shall not be less than 450 kg /m3.

• Average compressive strength for many samples shall not be less than 55 Map, and the

strength of any sample shall not be less than 50 Map as determined by AASHTO T-22

method.

- 309 -

You might also like

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- 32 12 16 - Asphalt PavingDocument4 pages32 12 16 - Asphalt PavingSteve LezamaNo ratings yet

- 02525Document3 pages02525uddinnadeem0% (1)

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- Pothole - Method StatementDocument5 pagesPothole - Method Statementmemekenya100% (3)

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- EASA Part-66 Exam Questions of Module 01 - Part IIDocument24 pagesEASA Part-66 Exam Questions of Module 01 - Part IISteven J. Selcuk100% (2)

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Boq - Civil - For ShedDocument8 pagesBoq - Civil - For ShedMariNo ratings yet

- BOQ - External Development WorksDocument5 pagesBOQ - External Development WorksAmit RuhilNo ratings yet

- 809.2.2. Concrete Barriers Shall Be Constructed With M 40 Grade Concrete and With TMT Fe 500 D Reinforcement Conforming To IRC: 21Document2 pages809.2.2. Concrete Barriers Shall Be Constructed With M 40 Grade Concrete and With TMT Fe 500 D Reinforcement Conforming To IRC: 21sat palNo ratings yet

- MS- FLEXIBLE PAVEMENTDocument14 pagesMS- FLEXIBLE PAVEMENTMoganadass RKNo ratings yet

- Raw Material ModificationDocument4 pagesRaw Material ModificationreddyrabadaNo ratings yet

- Reference Standard Materials and Mix Proportion Batching & MixingDocument3 pagesReference Standard Materials and Mix Proportion Batching & MixingMital DamaniNo ratings yet

- Boq 212405Document10 pagesBoq 212405Paladi RaviNo ratings yet

- ITEM 600 To Be UsedDocument14 pagesITEM 600 To Be UsedMj RequillosNo ratings yet

- 2287 Technical SpecificationDocument9 pages2287 Technical SpecificationBasava NNo ratings yet

- 3. Technical SpecificationsDocument50 pages3. Technical SpecificationsrotisnoNo ratings yet

- Method of Statement - Road Works For Katibas (Pavement Work) (18.5.2020)Document9 pagesMethod of Statement - Road Works For Katibas (Pavement Work) (18.5.2020)Dominic Chupong Joss BawingNo ratings yet

- BOQ For Misc. ItemsDocument2 pagesBOQ For Misc. Itemspiyush1266No ratings yet

- Estimate of PQCDocument6 pagesEstimate of PQCMital DamaniNo ratings yet

- S-1 (2104) Remove and Replace Bituminous Pavement (Ada)Document7 pagesS-1 (2104) Remove and Replace Bituminous Pavement (Ada)George ClooneyNo ratings yet

- Technical Specifications Proposed Two Storey ResidentialDocument9 pagesTechnical Specifications Proposed Two Storey ResidentialZara DesignNo ratings yet

- Cost of ProjectDocument31 pagesCost of ProjectHayman Ahmed100% (1)

- Specification Jila Seva Sadan - 3Document176 pagesSpecification Jila Seva Sadan - 3Jignesh P KoratNo ratings yet

- Guidelines From MSRDC PDFDocument15 pagesGuidelines From MSRDC PDFSreekanth SattirajuNo ratings yet

- Pavement RoadDocument6 pagesPavement Roadkartick adhikaryNo ratings yet

- Road Works PDFDocument13 pagesRoad Works PDFSasidhar ReddyNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Compound Wall OfferDocument4 pagesCompound Wall OfferMd AbidNo ratings yet

- Specifications Section 1 GeneralDocument4 pagesSpecifications Section 1 GeneralAgia Dela VegaNo ratings yet

- 150920211801boq Sbirb Road WorksDocument4 pages150920211801boq Sbirb Road WorksMohomo AlrrahalNo ratings yet

- Method Statement - Structural ConcreteDocument7 pagesMethod Statement - Structural Concretearif_rubinNo ratings yet

- New Carparking BOQ - Gate2Document3 pagesNew Carparking BOQ - Gate2Siva SankarNo ratings yet

- 02515Document5 pages02515uddinnadeemNo ratings yet

- RA For CopingDocument26 pagesRA For CopingkunalNo ratings yet

- AbstractDocument8 pagesAbstractcivilNo ratings yet

- Sub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7Document6 pagesSub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7alfaza3No ratings yet

- General Premix Road DesignDocument6 pagesGeneral Premix Road DesignAyie Khairi100% (3)

- General Specifications - Imus SiteDocument5 pagesGeneral Specifications - Imus SitelesterjohnmolinoNo ratings yet

- MOS -ROADWORKSDocument8 pagesMOS -ROADWORKSMoganadass RKNo ratings yet

- Abstract of CostDocument4 pagesAbstract of Costcomedy INSHAAN. 12.2MNo ratings yet

- Specification WarehouseDocument18 pagesSpecification Warehousemohd sumerNo ratings yet

- RD Segm PavingDocument4 pagesRD Segm PavingAurelius GoraNo ratings yet

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- ITB# 01-17 WRF Vacuum Truck Disposal Site Concrete SpecificationDocument4 pagesITB# 01-17 WRF Vacuum Truck Disposal Site Concrete SpecificationMarco TitorNo ratings yet

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Schedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDocument2 pagesSchedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDada Chandan Das A&R DevelopersNo ratings yet

- Section 20 Deck Overlay and Concrete RehabilitationDocument20 pagesSection 20 Deck Overlay and Concrete RehabilitationSolomon AhimbisibweNo ratings yet

- SECTION 8 (Incidental Construction) (FINAL) PDFDocument119 pagesSECTION 8 (Incidental Construction) (FINAL) PDFMohammad SahmoudNo ratings yet

- 7c2de2dd-8148-44ca-a2d6-5dc6ecf36b44 (9)Document10 pages7c2de2dd-8148-44ca-a2d6-5dc6ecf36b44 (9)Jugal upadhyayNo ratings yet

- 17.02.2024-BSCPL Boq Vibhutipura Civil R00Document24 pages17.02.2024-BSCPL Boq Vibhutipura Civil R00Darshit VyasNo ratings yet

- Re Civil BOQ Format For Electrical Works - Manfo - BengaluruDocument25 pagesRe Civil BOQ Format For Electrical Works - Manfo - BengaluruDarshit VyasNo ratings yet

- 6SecIX IX.2.03 Masonry&Allied WorksDocument12 pages6SecIX IX.2.03 Masonry&Allied WorksAnonymous 7ZYHilDNo ratings yet

- WPROOFING Falcon ViewDocument11 pagesWPROOFING Falcon ViewDevinder ChawlaNo ratings yet

- Concrete PathwayDocument1 pageConcrete PathwaymrameshceNo ratings yet

- MS - Masonary Block WorkDocument14 pagesMS - Masonary Block WorkZaheer HussainNo ratings yet

- Vehicle Crossings DrawingsDocument13 pagesVehicle Crossings DrawingsfedajxzcfampflohwvNo ratings yet

- Dado Rate Analysis and Approximate Estimation of BridgeDocument14 pagesDado Rate Analysis and Approximate Estimation of BridgeNikhil RathiNo ratings yet

- Precast Concrete CurbsDocument3 pagesPrecast Concrete Curbsgskodikara2000No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- LEED CC ScorecardDocument1 pageLEED CC Scorecardahmed sleemNo ratings yet

- Inverted SiphonDocument3 pagesInverted Siphonahmed sleemNo ratings yet

- Seg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test StatusDocument3 pagesSeg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test Statusahmed sleemNo ratings yet

- MOBILE CRANE Grove RT58D CLPDocument9 pagesMOBILE CRANE Grove RT58D CLPahmed sleemNo ratings yet

- Unit I-Cloud ComputingDocument29 pagesUnit I-Cloud ComputingAR OFFICIALNo ratings yet

- HwyconstDocument23 pagesHwyconstAmulie JarjuseyNo ratings yet

- CD Dye RD0005Document7 pagesCD Dye RD0005Juan CarlosNo ratings yet

- Neisseria Gonorrhoeae and Neisseria MeningitidesDocument3 pagesNeisseria Gonorrhoeae and Neisseria MeningitidesAmador Gielas0% (1)

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- Mec R2018Document227 pagesMec R2018Kishore Kumar RNo ratings yet

- SOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.Document20 pagesSOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.arfaoui salimNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Carbohydrates Lecture Bio024Document17 pagesCarbohydrates Lecture Bio024mike angelo albacieteNo ratings yet

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Environmental Science For AP Second EditionDocument61 pagesEnvironmental Science For AP Second Editionjoshua.little480100% (50)

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Al55 66 Technical Manual v11 EngDocument60 pagesAl55 66 Technical Manual v11 EngProblem VelikiNo ratings yet

- Intensifying AdjectivesDocument2 pagesIntensifying AdjectivesReena JimmyNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- Edible Oil - Case StudyDocument8 pagesEdible Oil - Case StudyVansh Raj GautamNo ratings yet

- Understanding Your Electricity Bill in PakistanDocument13 pagesUnderstanding Your Electricity Bill in PakistanGhayas Ud-din DarNo ratings yet