Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

38 viewsSplit Tee - Triber #150 6x6x4

Split Tee - Triber #150 6x6x4

Uploaded by

zat572000Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- THJ-Report - Attachment - MIR TEE BAUTDocument7 pagesTHJ-Report - Attachment - MIR TEE BAUTzat572000No ratings yet

- EFRATA-Report - Attachment - BA Pekerjaan Pemasangan Anoda Korban 1Document1 pageEFRATA-Report - Attachment - BA Pekerjaan Pemasangan Anoda Korban 1zat572000No ratings yet

- RC 327607Document2 pagesRC 327607zat572000No ratings yet

- MDR Fitting Split Tee 6 X 6 X 4 ANSI 150Document32 pagesMDR Fitting Split Tee 6 X 6 X 4 ANSI 150zat572000No ratings yet

- Stress Analysis of Piping Systems and Pipelines Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines Harvard Universityzat572000100% (1)

- Table of Content: PT Perusahaan Gas Negara TBKDocument3 pagesTable of Content: PT Perusahaan Gas Negara TBKzat572000No ratings yet

- EDL Panduan Desain Rev 1Document3 pagesEDL Panduan Desain Rev 1zat572000No ratings yet

- Isometrik Joint PT Pangansari Utama TBKDocument2 pagesIsometrik Joint PT Pangansari Utama TBKzat572000No ratings yet

- Nomor: 004800.ND/LG.02/ROM-SOR2/2020: Nota DinasDocument2 pagesNomor: 004800.ND/LG.02/ROM-SOR2/2020: Nota Dinaszat572000No ratings yet

- Split Tee - Chevron 4x4x4 #300Document31 pagesSplit Tee - Chevron 4x4x4 #300zat572000100% (1)

- Split Tee CA TangerangDocument8 pagesSplit Tee CA Tangerangzat572000No ratings yet

- RT API1104 Luindo PrimaDocument11 pagesRT API1104 Luindo Primazat572000No ratings yet

- Welding Circuit and Arc BlowDocument4 pagesWelding Circuit and Arc Blowzat572000No ratings yet

- Laporan Mechanical Test - 2 Herman M-02 PDFDocument7 pagesLaporan Mechanical Test - 2 Herman M-02 PDFzat572000No ratings yet

- Format Laporan Piket Natal 24-25 Des 2019Document6 pagesFormat Laporan Piket Natal 24-25 Des 2019zat572000No ratings yet

- FAT Procedure Rev BDocument15 pagesFAT Procedure Rev Bzat572000No ratings yet

- BA Pemeriksaan MaterialDocument7 pagesBA Pemeriksaan Materialzat572000No ratings yet

- Berita Acara NDT & Daily ReportDocument33 pagesBerita Acara NDT & Daily Reportzat572000No ratings yet

Split Tee - Triber #150 6x6x4

Split Tee - Triber #150 6x6x4

Uploaded by

zat5720000 ratings0% found this document useful (0 votes)

38 views32 pagesOriginal Title

Split Tee -Triber #150 6x6x4

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

38 views32 pagesSplit Tee - Triber #150 6x6x4

Split Tee - Triber #150 6x6x4

Uploaded by

zat572000Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 32

WeldFit

“TABLE OF CONTENTS”

CUSTOMER: Triber Nusantara Sukses PT.

PURCHASE ORDER: 0018P-WFIC HT

WELDFIT JOB: 532213-01

QUANTITY: 3

DESCRIPTION: Hot Tap Tee, 6° X 6" X 4° With 150# RF Flange

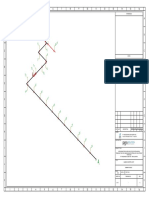

DRAWING No: 7404X -0404 —WPB ~ A105 ~ 107620

TAG: P.O Line ltem-05

Certificate OF Compliance.

Weldfit MTR on 6° X 6" X4" Spit Tee.

Original MTR on 0.630 Material (HT — T'5835 08 - M5355.)

Original MTR on 0.630 Material (HT — S 5835 —_08 - M.85355;)

Original MTR on 4° 150: RF Material (HT — F 52550 —M.85365.)

Original MTR on 4/8" X 0.50" Backing Stips (HT-L 4435.)

WPS WE-1-1-005 Rev.3 & POR

Approved Drawing

‘Approved Calculation

Radiography Examination Report.

Magnetic Particle Report

Utrasonic Examination Report

Final Inspection Report

a

Severstal

CERTIFICATE OF QUANTITY AND QUALITY

Seller (exporter)

JOINT STOCK COMPANY “SEVERSTAL*

JSC *SEVERSTAL*

Quality system was Certified For Compliance with ISO 9001-2008

85355 NPOMNOPT

27.847

EXPORT 10030054

INSPECTION CERTIFICATE EN 10204.3.1

ORDER No

98835

POZ 10

Consignee CONTRACT No 756/00186217-30217 SPECIFICATION No 98935

*SEVERSTAL EXPOR OMEN”

Country of destination UNITED STATES OF AMERICA Subject License No. Subject Of License

Freight CarNo 54302577 Sheet 1 Sheets 1

Description and code of goods WAY _ Standard ‘Type of pakage

T ASTM A SS8/AGGOMSb

HRC ASTM A $58/A568M-11b

ASTM A $58/A668M-11b Coll

Tem | yardness | piateno | Grade | Dimension mm (Inc) | Quantity | Max ke (tbs)

No. Thickness min Gross [_Net

1 13753 53221301 SAE10i0 137 1219 7 18790 18780

(0.034) (48.000)

1 13753 $3221302 SAE1010 137 1219 1 18750 18740

(0.034) (48.000)

a 13753 $3213.01 SAEI010 1.37 1219 1 18790 18780

(0.034) _ (48.000)

336330 56300

Cutting Group Of Surface Class Of Precision Hardness Edge

“Steel Rolled in continuous mill un

sd uncolled non-skin passed

It is hereby certified that the quality of goods mentioned in this shipping document is in conformity

with demands of specification to contra

\d the goods my be exported

Quality Characteristic of goo

Chemical Composition

CR] HR [wR | SK [PH Torx] wn | COX [ALR [MOK] VX [NON [Te |

100 *100_| +1000 | +2000 | » *100 | +109 | +200 | +100 | +100 | +100

10 3a_ {32 | aa 6 | 4 | oa |o2| 02 [02 |

1o | 1 | 3a | 32 | a4 [3 [6 [4] o«}o2}o2 |o2

~ Mechanical Properties eee

Tem | Cold Tensile Strength Yield Point Elggation Cold Bend Test ]

No | Test | MPA MPA Z

L 409 304 3 is _ Satisfactory

2 408, 303 \ Satisfactory

Marking PO#21.397 Houston Signature“ acaayseis \, Controller Christyacova LV

‘will 2000

OXKC Boxtox Ine

‘Nevard 01.16 2017. 2:39:59

480405170

WeldFit

CERTIFIED MATERIAL TEST REPORT

Sold To: Triber Nusantara Sukses PT. PO No: 01eP-WFIC-HT

MTR No. 532213-01

Date: (08/08/2018

EEE WELDFIT S.0. 532213-01 HEAD NUMBER _

eM | TY DESCRIPTION MATERIAL MLL WELDFIT |

Ot | 03 | SplTes 6x6" x4" 0.630" WT ‘A234-WPB S58 | 5835-08 M85355

Design Criteria,

"ASME B31 4/8 285 Psig 100 F° |

(04 Design Factor

0,00 Corrosion Allowance.

— CEABSTRY, (Ladle (P) Product

HEADNo | C [Wn [ P [| S | S | cr | Mo wo TV [CE]

85355) | 024 | 7.09 | 0076 | 0.009 | 0.33 | O07 | O01 0.01 | 0004 | 0.43

PHYSICAL PROPERTIES _{YIELD/TENSILE UNITS ARE KS!) a

HARDNESS | Charpy V Notch Test Resulis I

Sete sults | ]

HEAD No | Yield | Tensie | %Eing | Sora. | TYPE | VAL | Temp | Fi Pounds | % shear | WiSlat | UT |

a Ep. | OW

85355 | 45.0 | 79.0 | 37.0 | mir | nit | mir | -50°F | 20-18-22 nit air oe

Heat Treatment:

Hot form between 1,800°F and 1,50°F and cool in stl air

| nereby certify this report to be in compliance to EN 10204 Type 3.1 and a true and concert representation of data

resulting from test performed by the WELDFIT Corporation, Independent testing laboratories,

Or the material manufacturer, to the best of my knowledge and belief

WELDFIT

Hadrca Gomeg Q. A. APPROVAL

Andrea Gomez

‘Quality Assurance Manager

Weld Fit

“TABLE OF CONTENTS”

CUSTOMER: Triber Nusantara Sukses PT.

PURCHASE ORDER: 0018? - WFIC -HT

WELDFIT JOB: 532213-01

QUANTITY: 3

DESCRIPTION: Hot Tap Tee, 6” X 6" X 4" With 150#RF Flange

DRAWING No: 7404X —0404 - WPB— A105 - 107620

TAG: P.O Line ltem-05

THIS IS TO CERTIFY THAT REFERENCED PRODUCTS ( Hot Tap Tee, 6” X 6” X 4" With 1508 RF Flange )

ARE IN COMPLIANCE WITH A 234 - WPB — S58 AND MEETS CUSTOMER PURCHASE ORDER ( 0018P —

WFIC-HT) DRAWING No: 7404-0404 WPB - A 105 - 52550 TO THE BEST OF MY KNOWLEDGE AND BELIEF

WELDFIT

Hudnea Gooey Q. A. APPROVAL

aisechieiies DATE:_8 /29/90/8

Quality Assurance Manager

Feneg

4 D.

“wopweiodsog aypiom™,

‘SauldXB NOISSIWWOD AW SONVUNSSY A.

AdO9 ANVOS YSIWOLSNOD

‘eAOge YOoIG SUONBOYJOedS OY)

#1 04 19WO¥SND byyowioynbos uy Um GoUEY AUi0o Uy} 8,2 Jos

auiey 10W0\sn9 sioneiodo pue

‘aie ode, 8149 40 S]UB}U0D ey) ILA AjIIe0 AqeseY |

st02/s0 / €0 HLONS1 3ONVO HON! 00°8 NO G38VE NOLLVONOTS |

i ] T

Z.UIN AY EZT UN ay EZT JIC g (o0z)=19, {oz9-ser) 06-02 uw(sbe)os Slay sales.

NHg | uojsuedsa jexaye7 (savag) ABioug | ojugg | Tumtujur aad 8 | (ZUW/N) IH (zuwi/n) 191

| sped Adseyo i woneuog sua, | yiuanis piaia pep

sapredoug jeoqueyoayy

| | tors 6290 | sayas area

20'0 evo “oo | 970 zoo | 6000 | 90°T 610 8T0 0€9'0

“OW | IN| 7D ‘s ‘dT uA ee youl sseuyaiqs | ‘apes

% wopisoduioy jesywreyy | |

| Taupe

| i ‘Weijduiog 2°T'z oes EOTO UW ZT'Z XINNY

\ SLTOUIN 39VN 281d PezI/eWJON ETOZ ‘epuEpPY ETTOZ/OTOZ

| ‘DAd 09/59/02- 9TS VS aWSY OT - 09/59/02 9TSV WLSY

| dNOUD LiEGTaM =: OL Pos s000'08P X ,000'02T X ,0OE9'D =: UOe2yIDadS

BOSEORXALL ON AIIYAA

L | 7 =

(_trest9zz oN Jep0 3sn9 | T/Sb88ET : ON 49pI0 1D Grates: ONPeor| etseseOn Val stoz/so/eo + —aied

'eInRON NO $41 HOOMIN

eidens pur eoyced sad ej cue pathy

ue> ae eg 2209 4a pangs

‘vannnaauniovannn avy

1YOdaY ISAL THW GaldLLdao

55

2 GIST ILSENBURGER

GROBBLECH

A

{ Inspection Certificate 3.2 Nodiity 583508

DIN EN 10204 Page Yo

Code Date 05.13, 2018

No diy) HOU -—5379-TG 03.07.2018 No(Acl

Purchase Universal Stee] America Customer Universal Steel America

0g HOUSTON INC 0g) HOUSTON INC

HOUSTON, TEXAS 77073 USA. HOUSTON, TEXAS 77073 USA

Product Heavy Plate WONo 0000073617

Inspection WS

Steel Grade and terms ofdelivery Grade70 MT LTV

ASTM A5I6 -10, 20 - 13

ASME SECT.11 Part A ed2013

ASME SA 516, SA 20

Coasof [B= Thickness. x A= width. X E=Tengih.

Delivery | Bin x Ain x Ein

0.63 X 221.000 X 270.000

0.63 X 221.000 X 275.000

0.63 X 921.000 X 337.000

0.63 X. 975.000 X 337.000

0.63 X 275.000

0.63

[or 5 532213 OL

or} 3 | saza14 or

2] 4 582214 02

o] 4 SO2214 02

o | 2 | 532s or

o ] 2 532215 0:

| z2zzzzzzz|

oa} 8 58216 O1 0.68

ot 1 532217 O1 0.63 X

OL 5 Weight 150 -300Ths — ‘Normalized

o | 3 180 ~ 300 Lbs

03 1

4 1

05 2 220

06 2 260 ~ 300 Lbs

wi] 3 4150 -

08 1 150 - 100 Lbs

‘We here by certify thatthe delivered material completes wit the terms of the order

‘OM-Sys Certification As per ISO 9001 since 2s February 1990

Code

Tnspection Certificate 3.1

DINEN 10204

Nogin HOU~5379-TG

Purchase Universal Steel America

Page

Date

03.07.2018 Nocac

A ILSENBURGER:

Jj) GROBBLECH

46

Noli 583508

05. 13. 2018

Customer Universal Steel America

| ‘Trademark Steel grade / Heat-No Product-No / Inspector’s Stamp

409 HOUSTON INC (soc) HOUSTON INC.

HOUSTON, TEXAS 77073 USA HOUSTON, TEXAS 77073 USA.

Product Heavy Plate WONo 0000073617

Inspection WS

Steel Grade and terms ofdelivery Grade70 MT LTV

ASTM A516 - 10, 20 - 13

ASME SECT.11Part A ed 2013

_ASME SA 516, SA 20

‘Marking of the product

Ladle analysis (C70-C93)

We here by certify thatthe delivered material completes wit the terms of the order

OM-Sys Certification As per ISO 9001 since 23 February 1990

et

OX»

Mark

Manufacture Standard

HeatNo| C% | Si% | Maw N% | Al% | Gus | Gr% | Nis

035-150 | <0.025 0.0% |

A epee

15 mm

i. 4.

7 8

1153 BY 2. a 3. 187 RY

Aio7 ey 5 ise ey 8 IMA HY

‘iat ey 8 iso Me oa isd ay

10197 BV 11 180 HY 12177 HY

13. 202 HV 1A 165 HV 15. 15 HV

16. 201 HY 17, tea HY 18. 177 BY

18: 187 ay

a oe

ae

gues. tars a are lh exo uit spray. Ou eg apy ony to

Eo siete agaia ar ly see re athe peti, Alieslepectin

Signed:

coum BAT pot sa a bs epkeed ein AS

Page No:2 weidiitieseperageieins 2 page(s)

QA Depar

WeldFit :---=-

CHER GE ERO UE. —_MoesionTen, 7092

[Pox waar Westmont

frempcer

cu bean S21: ent St 8C004SS2

Toe cubed og ued

‘ered Denia Gases Were

Cex] on | Genre [ape spesion,

re eT] rm a5

ers | os | ocr [= =

ation

‘Sieoncen Seamer

TRUE COPY

Weldfit Corporation.

QA Depart

Date Page

: 99 to

(oceare Gaetan Reman essa ary Caer _ orn

Tee ea

patna! fission une Ynce| cng | gon | HOCotPobve and

Specimen ober we sees | i

Taominenen | ee | eae ame [eo |e |e | ee |

foeanes2,Tonswse [ove [eax | oa] suo [| ruc [28 | 59 | octet

f

L i {ny

Beets TET)

we qT Rete

Benen “aden

sete Satsoaor

Suto sstsaery

Sees Ssioaory

TooimessTess | specment | Spedmee? | Specins | Acne | Temperuce's | see

Ta = = s @

Tatas | 7 = % =

Tes a @ st s

wes [Fst 2 = o. 7 0 | so2snm

Tite ne | a = 2 A

dene src adn:

fwd [174

[waz — [7a HW

Base —[ 152 Hew

i Gran ea Tote me ae

eters tone: err totes sonore. 2

ile Tet Contced by Sess

Lbressconencedoy ——“FEBTeng

teria Tet tepotnanber 250

ve cet at tb stents Dred cee nd at wl wee neh waded nee dace wh regurenens ef Seton the

{ov sotrand ree eu Cae.

a

‘hmoti-dcuneoe cnntea son tng nue soy

‘Cw! 10000001

QCHEXP. BHMZ018——Reisencethet sort has owe __soynposs

Tretson

te List of evsions Author Date

0 ina release Scot thompson — | TO31/2UTS

T IG CoE pos n tense dat and FOAW aie Jared jonnson | 5/a/2015

z ‘Ad WS ony Tored Johnsen] 1972772038

Page 2 0f2

%

£533

0 pox sme OB

To: WELOFIT CORP. Cust Acct: WEL22100

4193 Southerland

HOUSTON, TX 77092

POH 60760 JWN42843-01(1) WELDER STENCIL D

Meterat: A516 GR 70160 DUAL CERTIFIED 3@*THK PIN WPS# WF 492

IDiHeat: WELD POSITION 4G FLAT

Job Info: PER ASME SEC IX

‘Tensile Test Results

a Ce aaa

(in) (in*2)__(ibs.) (pst) (pst) (%) (A)

——

a ae ae ae ese

en le, I OO Ba

ou

eet eyes

ee

re Eee eee Ee eae

ones Ssctande__S_ nat

i= nee mee ese

vmvonnen de cami

ve

CHARPY SIZE = 394" X .295* (3/4 SIZE)

Ta

“Type of Test_ Results

: Baie cosas ——

i igeemense eam

: Tear Soe So ee

3 music snesee ‘arias

TRUE :

See [eae sony

gine gry

Signed:_ ‘Pore Beene ee

MIKE MASON at EXP. 7420

(ucapns ap ferth aco ure fer custo an cur are ny be use ily vy or witen zara. ep tothe

asbe eetinpec Sd can ren geal sae ee ein sar OF megs app cy oth

{seta cafes lo RSTM Acarwcitonenis tess bans Sted sar rebeceeeaey 2

‘len spprval of P88 Teng bas

Page No: 1

0. BOX 924469

HOUSTON, TX 7292

PHONE: (73) 290-8490

To: WELDFIT CORP.

4989 Southerland

HOUSTON, TX 77092

PO#: 60760 JUN 42843-01(1) WELDER STENCIL D

Meteriat: AS16 GR 70/80 DUAL CERTIFIED SB"THK PINWRSEWF 499

1DiHeat: WELD POSITION 16 FLAT

sob Info: PER ASME SEC 1K

WeLD: 174 HW

HAZ: 174 KEW

BASEMETAL: 152 HBW

6645 W. TIDWELL

HOUSTON.TX 77092

AX: (713) 290-8627

Report Dato: 10/3013,

Report No: 252023.0

Rev: A

Cust Acct: WEL22100

Ver1.6.1

Wi Proposal Drawing

Weldfit Corporation eld Fi it 88358-01-A234WPB-A105-52553

Reference Number | 583508 DW,No7404x—0408 Design By | ML Date | 06/13/18

‘eon unber fz - cheeky [Tw [bate | os/2s/a8

Customer | Tiber Nusantara Sukses PT ‘Approve By | te a

Part Number '532213-1-A234WPB-A105-52550__| Revision Date

Fitting meets design requirements

PASS | soecial considerations - PASS ROME net een

Fitting Type Hot Tap Tee Flange WNRF — Sch 80 Material eit

Fitting Size & Class 6 NPS x4" x WN 4” 1508 Run ‘A234 Gr WPB 7

Fitting & Tee & Flange Type Extn Branch ‘A234 Gr.WPB +H

Design Pressure Equal Tee it

Design Temper Flange A105

Corrosion Allowance __ | LORPhug

Fitting Deta |

Nominal Thickness T tach

inside Diameter D inch |

inch |

Tach

Outside Diameter Inch

tength L inch

Material stress 5 Psi

Material Stress Ratio S/SH

Design Factor F Pa

“Weld Joint Factor Te z

Temperature Factor 1 a

|| Negative Thickness Tol. = = = = Inch

[ corrosion atowance fe = [eo

acking tip Size | L000 inch X0.138 neh XT0.000 inch

Beveled ends 0375 tach at as"

8 31.8-841.1.1(a) Required Thickness Calculation

Required Thickness t i | o.00610714 | 0.059375 | inch | 38% :

| Thickness check 0.335 0335 5

6 31.8-831.6 Betruded Branch Calculation =

Branch inside Diameter de 3.850 ‘inch | Upper Flange Area ‘A2t [0.056982 | inch*2

Half Width Of Reinforcing [ri 4530 ‘inch | Available Branch Are | A2 | 0.249019 | inch’?

Corroded Finish OF Outlet | To | 0337 | Inch B 0 inch"?

“Height OF Reinforcement | 017229008 | Inch ae > toch "2

Min atude OF Brusion 05625 | Inch m9 [0 | neh

Evalue «_| 09018868 [a] oma96982 [neha

‘Available Header Area ‘Aa [1.97327 | tnch*2 | TotalAvailable Area | At | 2.2281811 | inch*2

Tower Branch Area ‘Az | 0.979196 | Inch"? | Area Check PASS |

Radius Special Considerations [Run Brach_ | Flange |

Min. Radius Of Outlet_ | rmin | 0.225 | Inch | Do/6 Ratio i 075

‘Max Radius Of Outlet | rmax | 1.25 | inch | P/SERatio2 | \ | 0.079167

Radius OF Outlet ro | 0.0375 | inch | Ratio 1 Chee Fa

[Radius Check [pass [ Ratio 2 Chea

| ‘QC LABORATORIES, INC. Report No: | 123850

| 10810 Northwest Freeway Houston, Texas 77092 Date: ‘Augs 13 2018

| shone: 713-695-1133 Fax: 713-695-0808 _| Revision: _| 0

feb Site: wwrwqclabs.com_| E-mail: qclab@qcl.com_| Page i [lot a

ciisiaunacniti RADIOGRHAPIC INSPECTION REPORT

Costumer 'WELDFIT ENERGY GROUP P.O. Number | 5312

Contact Person Luis Guerra — Phone | 713-460-3700

Email Address | N/A a " Fax | N/A

Part Description Hot Tap Tee 6” X 4” With 1508 RF Flange ‘W/O Number | JN: 532213-01

Part Number ‘A234-WPB S 58 -A 105-150 ~_SO Number | N/A

Serial Number HI-F'52550 1 5835-08 M.85355 Heat Number | N/A

Procedure Qc2003 Rev.0 [_Aeceptance Criteria | API i104 24st

oe Exposure Technique

Qu Cur Ok) [oat | bab

ee) a) | Oalll | Oat

‘Source OF Radiation Source Curies [26.2 Kv/Ma [N/A

Material Thickness (i) Film Type Film Size | 70mmxi" [No Film [6

‘Source To Weld Distance » | Source Side of weld ‘Geomettic

| in) 45° | tofimdistance (in) _| 978 Unharnessed | “0020”

Penetrameter Penetrameter

Penetrameter Group a "placement | 7S size [® | ote or wire | 22"

Single Load Cassette Yes | Multiload N/A | Exposure time | 53s Pb.010" FRB

LL Z Cassette Baa ae

Source Film Arrangement || shimMaterial | N/a _| shimThickness | N/A

Processing zu pete

‘Automatic (A) or Manual (M) M | Temperature (°C) [28 Developer Time (Min) | 2 Minutes

_ — | [Wash Time (Min) | 2 Minutes Dry Time (Min) | 2 Minutes |

Inspection Result 7

Code: Accept (A), Reject

(R), Slag (S), Porosity (P), Crack (C), Lack of Penetration (LO),

_ lack of Fusion (LF), Burn Thru (BT), Under Cut (UC), Surface (SI

—Weidlio- ALR] Ss |e [cw lir| sr[uc| sl

L a

HI-F 52550 7 fe

wel a By

+} tt +

5835-08 £ |

M.85355 f ae

L a I

Remark] ~ c

nee Jacob Briones NDT level It NDT Technician deste

Technician: Signature: |”

—— ty oeeinee

QC Laboratories See

Representative: oa foam coven |

Customer Signed

Representative: 7

f

“Tis report ropresents only the materi ested ands netindicative of resul that my be

obtained fram slr materials This reper shell nt be repreducesexceptin entirely and nt shel wed

‘for commercial purpose without wetten permission of QC borates, c

[QCIABORATORIES, INC Report No: | 123851

10810 Northwest Freeway Houston, Texas 77092 Date: 20018

Phone: 713-695-1133 Fax: 713-695-0808 Revi ee!

Web Site: www.qelabs.com | E-mail: qclab@qc.com | Page i [Lo [2

—— | RADIOGRHAPIC INSPECTION REPORT

Costumer ‘WELDFIT ENERGY GROUP P.O. Number | 5312 7

Contact Person Luis Guerra Phone | 713-460-3700

E-mail Address N/A Err ore ae | AZ

Part Description | Hot Tap Tee 6” X4” With 1500 RF Flange W/O Number [J/N:532213-01__|

art Number ‘A.234-WPB S 58 -A 105-150% i SO Number | N/A

Serial Number HT-F52550 15835-08 M.85355 Heat Number | N/A I

{0¢:2003 Rev. 0 ‘Receptance Criteria | APL 1104 24st

— — -

my | Ghh [ ld.

OH) (Bb |e al | Osi |

Source OF Radiation ir132 [Source Guries [262 — /tla q

‘Material Thickness (a) 0337" | iim Type Film size] 7ommxa0"_| No Fim ie

‘Source To Weld Distance so Source Side of weld Geometric

as 2

apc tofilm distance (in) _| °78° __| untamessea | “2-20”

Penetrameter Soniaomer tssential

aaa 1 A 8 .

Aeterna placement | */S Size Hole or wire | 920”

Single Load Cassette Yes | Multi load Cassette |N/A | Exposuretime [53s | Pb.010"F&B

Souree Fim Arrangement | 5 iT Ws

‘Automatic (A) or Manual (Mi) M | Temperature (°c) [28 | Developer Time (Min)

Wash Time (Min) | 2 Minutes Dry Time (Min)

Inspection Result

Code: Accept (A), Reject (R), Slag (S), Porosity (P), Crack (C), Lack of Penetration (LC),

Lack of Fusion (LF), Burn Thru (BT), Under Cut (UC), Surface (SF)

Weld ID. View No. A R Ss Pp c | up | tr | Br | uc} oF

1-217 a

HF 52550 2-37 a 7

aw ae

1 5835-08 ze L

M.85355 as ptt 7

a3 I a ——

Remark I es

Not NOT Technician a

Jacob Briones NDT level II e

Technician: Signature : qa“ :

AC Laboratories

Representative:

Customer

Representative:

‘This report represents only he materi! tested and is ot indicative of real tat my be

obtained from snr mates This report shell nat be reprodaces except ins enely and not shellbe used

‘or commercial purpose without written permission of (laboratories, ne

(QC LABORATORIES, INC. Report No: | 123852

10810 Northwest Freeway Houston, Texas 77092__| Date: ‘Augs 252018 |

Phone: 713-695-1133, Fax: 713-695-0808 | Revision: _| 0

‘Web Site: www.qclabs.com | E-mail: clab@qcl.com | Page 1 [of [3

RADIOGRHAPIC INSPECTION REPORT

Inspection Result zee

‘Code: Accept (A), Reject (R), Slag (S), Porosity (P), Crack (C), Lack of Penetration (LC),

Lock of Fusion (U)Sur Tru (BT), Under Cut (UC), Surace (SF

WeldiD. | ViewNo | a[R|s | P| c [uw] i] er] uc| SF] Comments

L | te

HEF 52553 ft ee

if E

[ i a =

1-2 i eee

1'5835-08 2-3 T f

M.85355 31 7

‘Remark Ett EEE

NoT ‘Mike Johnson NDTIevell! | NDT Technician

Technician: | Signature :

QC Laboratories Nor

Representative: i ee assistant: | 5 ctson a

{ oe

Customer

Representative:

cbtained from sila materi This report shel at be

rte pte caeteo

Tor cammerdl purpose without

QCTABORATORIES, INC. 123853

10810 Northwest Freeway Houston, Texas 77052 ~ | Augs 25 2038

Phone: 713-695-1133 Fax: 713-695-0808 | Revision:

Web Site: www.gclabs.com | Email: aclab@gclcom | Page

SRS MAGNETIC PARTICLE REPORT

[eustomer | Weidit energy Group | 0. Number] S312 7

Contact Person | BilRushiow Phone 7]

Email address NA = ec raf

| Hot Tap Tee 6” x4” With 150# RF Flange w/0 | s/N: 532213-01

Part Number/Rev. ‘A.234-WPB S58-A 105-.150# 5/0 | N/A oI

Serial Number HI-F 52550 T 5835-08 M.85355 ~__Heat Number | N/A

NDE Procedure (QC 4002 Rev.4/E709 ‘Acceptance Criteria | ASME Vil Div.1App.6

Faia ae Latest Edition

Scope Of Examination | 100% Accessible Bevel Areas ‘Welder Number | N/A |

Traceability Code Welder Symbol | N/A

Equipment —]

Manufacture __| Calibration Date | March 07, 2018

‘Temp. OF Material Current (AC/HWDC) | AC

Longitudinal ampere

(amperes x Turns) Leg Spacing (In.) | 4”-8"

Wet / Dry il Particle Color | Yellow

‘Demagnetzed

(Yes/No/N/A) N/A Particle Concentration | N/A

Black Light Intensity White Light

uw/cm/5q.@ 15" | N/A _| intensity @ Surface _| 110 FC Batch Number

tem | Quantity Description _ ii

1 3__| Hot Tap Tee 6” Ka" With 150# RF Flange ee

Remark = : roe 7 za

Not Jacob Briones NDTIevll | NOT Technician fr d xp

Technician: ‘Signature : i

QC Laboratories ‘oT

Representative: Assistant ike Johnson

Customer Date: | Augs 25 2018

Representative:

‘Ths report eposents nly the materal estes nds ot indicative of rat that my be

‘QC LABORATORIES, INC. 123854

10810 Northwest Freeway Houston, Texas 77092 ‘Augs 25 2018

Phone: 713-695-1133 ff 713-695-0808 0 a

‘Web Site: www.qclabs.com | E-mail: qclab@qc.com | Page 1 [Lo] s

ULTRASONIC EXAMINATION REPORT

| Customer Weldfit Energy Group P.O. Number | 5312

Contact Person Bill Rushlow a Phone | 713-460-3700

Email address N/A Fax

Part Description Hot Tap Tee 6” X 4” With 150# RF Flange w/o

Part Number/Rev. | A234-WPB § 58 A 105-.150H 5/0

Serial Number 550 T 5835-08 MB5355 Heat Number

NDE Procedure Rev.4/E709 Acceptance Criteria

Latest Edition

‘Scope Of Examination | 100% Accessible Bevel Areas

‘Welder Number | N/A

Traceability Code

__ Welder Symboi | N/A

‘Standard (5)

ot SS ____TESTPARAMETER Pee

Instrument | Olympus—Epoch 800 _| Serial Number | 120458112 _| Calibration Date |

Longitudinal

Frequency MHz | 225 | Size |0.50m_| Manufactures | Panametrics | _ Serial Number

‘Shear Wave

Frequency MHz |N/A | Size | N/A | Manufactures | N/A Serial Number | N/A

Coulpant ‘Water ‘Surface Finish | <250ms | Calibration

[Reference Level | a0 FSH [Scanning tovel wave) | 6 es

[ 0 Degrees (db’s) | 30 | 45 Degrees (db’s) [N/A [60 Degrees (db’s) [N/A | 70 Degrees (db’s) | N/A

item | Quantity Description Result

1 3___| Hot Tap Tee 6” Xa” With 150# RF Flange z

‘Remark oe EEE

Nor CW.Hayes ACCP level I NDT Technician

Technician: Signature = “

QC Laboratories _ NOT

Representative: ob. Assistant) ike Johnson

Customer Date: | Augs 25 2018,

Representative:

This report represents only the materia tested and is ot indicative of result that my be

obtained from sila materials This report shel ot be reproduces except ins entiely and nt sell be used

sieve, sovemnssy Aer

otto ose

Tangy oxpnge fe poyeedsuy

ST _| Se T_T ST RR Serr Sag BODES

‘sae | oases | osgz3 oases Meh 09828 31H 86UBi 7

Bjaeldeasy | SigeiGecy | siaeidecsy | sqeideocy | eigeideosy | — aineidacsy Bucaieag “|

0-558 | s0-se6e | g0-seGa | e0-se0e BR 80-9683 | JOqUIN L LH 881

08, OE, «0 |e au 08, [oteg weds Bucy

aigerdenoy | aiececoy | armerdenoy | aigedecoy | aigerdanoy YORHO. ool 0} OBE

‘aigerdeooy | aiqeideoay | alqeideosy | aqeidecy | ayqeidecoy wO3HO [88110 ue UY BUeL JO NET

SHINSO | SMINEO _|SHINSO |” S4INEO aed V0 61,0 DUE OF eh

BHIN3O | SHIN3O | ~S4IN3O_|~SYIN3O | S4IN30 eo 38] JO He 0-601 OF

aS BS pS BS ps | 8 | 82 @A65Ig 6018 MO

ews | oews | opus | Oews | pgs ae ‘ete )0 GL

‘Adig jenIoy | Sdig jemay | edig ienioy | ediq fenjoy | add jenoy | gz ‘aL yeH 10 GOL Gi

gh | [sce #81 J0 401 GI

gue | sae OL TOW

o | au 5 JO WORE g GO} UsBIER GeH [eUIPHIDUOT

| aigeideooyour ‘SEiigB aij ue 60) 64 UeeMog SGD 10, puB Yee

aige\deooy aiqejdsooy | eiqejdecoy | alqeidsooy | aigeideooy | aigeideoay ‘yoayo 3g |. e6ine6 6 UO 9} 613 Jo sanj2y WIOg Jeg

| ‘yqeydeaaynouy '}93)9p Bujoc}eygesoy0u

aymeideooy | eperdeooy | ageidecoy | eieideooy | agerdecoy | “Sterdenay fue acy 02 jo tre 5 doy woaocou] oray,

8 + t z +

STO STRUT PAULAA — eee

Ses equim gor ee TEL Jequinn yeeH

RSW BS GaN ELBE ¢ soquuny weg + 9uleN Auedwiog

Tens, =

wopuee! = ¥

‘ayaidwog = 01 del joy

‘9 uowoadsul 40 ody 133HS VLVG NOISNAWIG "AN

Weldfit Corporatior We Id F

it

Proposal Drawing

532213-01-A234WPB-A105-52550

Veri.6.4

Reference Number | 583508 DW,No740ax—0a04 | Design By [IML | Date | 06/13/18

Item Number | 2 Check By | HTM | Date | 06/23/18

Customer Tiber Nusantara Sukses PT. ‘Approve By Date

Revision Date

Part Number '532213-01-A234WPB-A105-52550

oe Fit

ing meets design requirements

PASS | special Considerations - PASS foe eete ee

Fitting Type Hot Tap Tee Flange WN RF—Sch 80 _| Material:

Fitting Size & Class 6” NPS x4” x WN 4” 1508 (A234 Gr.WPB

Fitting & Tee & Flange Type _| Extruded —Hot Tap i ‘A234 Gr.WPB

Design Pressure 285 Psi Equal Tee

Design Temperature 100" F _ Flange ‘Ai05

Corrosion Allowance Oine __—*(| DF:04 LOR Plug

Drawing Notes: a Sara

41.,100% MT Field Weld Bevel |

ema HO Oughta

[fas

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- THJ-Report - Attachment - MIR TEE BAUTDocument7 pagesTHJ-Report - Attachment - MIR TEE BAUTzat572000No ratings yet

- EFRATA-Report - Attachment - BA Pekerjaan Pemasangan Anoda Korban 1Document1 pageEFRATA-Report - Attachment - BA Pekerjaan Pemasangan Anoda Korban 1zat572000No ratings yet

- RC 327607Document2 pagesRC 327607zat572000No ratings yet

- MDR Fitting Split Tee 6 X 6 X 4 ANSI 150Document32 pagesMDR Fitting Split Tee 6 X 6 X 4 ANSI 150zat572000No ratings yet

- Stress Analysis of Piping Systems and Pipelines Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines Harvard Universityzat572000100% (1)

- Table of Content: PT Perusahaan Gas Negara TBKDocument3 pagesTable of Content: PT Perusahaan Gas Negara TBKzat572000No ratings yet

- EDL Panduan Desain Rev 1Document3 pagesEDL Panduan Desain Rev 1zat572000No ratings yet

- Isometrik Joint PT Pangansari Utama TBKDocument2 pagesIsometrik Joint PT Pangansari Utama TBKzat572000No ratings yet

- Nomor: 004800.ND/LG.02/ROM-SOR2/2020: Nota DinasDocument2 pagesNomor: 004800.ND/LG.02/ROM-SOR2/2020: Nota Dinaszat572000No ratings yet

- Split Tee - Chevron 4x4x4 #300Document31 pagesSplit Tee - Chevron 4x4x4 #300zat572000100% (1)

- Split Tee CA TangerangDocument8 pagesSplit Tee CA Tangerangzat572000No ratings yet

- RT API1104 Luindo PrimaDocument11 pagesRT API1104 Luindo Primazat572000No ratings yet

- Welding Circuit and Arc BlowDocument4 pagesWelding Circuit and Arc Blowzat572000No ratings yet

- Laporan Mechanical Test - 2 Herman M-02 PDFDocument7 pagesLaporan Mechanical Test - 2 Herman M-02 PDFzat572000No ratings yet

- Format Laporan Piket Natal 24-25 Des 2019Document6 pagesFormat Laporan Piket Natal 24-25 Des 2019zat572000No ratings yet

- FAT Procedure Rev BDocument15 pagesFAT Procedure Rev Bzat572000No ratings yet

- BA Pemeriksaan MaterialDocument7 pagesBA Pemeriksaan Materialzat572000No ratings yet

- Berita Acara NDT & Daily ReportDocument33 pagesBerita Acara NDT & Daily Reportzat572000No ratings yet