Professional Documents

Culture Documents

Casting Inspection: Machining Inspection

Casting Inspection: Machining Inspection

Uploaded by

zat5720000 ratings0% found this document useful (0 votes)

23 views2 pagesOriginal Title

INSPECTION STANDARD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views2 pagesCasting Inspection: Machining Inspection

Casting Inspection: Machining Inspection

Uploaded by

zat572000Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

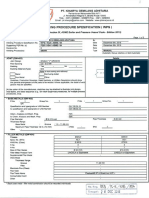

Casting inspection:

Casting surface checking (caverns, scratches, misruns or other defects) 100%

Machining inspection:

Major body sizes checking and parts' sizes checking

(plug, seat, stem, flanges) 100%

Machining quality checking (roughness, tearing, unproper machining) 100%

Assembling inspection

Assembling quality checking

(galling, jamming, mismatching of connecting dimensions) 100%

Checking of valve design correspondence to confirmed drawings 100%

Valve components quality checking

(gaps, materials, assembling, grease etc.) 100%

Smooth operation of valve checking

(galling, jams, enhanced operation forces, gaps etc.) 100%

Valve visual inspection

Valve external surface quality checking 100%

Dimension and weight checking of valve (major sizes) and it's components

(counter flanges, gaskets, studs, nuts etc.) 100%

Hydraulic and air test inspection

Shell test 100%

Water seal test 100%

Back seal water test 100%

Air seal test 100%

Painting inspection

Valve surface preparation checking. Degreasing checking 100%

Primer painting checking 100%

First layer painting checking 100%

Second layer painting checking 100%

Final assembling inspection

Valve assembling with counter flanges, gaskets and fasteners checking 100%

Nameplate data and fixing checking 100%

Valve preservation checking 100%

Packing inspection

Packing quality and reliability checking 100%

Loading of valves and components in boxes checking.

Monitoring of fixing and painting integrity 100%

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- F-Liquid Penetran Exam Report Ke2Document24 pagesF-Liquid Penetran Exam Report Ke2zat572000100% (1)

- Table of Content: PT Perusahaan Gas Negara TBKDocument3 pagesTable of Content: PT Perusahaan Gas Negara TBKzat572000No ratings yet

- THJ-Report - Attachment - MIR TEE BAUTDocument7 pagesTHJ-Report - Attachment - MIR TEE BAUTzat572000No ratings yet

- EDL Panduan Desain Rev 1Document3 pagesEDL Panduan Desain Rev 1zat572000No ratings yet

- Stress Analysis of Piping Systems and Pipelines Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines Harvard Universityzat572000100% (1)

- FAT Procedure Rev BDocument15 pagesFAT Procedure Rev Bzat572000No ratings yet

- Split Tee - Chevron 4x4x4 #300Document31 pagesSplit Tee - Chevron 4x4x4 #300zat572000100% (1)

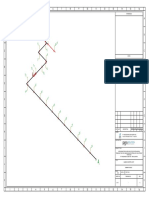

- Isometrik Joint PT Pangansari Utama TBKDocument2 pagesIsometrik Joint PT Pangansari Utama TBKzat572000No ratings yet

- Berita Acara NDT & Daily ReportDocument33 pagesBerita Acara NDT & Daily Reportzat572000No ratings yet

- Laporan Mechanical Test - 2 Herman M-02 PDFDocument7 pagesLaporan Mechanical Test - 2 Herman M-02 PDFzat572000No ratings yet

- Sertifikat WelderDocument7 pagesSertifikat Welderzat57200067% (3)

- Serial Number RS UG PDFDocument4 pagesSerial Number RS UG PDFzat572000No ratings yet

- WPS ASME Kinarya PDFDocument16 pagesWPS ASME Kinarya PDFzat572000No ratings yet

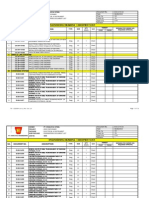

- Inspection Measurement & Test Equipment List PDFDocument1 pageInspection Measurement & Test Equipment List PDFzat572000100% (1)

- Instrument Location TransmittalDocument1 pageInstrument Location Transmittalzat572000No ratings yet

- MC No.814 1088 BTGDocument52 pagesMC No.814 1088 BTGzat572000No ratings yet

- Summary Mechanical CompletionDocument14 pagesSummary Mechanical Completionzat572000No ratings yet

- MC No.762 977 BTGDocument42 pagesMC No.762 977 BTGzat572000100% (1)

- F-Liquid Penetran Exam ReportDocument24 pagesF-Liquid Penetran Exam Reportzat572000No ratings yet

- Document List DrawingDocument13 pagesDocument List Drawingzat572000No ratings yet