Professional Documents

Culture Documents

W580e 01

W580e 01

Uploaded by

Александр Кулаков100%(1)100% found this document useful (1 vote)

237 views444 pagesOriginal Title

W580E-01

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

237 views444 pagesW580e 01

W580e 01

Uploaded by

Александр КулаковCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 444

Workshop Manual

EX8 €X22

E€Xl2 EX30

€xX15

Excavator

HITACHI

INTRODUCTION

SAFETY ALERT SYMBOL AND HEAD-

LINE OF NOTATION

nhs manus tefotowing sale le yb and

tha header ntaton so ed woane mpaaee

ina an tongs

BA Biss esate symbol. When you se

tts sym e let othe poeta for

persona ijn.

Avert ow the sity

Inerctons pesobed sang wth he

ioty aa ym

“The word "NOTE" is heading to supplement an a

ional toctscal formation or ku how

TO UPDATE THE CONTENTS OF THE

TECHNICAL MANUAL

“Tho each technical nana is seraly numbered and

is embers racorded by us wih the name of te

orson wo ecetvod tho acres! manual

Jd they ae refered when the desverd tochrial

‘manuals ae roquited fo bo revised by up toca n+

formation as such formation must be supped

quickly and corey.

Pasa, advice us the nana of person who keeps

tho technical manual and s responsi to Koop &

tp toda by sonding back Yo ue th sp of he ship:

Ping iformation shoot onsen ho totes!

Irate that the personal administration change Is

‘ao, pnaso ior uso the namo a he person

‘who new appointed te maa te technics,

manual

‘TO KEEP CONFIDENTIAL

Pease, keop he octea formations and know:

how contaned nthe chris manual confient to

the outaders,

Iwo1

INTRODUCTION

| Safety

FOLLOW SAFE PROCEDURES

Lnsale work practices ae dangerous. Undectae s

ee provedie belore doing work dont atop shat

PREPARE FOR EMERGENCIES

Kap a est ait and eo extinguish handy.

Keep emergency numbers for doctors, sul

———— ————

HANDLE FLUIDS SAFELY AVOID FIRES

anil ue wit cares is high farmable, Oo no

reinenceys ate tamon cone Sm |

aks. Ansys ston engine belore rtuelng mach,

Sie annie fide nay hom fe hazards, Do et |

—

| |

sao1

Safety

PREVENT BATTERY EXPLOSIONS

Koop soaks, lighted matches, and ae away fom the

top of Daley. Bary gas can explode,

| Never check batty charge by lacing ® meat object

‘across the posta. Use a voter ee hyomete,

| 0 not charge a fazen batty: may expe, Warm

ator to 18°C (60°F),

so

PREVENT ACID BURNS

Sullric acid in avery eectolne & poisonous.

eh tas sh, et Pes ncn, a

Cause bindnese splashed ito eyes

"Flog bates ia wall vena aoa,

2. Wearing eye protection and rubber gloves.

3. Reoding eating fume when electeyto is

4 aidog spill oF dipping ela

'5 Use proper jump stat procedure,

yo st 0 or

sh your skin wih water

2. sop balag Soda fee 1 blp nese the

oo

8. Fish your eyes with water for 10-15 minutes. Get

‘mesial alent immed.

I acid is swale

1 Dink age anaunts of water or mi,

2 Than ok ml of maga, ese ep, ve

3. Get medic! steton immediately.

Safety

AVOID HIGH-PRESSURE FLUIDS

Escaping tit under pressure ean penetrate the skin

‘vod the hazard by rabeing presse Belore dco

ectnghydraue or afer nas. Tighten all conmectons

betere appv pressure.

Search for leaks with a piece of cardboard, Protect

hhands and body fom high pressure ids.

| 1 an scien acu, so a doce ody. yt =

itt tow paws oraugrone oy eats

WARN OTHERS OF SERVICE WORK

LUneapected machine movement can cause sao i

tag on tha night side controle Iver.

Safety

PARK MACHINE SAFELY

Before working onthe machine:

Park machine on a fove surface

Lower buckat the rou.

Turn a swish of

Fn engie at 12 spend without load for 2 mis,

Turn kay sich 16 OFF Yo stop engine, Rove koy

from sch

‘Move pt cont shut iver to locke postion,

‘Alou engine 0 oo

‘SUPPORT MACHINE PROPERLY

‘ways lower the attchento¢enpement to the ground

toe you work on the mace. H you must wor on

ited racine attachment, seeutly suppor Be ma

Do not work undar a machine that is supported sty

by a jack Folow recommended procedures ths ma

OPERATE ONLY FORM OPERATOR'S

SEAT

| Avoid posse inuy and mactine damage, Oo not stat

‘gine by shring across starter rma,

NEVER slat engine we standing ground, Start on

‘ne only rom operators ea

sA04

STAY CLEAR OF MOVING PARTS

Enlangloments in moving pans can cause serious hy

To prevent accidents, use cio whan working arcund

rotating pats.

Safety

AVOID POWER LINES

Serius sry oF deat can result fom contact wit

Never move any prt ofthe mactiow of fad closer to

tect tw than 3m (10) pu ic the ne ssuator

tent

USE HANDHOLDS AND STEPS

tives point contact wits the stops and handrails and

ioe

Never jump on or of he machine, Never mount or dis

mount a meng machine.

Be carlut of slippery conations on platforms, stops,

fd handrals when geting of th macsine

Safety

KEEP RIDERS OFF EXCAVATOR

Oniy alow tne operator en the excavator Keep siders

of

‘ides on excavator aro subject to jury such a8 being |

struck by foreign obec ang lng tows of he exca

Vator, Riders aso obenit the operator’ view resting

MOVE AND OPERATE MACHINE SAFETY

Bystanders can be run over. Know the lcaion of by.

Slander blows mowng, swinging, oF operating te a

Aye heap te vol tm wring condo, ie

Use a signal person whan moving, swinaing, or opera

ing the machine n congested seas, Coordinate rand

sionals before staring the excavator,

WEAR PROTECTIVE CLOTHING ~

® a

% Q

@ e&

8A.06

Safety

PROTECT AGAINST FLYING DEBRIS.

Guard aginst injury trom fying pieces of metal or de

ths; wear goggles or saat glass.

PROTECT AGAINST NOISE

td eae

ILLUMINATE WORK AREA SAFELY

urinate your work sea adequately but slay. Use

Pty gt otra nse

Shine, Make aie tho ube enone by 2 age cS

Tn ho aman fon accdotay broken ula ean Ro

ite spied tue or 08 “ee |

| SERVICE MACHINE SAFELY

Tie long hair behind your head. Do not wear a necktie, |

‘scart, loose clothing, or necklace when you work near C}

SA.o7

Satety

REMOVE PAINT BEFORE WELDING OR

HEATING

Avoid potontaly tole Kanes and st

Hazardous fumes can be generated wien paint is hes

(03 by welng, sidering, or Uang a toch.

o all work outside ori 8 wo ventilated arb, Dispose

of pala solvent propery,

Femove pa before waking cheating

I you sond or grind pint avok esting tho ds

Wor an approved reaprae

1 you use solont or paint stripper remove stinger

wih Soap and wator bolo weling Remove sant

Pt stopper contanors and other ammatie mato

from aroa: ow fumes to aisperse atleast 16 minutos

bots welding or hating,

AVOID HEATING NEAR PRESSURIZED

FLUID LINES.

FFammatle spray can be ganerated by hosting ner

resurized fu nes, costing In sovere brat you

Sal! and bystanders. Oo not heat by weldes, soloing,

‘areata sterile

Prossczod Uns can be accidentally cut when heat

00s beyond the immediate tame ara. sta ee

‘sng quads to protect hoses or oor mata

Safety

Froventasphysiaon. Engin

aust tes an cause

It you must operate a bung, be postive there is

fduate veniaton. Ear uso an exaust pe extn

‘Son to remove the oxhaust Tunes or open coors and

twodows to Bing enough ouside ait he area

BEWARE OF EXHAUST FUMES

‘SERVICE COOLING SYSTEM SAFELY

Explosive etase of tis ro prossrizod cooing sys

tem can cause serious burs,

Shut off engine. Only remove filer cap when cool

fought ouch with bare Pans

Inpropedy disposing of ids can har the envio:

inant and ecology Before dsog any this, tnd out

the proper way to iepose of waste fom your local en

ronmental agency

Use proper continars when daring fide. Do nt use

food or beverage consinere that may misled someone

ino dking tam ten

120 NOT pour ai into tho ground, down ain, oF ito

‘steam, pond, or ake, Ose rolvant rman

fal protacton roguatons when oposing oto 1

Coolat brake fad fates, Bates and other harm

sA.09

DISPOSE OF FLUIDS PROPERLY

Safety

WORK IN A CLEAN AREA

Before staring a job, clean the work ara. Remove ob

jects that may be a safety Hazard tothe mechan oF

bystandre

USE TOOLS PROPERLY

Use tools sppoptite to the work. Makestit tools

Pats, and procedwres can crate salty hazards. oe

Use power oa ony to loasen threaded too las

For loosening and totaning hardware, use the const

size tose DO NOT use U.S. measuromert tol on

‘otc Tastonors. Avoid boy inry caused by spin,

‘irons.

Use ony recommonded replacement pats, (See Part

Cataoo.)

REPLACE SAFETY SIGNS a

Replace missing or damaged safety signe. Sa the so a

chine operator's mata or covet sey fn pc ee

SA10

Safety

LIVE WITH SAFETY

Before returning machine to customer, mako sore ma

‘chine is funcbong propery, especialy the ste Sy5-

toms, fal al guards and sheds,

sat

sat2

KMs206-01

seo:

WORKSHOP MANUAL

EXCAVATOR

‘SECTION 03 SPECIFICATIONS

moe ft

SECTION 02 UPPERSTRUCTURE

worm kat te Gl oe

‘SECTION 03 UNDERCARRIAGE

moxie Fb HT fe

Lo

“TION 04 FRONT ATTACHMENT

am | POD hP RY FAYE

‘SECTION 05 SPECIAL TOOL

mos | AR

‘SECTION 06 ENGINE AND ACCESSORY

(Ex8)

SECTION 07 ENGINE AND ACCESSORY

(EX12, 15, 22, 30)

SECTION

Group oF

(Group 02

‘SECTION

Group oF

crop 02

Group 03

Group 0¢

Group 05

Group 08

Group 07

Group 08

Group 08

SECTION

Group 01

Group 02

Grovp 03

Group 04

Group 05

Group 08

(Group 07

‘SECTION

Group oF

‘Group 02

EXCAVATORS

WORKSHOP MANUAL

SECTION AND GROUP CONTENTS:

01-SPECIFICATIONS:

Tightening Torque

Name plato

02-UPPERSTRUCTURE

‘cab

‘Counter Weight

ump Device

Conta Vave

Swing Dovicos

Plot Vato

Lock Valve

Solenid Va

(09-UNDERCARRIAGE

Swing Boson

‘Travel Device

Center Joint

“Track Adjustor

Front er

Upper and Lower Ror

“Track Link

04-FRONT ATTACHMENT

Front Attachment

Hyeraul Cyr

SECTION 05-SPECIAL TOOL

Group 01 Special Too st

Group 02 Drawing ol speci! too!

SECTION 06-ENGINE AND

‘ACCESSORIES (EX8)

(Group 01 General rormaton

Grou 02 Engine

Group 02 Lubieatng System

(Group 04 Cocing Sytem

Group 05 Fuel System

(Group 05 Troubleshooting

(Group 07 Special Tot

‘SECTION 07-ENGINE AND

ACCESSORIES

(€x12,15,22,20)

Group 01 Genera oration

Group 02 Engine

Croup 02 Luriatiny Systom

Group 04 Cocing System

(Group 05 Fuel Sysiom

(Group 08 Troutestaoting

Group 07 Specie Too!

‘sB0w-01

ss0w-02

SECTION 01

SPECIFICATIONS Be

CONTENTS

Group 01-Tightening Torque

“ong Tee woro1e |

GGroup 02- Name Plate |

ue te wor.0201 |

580W-01-01

‘s80W-01-02

SPECIFICATIONS /

ightening Torque

Tightening Torque Spectications

Exe

tude |g, [wow sm] Taam

las mma mn OY | ine) [Nem (kgm, ttt)

7 [rae eon nor mga ee Casio | ar 20, 1aasy

2 mie tckt moun om ioe | eenim | e904 50, 26

3 yan of nk retig ta 1 [os [enn | ss04 sa. 3617)

7 ]Fut rk wring bat wo [2 | eanin | 400m 6a, 3617)

z _ 2 | | sit | “see 10.720

3 vn ona in oi ay area) | aaa 80, 2170)

prose cure | aan 40, 1179)

pve toner | ena 68, 2709

= pre awe) | feran t40, 10126

|e ania tak . asia) | aan, 10,72

7 | on! ao mou ak ° esi) 1a. 7a

Covel ave tact ong tok te ann s0_a6in

Seng not onig bat ‘0 asm 50.3617]

9 | ate rnin on ¢ “a2at0 a5, 36

70] Sxing boing mourn bao wopwerice | — 10 oer 50, 361

Sung being noting toto tearege | 10 cen eo

Ti ave deve ing ak ‘a 0948 5036.7

12] Socket nonin bok ‘0 316) | aa0u 80.617)

13 [Crit os mating Sa z ~ |

[74 Teck oer mouning bok ya |axa| earn) | 166701 17.0, 12296)

15 act swe mong bak. a

16] cover mrtg bot 2 aay | 38 40,73

erin | sso 0.261

77 [casei ning we ab oveie. | aaa 25 250

ae: (1) Aly ant (69 he cn 8 sso spe i) fo ta an aso staize he on

{@) Make sure bot and rut dvoads ae clean belo instaling

{2} Aoply Locite to Beads beore nealing and ightonng Swing beating mowing bots

fod

wor-01-01

‘SPECIFICATIONS / Tightening Torque

Tightening Torque Specifications

X12, EX 15,

7 = Bot ia | gy | Winch io Tore

("| came cs inom | _ tem gtr, ety

1 | Enane coshion rubber mauning naan) 2 | 2] 07509 | 902% 90, e509)

Engine bracket meuring boost v2 | 2] ores | sez6 90.65.05)

2 | Myer of tank mounting botlront) | 7 | asm | 4904 6.0, 96.17)

2 | Hyco tank mowing bot 10 | 3 | o.6nr7) | ao0a 50.36.17)

| Foot tank mounting bot e+ | oss) | 1970 20, 1446)

5 | Mydrauiehooses and Union Janis Pra 075119) | 2040 90, 21.79)

Peaee oar) | s02q 40, 11.79)

Prva 1o8e7) | 63.7% 65, 47.02)

Pear 1.26(92) 137.90 180, 101.26)

PEMA 1.41135) 176.52 180, 190.19)

6 | Main pup morting bok wo | 2] esr | 90a 50, 3617

Pilot pump mounting bt wo | 2] osm | 904 50, 36.37)

Pump cover mounting bot w | 6] osm | soy 50, 3617

Pump cover mounting rut | | 2] enn | 904 so 2617)

7 |Contct valve mounting bolt 10 | 2] 0677) | 904 50, 9617)

Contr! valve mounting nt wo | 2] oom | oom so 61

Contre valve base mounting bl wo | 2] osm | sou 50361

8 | Swing Device mounting bot v2 | 4] eve) | 6261 9.0, 68.09)

13 | Contr pwn moi bo 8 | osnrs) [or 20, 1446)

10] Barory mosting bot 5 2 | ose | 490105, 3.61)

11 | Sa nna ta |e | eereer | vars v8.0, 101 2)

12 | Swing bearing mounting bat (Carer) ro [16 | o6nr7) | saew 60, 43.39)

Swing bearing mounting bot_(Track) so_| | osm | se0K 60.4339)

73] Travel dovce mounting bl wo | 6] o3ne | 904 50 3617)

Sprocket mounting bolt wo | osn | s0% 5036.17)

[74 eu mouning bo wo | 8 | 0677 | 204 50, 36.17)

16 | Track roller owning bo 4 [v2 | onnea | 106.70 7.0, 122.86)

16 Cover mounting bot ® ‘osi3) | 1971 20, 1446)

10 067117) | «08 50, 36:17)

77 | Coonterwaight mounting Union bo we [4] 07s | vo787625@0, 65.05)

Counteweight mousing belt 2 | 3] ove | 926 90, 65.05)

ote

(1) Apply lubvicant (eg white ane 8 cisoled into sina oto Boks and ts to stabilize tak ton

ooticiont,

(2) Mako suro bolt and nut toads ae clean before instaling.

(2) Aoply Loctite to Breads bore insaling and ightning swing beating mounting bots,

‘wo1-01-02

SPECIFICATIONS / Tightening Torque

natcont

(2) Make sure bolt rut toeds ao clon bolre instating.

{3} Aoply Loci to treads Belore installing and Ughtning swing boaring mounting bolt.

‘Tightening Torque Specifications

x22

i a Gon | gy | Wrench Sa] Torque

me in rm) | _ Wm Gt, my

7 | Engine eustion rubber mounting nut 2 | o7sri9) [3826 9.0, 65.09) |

2 | Engine bracket mountog bot wo | 7 | csr | 4904 50, 36.17)

Engine bracket mounting rut wo_| 1] osni7 | so0K 5.0, 36.17

3 [Tank mounting bo wo | + os7a7 | ao0u 5.0, 36.17)

«| Hycrauehooses and Union Jone Peve ore) | 2942 30, 2173)

Praer oor) | 392 40, 1173)

Pevee 067 | 6975 65, 4702)

Pra 12632) | 19730( 140, 101.26)

Pewee van@6) | 17652 180, 130.19)

Pern s.41(96)_| 20804 2.0, 161.09

3 [Pump movnting Bat so [2] oensy | «oom 0.3617)

1 | snp cover mounting bot wo | 6] asra7 | 400% 60, 36:17)

Pap cover mounting nt so _| 2] os | sou 50.3617

7 | Contra valve mousing bolt so | +) os7a7 | aoa 50, 36.17)

onto valve bracket movetng bot w_| 6] osra7 | som 50. 3617

2 Swing device mounting bt ve [4 | 075) [2826 90, 05.00) |

12 | Sing moter runing sockat ba e+] ozye) | 3235133, 2508)

10] Botery mounting nut 6 [+] osauo) [404 05, 3.61)

$1] Canopy mourn bat 34) «| ora) | 197.0( 140, 101.26)

12] Cab mounting bot 16 | «| onatzay | 197.90 140, 101.26)

13 | Smog bearing mounting bot to upperstuchxo | 12 | 13 | 0.76(19) | 10287 105, rev)

Swing bearng mounting botio undercariage | 12 | 16 | o7stia) | 10297 105. 75.94)

14 [Travel device meuniing bot v2 [18 | over | 6269.0, 65.08)

15 | Sprocket mounting socket bot 12 [| os) | 926( 2.0. 66.09)

16 Track roter mounting bat ve | v2 | oanea) | 166711 17.0, 122.96)

17 | Cover mounting bot 10 ‘osni7) | 4908 80, 36.7)

2 o7sis) | 0.26 90. 65.09)

78 | Coutorwaight mounting bot v4 [| osnea) [rar201 140, 101.26)

Note: (1) Apply Morcant (emit zine 8 assolved ino spindle al to Lots and us o stabilize thet ction

1wo1-01-03.

conticint,

(2) Make sure batt and rut had ae clean before isting

(@) Apply Locte to treads befor insaling and ightening swing bearing mounting bots.

SPECIFICATIONS/Tightening Torque

Tightening Torque Specifications

x30

Bot 18 vrenen Size Torque

7 ranean mm | O | item | nem aot,

| Engie custion mibber mounting nat 2 | «| 07609 | exam 90, 650)

2 Engine back mounting bok a ee

Engine bracket moueing nut wo | +] osm | «ou 50.361

a Tank mount bot wo | «csr | 900 5.0, 96.17)

“¢] Paulie hooses and Union Jams cag 0.7518) | 204% 30, 21.79)

Pesce oara2) | 3924 40, 11.79)

Pever sos) | sa7{ 65, 47.00)

Pra s.ze(a2) | 197.90 149, 101.26)

Prave arias) | 17652( 180, 120.19)

- Per 1.41196) | 205.04 210, 151.69

5 Pump mouning bat 2 [2] eres) | 0826 9.0, 65.00)

6 Pump cover mounting ba w | 6] asm7 | 904 50, 36.17

Pump cover mouming bl so | 2] osm | sou 603617)

‘Cont! vale mounting bolt wo | | o6m7 | «90a 60, 36.17)

Cont valve bracket mounting ble wo_| 6] osm | soa 50.3617

@ ‘Swing device mounting bot 2 | 6] 0751 | 0269.0, 65.09)

[2] Sing moter mounting socket bol e+ | ozs) [32064 33,2586)

10 Batery mouting nut 6 | 4] soo) | 494 05,360,

1" “canopy mounting bot v6 || conan) | 9790 140, 10126)

2 ‘Cab mounting bot se [| ose) | 197.0( 140, 101.26)

13] Swing bearing mourong bor wo uppersmucure | 12 | 20 | ven | ruzwq vue, rose)

Swing boarng mowing bot to wndercariago | 12 _| 20 | 076119) | 1297 105, 75:94)

a “Travel device mounting bot v2 [ve | ors [10297 108, 75.94)

15| Sprocket mounting socket bot 2 [re | esai0) | 826( 3.0, 65.08)

16 Caio rotor mounting bat sa] 2 | ogra) | 197.001 140, 101.25)

v7 “Track rol mounting bok 14 [ss | owrea) | 166.70 17.0, 122.98)

18 ‘Cover mounting bot 0 centr) | 40a 50, 36.17)

2 ars) | 22 90, 65.00)

79 ‘Counterwight moaning bat 4 [4 anes) [1730 140, 10.20)

"Note: (1) Apply lubricant (eg. white ne 8 dissolved into spindle 0) to bots and nuts to stabil ther on

wo1-01-04

SPECIFICATIONS / Tightening Torque

Torque Chart

(1) Be sure to use bots of correct length. Bots that ate too long cannot be gone, as th bolt Hp comos in

to cortact with the bottom oft Bat ole Bls thal are too shot cannot develop sufciont tightening orca

td to shoror tread lng

(2) Tilton bots or nts conecty to torque spacications. vee kinds of bots, T, Hand M, each diferent in

Inatoral re used. Make aur o employ coroct bolls and Ughan corey when asorbing tho mac oF

@- @- @-

Metic Bolt Torque Chart

‘Nomina! Tit (SONS) bot (400) bor (6541) [Wrench Sizo

ia remy | __ Nem that tt) am hn, a) Nm (agi, (nm)

6 ‘30042 10

(0360.43, 2468.19)

8 | asa a0, 2.70] r981¢ 20, 1447) sass8i 13

(0.90.00, 651-723)

10 | 6a75( 4s, 4702)| an0a( s0, 98.17} 961 20 144) 17

12 | sree (110, 7956) | a8.26( 90, 05.10) | 4a2( 3, 2502) ) 19

14 | 17659(190, 19089) | 19790( 140, 101.26} sage ss, 997) 2

we | 26479( 27.0, 19629) | 20595(21.0, 151.89) | 7846( 80 87.86) | 24

sa_| aorncaon, 20932) | 2042r(an0. 216.00 | 7.08 126, assy | 27

‘Note: ex. EXB Swing bearing mounting bots

Bat cia (10 en)

‘Tigo oq 388.54 New(6.0 kam, 48:99)

wo1-01-05

SPECIFICATIONS / Tightening Torque

Inch Bott Torque Chor

Nominal eit (SONS) ‘bat (8541)

lary) | Nem kgm a) Nem (kgm 4)

ae 137s W785( 14 18, 1048 1008)

we 39.34 4707( 34 48, 2459. 94.72)

se 6963. 87.20( 71. 89, 6269- 6497)

ar | s0939( 650,397.82) | 12749.15691 (190-160, 9809-11579

Note: The torques given are standard gues. Any tows specifically dasccbed his manual have price

ite

(2) When tightening two or more bos, tigton them atlemately as shown below to be sire that they are ight

‘ned even.

at on ped ato onconte

‘ter tion eto gray massa

_ 8009008

Rad s0e¢eoo

‘wo1-01-06,

SPECIFICATIONS / Tightening Torque

ee yess cnerten- dno Jon Tome mone

Para e

eoanewne wes nee gece» — pee vt

metus mst,

roe

eee ee ee

mesma rym tmernios, = wee, ee

och ram cant

oe

Mat Teper Noo sae

“Tightening Torque Specifications me ee

“Tohtoning Torqve

Nominal Toad Size neem irnch Sizo

- Union Joint Pipe Threads =

(igh pressure) (om pressure)

v8 sarc 15, tag | 10

7 aaoac ao asin | saerc 20 tan | 19

3° e965( 70, 5069 | 2042 30. arm |

wi7( 95, ary | a90a 50, 6am | 7

19790(140, 10125 | aes 70, sos |

17659( 180, 190.19 | aes; 70, soe |

a 205.95(210, 18109 | worse( 10, yes | 4

243.25 (250, 269.16 | 15691(160, 11579 |

30.90 (550, 097.80) | 106.14 (200, vance) | 6°

z ‘eae (600, 42308) | 25498(260, 108.00 | 7

‘Note: The torques given are for fre tread of SSAT, Horna weed i f cast en, Uo longue must be r=

ced eppronaty 10%.

‘wo1-01-07

SPECIFICATIONS / Tightening Torque

(9) Aoply Teflon tape to treads just enough 10 tl up

teas clearances, as shown. ‘Dp not t0 apply 100

much 1 evo loosening o he screw. on tent

‘wor-01-08

SPECIFICATIONS / Name Plate

LOCATION OF NAME PLATE

covet 00% on sear SE

e @

1 age te er 1 rae 1 tamer ame st 28~ tara rateeT. 3H Hama NTE: Dea ©, ave ecto atch.

2 Name ite (ame ot ‘te vO. OH «17- Name Pate (Lover——31~ Name Pate ving «25 Nome Pat (STO,

Smee ° tae" too

a ‘mean (eSEreanon

3 Name me (Acar)

Name ne 14 Naa te (Opaction) 18 Home ate Kame Pa 80k

ee (30) (Speco ‘hse

5+ amen (ezen) 16 Name te Gpaeon)

wor-02.01

SPECIFICATIONS / Name Plate

exrzexis

ras

ohn sti

2

SE ho

INSDE vw oF sear ‘MEWenow ABOVE OF FOOT

\VSW ROW TOP OFTHE FUE LEVER BOTTOM OF THE Seer

$1 Name te a 19 Nameiate(iLe) NOTE: Detal ©, ®, ©, @ ore crecon of ateching.

$2 Name ate (HF Nay 20 manera (Sung

V4 Nome lte Laver 18 Name a ame ot

cay Ensen

~ [Gpucamso)

wor-02-02

SPECIFICATIONS / Name Plate

x22 €x90

NOTE: Deal ®, ®, ©, @ wo direction of actin,

wo1-02-03

‘SPECIFICATIONS / Name Plate

wor-02.04

Group 01-Cab

Removal lastalaton

Group 02-Counterweight

Removal and lstalaon|

Group 03-Main Frame

‘Removal and instalation

Group 04-Pump Device

Removal and isan of

Pump Device

Disassembly acd Ascobly of

ump Devico

Maintenance standord

SECTION 02

UPPERSTRUCTURE

CONTENTS

wo20101

wo2.2.01

wo2-02-01

wo2-0401

wo2-04.08

wo2.04.24

Group 05-Control Valve

Removal and instalation of

CContorl Valve

Disassomby and Assembly of

(Control Valve

Group 06-Swing Device

Removal and Instaiton of

‘Sing Device

Disassembly and Assmbly of

Swing Moto

Group 07-Pilot Valve

Removal and istaaton of

Pot Valo

Disassembly and Assembly of

‘580W-02-01

Wo2-06.01

Wo2.0513

wo2.06.01

wo206-13

woo.07-01,

Wo2-07.04

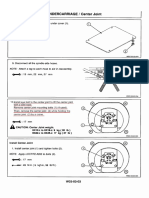

UPPERSTRUCTURE / Cab

REMOVE CAB

(on2ens622600)

[A iqures shown i Wis Section are for EX 30.

{Remove Tour seat mounting bos (1) 1 rove the

me IT

<=

2.Discannect wire harnossos.

me 220m |

2. tach the ng bis tothe ca,

A caution: cas wean

[EXIZEXIS: 297 (100 ka)

X22 E120; 419 (100 6)

oe

4 Rove the cat mousing tli |

Showy eit and remove the cab using a crane.

me: 2 00

|

|

|

[oe

wo2.0-01

UPPERSTRUCTURE / Cab

INSTALL CAB

'5.Atach the sg bats tothe ca,

Host the cab’ and put i on the fame using the

6 instal four cab mounting bots (2 to secure tho oa,

me 24.01

at 187 Nem (108 Bt 14 ktm)

“Put he seat back

Install four seat mouning bots (1) to secure the

‘oat

ee Tom

ae 249 Hn 8 kot)

8.Connect wire harnesses

‘wo2-01-02

UPPERSTRUCTURE / Counterweight

REMOVE COUNTERWEIGHT

(ouzexisex22 2x20)

[igus anown nis secon are for EX. 30.

1.Romove four engine cover connecting plas (1) and

tw stopper pins (2) to emove engine cover (3)

eee mm

=<

2.Remove wo counterwaight mounting Bos (1),

Ie 22 009

‘.Atach wire rope to counterasight (1) and hold it

tip using & crane. Remove two. remaining

‘ounlonealght mounting Bots (2)

A. crvti0s: cao wesenr

Sxo:e8b 124)

Sia! foo (eee)

xis: rf 041)

‘a2: 25 fe (0519)

x30 90 1 (10 KD)

ome: 20m

‘4.Belore heisteg the counterigh, ws the cane 0

‘move away tom the machine.

‘wo2-02-01

UPPERSTRUCTURE / Counterweight

INSTALL COUNTERWEIGHT

Stach a wie ope tothe counterweight

‘Using a erane, host the countorwaight away frm

the machine belore mowing t back into pace

“Tomporety inal two Countarwnight mounting bat,

Remove te we rp,

ae 20m

instal wo remaining countormeght mounting bots

{2} the tighton a four bots 1),(2) 0 specication,

PO ex exi2EXI5: 19 mm

{522 E390: 22 mm

SEEK 341m (251, kgf)

[EXIDEXIS: aa Nn (6 bt, Seen)

{EX22 EXO: 197 Ne (101 i, Akt)

insta four engaw cover atahing bots (1) and two

Stopper pins (2 sal the engine cove.

me 17 om

=<

SE; 49 No (86H, Seg)

‘wo2-02-02

UPPERSTRUCTURE / Main Frame

REMOVE MAIN FRAME

(DBEXHENSELLO0)

[igus show ts Secton a0 for EX 90,

Ai cavTion: escaping tis under pressure can K |

BSG ne evar by fling pressure betes

disconnecting hydtaute or ote ines. Tighten

Si connections betore appiying pressure

Search for leaks vith 3 pce of casos

| Fake"eare to protect hands. and body tom

igheressure fra oo

an accident occurs, get immediate medica

tktention. Any id injected Into the ek must

be surgeally removed within a few hours or

‘angrene may result

Toosoning cap (1) located on te op of bo ok

Remove cap (1

2.Remove mounting bots (1}(2,(9,4) to remove the

oor patos.

amet

wo2-03-01

UPPERSTRUCTURE / Main Frame

‘Remove eght 0! mounting bots to remove the ro

me irom

Using vacuum pump, reduce tho hydause tank

pressure into the negative range and! conine to

‘pera te pur wil working

“Remove al vpperstucura side hoses except conor

Font ete hosts (1)(2)(0)

‘Als, be sue To nove the swing bearing easing

hose

De: torn, 22M, S21, 980mm

‘Attach wire ropes as iustated to balance thy ein a

‘rame,

5. Romove rane mounting bol (1).

O17 mm SHB EXIZEKIB), 19 rn (OH22)

20 mm (X30)

‘wo2-03-02

UPPERSTRUCTURE / Main Frame

7Hoist main kame (1) use a eran.

AdcauTion: main Frame ( Upperstucture+ Front

‘tachment ) Weight

EX 8 1043 fb (473 kg)

Ext2: 1702 6 (72 K9)

xis: 1241

(2x22: 2873

2X00: 3011 1 (1502 kg)

INSTALL MAIN FRAME

fa.tach wire ropes as illustrated to balance te rain |

‘ame.

8.Slowy put the mainframe onto tho undercariane

Using crane. Take ‘care not 10 damage the

Undoreariage side hose,

me SERB ERIZEXIS) 17 mm

(©226%49) 19 mm

=H: (EX8) 49 Nm (6B, 5 hat)

{EXIDEXTG) 69 Nm (49 Br Bhat)

{622.600} 109 em (75, 105 Koh)

10st he main rae mounting bot

Remove the wee pes.

ae sri

aH: 42m 6A, Skate

wo2-03-08

in Frame

UPPERSTRUCTURE / M

‘last a uppersvuctute side hoses

‘iso, be sur to instal the swing Bearing greasing

PX 519.00, 22mm, 92, mn

Zot 22 3 gm)

oN (29 ry aes)

aN (a7 bf, 85 4ghm)

17 (101 A, 14 aah)

{2install the floor plates using mounting bolts

C.2}.0}.

met mm

mt 480 (9 BA 5 kam)

{8.osta the roof using eight bots (1),

me aT

ae 488m (6 5 kam)

wo2-03.04

UPPERSTRUCTURE / Pump Device

REMOVE PUMP

Xa EXIBEXB2 X20)

iyues shown Hs section ae or EX 30

Bi cxxTi0s: escaping tld under pressure can x

pene the sin, causing serious ur.

fold ths hazard y velovng pressure Deore

Gioconmecting hydrate or other tines. Tighten

SI connections before applying pressure

Search or leoke wih 9 plece of cardboas

{Tone care to protect hands and body tom on

‘atepressore fs

Wan

ident occurs, got immediate medical

‘Any fluid injected ito the skin must

ically removed within a few Now's oF

‘angrene may result

‘ease ai presse fom tho hysrauic ol tank by

Toosening cap (3) lated on te oy of He a

omove cap ()

a ~—E—rtétéi‘_sés—SO _

ho cpp fn 1) 1 anor gine covet 2 2

ee Tim ie

<

‘wo2.04.01

UPPERSTRUCTURE / Pump Device

S.Romove moving bots (1) snd (2) to remove the

et countwesght

me: 218 ~15(12 an), B422~90414 mm)

Remove muffler mouning bots (1/2 pieca2}4

pies) and nus (3,4 pcos) a romove io (3).

‘oe: On model EXS, removing the muller is not

necessary.

me 17m

Using a vacuum pump, reduce the hydrauie tae

pressure Ilo the nogave range and continue to

parte the pnp wie woking.

5.Romove two detvery side hoses (1) and pl tater

‘de nose (2,

me 191m, 22 0

wo2-04.02

UPPERSTRUCTURE / Pump Device

plot pump side hose).

‘mouning Bots (2) 10 remove tho suction

sie pipe

ame 19 ne

Fo 8

{8.Tghtan sng bet (1) around pune (2)

‘ach ling bo (3 10a crane fo Secu pump (2.

A caution: pump vevice weichr:

12X90: 86 (9.4 ko)

x22: 47 i (1.4K)

XYZ EXI6: 36 8 (16 ko)

x8: 1616 (akg)

9-Romove mounting bos (1)

Remove pump (2) using Yh crane

me 19 ne

INSTALL PUMP

10,Using a eran, hoist pump (1) and secur it wit

mounting bots (2.

le: 18.0

pe 98 Wm (72, Tate)

wo2-04-03

UPPERSTRUCTURE /Pump Device

‘natal ot pump side hose (1,

Insta the suction se pipe using mounting bots (2).

19m, pam 29 8m 22 WH, 3 kgm)

[8,98 Nm (72 HB Hay

"instal Wo dBvery side hoses (1) and pit ol ier

‘de nose (2,

ame 2191, 22 mm

at: 20 Ni (22, 9 Kg),

38 Nem (29 Bt, 4 kgtm)

12. insta the mute and sooue using mauntng bots : a

OA).

mest nm

4 Nn (96, 6 atm)

14. Rumove sit tossing plug (1). Fil hyraute ol from

‘ho pg hole ntl te ol comes ou om the ha

‘Tighten log (1) tmperay

Fun te engin at sowie,

lee ai om tne pomp by loosening pl (1) vs

the ol comes out Sap the eng. Tghton pug (1)

to pectic,

I 390m

a5 Nm (40 1, 58k)

‘wo2-04-04

UPPERSTRUCTURE / Pump Device

‘Sita Tol counteweight (1) using mounting bois

Ao.

PE 519 mene E19), 226220)

at He (25 3.5 kg NEE)

Bos): 108 Wn (@D 1 KymyEX12~EX5)

Bots (2): 88 Nim (65 tt, 9 ken EX12~EXIB)

{37 Nim (10 Bi, #4 Kal 22~ EXO)

16: Intal engine cover (1) sing four bls (2) and two

pins

me stom

=e 49 Nem (95 ot 5 kat)

<=

‘wo2-04-08

UPPERSTRUCTURE / Pump Device

DISASSEMBLE AND ASSEMBLE PUMP DEVICE (EX8, EX12, EX15, Ex22)

xe

‘wo2-04.06

UPPERSTRUCTURE / Pump Device

UPPERSTRUCTURE / Pump Device

ie eS

a ale sh

UPPERSTRUCTURE / Pump Device

DISASSEMBLE

Clean the ouside of tbe pump and place it on a

work bone Belre dsassembiing, make matting

‘marks ‘on Dodes 119}, 2(8). pat (2), boos 1

ron cover (16), and cover (8 10 ad i assy.

1. Clamp front cover (16) ina vio. Loosen socket 2, Remove the pump tom tho vise. Pull out

bats (1 feckat bos (11) to dsassembie tho pump to

Sub assembles of: ont cover (18), boay 1 (1).

Noe: For EX8, clamp body 1 (1) n a vise pinto (22) and bodies 2 8) and 3 (9),

T— : mm Note: Subascombies fr EX8 ave: bodes (1) and

2(@), and cove (21,

Sabssembles fr 2X72 and B15 ae: tort

over (16) and boas 1 (7) ad 2 8).

xz

t= boos 7 wen Genet 1 water Be bose a

Ghat 105 Seven Gewr 2 18= Sovping 2 Pow

wo2-04-09

UPPERSTRUCTURE / Pump Device

8, Remove retaining ring (18) and ol sal (14) rom

cover (18),

4. Remove gasket (2) om tont cover (16).

5. Remove side plate (2) and sto! bal (6) rom

body (th

ese: For EX8, remove plate (2)

te: On sie plate (2), mark the sucton port side and

the dotvry pore fo ain ctmgusting thor

nasser

15. Remove dive gor 1 (6) and ven gear 1 (7)

from boay 110)

17, Remove side plato (2) om Boy 11)

Noro: For EXB, remove plate (18) retaining rng (13)

‘and of 09114).

Noe: On side plato (2), mark the suction por side at

te dovery por side fo aid cstngushing thom

in assoney.

{8 Remove gasket (4 rom body 1 (1).

9, Remove coupling (15) and col (23) rom pate

2).

10, Remove gaskot (4) rom pat 22).

11. Remove sept (2), sto! bals (6), oars 2 (8)

nd (10), se plate (2), and gasket @) tom body

(0) nha onder long to stop 6128.

‘Noo: For EX, move plate (2), dowel pn (5), goars 2

(9) and (10) plete (18, couping (15), sea (4)

ing (7a boy 2) ren 1 ss,

12, Ramove sido plato (2), ston bal (6), gors 9 (20)

‘and (21), and sido plat (2) rom body 3 (18) 0

{at oxdr rong fo saps 8 07.

Note: For EXB, remove dowel pin (5), so (4, ning

(17) rom cover (19} ering stops 5 and 8.

wo2-04-10

+ toys oor 9

wo2-04-11

UPPERSTRUCTURE / Pump Device

Betore assombing. clean the isassombiod pans with

solvent and rythm wth compressed a

iso, apply sof hydra o othe ner pats

pce al gaskets, seas, Oogs, an of saa with

ASSEMBLE

1. Ins of sal (14) ito ot cover (16), then instal

‘etaning neg (13 10 ont cover (18)

Nee: For EX8, insta ol sat (14) and retaining ing

(13) 10 boay (1)

2. Clamp ont cover (16) wh ts of saa ite facing

the ground n ase.

Note: For EX, clamp body 1 (1) with itso sea side

facing te round in a vie

23. tnstall gaskot (4), sido plat 2), and soot bas (6)

to hoot cover (8),

te: For EX 8, insert plat (18) ino ody 1 (1), thon

Insta dowel pis (5)

Noto: Apply grease to gasket (4), ste! bas (5), and

‘owe! pine (3

Note: Apply fm of ya to side poe (2).

‘When instatng side plate (2), take care nfo

Cntise es surson side ant deiory si. neal

"ide plate (2) wh is gasket sie facing

onnwera.

‘Nee: For EXB, apply atin of yr oo plate (1)

When instatng plate (18) tae care nat 0

Contise te sueson sie And dohvory de. sal

plate (18) wh is copper aly sie facing

Cowra

4, testa drive gear (6) and kvengoar (7) front

cover (18)

Note: For EXB, insta gears (6) and (7), and plate (2) to

body # (1 Instalcouping (15) to goa”). Be

sure fo apy afi of hydra of plate (2)

botorehana. Wan istating plato (2), Take care

otto cantuse ts sucton se and devon

Instat plete (18) with ts copper ay side facing

downward

te: Apply Sn of Pca 10 the contact areas

(of cars (6) and (7), and plate (2) beforehand

wo2.04-12

5 Inn side plat (2) into body 1 (1) 7. Roply grease to gat (2) and instal into

booy 1h

exe: Apply tin of hyrautic 0 ste plate (2)

linen instatng Sie pate (2), take care not

Conluse de sucton sie and devery side

Instat sio plate (2) withts gasket de

facing downward:

ete: For EXB, instal seat), ng (17), plate (18),

and dowel ns (5 10 body 2 (8).

‘ote: Be cure to apy grease fo soa (2) and ving

(G2) leo, apy ati of hycabe a plate

(18). Wn stag plate (8) tke care rot

{o conse ts sucton side and delvery se.

Instn plate (18) ith &e copper ay 830

acing downward

6, infront cover subagsombly (16) and body 1

Zbassombly (0, algnog tbe matching marks

te: For EXB, i Body 1 subassembly (1) and

body 2 (8

eae

1 boars Dives Gear se waoe

2 aerate Boar 2 fain Reg

te Gate ines ew 48 Souping

12> oor 3

UPPERSTRUCTURE / Pump Device

{Inset cll (28) and coupling (15) to body 1 (1)

8, din boxy 1 subassembly (1) and plate (2),

Aigning the matching masks.

10. Apply grease to gesket (4) and sto! balls (5),

‘ply aim af hye oso plato (2),

Insta gasket (4), ie plate (2, and sel tals (5)

to plate (2

oe: When instating side plate 2), take care no to

Contuse is sucton tide and daivery Instat

Sint 2 tga 8

1% Install dive gear (8) and even goa (10) t plate

22

ese: For EXB, instal gear (2) and (10), ad plate (2)

to body 2 @). Apply 9 lim of hydraute oo pate

(2) belsehand, When inetaling late (2), ake

fore otto conte ts sucton aie and dear

‘Sie. sal plate (2) wh is copper aly side

facing downward

Note: Apply 9 Sn of Pac of 0 to contact ares

(af 9oo' (2) and 10), and se plate (2).

12, Aoply a kn of hydaute ol side plto (2) ond

insert tint body 2 (8),

‘Note: For EX 8. apply grease to seal (4) and ing (17)

‘and instal ham fo cover (9).

ove: When instating side plate 2), take care nfo

Conse ts sveton sie and Gaivey et

‘Sie pao (2) wih is gasket sito Tocing

owns

1, Join plate subassontiy (22) and body 2

‘aiasombly (@), kgrng the matching marks,

Nese: For EX 8, jin body 2 subassomtiy (8) and cover

subassomby (19).

14 oly grease to gasket (8) and sts! bal (6).

‘Apply tim of you oft side pet (2)

rsa gasket (side plate (2), nd stool als (5)

to body 2 (8

Nee: When insating side plat 2), take care no to

confise ts sucton de and devory sx. natal

‘io plot (2) with Hs gasket se facing

ownwora

wo2-04-14

16. instal hive gear (2) and diven gear 24) 10

ody 2

Note: Apply a fim of arate ao the contact

{7088 of gears (20) and 21), and sd plate

@)betorenana.

16, Apply fn of hyau ot sido pat (2) and

Insert int body 319),

ete: When intaing sid plato (2 take care not 0

canfise #8 suchon de and delivery 06

Insta site pst (2) wih ts gasket se

facing dowd

17, soln wody 2 subassembly (8) and body 3

Subassembl (19), aligning he matching ark,

1 To secure tha jit bodies, ahen socket,

ots (1) wth war (12)

Fs 800m

ts 4-49 18m (4.5~5.0GF) (09-985

woe (©)

38~23 Nm (99~44 Hg) (28~82

ree (EXt2, Bxt5, 2),

Feng Rg 2B bnew 9,

wo2-04-15

UPPERSTRUCTURE / Pump Device

UPPERSTRUCTURE / Pump Device

DISASSEMBLE

CGiean the outside of the pump. Bolo asassembing

‘make matching marks on body 8 2), body it8), body

{WO}, and oove (14) to dn assemty.

1 Hoist the pump using a crane and securly put it

fon a work bench

2, Remove socket bol (26) an body (40)

T : 5mm

8, Remove O-ing (14 rom body (40.

4, Remove diva gear (38), bushings A (89) and 8

(27), ad riven oar (2) om oy (0)

5. Remove bushings A (69) and B (37) tom body

(40.

@ 2

f

@ 4

Ot

@-| TF

®

fax

fini

@

3@®

toes 25- Seat sot 28- bre oar

1 Save i ocog Se some

1 too aa eran

‘wo2-04-17,

UPPERSTRUCTURE / Pump Device

{6 Remove socket bos (18) and sloove (14.

T— : Gam

7. Remove rods (16) and Oving (15) fom soove

(i

8. Remove spring cover (27.

me: 20mm

8, Remove convo piston (17) om Boy H (1).

10, Remove spring holder (92, erings (30) ant (3),

‘nd spring guide 29) rom body H (18),

11, Remove O-ing (28 rm spring guido (2).

12, Loosen sockt bolts (12) to rove body § (4) and

shat (0) aesombly 98 packing (2).

T : 8mm

13, Remove retaining tng (10) tom oxy (4).

at

14. Bush out shat () and ball bearing (6) assembly

and sol holder (9) Hom body 8 (A) by tapENg

thom witha plas hammer

eH

16, Reenove of sal (7) and Ong (8 rom seal holder

@.

18, Remove pis (3) and swash plato (1) om boy H

(9,

17, Remove rer (24) and piston (35) assomy tom

boy H (8)

18, Romove pistons (5), hold (34, busting (9)

and neadies (25) rom rotor 28).

18. Remove retaing sng (2), retainers (22) and

sping (23) for ror (24)

at

20, Remove valve pat (20) rom body H (18)

wo2-04-18

& Q® Oe DO) G

oor

=) Bs Nowe

SP Seater ES come

‘wo2-04-19

UPPERSTRUCTURE / Pump Devi

ASSEMBLE

Belov assembling, clan disassembled pats wih sot

‘ont and dy them wah compressed at

‘Reply af of hyraute of the ne pats

Replace af O-ngs of seal, packing, and needle boar.

tng with now ones, disassombiod.

1. Insta valve pat (20) nto body (1).

2 Incr roainors (22) ad spring 29) no roar (24).

Push down an hol retainers (22) and Sp (23)

ting a e035 Bon tal rtaing ng (21) 1 0

tor 2,

at

8. Intl needs (25) to ror (24).

Paco tshing (3) onto noodle (25).

“4 Reply atm of hydra o to pistons (35).

Insta piston (25) and holder (04) assembly int ro

tor 4

5, Install rotor (24) and piston (25) assembly nto

ody H (18),

Nese: Apply a fin of raul of to the contact areas

(of vale plate (20) aed tor (24).

6, Plo swash plate (1) ont rotor (24) and plston

(95) assomby

Note: Apply a Km of tydraulc of fo the contact areas

of piston (85) and swash pat (1).

7. nso ins (8) into body H (18).

£8, Place packing (2) onto body H (1)

9, Push shat (6) and ball bering (5) assembly into

body (4) by tapping the assembly with 2 laste

ame

—

10, Aoply grease to Oring (8) and ol seal (7) and in-

‘or thom nto sol hair (9),

11. Tap soa holder (2) no body S (4) wih plastic

hammer, ten instal rotiing Hg (10).

te

sot

‘wo2-04-20,

12, din body 5 () and sat (6) assembly and body

H(i), aging tho matching marks

‘Tignon socket bots (12) wih washers (1).

a

Fmt SI =64 Nn (5565 ha) (40-47

13. Apply groaso to Oring (15) and a tn of hydric

cto rds

{sort Oring (1) and rods (16) io sleve (14),

2 pasang

UPPERSTRUCTURE / Pump Device

14, Aoply a fim of hydrate lo conte piston (17)

fd nse tino body H (18).

15. Insta loo (14) to body H 18) aging the

‘matching marks, then tighten socket bos (13).

T— : 60m

+ 20-24 Nm (2.0~25 kat) (22~25 Bt)

18. Aon grease to Ong (28) and inset into spring

0 (2)

17 tnsor spring olor (82), springs (80) and (31),

and soring guido (28) into ody H (18), then

titan spring cover (27)

mt: 20mm

=e 490-590 Nim (60~70 ken (260~610

win)

18, Apply a fn of hyrauic oo bushings & (37) and

£8 (28) and inson ta into body (0)

Note: Insert bushings (37) and (38) wiht Osing

‘ie acing dowrward.

18, Inco deve gar (88) and criven gear (42) into

body (40,

Noe: Insta cive goa (28) to bushing B (29) and

hve goar (12) fo bushing A (37).

20, Insta bushing A (7) hve gar (98) and

ahing (2) todo gem 3).

te: Apply of Pyrat ol to bushings (27) and

(30) betoehand, and be suet instal hom with

{hte Oving sie facing downward.

21. Apply orease 1 Ong (96) and insert into body

()

wo2-04.22.

22, Inaall the assombiy of body (0) and gors (38)

‘a (42) wo body (18), aging the matching

f~ : 6mm

Fae 5 29-98 Nim (3.0~35 kan (22~25 Hh)

2 Q@QOOD® @

@

©

@ r

@ peo

@) +

fect

a [

@

soot ot 27 spreacovr 38 seena 38 oi com

Soe Sa pmo

soe a7 Sung A

wo2-04.23

UPPERSTRUCTURE / Pump Device

MAINTENANCE STANDARDS (EX30)

1. The clsrance between the ouside damtr of he

‘ston and th ise ameter othe roto ( id).

0.420.060 mm

2, The clearance between he piston and the shoe

45020

al

4

T

2, War ofthe ol sal contact srtce

Mossore the simoters ofthe worn areas an an

\uawornafea on the shat. The diforonco i he

‘wear of the of ea contact sac

‘Th service iit of wer ofthe al sea contact suracs

ie 20025 mm

‘wo2-04-24

UPPERSTRUCTURE / Pump Device

4. The clearance betwoan the outside ameter of tho oy Can Pat ounva

contol pat a the nso daete ofthe r

bushing (0-9)

monn Se

cc

wo2-04-25

UPPERSTRUCTURE / Pump Device

UPPERSTRUCTURE /Control Valve

REMOVE CONTROL VALVE

(oo E02En622060)

Ja igures shown Bus secon ae for EX 30.

Brcaution: escaping tid under pressure can mK

enewato the skin, causing serious injury

fold this hazard by flioving pressure beloro |

disconnecting hysraute or other lines. Tighten

Sil connections Detore. applying. pressure

Search tor leake with a plece of caraboar

Take care to protect hands and. body from

high-pressure

an accident occurs, get immediate medion!

tention. Any fig injected into the ekin must

be suigeally removed within a few hours of

Gangrene may result,

‘.Release a pressure frm the hyroule of tank by

Teosenng cap (1) located on the tp of he tank

Remove csp (1),

2.Reenove mounting bolts (1)~(8) to rrnove the Noor

me trem

wo2-05.01

UPPERSTRUCTURE / Control Valve

8.Usig a vacuum pump, reduce the tydraulic tank

‘rescure ta the nega a

‘porate the pap who woking

‘and continue 10 >

S

ee 27 00m

assonby

4. Remove aval hoses (1)~(8).

Note: (1) Make a note of disassembly order and port

umber and atach it each hose fo 34

Noe: 2) Port locations may dif for each mode

[Reler t.ho. confol valve socton of the

TECHNICAL. part of Be manual for each

model's pot locations.

Pk 21 nen, 22 en

§.Ramove boo, arm, and bucket hoses (1)~(@)

‘is, remove srs hose (7).

ame 20 0m

S.Romove boom-swing hoses (1}(2), blade hoses

(Gha), and swing hoses (5.6)

UPPERSTRUCTURE / Control Valve

{Remove ol cote pings (1,2)

ae 27

@.Ramove solenoid value pit Nose (1),

me 1910

9.Romove pnp noses (2).

ee 20

10. Rernave right sie pot valve hoses (1)~ (8

me 19m

‘wo2-05-03

UPPERSTRUCTURE /Control Valve

11, Remow ft sg plot vv hoses (1) (4),

ae 19.0

12,Remove outs (11,2).

Remove cotter pn (94) and ins (5.6).

Note: Ex employs mecharical conta! levers, 20 that

thre ere more lever inks" Remove all over

links, eering fo We above

sm

wo2-05-04

UPPERSTRUCTURE / Control Valve

“Bones at) ph bom oO

move ut (3) and pn (2

me 7m

"For Bx, remove mounting bls (1) to remove the

‘engine cover.

ae 0m

15.For EXE, omove buttery terminals and brackst

‘mounting nuts (1)

me 10mm

‘W02-05-05,

UPPERSTRUCTURE / Control Valve

16 Remave bracket mounting bat (1).

me 70

‘Atach oye bats 10 Nast the conto valve withthe

‘late and remove Irom the machine ising & cane

ae 1mm

1.Romove bots (8,4 © disconnect corr valve (2)

‘rom plat (1)

me 17m

INSTALL CONTROL VALVE

18.PUt the contol valve 00 the plate and tigen four

‘mounting ols (1.2.

me Nim

aH 49 im 6 bt, 5 kgm)

wo2-05-06

UPPERSTRUCTURE / Control Valve

‘2.Atach aye bots (7), Host ho cool valve with the

ato using a crane

ut ton the fro and bon bots (2)

e170

ae 49 Nin (86S kgm)

21.Connect the bade spool tthe red using eater pn

(8) and pin (2,

Insta not (1) to he lave.

me 17 mm

at AS Hen 85 Bi, Skah

=<

22.Cennact the booming spo0! to joa (1) using

‘ter pn (3) and pin 2).

Ia nt) to th love.

est7 0m

ana nm (stom, Sate

ox

wo2-05-07

UPPERSTRUCTURE /Control Valve

28.Connact the spool to the ro (2) using pin (2) anc

cater pin 3).

Inet ut (1)

me 17 mn

eam (96. Shae

Noto: EX employs mechanical conte lovers, 0 that

‘hore are. move lever links. Ist aloe Inks,

relent the above

24, Isa ight sept valve hoses (1)~(4

ame 18 mm

Fa 201m (221 3 Ham

25, Isa td pot vv hoses (1)~(-

me 190mm

ae 220 (2 9g)

‘wo2-05-08

UPPERSTRUCTURE / Control Valve

26 neal ole valve pot hose (1),

me 19mm

ae 28 Nin 22 bt hat

27 Intl boom

‘swing ho

19 hos

8.6.

(1,2, bade hoses (9.4,

eI mm

at: 98 Nim (69st, 95 Fon)

26.intal boom, am, and bucket hoses (1}~()

Ina ran hase (7).

me 27 mm, 22m

at 80 Nm 69, 85 kok),

230 Nn (20 Bo 4H)

29, travel hoses (1)~().

oe 27 mm

a 99 Nim (69, 95 kghm)

‘wo2-05-09

UPPERSTRUCTURE /Control Valve

30.nstal ol cooler pipings (2/2).

me 190mm

pe 29 Ne (2, 9h)

“Floste pup hoses (1),(2,

me 27

A185 Ne (69 HH, 95 kgm)

‘2.nsal the floor covers ung bots (1) (2

me trom

149 fm 96 ot 6 kgm)

35.For EX, secre he battery using bos (1),

‘Aach th trminl,

ae 10mm

PHS Nm (35 05 tam

‘Wo2-05-10

UPPERSTRUCTURE / Control Valve

{94.For EX8, instal bo engine cover using bats (2.

ome AT wen

ae Nem (96 i, 5 Agen)

26.netal cap (1) loeated on the top ofthe hycaube of

tank

Note: Check hyraut ol evel. Ads oi necossay

wo2-05-11

UPPERSTRUCTURE /Control Valve

‘wo2-05-12

UPPERSTRUCTURE / Control Valve

DISASSEMBLE AND ASSEMBLE CONTROL VALVE

exe

wo2-05-13

exens

UPPERSTRUCTURE / Control Valve

joonwee)

UPPERSTRUCTURE / Control Valve

UPPERSTRUCTURE / Control Valve

UPPERSTRUCTURE / Control Valve

DISASSEMBLE CONTROL VALVE

Ctosn the contol va

‘work ban

Xmen desscembing, take care not to mix parts

‘among sections.

and place & securely on 2

“REMOVE RELIEF VALVES , MAKE-UP VALVE,

BND SHUT-OFF VALVE®

1. Remove the rain cole valves (6), overload

abel valves (Oh makeup vale (27) and shut

‘oF vals (4.

Main at vaio vers roi valve

49 mm (€X8, 0) pent 181m 20)

22 mm (22) 22 men (EXE, X22)

24 mm (©x12, EXI8) 24 mm (EX, 8115)

Make-up vale Shuto valve

pene: 4. mm (220) me 24 mm (612, X15)

47m (6X2)

2B mm (X12, X15)

x2, 615,

Eno

OAS!

OOO

I

d to oh

wo2-05-17

UPPERSTRUCTURE / Control Valve

“DISASSEMBLE MECHANICAL-TYPE SPOOL

ee [A Sections, except the Remove wiper (15) and Ong (45). (EX 12

Swizh Valo Section) Cy

(2x12, £418, 22, 90: Right Travel, Boom:

———

“Trav, lage Sections en dsessembling socket bolt

“st 7 (10), Soeke batt (10) andor spring

seat (11) may fly off by spring (22),

force. Kexp pressure on sping

seat (11) and spring (12), while

Slowly loorening socket bot)

omove ol sal (1). X22, 490)

1. Remove socket bots (7), (8), cover (9), and

at (19) aba egie accom

I: 4mm (2x9, 2x12, Bx)

5 ren (E322, BXD0) 4 Paco spool (14) ina vse. To prvent the spo0t

trom being damaged, pace 2 Soft otal plate {

as: (2x12, x15) ‘aninum, copper )batwean the spodl and vse

furlacos. Romove socket bol (10). sping seat

— (19) tang (35), spina (12) and ae (19).

2, Pullout spoo (14) wih socket bolt 30), spring

seats (11), etainer (85), spring (12) and plato [= 5am

(13) as a singe assomby

NOTE: For spool (14) ofthe EXI2 and EXIS,

3. Remove packing (1) rom body (1). (EXE) remove spect head (46) 9 adson 10

the above

exe(alede)

SOOO

oor 2 come 12 Spang 5- Peing

Soaks ba 11> Sing Sant 1 Seon,

wo2-05-18

UPPERSTRUCTURE / Control Valve

DISASSEMBLE PILOT PRESSURE-TYPE

‘SPOOL > 2. Place spoot (23) in a vise, To provent the spoct

from beng damaged, ace a Sat meta plate (

(2112, 15 + Bucket, Boom, Switeh Valve, Arm, slum, copper) between the spool and vse

‘Swing Sections) Surfaces” Remove so:kat bot (20), spong Seat

(oar Boom 1, Bucket, Arm, Boomtt (21) and. spring 2.

Swing Sections)

(oa0 Boom, Bucket, Arm, Swing fee

sections) — ay

6 mm (EX, 5, EXD)

1. Remove socket bois (16), covers (17), (18) and

Oxngs (19), 4 Pul out spacer (48) spring (48) and poppet

FH 5 4m x2, 215) (60) fom spool 23}

fom (2X22, ©

ee NOTE: Uso 2 tonporary bot (MXPich 0.8)

2, Pull out spoo (25) wth socket bok (20), spx9 remove space (4).

Sons (21) and ping (22) a single asso.

Ai caution: when disassembling socket bolt

{20}, socket bolt (20) andor spring

feat (21) may fly of by spring (22)

foree. Keep pressure on spring

seat (21) and spring (22), while

Slowly loosening socket bolt (20).

x12, x15 (Arm)

PEW

: aq ©

\

® © 3d6 Mi

‘wo02-05-19

UPPERSTRUCTURE / Control Valve

-< DISASSEMBLE SWITCH VALVE »

1. Remove lua (80). Pul out sping (81, spool

(22), and shen (20)

[— : ame

me! 4 rn (2x22, 2180)

2. Pace spo (92) @ visa To prevent the spo0!

from being damaged, piace sot met pate {

aluminum, copper } between the spo and vile

Selnces. Remove pug (37). Pu ou sping (38)

Bd tl bal (39) For spot (32).

{8 Remove plug (40), Pullout sping (81), srg

oat (42), and 56h (9),

me: 22 mm

xB (Switch valve)

@

1 boy sping a= Spieg

StH Spina 0 Pia

‘wo2-05-20

UPPERSTRUCTURE / Control Valve

“4 DISASSEMBLE LOAD CHECK VALVE >

4. Remove plug (28). Pull out spring (25) and

chock vate (28)

fm ©, 820

— 8 mm (EX30)

x8 Blade)

°

oy

1+ ty Pn 2s-somma

wo2.05-21

UPPERSTRUCTURE / Control Valve

“DISASSEMBLE BODY >

1. Remove nuts @) to pull ou rods (8) so that: mm exe

body (1) ean be cided ito sens. 32 mm (EX12, X15)

14 rm (B22)

2 Pull owt Oving (2), spring (28), check vale 37 tam (30)

(29), and valve (5) kom boy (1)

E12, EXIS,

ad ame Bote vane

wo2-05-22

UPPERSTRUCTURE / Control Valve

[ASSEMBLE CONTROL VALVE

Befor reassembling, thoroughly cleen csassered 2, Polton bodies in the ordr thoy wore botre

pars and ry thom wih compressed a. Roplace ddeacserby

trom or damaged parts with naw ones. Inoert rode (4 ito bose (1) and secure them

Prepare new seis ( O-rngs, of sons and back-up veth nuts

ngs) fo oplace od ones.

“ASSEMBLE BODY = NOTE: Apply LOCTIE t the treads of rods

@.

1. nal va (61), check valve (29, sping (28)

fd Oring (2) © each body.

FT = 10mm 2x9)

NOTE: Apply a Sm of hye fo valve (51) 2mm (EX'2, X15)

‘an eheck valve (2) belorhand, 4m (E322),

‘iso, be sure fo apply grease 1 spring $7 ton 2)

(28) and Oving (2

OMT ig (XB)

19201. kgf X12, X15)

85 Kin (22)

eas ghn (E20)

x12, EXIS

1= oy 3 mw some svat

wo2-05-23

UPPERSTRUCTURE / Control Valve

“< ASSEMBLE LOAD CHECK VALVE »

1. sort check vate (25) 2nd spring (25) into

body (1). Thon pg 24

NOTE: Apply a Sim of hysrautis ol fo check

valve (2) betorehand

6mm x, ex22)

‘mm (x30)

Pt 19225 tate 68)

‘85-08 kghm (x22, €%30)

xa lade)

4 ao0y zr 2-Sem0 ss-chmah vie

wo2-05-28

UPPERSTRUCTURE / Control Valve

“< ASSEMBLE SWITCH VALVE >

1. Insaspoo! (49) into body (3). Inset sping

(43) and spring seat (42) ta lug 0}, and

tgren 1 body (1

NOTE: Apply afin offal ot poo! (4)

me: 22 mn 8)

mt: dS. ex)

2, Place spo (22) n 8 vse. To prevent he spool

‘rom being damaged, pace a soft metal plate (

‘minum, copper) betwoon the spool and vise

Surfaces, ioe steal bat (39) and spring (28)

‘Spool 2), then ight pug (27

NOTE: Apply a tim of hycraulc ot ste! bat

(G3): Aeply LOCTITE to pg (97)

mnie

x8 (Switch valve)

3, neat spool (22), she (36) and spring (1) into

ody (1) Tihton plug (30).

Fo eam exe,

me 514 mm x22, £430)

pat 81-88 tan (x8)

3-08 igh (x2, £30)

@

st Se

2 Sng eat

Spe

‘wo2-05-25

UPPERSTRUCTURE / Control Valve

“SASSEMBLE PILOT PRESSURE-TYPE SPOOL»

(092, 8X15 + Bucket, Boom, swith Valve, Arm,

Swing Sections)

(war Boom 1, Bucket, Arm, Boom,

Sing Section)

(eo Boom, Bucket, em, Swing Sections)

1. Insert poppet (50), sping (49) and spacor (48)

Into spoo (2).

NOTE: Apply a tn of hydra a © poppet

(80) and spacer (48).

2 Pace spel (28) ina vis. To proven ho spo

from being damaged, place & So maa plate {

_aninum, copper) between th spool and we

Surfaces. instal spring (22) and peng seat (21)

to spect (23) Tighten eocket bot (20,

NOTE: Be sure to apply LOCTITE to socket bot

rc

a 09~05 sot (exr2 EXI8)

Dor gh (E22)

"Tees kgf (€a0)

4m (Ex22)

‘5mm (X12, Ex15, X90)

3, Inspect assembly it body (1).

NOTE: Apply a fim of arate o fo spo0 (23).

4, Install Onings (19) to cove (17h, 18.

Install cover (17), (18) 19 oy (1) wih socket

Bois (15) and (1),

NOTE: Apply 2 tim of roase to Ovings (19)

beforehand

‘Also, be sure 10 apply LOCTITE to

so0ket Bs (1516).

@ 4 12, 48)

To Si ti 2)

ae: 0741.02 hot x2, 2x15)

158 Agr (2X12, EXt8)

ban, BAIS Am)

@Q @ poe =) ® ®

(masa SS a @

EnZ"

2 J

oS i

1 07 12 come 2 Sina Sot > Suet

1 Sean 1 nn 2 Ss Se tn

te Sen > Sco 3 Spot 5 Povet

‘wo2-05.26

UPPERSTRUCTURE / Control Valve

4 ASSEMBLE MECHANICAL-TYPE SPOOL »

ee [A Sections, excpt the

Switch Vaio Section)

(2412, X16, 122, X90: Right Travel, Boom:

owing, Spare, Lett

“Tra, Blade Sections)

1. Place p00! (14 i 2 iso. To provont the spoo!

fro being damaged, piace a so mola pato (

flumnam, capper) betwoon Dra soa and Vo

faces, natal pate (19), sping (12). otainor

(85) and sping Seat (11). Tighten scekor bale

0)

NOTE: For EX12, EX16, remove spool head (46)

in adaton fo above.

NOTE: Apply LOCTITE tothe toads of socket

‘ol (0) and spool head (4).

I = & mm 22)

‘mm (EXB, O12, EXIS.EXIS)

me 005 ten (EX)

880.75 kgm (X12, EXI8)

(0.6 +02 kg (2X22)

Te kghen (©30)

exa(slede)

2, Inst packings (15) ints body (1).

NOTE: Apply grease ‘0 packing (15), O-ring

(49), par g (19), and oi oat (18).

{, Inset he spon! assembly nto Body (1

NOTE: Apply atin of yaa of fo poo! (14)

bofrehana

4 last cove (9 a pt (19) to Body (1), 298

Ughten socket bots (7; 2 (8)

NOTE: Apply LOCTITE othe Oveads of socket

bats) ana

[= 4mm ©, E12, BxI5)

5 n (€22, X30)

an: 412, B11)

pan: 05-08 kan (EXE)

0.74~1.02 gh (EX02, X15)

1 +n ngtm 22, E00)

me 026-03 gH (x8)

:

2 Some > ie

‘wo2-05-27

UPPERSTRUCTURE / Control Valve

{INSTALL RELIEF VALVES, MAKE-UP VALE

AND SHUT-OFF VALVES

1. Instat main ret vaves (6), overioad rai

ales (6) make-up vae (27), and. shut

ves (44 0 booy (1).

Main oi ate vores rot vave

ame: 390mm 8, 20) ame 19 mm ©)

zamm (6x22) 22 mm (Ex, E122)

2a mm (x12, EXI5) 2a mm (X12, B19)

me 3-4 katm Ex) a2 4kgtn 0x8)

42-5 ptm (X12, B15) 42-5 gh (6x12, Bx15)

35 ¢0bkghm (82, B20) a0 kgm (0128, E00)

Makeup vave Shuto vate

ame th (20) mies 24 men (EX, £15)

a7 em (2),

2a mn (BX32, X16) Fae: 42-5 kim (0x12, X15)

Pome 42s kate (xi2, x15)

35 e8 hgh (E422, 30)

EX EXI5,

é

Shy co

oe eae

GOGO”

OOOO

wo2-05-28

UPPERSTRUCTURE / Swing Device

REMOVE SWING DEVICE

| e250

[AF gues shown in tis section are for EX 90.

A. caution: escaping tu under pressure can m

penewato the skin, causing serous inn.

Avoid tis nazrd by relieving pressure befor

loconnecting hydaute or ote ines. Tghen

| Sr" conmectone before appying pressure

Search for leaks with 2 pice. of cacboard

Sane care to protect hands and body om

ghepessure ta

Wan aceldent occurs, get immediate mastcal

tention: Any fuld injected into the skin must

be surgically removed within & Yow hours or

‘engrene may result

“Release air pressure tom the hydra

ng ca (1) cated on he top

cap)

2.Remove mounting bolts (3) to remove the

‘oomlates

mer me

‘wo2.06.01

UPPERSTRUCTURE / Swing Device

3.Using a vacuum pun, resica he hale tsk =

‘ressue ‘othe regis ange and conn To <

NE

‘operate the pun wie woking.

ug them.

Pe 191, 22 mm

§5.Rerove swing dovce mounting bots (1)

me 10 0m

2x22: €0 b emg)

B00: 62 (24k)

6-Rerove pi (1)

Install eye bot (2) nto he plug hoo

‘tach a wie rope to oye bal (2),

ost the swing dove using cane.

[— :80m

‘wo2-06-02

UPPERSTRUCTURE / Swing Device

INSTALL SWING DEVICE

“Install eye bo (1) tote swing vice. tach @ wie

rope to oye bolt (1) o hast he swing davis. Put

the swing dove onthe mounting locaton.

E10 my at 4 Ne (96 5k)

CAUTION: SWING DEVICE WEIGHT:

{©x22: 601 (27 4a)

EXa0: 62 (28 kg)

.Remove the oye bot bal ug (1).

esa ol 2) secure th suing davis.

E518 me pa £291 (221, OH

[28m ae :99 Nem (20, 4h)

atch hoses (1)

pes 19 mm, 22 m

ae 29 Nm (22 et 3 atm,

‘39 Nem (29,4 wae)

1st the tor pate using mounting bots (1)~(.

move tw vacuum pump. Reinstall the cap on he

yer a ak.

metre

at 240th (96 et, 5 glen)

‘wo2-06-03

UPPERSTRUCTURE / Swing Device

REMOVE SWING DEVICE

(@eexi2E)

‘Al igues shown inthis section ae for X 16.

A.caurion: escaping tui under pressure can 6G

enetrate the skim. causing serous. Injury,

Svold this Marad by releving pressure befor

iaconnecting hydraulic or other lines Tighten

fll connections before applying pressure,

Search for leaks with a plece of cardbosre;

Take care to protect hands and body tom

high-pressure fu so

Wan accident occurs, get immediate medical

attention, Any uid Injected ino the skin must

be surgically removed within 8 few hows oF

‘angrene may rel,

“Release ait passe fom the hydauc al tank by

Toasering cap (1) local on the fp othe tn

Remove cap (0

2.Romovo si mounting bots (1) t9 remove the Hoot

ates,

ett

‘wo2-08-04

UPPERSTRUCTURE / Swing Device

Remove fou hago mounting bots (1) two bos (2).

‘ad wr rope (3) to romove Sea ().

ame 17 om

Remove = (ak) terina (1) fst then romove +

(ted) teina (1),

Usosen four mounting bolls 2) © remove batiory

©.

es? men

S.Remove sx bots (1,2) 10 romove cover (8) and

He (8.

me 19 0m

{6.Rmove bat (1) t0 remove ralay bracket 2.

mt 190m

UPPERSTRUCTURE / Swing Device

7-Remove 10 bolts (1),(2)(8) 10 remove covers (5).

me 7mm

8.Using a vacuum pump, reduce the hycraule tank

‘rosso to the negeive range and continse 10

‘pera the pump whe working,

me iT

'8.Rermove swing mato: hoses (1)~ (4) and lua thom

me 19 mm, 22

10,Remove for swing device mourtng bolt (1).

ame 19mm

rz: 45 (20.540)

BOB: 47 b 18g)

‘wo2-06-06

UPPERSTRUCTURE / Swing Device

11Remave plug (1st oye batt 2) into tho plug

ole.

‘tach @ wire rope to oye bet (2), and host the

fing dvi using ears.

e

INSTALL SWING DEVICE

12.Use a crane to hoist the swing dviea end place it

‘on te mounting postion

me 9m pa 49H BIR Sha)

A cxurion: sua pence wera:

X12: 45 fb (20.5 ka)

EXIS: 47 1b (21.5 Ha)

144Remove tho oy bots and instal the pug.

‘Tighon bal (1) socuro be swing dvi.

me 1mm Pam 49 Nn (95 HFS Kgl

ltl hoses (1)~(4.

me 101mm, 220m

et: 20 Nm (221, shat),

‘30 Nem (29,4 age)

‘wo2-06-07

UPPERSTRUCTURE / Swing Ds

15.istl covers (1(2,(9) using 10 bots 4)(6)(0,

SEITE A

16. Intl olay bracket (2) using bit (1)

ET ren ae: 49 Nem (96 BH, Sham)

17.Intal cover (9) and pat 8) using si bots (1,2.

ET me pam: 49 Nh (86 i Sham)

18.Put atiory (1) back. Tighten bots (2) to secure

‘batory (1) Connect bateyteninas (84,

E17 me pa: 49 Nm 8 WH 5 am)

‘wo2-06-08

UPPERSTRUCTURE / Swing Device

18.Put sas (1) back. Intl hinge mounting bas (2),

weo rap (3), and bot

EAT pa 248 Nem 95 Bt Shot)

2oLinstall the Foor pao using sx tots (.

ET en AH 4B Nim (86 HS Hg m)

21.Tghtenc9p (1) Sate on he hyaute ol an

ae 19 mm

Note: Check hyeraute ol lve. Als necessary.

wo2-06-09

UPPERSTRUCTURE / Swing Device

‘wo2-06-10

UPPERSTRUCTURE / Swing Device

DISASSEMBLE SWING MOTOR

Clean the outside ofthe swing motor ae put & on 8

work bench Bolore aeassombing, make matching

marks en housing (2). valve pate (10), gerter (13),

‘wea plato (15). ana housing (18 10 ad assem.

1. Using eran, host the meter and clamp it in 2

2, Ramove bots (11,

ek: oti,

8. Remove housing (2,

4, Remove O-ing (6 rom housing (2).

5. Remove springs (3), pins (4). sols (6) and (7)

at (8), and valve (9

6. move vate dive (12) and valve pao (10,

7. Remove Oxing (1) rom vale plat (10).

1, Remove goo (19).

2, Remove dive (1) and wear plat (15).

10. Romove Oring (11) and soa (16) fom wear pte

(5)

11, Remove retaining rt

at

12, Remove housing (18) fom the vise.

1 Pull out pron goa (24) om housing (18) using a

prose

14 Remove Oxing (11) rom housing (18).

15. Clamp housing (18) in a vise agin. Remove sock:

‘et bl (21) and retainer 2.

55mm

18. Remove back-up rng (29) and sing (22) hom ro

‘anor (20),

wo2-06-12

UPPERSTRUCTURE / Swing Device

_. MONDE

CVO © ei |

6 Jsbbbb bbb. bbs

et —@

‘wo2-06-13

UPPERSTRUCTURE / Swing Device

ASSEMBLE SWING MOTOR.

loan disessemtiad parts with solvent and dry thom

wih compressed ai. Apply 2 fn of Pyrat 10 i

Prowde now Oring, seae, end ote to replace used

1. ply grease to back-up ring (23), Hing (22), and

(ring (1) ac insta thor to retainer (20),

2. Aoply LOCTITE to sockt bats 21,

Insta retainer (20) to housing (18), then ghten

socket bot (21)

T— : smn

ae 212216 Nm 1.21.5 kan) (9~11 HY

3. Push pinion gear (24) into housing (18) using a

press.

4, Insta retaining ing (17) pion oar (24)

at

5. Apply grease to Oring (1) and neal to hows

nota)

6. Clamp housing (18) in vise, wih He gear side

ang dowd

7. Insert ive (14 int pion gear (24.

8. Aopty grease to sal (16) and Osing (1

‘or thm into wear pate (15).

8. Jen housing (18). wear plate (15), and geotor

(13), ang matching mars.

wo2-06-14

ittiaia

i

t

wo2.06-15

UPPERSTRUCTURE / Swing Device

10, Inert wave drive (12) into gevoter (13)

11, Apply grease to Oxing (11) andinsertitint valve

plate(io

12, nal geo aning ne

‘matching marks. "

13, Place valve (3) ont valve pate (10)

IMPORTANT: Refer tothe lilustration below to

correctly instal valve (3).

14 Apply grease to O-ring (5), spring (3), and pin)

and inser them into housing (2).

15. Apply grease to seal (6) and (7 and install her

replace).

‘wo2-08-16

UPPERSTRUCTURE / Swing Device

16. Insert plat () into housing (2.

Note: Apply a pony of grease to the contact euraces

‘of hovsing (2) and plate (8)

17. Join va plato (10) and housing (2), again the

matching marks and ighien bts (1)

at. : 216%

S54 Nm (50~6.5 kfm) (36~40 be)

wo2-06-18

‘wo2-08-19

UPPERSTRUCTURE / Swing Device

(EX12, EX15, EX22, X30)

x12, xis

UPPERSTRUCTURE / Swing Device

x22, £xI0

wo2-06-21

UPPERSTRUCTURE / Swing Device

DISASSEMBLE

Clean the ouside of the swing motor and securely

place ion @ work bone

1. Gam the motor aa vise

Remove socket bolt (6), bake valve (8), and vave

plat (12)

— : 0mm

2 Remove pin (7) and Ong (3) rom housing (8

3. Remove housing (4 from the vee. Remove rotor

(17) nd pston (20) sesombly and the wut plato

en,

4. Remove pistons (20, retainer (19) bushing (18),

sd in (8) rom rotor (17).

|Acaution: nen removing retning sn (9,

rere to pace snd NOM eens (0 Sd

Sarin (15 ating the spe ot an eve

Wma te opel Wook retain ng 2)

reaher (1) ant sing (19) may Ren ou!

gin severe prone nr

5. Remove retaning rg (12) whde holding down

washer (14) and spring (15) with to oped tool

and a press

Specie Toot ST 4114

at

6. Push out shaft (1) and tlt bearing (2) assembly

from housing (4) using a pase aren.

—

7. Remove Oxing (5) from housing (4)

wo2-06-22

E12, EXIS

‘wo2-06-23

UPPERSTRUCTURE / Swing Device

ASSEMBLE

Coan cisassombled parts with sohent and dry thom

vei compress a. Apply 2 Mn of rau of 10

er pats

Prowde now Orings, seals, and etc to replace used

1. Roply grease to Ong (6) and instal to hosing

2, Push shaft (1) and ball bearing (2) assembty ito

hosing () us laste hme.

‘Noe: Apply af of hyaule oo the contact area of

‘bal Bearing (2) Dowsing (4).

—

2. Insta colar (16), spring (15), and washer (14) no

rotor (17).

4. Install retaining tog (13) whl holding down wash

fr (14) a apg (15) wit tho spocal oot and &

press.

‘Soncal Took ST 4114

at

‘5, Install pin (8) to rotor (17), thon put bushing (18)

onpin

6, Aopty fn of hyde ci to piston (20)

{eta pet (20) and rotamer (10) sezombly ite

voter (7

7. Install trust plat (21) into housing (4.

18. Appt afm of hyrauc of to he contact surtaces

ot piston (20) and rust plats (21),

Insta rotor (17) and. piston (20) assembly ito

ving

8. Clamp hosing (in vis,

10. Apo groaso fo Oring (8), fsa! Ong (9) and

fn ino Dosing (A

11, Agply grase to the contact sutaces of brake

‘ae (8) and vave plate (12)

Insta vale plate (12) ono brake valve (9)

‘wo02-06-24

12 tata cake vate (9) and valve plato (12)

‘ssembly to housing (4) and igton socket BOS

©.

— : 10mm

a 119 Nem (11.8 fm) (891

’

5 0 fl} 6

A 0 38

3

oSSU I PTE 3

am -®

GG {|

} | Le

RS

De

UPPERSTRUCTURE / Swing Device

‘wo2-06-26

UPPERSTRUCTURE /Pilot Valve

———————

REMOVE PILOT VALVE

(eEc2O086x220100)

| fatigues shown Bis section ae for EX 50

i. cavni0n: excaing ta under pressure can i

Mets is hacar by slevg presse bets

| Giscenneeting hydrate or other tines. Tighten

Sl connections ‘before applying pressure,

‘Search for leaks with a plece of cardboarG;

‘Take care to. protect hands and body from

high-pressure tld

get immediate medical

Sted Into the skin must

‘within s few hours

—

‘.Reloase ar pressure from the hydric ol tank by

‘Gosening cap (1 located on Bu Top of he a5

Remove cap (1),

2.Loogen lock ut (1) 10 removo lve (2)

{Loosen tot (3 6 remove boot ()

19:0

Note: For the to cont lever, also remove wire

hamesses a clps

wo2.07-01

UPPERSTRUCTURE /Pilot Valve

{Remove moxeting bol (1) to remove the sand

19mm

4.Disconect pot hoses (1)~(6). Rameve mounting

bolts 710 romeve pilot va (8),

mt 9.0m

INSTALL PILOT VALVE

S5Tighten bolt (2) to sooure pct valve (1). Connect

lot hoses ()~ (8.

190mm

Blot ho stand using bo (1)

me 19:00

wo2-07-02

UPPERSTRUCTURE /Pilot Valve

7 instal boot (8) using mouring ols (4)

instal lover (1) using lock nu 2). ®

pee On os

wo2-07-03

UPPERSTRUCTURE / Pilot Valve

FRONT PILOT VALVE DRAWING FOR DISASSEMBLY (EX12, EX15, EX22, EX30)

UPPERSTRUCTURE / Pilot Valve

-

1. Wie off he boot cari and cean the outs of j

av, hen place Wo valve unt on aio wih

fo peo ace Lb

the bck ot, and remove tho conve Sever

atta’

me 191mm, 22m

2. Remove jot sere (1). 7

19m, 24 mm ,

ame : 190m, 24 on, :

—_

UPPERSTRUCTURE / Pilot Valve

3. Remove cam (2,

‘Secure the plate with wo MB xpitch 1.25 bol O- i“

me 2b wen

4 Locsin universal jit 2) nd remove i rom the

cing.

me 7 01

6. Turn over casing (16)

Disassembling of easing >

6, Loosen and remove socket bot (14),

1: 100m

wo2-07-06

UPPERSTRUCTURE / Pilot Valve

7. Pa ot pile (1) ng 8 ig WOH OE « 2, on ee

<

ir

—

8, Remove O-ng (11) kom he plate { ee

8, Remove Oring (12) rom to casing,

wo2-07-07

UPPERSTRUCTURE / Pilot Valve

11, Tur over casing (1)

-

12, instal he to the eiversl jit mounting halo of

the casing hon ighton pat (23).

Jig No: ST 7924

14. Groduaty loosen the jg, The spook assembly and

at (29) are ited by sping pressure

wo2-07-08

UPPERSTRUCTURE / Pilot Valve

Remove thei tom the casing

ia No: ST 7928

Remove plate (2)

omove the pusher assembiy.

18. Remove pushers (4) and (27) kom bushings (6)

nd 28),

UPPERSTRUCTURE / Pilot Valve

18. Romove O-ings (7) and (4 trom bushings (6) ad

5)

20, Romove ol seals (6) and (26) om bushings (6)

and (25),

@

‘Disassembling of spoot assembly >

21. Remove tho spool assembly fom each por.

NOTE: Do not torget 10 cae the port No. on

ach pot femoved, inorder 1 avoid them

from becoming med up.

UPPERSTRUCTURE / Pilot Valve

22. Compress sping (9) and (2), and romove spacer

(22) tom soot (17),

28, Remove springs (9) and (20) and shim (18) kom

spoat (17).

24, Remove sping guides (8) and (2) and springs (10)

fan (19) rom each por.

wo2.07-11

UPPERSTRUCTURE / Pilot Valve

FRONT PILOT VALVE DRAWING FOR ASSEMBLY

UPPERSTRUCTURE / Pilot Valve