Professional Documents

Culture Documents

ButtonHead Brochure RevJ

ButtonHead Brochure RevJ

Uploaded by

Sergio Ito SunleyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ButtonHead Brochure RevJ

ButtonHead Brochure RevJ

Uploaded by

Sergio Ito SunleyCopyright:

Available Formats

PRODUCTS INC.

A SUBSIDIARY OF FC INDUSTRIES, INC.

BPI® BUTTONHEAD BPI® BUTTONHEAD EXTENDER

COLD SWAGED HEADED REBAR DEVICE COLD SWAGED HEADED REBAR DEVICE FOR FUTURE EXPANSION

BNH 5Ab HEAD – for transmitting bond force from the reinforcing bar to concrete by a DUAL USE – behaves as a headed reinforcing bar device by itself, AND OR as a full

combination of head bearing & development length.* A ‘standard’ head size for most applications.

CALTRANS Approved. mechanical splice when connected to a standard GRIP-TWIST® male coupler.

BNX 10Ab HEAD – has larger area to transmit full force in bar by head bearing alone. Generally 5Ab HEAD – has the same bearing area as the standard BPI ButtonHEAD.

used in sections that may be required to withstand higher forces.

POSITIVE INTERNAL STOP – for easy control of rebar insertion before shop-

SHOP INSTALLATION – Attaches directly to the reinforcing bar - no thread cutting required. Shop swaging.

swaged quickly and efficiently.

HIGH STRENGTH – Connections to bar exceed the specified yield strength of the bar, fy, for TAPER THREAD – for self locating and quick assembly when extending the reinforcing

ASTM . A615 and A706, Grades 60 and 75 as required by ACI 318 Section 12.6. Confirming in-air bar into the next phase of construction. Plastic thread protection is included.

tensile tests develop the specified tensile strength of uncoated Grade 60 bars, A615 and A706.

REPLACES HOOKS – No special bend direction – alleviates congestion – for beam-column joints, TYPE 1 STRENGTH – as a full mechanical splice per ACI 318 Chapter 12, 1.25 x

knee joints, pile caps, column roof slab connections; replaces stirrup bars used as confinement steel. specified yield, fy, ASTM A 615 or A706 Grade 60.

KEY ADVANTAGES – Avoids lengthy hook extensions / complex stress patterns. No heat, welding TYPE 2 CAPACITY – as confirmed by in-air testing to 90,000 psi minimum for uncoated

or hot forging – no special chemistry or rebar grade requirements, no bending or cracking of rebars. ASTM A 615 Grade 60. 80,000 psi minimum for uncoated ASTM A706 Grade 60.

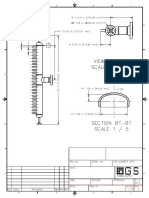

ButtonHead BNH, 5Ab Rebar Swage ButtonHead Extender, 5Ab Rebar Swage

(Before Swaging) Size Length (Before Swaging) Size Length Length

B

US [Metric] B (in.) US [Metric] B (in.) L (in.)

B

Sizes Sizes

#4 - #11 #14, #18 #4 [13] 7/8 #4 [13] 7/ 8 2

L

D D #5 [16] 15/16 B #5 [16] 15/1 6 2 5/8

#6 [19] 1 1/4 #6 [19] 1 1/4 3 1/16

#7 [22] 1 3/8 #7 [22] 1 3/8 3 1/2

D

ButtonHead BNX, 10Ab #8 [25] 1 1/2 #8 [25] 1 1/2 4

(Before Swaging) B

#9 [29] 1 3/4 #9 [29] 1 3/4 4 3/8

Sizes #4 - #11 #10 [32] 1 7/8 #10 [ 32] 1 7/8 5

D #11 [36] 2 1/8 #11 [36] 2 1/8 5 11/16

#14 [43] 2 7/8

#18 [57] 4 3/8

®

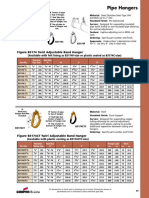

ButtonHead BNH, 5Ab Head Diameter and Weight Head Diameter and Weight ButtonHead Extender, 5Ab

BNH 5Ab• Series BNX 10Ab•• Series 5Ab • Series (After Swaging)

Sizes D (in.) Wt (lb.) D (in.) Wt (lb.) D (in.) Wt (lb.)

#4 - #11 Sizes

#14, #18 #4 1 3/8 0.31 1 3/4 0.50 #4 1 3/8 0.46

#5 1 3/4 0.54 2 3/16 0.90 #5 1 3/4 0.96

#6 1 7/8 0.74 2 3/8 1.20 #6 1 7/8 1.33

#7 2 3/8 1.34 2 7/8 2.25 #7 2 3/8 2.34

#8 2 3/4 2.04 3 1/4 3.45 #8 2 3/4 3.63

ButtonHead #9 2 7/8 2.55 3 9/16 4.25 #9 2 7/8 4.30

BNX, 10Ab #10 3 3/8 3.84 4 6.25 #10 3 3/8 6.91

Sizes #4 - #11 #11 3 13/16 5.60 4 1/2 9.35 #11 3 13/16 10.7

• Head Cross Sectional Area is approximately 5 x Rebar Area

#14 3 7/8 9.55 •• Head Cross Sectional Area is approximately 10 x Rebar Area

#18 5 18.6

** HOW TO SPECIFY BPI® BUTTONHEAD HEADED DEVICES

By Name: By Generic Description:

BAR-TO-HEAD ®

BPI ButtonHead Headed Ends for reinforcing bars shall be the cold-swaged head type, installed by

by BarSplice Products, Inc., Dayton OH octagonal dies to produce a 5Ab or 10Ab Head size (Specify Head Size).

BAR-TO-HEAD EXTENSION BPI® ButtonHead Extender Headed Ends for reinforcing bars with provision for Future Extension shall be the

by BarSplice Products, Inc., Dayton OH cold-swaged head type, installed by octagonal dies to produce a 5Ab Head size.

** Include bar size(s), bar type and grade. Include statement: “Parts shall be manufactured to the quality requirements of ISO 9001.”

BPI® ButtonHead cold-swaged headed devices are made from high quality steel that meets the chemistry

and grade requirements of ASTM A519 or A576. Installed performance satisfies the CLASS HA requirements of

ASTM A970-12 and ACI 318-11 Section 3.5.9. Develops the specified tensile strength of uncoated Grade 60 bar.

Powerful hydraulically actuated presses with color-coded octagonal die sets are utilized in fabricating shops for the most efficient swaging

operation. Swaging pressure is factory preset and equipment is automated to release after each swaging ‘bite’ or pressing. When components

have been compressed onto the reinforcing bar by cold-swaging they become mechanically interlocked with the rebar deformation.

Cold swaging technology for mechanical anchorage and splicing is one of the most established, developed, and refined connection methods worldwide.

Key to cold swaging success is its simplicity, low cost and adaptability. There is no loss of reinforcing bar cross-sectional area at the anchorage location

so the system is a natural choice when considering the objectives of seismic design and safety related applications. BPI-Grip swaging equipment is

easy to use and may be leased or purchased. Splicing manuals provided with equipment explain step-by-step installation and safety information.

While the information contained in this document is believed to be accurate at the time of publication, BPI reserves the right to make changes, design modifications,

REV.J 11/20/2012

corrections and other revisions as it sees fit, without notice. All products described herein are supplied in accordance with BPI’s standard Terms and Conditions of Sale. This

document is of a promotional nature only. Aspects of structural design, evaluation of product fitness for use, suitability or similar attributes are the responsibility of others.

BarSplice Products, Inc., 4900 Webster Street, Dayton OH 45414, USA ®

Tel: (937) 275-8700 Fax: (937) 275-9566 E-mail: bar@barsplice.com

MEMBER Copyright © 2012, Barsplice Products, Inc., “BPI”. All rights reserved. MEMBER

You might also like

- Fibroblast Training ManualDocument49 pagesFibroblast Training Manual72034430100% (14)

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 12-2103471 Heat Transfer in EngineDocument12 pages12-2103471 Heat Transfer in EngineRamasamikannan RamasamikannanNo ratings yet

- Chap EDocument44 pagesChap ERANJITH K PNo ratings yet

- TAPER GRIP-TWIST DataSheet - RevC-red PDFDocument2 pagesTAPER GRIP-TWIST DataSheet - RevC-red PDFGonzalo AbarcaNo ratings yet

- Rotary Drilling Products Raise Bore PDFDocument3 pagesRotary Drilling Products Raise Bore PDFmanuel_plfNo ratings yet

- 4.3.7 HLC Sleeve Anchor: Anchoring SystemsDocument4 pages4.3.7 HLC Sleeve Anchor: Anchoring SystemsjavierNo ratings yet

- Swivel Direction Flag BlockDocument1 pageSwivel Direction Flag BlockNaval2014DNNo ratings yet

- Ny-Wg enDocument2 pagesNy-Wg enСекретаріат ЄСNo ratings yet

- Browning Bushing HubsDocument8 pagesBrowning Bushing HubsJeff SauckNo ratings yet

- View BR-BR SCALE 1 / 15: Global SupplyDocument1 pageView BR-BR SCALE 1 / 15: Global SupplyAnderson RodriguezNo ratings yet

- HES 5000 Install InstructionsDocument6 pagesHES 5000 Install InstructionsYugandher BadanaNo ratings yet

- API 650 Tank Nozzle Stand Out - EditableDocument20 pagesAPI 650 Tank Nozzle Stand Out - EditableShaaban NoamanNo ratings yet

- BBI Master CatalogDocument53 pagesBBI Master CatalogJill McIntoshNo ratings yet

- KP0800 Te PDFDocument8 pagesKP0800 Te PDFisaac grossiNo ratings yet

- HCD Series: High Capacity Drum LouversDocument8 pagesHCD Series: High Capacity Drum LouversElvis Ruben Piza MerchanNo ratings yet

- Stainless Steel Weld Neck Flange Technical Data Sheet: TypeDocument5 pagesStainless Steel Weld Neck Flange Technical Data Sheet: TypeÁngela GarzónNo ratings yet

- Bujes y Manguitos BrowningDocument8 pagesBujes y Manguitos BrowningFranco Sanchez QuirogaNo ratings yet

- API STD 650 - Shell Nozzles (In) : Standards Flanged FittingDocument2 pagesAPI STD 650 - Shell Nozzles (In) : Standards Flanged Fittingwenfang leeNo ratings yet

- Presentasi Artas New 23 Rev.8 Link Gdrive-14Document1 pagePresentasi Artas New 23 Rev.8 Link Gdrive-14ilhamuddin haqNo ratings yet

- DIMENSIONS (Inches) : Rebar Size US (Metric) Coupler Outside Diameter (In.)Document2 pagesDIMENSIONS (Inches) : Rebar Size US (Metric) Coupler Outside Diameter (In.)Marco Antonio Quispe BerrocalNo ratings yet

- Table J3.4 - Minimum Edge DistancesDocument1 pageTable J3.4 - Minimum Edge DistancesUpadrasta HarishNo ratings yet

- Victaulic Balancing Valves TA Series 786H/787H/788/789 and Series 78KHDocument16 pagesVictaulic Balancing Valves TA Series 786H/787H/788/789 and Series 78KHal hidayatNo ratings yet

- Adjustable Anchor Channel Corner ConnectionsDocument2 pagesAdjustable Anchor Channel Corner ConnectionsMika SinghNo ratings yet

- B11-SD-S-FND-B2-006 - 00 Ver-02 (BBS)Document5 pagesB11-SD-S-FND-B2-006 - 00 Ver-02 (BBS)Yasir IqbalNo ratings yet

- HDI / HDI-L Drop-In Anchor 4.3.4: 4.3.4.1 Product DescriptionDocument5 pagesHDI / HDI-L Drop-In Anchor 4.3.4: 4.3.4.1 Product DescriptionjavierNo ratings yet

- ENG.001 Mechanical EngineDocument44 pagesENG.001 Mechanical EngineOmar Diaz Segura100% (1)

- LB&A CatalogueDocument127 pagesLB&A CataloguekingdbmNo ratings yet

- CATALOG K21 'Adjustabable Reamers'Document19 pagesCATALOG K21 'Adjustabable Reamers'Patrizio MassaroNo ratings yet

- C A 2018 DIAB DesigninfoDocument2 pagesC A 2018 DIAB Designinfoaandueza_1No ratings yet

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outace1205No ratings yet

- Whitworth Pipe Threads - BSPPDocument7 pagesWhitworth Pipe Threads - BSPPJONATHAN SOTONo ratings yet

- Pipe Hangers: Figure B3174 Twirl Adjustable Band HangerDocument7 pagesPipe Hangers: Figure B3174 Twirl Adjustable Band HangermiturraNo ratings yet

- Hreaded Ccessories: FIG. 38 Forged Steel ClevisDocument1 pageHreaded Ccessories: FIG. 38 Forged Steel Clevisabhishek yadavNo ratings yet

- Shaker Sewing StepsDocument3 pagesShaker Sewing StepsGhassan El-baalbakiNo ratings yet

- 360 Sled Kit Project Plans: Included ItemsDocument12 pages360 Sled Kit Project Plans: Included ItemsJaime Montiel100% (1)

- B11-SD-S-FND-B2-006 - 00 Ver-02 (BBS)Document5 pagesB11-SD-S-FND-B2-006 - 00 Ver-02 (BBS)yasirjurabaNo ratings yet

- Rebar RemeshDocument3 pagesRebar RemeshLeon ZidaneNo ratings yet

- ENG0011 DB DE Mechanical EngineDocument44 pagesENG0011 DB DE Mechanical EngineCinthya CollaguazoNo ratings yet

- Catalog Insert BowlsDocument63 pagesCatalog Insert BowlsahmedNo ratings yet

- Bar Bending Schedule Sheet FPSDocument2 pagesBar Bending Schedule Sheet FPSMuhammad Abdul Wajid RaiNo ratings yet

- VTB - XL With GearboxDocument10 pagesVTB - XL With Gearboxr rNo ratings yet

- Thread Roll Product ChartDocument3 pagesThread Roll Product ChartKhoirul FeriansyahNo ratings yet

- Catalogo Electrica Cqd-16hDocument2 pagesCatalogo Electrica Cqd-16hPipe BonillaNo ratings yet

- Casing Clean Up Tools Description: Casing Scraper Junk Basket Junk SubDocument3 pagesCasing Clean Up Tools Description: Casing Scraper Junk Basket Junk Subnurwinanto01No ratings yet

- Switch de PaletaDocument1 pageSwitch de Paletaeduardore.arcNo ratings yet

- FT - Estructura - Everest - CrossRail Tilt Up - CrossRail Tilt Up Technical Sheet US02-1016Document2 pagesFT - Estructura - Everest - CrossRail Tilt Up - CrossRail Tilt Up Technical Sheet US02-1016Josef Farias100% (1)

- IN33001Document2 pagesIN33001Khalid ZaeemNo ratings yet

- Trompeta Equivalencies Romera BrassDocument16 pagesTrompeta Equivalencies Romera BrassFrancisco Javier SernaNo ratings yet

- Vicflex Style Vs1 Dry Sprinkler Models V3505, V3506, V3509, V3510, V3517, V3518Document18 pagesVicflex Style Vs1 Dry Sprinkler Models V3505, V3506, V3509, V3510, V3517, V3518Riaz EbrahimNo ratings yet

- FAUDI Aviation Elements-EnDocument33 pagesFAUDI Aviation Elements-Enviktor_gligorov100% (1)

- B16.5 Size ListDocument3 pagesB16.5 Size ListSue EpicNo ratings yet

- Multi Nozzle DiffuserDocument20 pagesMulti Nozzle Diffusershahin msNo ratings yet

- Assembly and Installation Instructions: Document 451424 Wall Mount Collar For Sidewall Propeller FansDocument4 pagesAssembly and Installation Instructions: Document 451424 Wall Mount Collar For Sidewall Propeller FansCristhian Cevallos EstupiñanNo ratings yet

- Data Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Document2 pagesData Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Le DucNo ratings yet

- Small Size Valves CatalogDocument5 pagesSmall Size Valves Cataloguli hasibuanNo ratings yet

- Technical-Information-HILTI HITI HY 270Document13 pagesTechnical-Information-HILTI HITI HY 270michael martinNo ratings yet

- Casing SpoolDocument10 pagesCasing SpoolAli mohammadNo ratings yet

- Compact Manual: Parts DiagramDocument4 pagesCompact Manual: Parts Diagramluismf14No ratings yet

- Caja de Montaje BB-R Kidde 75-000000-006Document4 pagesCaja de Montaje BB-R Kidde 75-000000-006JORGE ALOR RODRIGUEZNo ratings yet

- Rotary Drilling Products Raise Bore PDFDocument3 pagesRotary Drilling Products Raise Bore PDFIng del PeleNo ratings yet

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 3 out of 5 stars3/5 (2)

- Tentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Document2 pagesTentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Yayang NasrudinNo ratings yet

- Supplimentary Material: LU DecompositionDocument14 pagesSupplimentary Material: LU DecompositionGilNo ratings yet

- Ibrahim Raja August 2022 Theraplay ReportDocument6 pagesIbrahim Raja August 2022 Theraplay Reportfatma522No ratings yet

- Company LawDocument15 pagesCompany Lawpreetibajaj100% (2)

- Syllabus: Cambridge Igcse First Language EnglishDocument52 pagesSyllabus: Cambridge Igcse First Language EnglishNdache PermataNo ratings yet

- 18-Soft Soil Creep Model - PlaxisDocument5 pages18-Soft Soil Creep Model - PlaxisVa Ni SkyNo ratings yet

- PM265 ch2Document47 pagesPM265 ch2M. AhmedNo ratings yet

- Word Formation - Practice 0Document4 pagesWord Formation - Practice 0Kim Ngân PhanNo ratings yet

- The 10 Commandments (MonkeyDM)Document45 pagesThe 10 Commandments (MonkeyDM)Claudio GonzalezNo ratings yet

- Huawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0Document5 pagesHuawei Enterprise Network CloudEngine S Series Campus Switch Portfolio - Print - A0pkielechNo ratings yet

- A8Ponetics: Series SystemsDocument86 pagesA8Ponetics: Series SystemsdmitroivanenkoNo ratings yet

- Letter From Harvard Leaders To EPA's Andrew Wheeler On Proposed Science PolicyDocument60 pagesLetter From Harvard Leaders To EPA's Andrew Wheeler On Proposed Science PolicyEmily AtkinNo ratings yet

- Fkasa - Norhamiza Rossli (Cd9298)Document24 pagesFkasa - Norhamiza Rossli (Cd9298)Farahana AnuarNo ratings yet

- ABB Control TP180DA DatasheetDocument3 pagesABB Control TP180DA Datasheetntdien923100% (1)

- Climate Variability and Climate Change 2016Document91 pagesClimate Variability and Climate Change 2016Laila Guarin100% (1)

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- 01 August 2023 - Manifest Boat Babo - LNGDocument1 page01 August 2023 - Manifest Boat Babo - LNGSeverinus SHIPBintuniNo ratings yet

- 2014Document106 pages2014Gokul100% (1)

- KVT FP Quick Fasteners en 21-03-2013 WebDocument16 pagesKVT FP Quick Fasteners en 21-03-2013 WebWK SinnNo ratings yet

- Polymer StructureDocument35 pagesPolymer StructureAlexander DavidNo ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- CV Hamza SadrijaDocument3 pagesCV Hamza SadrijaHamza SadrijaNo ratings yet

- D56261GC10 Les01Document36 pagesD56261GC10 Les01Elmer RodriguezNo ratings yet

- Chemistry 10th Edition Whitten Test BankDocument12 pagesChemistry 10th Edition Whitten Test BankEdwinMyersbnztx100% (64)

- Catalog 2010 - 2011 Optical Warning SystemsDocument56 pagesCatalog 2010 - 2011 Optical Warning SystemsSamir FerreiraNo ratings yet

- Analyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriDocument71 pagesAnalyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriAgnys Gomes - DR UNITECNo ratings yet