Professional Documents

Culture Documents

Design of Longitudinal Girders: Exterior Girder

Design of Longitudinal Girders: Exterior Girder

Uploaded by

teweldeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Longitudinal Girders: Exterior Girder

Design of Longitudinal Girders: Exterior Girder

Uploaded by

teweldeCopyright:

Available Formats

Design of Longitudinal Girders 26.

752 Gpa (Modulus Elasticity of concrete)

Diaphragm loadDiaphragm

on exterior load

girder

on=interior

(Dwi*(Dw-ts)*(Gs-b)/2)Yc

girder = (Di*(Dw-ts)*(Gs-b))Y

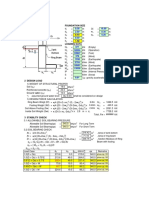

1. Dead load effect due to web and diaphragm wt. Own weight of web= b*(Dw-ts)Yc

Structural depth, Dw = 1430 mm 10.3 7.25

Web width, b= 350 mm 14.5

Own weight of web= b*(Dw-ts)Yc=10.3KN/m. , Yc=2400 Kg/m3

Diaphragm load on exterior girder = (Dwi*(Dw-ts)*(Gs-b)/2)Yc= 7.25 KN 25.069 KN/m

Diaphragm load on interior girder = (Di*(Dw-ts)*(Gs-b))Yc= 14.5 KN 1.851 18.88

19.248 0.926

2. Slab reactions (dead loads & live loads) transferred to girders 4.225 20.4

Exterior Girder 255.7038

Reactions, DC: RA = 14.769+10.3=25.069 KN/m (including web wt) 7.25 KN 12.5345

DW: RA = 1.851 KN/m 3.625

Moments, DC: M(x)= 255.704X-12.535X^2+7.25X/2 196.3296

DW: M(x)= 18.88X-0.926X^2 9.624

7.25

Interior Girder

Reactions, DC: RB = 8.948+10.3=19.248 KN/m (including web wt.) 14.5 KN

DW: RB = 4.225 KN/m 1

Moments, DC: M(x)= 196.33X-9.624X^2+14.5X/2

DW: M(x)= 43.095X-2.113X^2

3. Distribution factors for Moments and Shears

The distribution factors for moment and shear for both external and internal girders are obtained from the empirical formula given in

Table Art 4.6.2.2-1 of AASHTO 1998.

3.1.1 Distribution factors for Moment

a) Interior beams with concrete decks: [Table Art 4.6.2.2b and 2b-1]

Girder distribution factor with multiple presence factor included mg is,

One Lane loaded:

mgSIm=0.06+(Gs/4.3)0.4*(Gs/L)0.3*(Kg/Lts3)0.1 for preliminary design, (Kg/Lts3)=1 and L is c/c of bridge length.

Two or more lanes loaded:

mgmIm=0.075+(Gs/2.9)0.6*(Gs/L)0.2*(Kg/Lts3)0.1

Skew correction factor= 1-C1(tanθ)1.5; C1=(Gs/L)0.5*(Kg/Lts3)0.25

mgslm= 0.467 and mgmlm= 0.641

Skew Correction Factor =1

Thus, mgslm= 0.467 and mgmlm= 0.641

b) Exterior beams: [Table Art 4.6.2.2d and 2d-1]

One lane loaded: Lever Rule 0.517 0.431

∑MB=0 , R=0.431P mgsem= 1.2*0.431= 0.517

Two or more lanes loaded

mgmem=e*mgmIm 0.18

where, e=0.77+Cx/2.8 Cx= 0.18 m 0.834 1<

e= 0.834 <1, thus use e=1 mgmem= 0.641

3.1.2 Distribution factors for Shear

a) Interior beams (L= 20.8

mgslv= 0.36+Gs/7.6= 0.665 0.36+Gs/7.6 0.665 0.665

mgmlv= 0.2+Gs/3.6-(Gs/L)^2= 0.797 0.2+Gs/3.6-(Gs/L)^2= 0.797 0.797

Skew correction factor= 1+0.2(Kg/Lts3)0.3tanθ

Skew Correction Factor =1 mgslv= 0.665 and mgmlv= 0.797

b) Exterior beams

One lane loaded: Lever Rule

mgsev= 1.2*0.431= 0.517 0.517

Two or more lanes loaded

mgmev=e*mgsIv where, e=0.6+Cx/3 0.66

e= 0.66 mgmev= 0.526

Prepared by: Abrham Gebre Girder Design 1

0

Influence Lines for Bending Moment and Shear Force

4. Distributed Live Load Force Effects 0 2.04 4.08 6.12 8.16 10.2

Dual design vehicular loads are considered. 0 2.04 4.08 6.12 8.16 10.2

i) Influence Line for Live Load Moment (Truck Load) Rank 16 1221.40

X is the position of the rear wheel. 1227.294 X = 9.18 m Mtr(x)=1224.9 KN-m (IM is consid

At X = 9.18 m, Mtr(x)=1224.9 KN-m (IM is considered.) 9.18 1224.900

23

24 0.625

0.65 12.75

13.26 7.65 m1 4.78125

7.14 4.641

m2 2.09375

1.846

m3 -0.59375

-0.949

m2 2.09375

1.846

m3

00

Mtr 996.875

940.615

9.18

0.00 5.05

24.00 3.11

0.00 1.18

0

9.18 0.00

5.05 13.4813.48 0 3.11 17.7817.78 0 1.18 9.189.18 9.3KN/m5.050

13.48

17.78 3.11

1.18 145 145

20.4020.40 0.00 5.05 9.18

0 0.000 35 5.049

3.114

13.4813.48 5.6 3.57 17.7817.78 9.18 9.18 4.57 3.57

3.11

1.179

9.180

0.00

0.00 0.00

0.00 00 00 00 00 -3 -3

0.00

0.00 0.00

0.00 00 00 0 0 00

1.18

0.00

00.000.00

0 5 10 15 20 25

ii) Influence Line for live Load Moment (Tandem Load) Rank 19 1049.895

At X = 10.71 m, Mtm(x) =1049.895 KN-m (IM is considered.) 1056.495 X = 10.71 m Mtm(x) =1049.895 KN-m (IM is co

0 0.00 10.71 0 11.91 0

10.71 8.00 10.71 8.00 11.91 4.00

11.91 4.00 5.09

20.40 0.00

0 110 1104.46 0 0

0 0.00 0 0

10.71 9.20 11.91

10.71 10.4 11.91

10.71

0.00 0.00 0 0 8

0 0

0 5 10 15 20 25

0

iii) Influence Line for Shear Force (Truck Load) 20.40

Vtr =279.681 KN/m279.681

At X =0 m , the shear force due to truck load, Vtr(x) =279.681 KN X =0 m Vtr(x) =279.681 KN

0 0

0 0

0 0

9.3KN/m

0 20.4 1 0 1.2 0 16.2 16.2 0 0.206

145

20.4 0 145 0 -1 1.2 0.941 17.400 17.400 0 0.147

35

20.4 0 0 -1 1.2

0.941

1

0.789

0 1.6 1.2 0.578 1.6

0 2 1.2 2

0 0 0

0 5 10 15 20 25

iv) Influence Line for Shear Force (Tandem Load)

At X =0 m , the shear force due to tandem load, Vtm(x) =252.359 KN X =0 m Vtm(x) =252.359 KN

110 110

1 0.941

0.206

0.147

0 0

0 5 10 15 20 25

Prepared by: Abrham Gebre Girder Design 2

5. Select Resistance Factors 1 1

Strength Limit States (RC) 1 1 0.95

Flexure & Torsion Flexure & Torsion 1 i) Strength Limit State 1.00 0.95

Resistance Factor = 1 Shear & Torsion 1 ii) Service Limit State 0.90 1

6. Select Load Modifiers Concrete in strut & Tie model 0.70 1.05

i) Strength Limit State 1

i) Ductility 0.95 1.25 [Art. 1.3.3] dc 1.25

ii) Redundancy 0.95 1.50 [Art. 1.3.4] dw 1.5

iii) Importancy 1.05 1.75 [Art. 1.3.5] LL 1.75

Load Modifier = 0.95 1.00 FR 0.75

7. Select Applicable Load Combinations

i) Strength Limit State U=0.95(1.25DC+1.50DW+1.75(LL+IM)+1.00FR+TG)

Seismic Force Effects 1

From EBCS-8, the site and acceleration coefficients are selected for the particular site condition. 0.05 Site coefficient =

For zone I Acceleration coefficient = 1

a= Site coefficient = 1 Zone I I

A = Acceleration coefficient = 0.05 Zone II 1

Zone III

The seismic horizontal force is, FH = Wb*a*A Zone IV

where: Wb is the total weight of the bridge

Weight of components Wt. (KN) 108.468

Slab 620.736 Thus, FH = 108.468 KN 54.234

Wearing surface 252.057 Earth quake force transferred to one support is 1/2FH = 54.234 KN

Overhang Slab & Curbs 195.886 (This force is applied at the bearings)

Barriers 149.760 Total dead load reaction transferred at one support is 1/2Wb

1/2Wb = 1084.68 KN

Girders (internal & external) 857.002 The coefficient of friction between the bearing and concrete beam seat

Diaphragms 93.917 at abutment, μ is:

Total weight, Wb 2169.360 μ = 0.5 > 542.34

The frictional resistance force developed between the interface is μ * dead load reaction = 542.34 KN > 54.234 KN. 1000

Earth quake force is negligible. 1

8. Investigate Strength Limit State

It is necessary to calculate moment and shear force at different locations to determine the bar cut off points and to calculate

spacing of stirrups.

9. Design Shear and Moment Computaions

Distribution factors for moments and shear forces, mg is applied only on live load forces.

a) Interior Girder

i) Shear Force 0.797

X Vtr Vtm Vln Vdc Vdw VD VDU

0 0 279.681 252.359 94.860 203.580 43.095 921.725 545.184 298.509

0.1 2.04 247.181 206.599 76.837 164.314 34.474 781.657 457.030

0.2 4.08 214.681 170.079 72.627 125.048 25.853 659.893 379.886

0.3 6.12 182.181 147.529 68.536 85.782 17.232 538.286 302.836

0.4 8.16 149.681 125.529 64.564 46.516 8.611 416.836 225.881

0.5 10.2 117.181 103.529 60.710 7.250 -0.01 295.542 149.020

0.55 11.22 100.931 92.529 56.975 -117.797 -4.321 107.319 3.733

0.6 12.24 85.436 81.529 53.359 -137.430 -8.631 45.765 -35.442

0.65 13.26 70.936 70.529 49.861 -157.063 -12.942 -13.880 -73.730

279.681 94.860 921.725 921.725

VDmax=0.95*[mgv*1.75[1.33*Max(Vtr,Vtm)+Vln]+(1.25*Vdc+1.5*Vdw)] = 921.725 KN

Prepared by: Abrham Gebre Girder Design 3

ii) Moment 0.641

X Mtr Mtm Mln Mdc Mdw MD MDU

0.00 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.00000

362.5 2.04 504.250 390.720 174.163 375.252 79.120 1458.646 889.235 454.37230

4.08 875.900 691.680 309.623 670.401 140.654 2567.927 1570.975 811.05520

6.12 1114.950 902.880 406.380 885.448 184.600 3327.843 2045.221 1070.04871

8.16 1221.400 1024.320 464.435 1020.393 210.960 3738.393 2311.973 1231.35281

10.20 1195.250 1056.000 483.786 1075.235 219.732 3799.578 2371.230 1294.96752

11.22 1132.450 1038.180 478.948 1057.828 217.524 3681.595 2308.258 1275.35135

12.24 1045.740 997.920 464.435 1020.395 210.918 3489.367 2199.335 1231.31283

13.26

1221.400 940.615

1056.000 935.220 440.245 962.936 199.916

2371.230 3230.683

3799.578 2047.983 1162.85196

110

1294.96752 1294.968

MDmax=0.95*[mgm1.75[1.33*Max(Mtr,Mtm)+Mln]+(1.25*Mdc+1.5*Mdw)] = 3799.578 KN-m

b) Exterior Girder

i) Shear Force 743.094 197.009 0.526

X Vtr Vtm Vln Vdc Vdw VD VDU

0 0 279.681 252.359 94.860 259.329 18.880 743.094 475.218 197.009

0.1 2.04 247.181 206.599 76.837 208.186 15.102 623.418 393.722

0.2 4.08 214.681 170.079 72.627 157.043 11.324 515.822 319.492

0.3 6.12 182.181 147.529 68.536 105.901 7.546 408.329 245.324

0.4 8.16 149.681 125.529 64.564 54.758 3.768 300.941 171.219

0.5 10.2 117.181 103.529 60.710 3.615 -0.010 193.656 97.176

0.55 11.22 100.931 92.529 56.975 -29.206 -1.899 129.823 51.953

0.6 12.24 85.436 81.529 53.359 -54.778 -3.788 75.580 14.440

0.65 13.26 70.936 70.529 49.861 -80.349 -5.678 22.599 -22.487

279.681 94.860 #REF!

VDmax=0.95*[mgv*1.75[1.33*Max(Vtr,Vtm)+Vln]+(1.25*Vdc+1.5*Vdw)] = 743.094 KN

ii) Moment

0.641

X Mtr Mtm Mln Mdc Mdw MD MDU

0.00 0.000 0.000 0.000 0.0000.000 0.000 0.000 0.000

376.4 2.04 504.250 390.720 174.163 476.866

34.662 1515.959 946.390 511.527

4.08 875.900 691.680 309.623 849.400

61.616 2667.859 1670.936 911.016

6.12 1114.950 902.880 406.380 1117.603

80.863 3455.700 2173.638 1198.465

8.16 1221.400 1024.320 464.435 1281.474

92.403 3879.483 2454.497 1373.877

10.20 1195.250 1056.000 483.786 1341.014

96.235 3939.207 2513.511 1437.249

11.22 1132.450 1038.180 478.948 1324.265

95.261 3823.766 2452.432 1419.526

12.24 1045.740 997.920 464.435 1281.433

92.360 3630.406 2341.815 1373.793

13.26 940.615 935.220 440.245 1212.519

87.532 3366.915 2185.182 1300.051

2513.51144 1437.249

MDmax=0.95[mgm1.75[1.33*Max(Mtr,Mtm)+Mln]+(1.25*Mdc+1.5*Mdw)] = 3939.207 KN-m

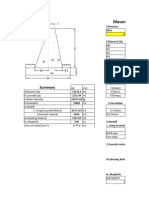

Checking the adequacy of the section 3939.207

The section is checked for the maximum design moment whether the initial depth under consideration is sufficed or not.

Interior Girder, MD = 3799.578 KN-m 3799.578

3799.578*E+6 (The section is 1.53

sufficed!)

dic =Sqrt( ) =479.875 mm.

0.254*b*f'c 479.875

Effective flange width, bi

1/4*Effective span =5.1 m 1/4*Effective span 5.100

bi < 12*tmin+bw = 2.51 m bi= 2.320 2.510

average spacing of adjacent beams= 2.32 m average spacing of adjacent beams

2.32

Check depth: d = 479.875mm (The section is sufficed!)

0.42*d = 201.548 mm > 180 mm (T beam ) 201.548

Effective depth = 1268 mm >

1268

Prepared by: Abrham Gebre Girder Design 4

Exterior Girder, MD = 3939.207 KN-m 3939.207 1268 T beam

3939.207*E+6 (The section is 1.53

sufficed!)

dic =Sqrt( )= 508.747 mm.

0.254*b*f'c 508.747

Effective flange width, be

1/8*Effective span =2.55 m 1/8*Effective span 2.550

be-0.5*bi < 6*tmin+bw = 1.43 m be= 2.140 1.430

average spacing of adjacent beams= 0.98 m average spacing of adjacent beams

0.98

Check depth: d = 508.747mm (The section is sufficed!) >

213.674

0.42*d = 213.674 mm > 180 mm (T beam ) Φ 1268

Effective depth = 1268 mm T beam

Development length, lb =

as= 803.84 Development length, lb =1215.29 mm

Reinforcement

a) Flexure

Interior Girder Exterior Girder

x (m) MD AS No. of bars Length MD AS No. of bars Length

0 2.04 1458.65 3095.599 4 Φ32 22320 1515.959 3217.230 5 Φ32 22320

6.12 3327.84 7062.485 5 Φ32 10595 3455.700 7333.829 5 Φ32 10595

8.16 3738.39 7933.772 1 Φ32 6515 3879.483 8233.198 1 Φ32 6515

Crack control

Positive moment reinforcement- Interior Girder KN-m/m

M= 2371.23 KN-m/m 2371.230 0.000 0 3095.599

2045.221 7680.717256 7680.717

Reinforcement : 2371.230 8905.023269 8905.023

Mpu Assume; j =0.875 and fs=0.6*Fy 8905.02

AS =

fs*j*d 8905.02

2371230000

AS = = 8905.02mm2 (Provided reinforcement)

(0.6*400)*0.875*1268

Positive moment reinforcement- Exterior Girder 0.000 0 3217.230

M= 2513.511 KN-m/m 2513.511 2513.511 2173.638 8162.97914 8162.979

Reinforcement : 2513.511 9439.35495 9439.355

Mnu Assume; j =0.875 and fs=0.6*Fy 9439.35

AS =

fs*j*d 9439.35

4

2513511000

AS = = 9439.35mm2 (Provided reinforcement)

(0.6*400)*0.875*1268

350 180

Provide additional 1 Φ 32 length =6515 mm 803.84

n As d be

Critical Moment of Inertia 1 7.00 8737.612 1268 2320

Interior Girder 10

X int = 239.211 mm 239.211

Icr, int = 75.185*E+9 mm4 75.185

1 7.00 9037.038 1268 2140

Exterior Girder 11

X ext = 254.029 mm 254.029

Icr, ext = 76.491*E+9 mm4 76.491

fsint 227.127 fsext 233.236

Int. girder fs=227.127MPa, (fsa=240Mpa),

Ext. girder fs=233.236MPa, (fsa=240Mpa), Provide additional 1 Φ 32 length =6515 mm

240.000 50

b) Shear Design

Nominal shear resistance

The section is check for maximum shear and thus shear reinforcements are designed.

3.313

Vc+Vs where: Vn is the nominal shear strength

Vn = min.

0.25*f'cbvdv = 3.313 MPa Vc = shear strength provided by the shear reinforcement

bv = effective web width

Vc = 0.083β*sqrt(f'c)bvdv β= 2 dv = effective shear depth

Vs = Avfyd/S S = spacing of shear reinforcement

Prepared by: Abrham Gebre Girder Design 5

Spacings d=

Determine VU (the design shear force) at a distance dv from face of support. 1364 2.320

33.55

Av f y d v cot q Av f y

S£ £

Vs 0.083bv f ' c

for VU < 0.1f 'cbvdv, S< 0.8dv < 600 mm

for VU > 0.1f 'cbvdv, S< 0.4dv < 300 mm

Interior girder m 23.827

d-a/2 = 1352.087 mm a =Asfy/0.8fc'beff d-a/2 1352.087

dv =max 0.9d= 1227.6 mm dv = 1352.087 mm a = 23.827 0.9d 1227.6

0.72D = 1029.6 mm d =1364 mm 0.72D 1029.6

1352.087

Vs=(Vu/ϕ)-Vc, ϕ=0.9 1325.04526 1081.6696 285.78

Vn=3.313 MPa and f'c=28Mpa Vn/f'c = 0.118 (<0.25) OK

M /d + 0.5V cot q 0.118

ex = D v D £ 0.002 Vn/f'c = 0.118

E A

s s From chart

x(m) Vu Mu Assumed θ εx (E-3) θ β Vs Spacing of bars

1.35 828.890 966.773 39 1.908 38.066 1.422 625.44 Φ 12 c/c 240 mm

2.04 781.657 1458.646 39 2 38.25 1.375 582.728 Φ 12 c/c 260 mm

4.08 659.893 2567.927 37 2 38.25 1.375 447.434 Φ 12 c/c 300 mm

6.12 538.286 3327.843 26 2 38.25 1.375 312.315 Φ 12 c/c 300 mm

8.16 416.836 3738.393 38 1.886 38.022 1.433 165.315 Φ 12 c/c 300 mm

10.20 295.542 3799.578 38 1.866 37.982 1.443 28.467 Φ 12 c/c 300 mm

Exterior girder 1364 2.140

m 26.846

d-a/2 = 1350.577 mm a =As*fy/0.8fc'beff d-a/2 1350.577

dv =max 0.9d= 1227.6 mm dv = 1350.577 mm a = 26.846 0.9d 1227.6

0.72D = 1029.6 mm d =1364 mm 1323.56546 0.72D 1029.6

1350.577

Vn/f'c = 0.118 MPa 1080.4616 295.219

1350.577

From chart

x(m) Vu Mu Assumed θ εx (E-3) θ β Vs Spacing of bars

1.35 663.774 1004.759 33 1.562 37.374 1.598 405.769 Φ 12 c/c 300 mm

2.04 623.418 1515.959 35 1.951 38.152 1.4 402.035 Φ 12 c/c 300 mm

4.08 515.822 2667.859 38 2 38.25 1.375 287.674 Φ 12 c/c 300 mm

6.12 408.329 3455.700 40 1.743 37.736 1.506 141.041 Φ 12 c/c 300 mm

8.16 300.941 3879.483 39 1.729 37.708 1.513 20.267 Φ 12 c/c 300 mm

10.20 193.656 3939.207 40 1.715 37.68 1.52 -100.391 Φ 12 c/c 300 mm

Interior Girder Exterior Girder

x (m) VD Vs Spacing VD Vs Spacing

1.35 828.89 625.440 Φ 12 c/c 240 mm 663.774 405.769 Φ 12 c/c 300 mm

2.04 781.66 582.728 Φ 12 c/c 260 mm 623.418 402.035 Φ 12 c/c 300 mm

4.08 659.89 447.434 Φ 12 c/c 300 mm 515.822 287.674 Φ 12 c/c 300 mm

6.12 538.29 312.315 Φ 12 c/c 300 mm 408.329 141.041 Φ 12 c/c 300 mm

8.16 416.84 165.315 Φ 12 c/c 300 mm 300.941 20.267 Φ 12 c/c 300 mm

10.20 295.54 28.467 Φ 12 c/c 300 mm 193.656 -100.391 Φ 12 c/c 300 mm

iii) Deformations

Deflection and camber calculations shall consider dead load, live load, erection loads, concrete creep and shrinkage. Immediate (Instantaneous)

deflections

Distributionmay be for

factor computed taking

deflection mg the moment

is the ratio ofofthe

inertia as either

number the loaded

of lanes effective

to moment of girders.

number of inertia Ie, or the gross moment

mg = of inertia

NL/Ng = Ig. 0.5

mg = NL/Ng = 0.5

The long-term deflection due to creep and shrinkage may be taken as the immediate deflection multiplied by the following factor.

(3 to 1.2) As’/As ≥1.6 if ddl is calculated using Ie.

(4)As’/As ≥ 1.6 if ddl is calculated using Ig.

Where:

ddl is the total dead load deflection.

mm

Prepared by: Abrham Gebre Girder Design 6

Interior Girder

ts= 180 mm 180 Yt, int= 974.18 855100 833021500

4

Dw = 1430 mm 1430 Ig, int = 1.673E+11 mm

bw= 350 mm 350 Mcr, int = 571.95 Mpa 571.95

bi = 2320 mm 2320

be = 2140 mm 2140

Dw-ts = 1250 mm 1250 Exterior Girder

Yt, ext= 959.77 822700 789605500

4

Mcr = fr*Ig/Yt Ig, ext = 1.627E+11 mm

fr = 0.63*√ (fc’) = 3.33 Mpa 3.33 Mcr, ext = 564.6 Mpa 564.6

Total moment due to dead and live load (unfactored)

Interior Girder

MDU int= 2371.23 KN-m 2371.230

2513.511

Exterior Girder

MDU ext= 2513.511 KN-m

a) Dead load deflection and camber 2169.36

The effective moment of inertia is calculated using the following equation: #REF!

Ie=(((Mcr/MDU)3)*Ig)+(1-((Mcr/MDU)3))*Icrt 0.0140331 0.98596692 7.648E+10 76.478

Interior Girder

Icrt, int= 75.185*E+9 mm4 Ie, int= 76.478*E+9 mm4 (effective moment of inertia)

Exterior Girder 0.01133392 0.988666077 7.747E+10

Icrt, ext= 76.491*E+9 mm4 Ie, ext= 77.468*E+9 mm4 (effective moment of inertia) 77.468

Maximum Dead load moment

Interior Girder, Mmax DL = 1294.968 KN-m 1294.968

Exterior Girder, Mmax DL = 1437.249 KN-m 1437.249

76477766156

The maximum dead load deflection of the girders is obtained by integrating twice the DL moment equation. 0.0764778

Thus, the maximum dead load moment at the mid span becomes:

ddl, int = 1/EIe*(32.72*X^3 - 0.8*X^4 -6808.73X) = 21.206 mm

ddl, ext = 1/EIe*(42.62*X^3 - 1.04*X^4 -8867.64X) = 27.252 mm

ddl, int= 21.206 mm 26.752 77468005292 0.077468

ddl, ext= 27.252 mm 21.206 24.229 96.916

Camber =ddl+long term deflection, Long term deflection = 3*ddl 27.252 25.5

Camber =ddl (1+3)= 96.916 mm (average of interior and exterior girder)

b) Live Load Deflection

dmax=L1/800 (L1 is in mm); the permissible limit =25.5 mm 20400/800 =25.5 mm

In the computation of live load deflection, design truck load alone or design lane load plus 25% of truck load is considered.

i) Deflection due to truck load

Pi1 =Pi2 = 145 KN 145

Pi3 = 35 KN 35

P i1 Pi2 Pi3

The second load is to the

-1.02 left

X1

at X1=9.18 m, Mtr =1224.9 KN-m/m (Location of maximum truck load) 13.48 6.92

Prepared by: Abrham Gebre Girder Design 7

The maximum deflection of the bridge due to truck load occurs at a wheel load position where moment is a maximum. In general, the

deflection at the point of maximum moment, X1, due to each truck load at a distance 'a' from the left support is given by:

X1 9.18

b 11.22 of the center

dki=Pi*b*x(L12-a2-x2)/6EcIcL1 (for x<a)

where:

dki = deflection due to each truck load. 6.92

a = location of the load to be considered 13.48

b=L1-a X=L1-X1 ( X is the point where deflection is computed, for the first load, X=X1)

Ie,int= 7.648E+10 and Ie,ext= 7.747E+10

a) First Load 0.01229m= 21930.612 108.5612

a =9.18 m, b =11.22 m, x =9.18 m 12.29mm 2.50E+08 9.51E-03

145*11.22*9.18 9.51E+00

dk1= (20.4^2-11.22^2-9.18^2) =0.01229m= 12.29mm

6*2.046E+6*20.4 2.05E+06 2.05E+00

2.05E+15 26752

b) Second Load

2.05E+06 0.00E+00

a =13.48 m, b =6.92 m, x =9.18 m 0.01045m= 10.45mm

145*6.92*9.18 1.49E+04 2.06E+02

dk2= (20.4^2-6.92^2-9.18^2) =0.01045m= 10.45mm

6*2.046E+6*20.4 2.50E+08 1.23E-02

1.23E+01

c) Third Load

a=17.78 m, b=2.62 m, x=9.18 m 0.00109m= 1.09mm 2.55E+01

35*2.62*9.18 2.22E+03 2.84E+02

dk3= (20.4^2-2.62^2-9.18^2) =0.00109m= 1.09mm

6*2.046E+6*20.4 2.50E+08 2.52E-03

2.52E+00

Using the method of superposition, the total live load deflection due truck load is the sum of each deflections, dki’s.

dkt=dk1+dk2+dk3 = 12.29+ 10.45+ 1.09 = 23.83mm 24.32mm 2.43E+01

Thus, Interior girder, ∑dki = 23.83mm

Similarly for exterior girder,

dk1= 12.13 mm dk2= 10.32 mm dk3= 1.08 mm 9.39

24.01 mm 12.13

dkt=dk1+dk2+dk3 = 23.53mm 24.01 2.49

ii) Deflection due to tandem load

The max. deflection of the interior girder due to tandem load occurred when a single concentrated tandem load is acting at the mid span.

dtl=Pstl*L13/48EcIc

where: dtl = deflection due to tandem load.

Pstl = Single concentrated tandem load = 110KN 110

dtl= 2*110*20.4^3/(48*2045933.2) = 0.01902m = 19.02 mm 1.90E+01 1.90E-02

1.90E+01

iii) Deflection due to lane load

WL1=9.3 18.6

dLa = 5*WL1*L14/(384EIe) = 5*(9.3*2)*20.4^4/(384*2045933.2) = 0.0205m = 20.5 mm 0.0205m = 20.5 mm

2.05E-02

2.05E+01

Thus, the total live load deflection becomes:

dk = 0.25*dkt+dla 26.458 2.65E+01

dkt = (0.25*23.83)+20.5 =26.458 mm (for 25% of truck load) 1.32E+01 2.65E+01

-1.23E+01

dmax=mg*dkt= 0.5*26.458=13.23mm (< 25.5mm) The deflection is within the limit. <

Prepared by: Abrham Gebre Girder Design 8

Investigation of Fatigue Limit State

U=0.75*(LL+IM)

U= Fatigue load shall be one design truck with 9m spacing.

Maximum moment results when the two front axles are on the span and the rear axle is out of the span.

Mmf= 0.75*1.15(Mmax)

24 L1 0 L2 m1 -4.3 m2 m3 m2 m3 Mtr

23

22 0.10

0.125 2.04

2.55

20.40

18.36

17.85 -2.02948

-1.526875 1.831920 1.077375

2.224875 0.913920 1.831920

2.224875 0.913920 478.82625

1.077375 398.14680

21

20 0.15

0.175 3.06

3.57 17.34

16.83 -1.05028

-0.599695 2.59182 1.326255

2.932755 1.21482 2.59182

2.932755 1.21482 617.55645

1.326255 551.9628

19

18 0.2

0.225 4.08

4.59 16.32

15.81 -0.17512

0.223445 3.24768

3.536595 1.41168 3.24768 1.41168 675.6072

15

119 0.25

0.275 5.1

5.61 15.30

14.79 0.596

0.942545 3.7995 1.471095

4.036395 1.5045

1.511895

3.536595

3.7995

4.036395

1.471095

1.5045 733.93563

1.511895 789.94

837.49113

75 0.3

0.325 6.12

6.63 14.28

13.77 1.26308

1.557605 4.24728 1.448655

4.432155 1.49328 4.24728

4.432155 1.49328 907.23363

1.448655 876.589

31 0.35

0.375 7.14

7.65 13.26

12.75 1.82612

2.068625 4.59102 1.281375

4.723875 1.37802 4.59102

4.723875 1.37802 943.16313

1.281375 929.425

24 0.4

0.425 8.16

8.67 12.24

11.73 2.28512

2.475605 4.83072 1.010055

4.911555 1.15872 4.83072

4.911555 1.15872 945.27963

1.010055 948.448

0.45 9.18 11.22 2.64008 4.96638 0.634695

0.83538 4.96638 0.83538 913.58313

933.658

10 86 0.475

0.5

0.525

9.69

10.2

10.71

10.71

10.20

9.69

2.778545

2.891

2.977445

4.995195

4.998 0.155295

4.974795 0.408 4.995195

4.998

4.974795

0.634695

0.408 848.07363

0.155295 885.055

12

13 0.55

0.575 11.22

11.73 9.18

8.67 3.03788

3.072305 4.92558

4.850355 -0.12342

-0.428145 4.92558

4.850355 0 820.5349

0 810.83215

14

16 0.6

0.625 12.24

12.75 8.16

7.65 3.08072

3.063125 4.74912

4.621875 -0.75888

-1.115625 4.74912

4.621875 0

0 796.4476

777.38125

17 0.65 13.26 7.14 3.01952 4.46862 -1.49838 4.46862 8.160 753.6331

948.45

415.07

74.49

Mmax occurs at x = 8.16 m and equals to 948.448KN-m 0 5.572

Mg SIm = 0.467/1.2= 0.389

Mmf= 0.75*1.5*Mg SIm*(Mmax) = 415.065KN-m 1.2 0.467

Mmf= the maximum moment for fatigue. 0.389

161.5 <

a) Tensile live load stresses

for interior girder

d = 1268 mm, x = 239.211 mm, Icr=75.185*E+9 mm4 239.211 75184802647 7

fsmax = n*Mf*(d-x)/Icr 39.76 239.211 mm 1268

fsmax= 39.757 Mpa

b) Reinforcing Bars

The stresses range in straight reinforcement bars resulting from fatigue load combination shall not exceed.

If fsmax < ff , then there is no problem of fatigue. Otherwise increase area of reinforcing bars.

ff is the stress range.

fmin is the minimum live load stress where there is stress reversal. For simply supported slab bridge, r/h is 0.30 and fmin is zero.

ff=145-0.33fmin+55(r/h) =145+55*0.3=161.5Mpa 161.5

fs < ff (39.757 < 161.5 Mpa) OK! fs ff

THE DESIGN IS COMPLETED!

Prepared by: Abrham Gebre Girder Design 9

You might also like

- Crack Width As Per ACI 318 - SpreadsheetDocument2 pagesCrack Width As Per ACI 318 - Spreadsheetmassive8590% (10)

- Reborn Apocalypse (A LitRPGWuxia Story) (Volume 1) (Kerr L.M.)Document515 pagesReborn Apocalypse (A LitRPGWuxia Story) (Volume 1) (Kerr L.M.)julian vegaNo ratings yet

- Design of Biaxial ColumnDocument1 pageDesign of Biaxial Columnnishusaini0% (1)

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FLenielle AmatosaNo ratings yet

- Yamaha Fazer-Fzh150 CatalogueDocument55 pagesYamaha Fazer-Fzh150 CatalogueAnonymous KoA00wXXD69% (13)

- CELTA Tip: Language Analysis Assignment - Elt PlanningDocument6 pagesCELTA Tip: Language Analysis Assignment - Elt PlanningTeddy BroughtonNo ratings yet

- 2.2 Simply Supported Beam V.2Document7 pages2.2 Simply Supported Beam V.2Hafiz95 ReactsNo ratings yet

- Desg of PurlinDocument4 pagesDesg of PurlinSEPL SEPLNo ratings yet

- RC DesignDocument11 pagesRC DesignZul FadzliNo ratings yet

- 2 Flight Stair CaseDocument4 pages2 Flight Stair CaseMaaz OsmanNo ratings yet

- Wall Design ProgramDocument12 pagesWall Design Programaaalcantara3520qcNo ratings yet

- BearingsDocument17 pagesBearingssubodhstudymaterialsNo ratings yet

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignTONY BOULOSNo ratings yet

- Design of Boundary Column & FoundationDocument7 pagesDesign of Boundary Column & FoundationAmarjit KulkarniNo ratings yet

- KAMC-CW Calc.Document45 pagesKAMC-CW Calc.MoustafaNo ratings yet

- Midas Gen: 1. Geometry and MaterialsDocument1 pageMidas Gen: 1. Geometry and MaterialsAkela RichardNo ratings yet

- Water Tank Design and Crack Width CalculationDocument15 pagesWater Tank Design and Crack Width CalculationGandhi Sagar100% (1)

- Footing Design For Footing Type F: S (Kpa)Document15 pagesFooting Design For Footing Type F: S (Kpa)natnaelNo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Structure: 1 Dimension Data Foundation Size: Qmax Qa, OK! Qmax Qa, OK! Qmax Qa, OK!Document5 pagesStructure: 1 Dimension Data Foundation Size: Qmax Qa, OK! Qmax Qa, OK! Qmax Qa, OK!dantevariasNo ratings yet

- EG0222032301 Solar Carport Mounting System-Area A ASCE 7-10) - 10x21Document20 pagesEG0222032301 Solar Carport Mounting System-Area A ASCE 7-10) - 10x21SalauddinAnsariNo ratings yet

- CACUALATION - (CORN Receiving) - Edit PDFDocument110 pagesCACUALATION - (CORN Receiving) - Edit PDFTrần TiếnNo ratings yet

- Wall Tie 1Document4 pagesWall Tie 1John SmithNo ratings yet

- Wind Load Calculation: Project Artesia Mid Rise Building (G+28) On Plot No.676-5408 (E006) Subject Wind LoadDocument5 pagesWind Load Calculation: Project Artesia Mid Rise Building (G+28) On Plot No.676-5408 (E006) Subject Wind LoadAbdul BasithNo ratings yet

- Rigging DesignDocument8 pagesRigging DesignDurgesh HingnekarNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- 2.TankSurge Plate FOundationDocument2 pages2.TankSurge Plate FOundationdanjidNo ratings yet

- SBC by IS Method-8.0mDocument1 pageSBC by IS Method-8.0mJack DoverNo ratings yet

- Design CalculationDocument26 pagesDesign Calculationtawas20100% (1)

- Design of Concrete Ring Type Foundation For Storage TankDocument5 pagesDesign of Concrete Ring Type Foundation For Storage TankFadli PunyeNo ratings yet

- RC Precast Slab Bridge: Institute of Technology of Cambodia Bridge Assignment Professor: KAING SaosereyDocument46 pagesRC Precast Slab Bridge: Institute of Technology of Cambodia Bridge Assignment Professor: KAING SaosereyPiseyNo ratings yet

- Load Calculations - 47 MsDocument3 pagesLoad Calculations - 47 MsPradip NikamNo ratings yet

- Design of Raft Foundation: Column Distance From A-A Name Load (KN) X (M) y (M)Document4 pagesDesign of Raft Foundation: Column Distance From A-A Name Load (KN) X (M) y (M)Anish NeupaneNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Supreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeDocument4 pagesSupreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeGautam KhadkaNo ratings yet

- Bab IIDocument22 pagesBab IIasnawi89No ratings yet

- Open Newel StaircaseDocument12 pagesOpen Newel StaircaseIshwor PrajapatiNo ratings yet

- Spreader Bar For LiftingDocument1 pageSpreader Bar For LiftingTran ThoNo ratings yet

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghNo ratings yet

- Slab 2Document1 pageSlab 2Vijay KumarNo ratings yet

- Dokumen - Tips - 132kv Sag CalculationDocument14 pagesDokumen - Tips - 132kv Sag CalculationKunal AwaghadeNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- Semion Kogan - : Civil Engineering ConsultantDocument4 pagesSemion Kogan - : Civil Engineering ConsultantSemion KoganNo ratings yet

- Staircase Design 01Document7 pagesStaircase Design 01ovpatel007No ratings yet

- Explanatory Notes For RC Concrete ProjectDocument32 pagesExplanatory Notes For RC Concrete ProjectJean pierre ManriqueNo ratings yet

- SBC in Sand BH 4Document16 pagesSBC in Sand BH 4vishal kumarNo ratings yet

- Sample Foundation DesignDocument13 pagesSample Foundation DesignDino AbdelaNo ratings yet

- Design Z Section PurlinDocument9 pagesDesign Z Section PurlinSudipta Hui100% (1)

- Seismic Load STG BuildingDocument6 pagesSeismic Load STG BuildingWahyu MunajatNo ratings yet

- Rafters British Standards 06-02-2023 0931Document4 pagesRafters British Standards 06-02-2023 0931João SidônioNo ratings yet

- Node Load Combination Forces Moments FX Fy FZ MX My MZDocument11 pagesNode Load Combination Forces Moments FX Fy FZ MX My MZjuliyet strucNo ratings yet

- Minimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)Document25 pagesMinimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)JHON CLYDE SEPADANo ratings yet

- Isolated Footing P & MDocument8 pagesIsolated Footing P & Mمحمد حاج اسماعيلNo ratings yet

- Isolated Footing P OnlyDocument14 pagesIsolated Footing P OnlyAhmed AbuoelnagaNo ratings yet

- (Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory IiDocument31 pages(Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory Iishinichi falcoNo ratings yet

- DesignDocument13 pagesDesignAnshulGuptaNo ratings yet

- Design of Primary BeamsDocument24 pagesDesign of Primary BeamsZyril BestoNo ratings yet

- Manual Compu Barangay Affairs BuildingDocument38 pagesManual Compu Barangay Affairs BuildingMeanne AzucenaNo ratings yet

- 1 Peak DB - Single Acsr Bear - Wz4Document64 pages1 Peak DB - Single Acsr Bear - Wz4Newton AdhikariNo ratings yet

- 4.3 Eg. Box Girder DesignDocument24 pages4.3 Eg. Box Girder Designananiya dawitNo ratings yet

- Beam Design by SP 16 PDFDocument1 pageBeam Design by SP 16 PDFRafeeq khanNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Chapter 2 LDocument9 pagesChapter 2 LteweldeNo ratings yet

- Math232 Extension Mid ExamDocument3 pagesMath232 Extension Mid ExamteweldeNo ratings yet

- RW QtyDocument8 pagesRW QtyteweldeNo ratings yet

- Cantilever Retaining WallDocument8 pagesCantilever Retaining WallteweldeNo ratings yet

- ShearDocument26 pagesShearteweldeNo ratings yet

- Math 231B WR - St. Four 2012-13Document2 pagesMath 231B WR - St. Four 2012-13teweldeNo ratings yet

- Pier ModelingDocument5 pagesPier ModelingteweldeNo ratings yet

- Math 232 Final 2007Document7 pagesMath 232 Final 2007teweldeNo ratings yet

- 18 M Girder Bridge ModelingDocument5 pages18 M Girder Bridge ModelingteweldeNo ratings yet

- Report Requirements For Surveying Two Field PracticeDocument1 pageReport Requirements For Surveying Two Field PracticeteweldeNo ratings yet

- Section 2 Group 1Document3 pagesSection 2 Group 1teweldeNo ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

- Chapter One 1.1 Introduction About The Construction IndustryDocument21 pagesChapter One 1.1 Introduction About The Construction IndustryteweldeNo ratings yet

- BC WingwallDocument88 pagesBC WingwallteweldeNo ratings yet

- Column ForcesDocument9 pagesColumn ForcesteweldeNo ratings yet

- ICAMT ProceedingsDocument53 pagesICAMT ProceedingsteweldeNo ratings yet

- Awash Rive Bridge-Tendaho Project-Feb-2014-1 (Repaired)Document35 pagesAwash Rive Bridge-Tendaho Project-Feb-2014-1 (Repaired)teweldeNo ratings yet

- Design Review of B+G+13: Structural AnalysisDocument16 pagesDesign Review of B+G+13: Structural AnalysisteweldeNo ratings yet

- Design Coefficientsfor Three Cell Box CulvertDocument14 pagesDesign Coefficientsfor Three Cell Box CulvertteweldeNo ratings yet

- MekebibDocument54 pagesMekebibteweldeNo ratings yet

- Addis Ababa University Addis Ababa Institute of Technology (Aait)Document2 pagesAddis Ababa University Addis Ababa Institute of Technology (Aait)teweldeNo ratings yet

- Economic EvaluationDocument52 pagesEconomic EvaluationteweldeNo ratings yet

- Engineering Economics (Ceng 5211) : Chapter 3:economic EvaluationDocument29 pagesEngineering Economics (Ceng 5211) : Chapter 3:economic EvaluationteweldeNo ratings yet

- Questions For The Entrance Exam of MSCDocument1 pageQuestions For The Entrance Exam of MSCteweldeNo ratings yet

- 3.2. Future W - PBADocument18 pages3.2. Future W - PBAteweldeNo ratings yet

- BC Qty SheetDocument4 pagesBC Qty SheetteweldeNo ratings yet

- SD Model T.xlsx2Document15 pagesSD Model T.xlsx2teweldeNo ratings yet

- Steel Structures - ProposalDocument12 pagesSteel Structures - ProposalteweldeNo ratings yet

- Appendix E Culvert Substructure Design 4 (3.2 To 7.2) ) SubmDocument15 pagesAppendix E Culvert Substructure Design 4 (3.2 To 7.2) ) SubmteweldeNo ratings yet

- Etabs 17.0.1 Ultimate Unknown Varies Eurocode 3-2005Document323 pagesEtabs 17.0.1 Ultimate Unknown Varies Eurocode 3-2005teweldeNo ratings yet

- 211-Article Text-399-1-10-20180522 PDFDocument42 pages211-Article Text-399-1-10-20180522 PDFAlex KanathNo ratings yet

- He Va Grass Roller 63 82 Spare PartsDocument48 pagesHe Va Grass Roller 63 82 Spare PartstotcsabNo ratings yet

- Thesis and Seminar Paper Guidelines Fuess 9-2018Document5 pagesThesis and Seminar Paper Guidelines Fuess 9-2018Odaa BultumNo ratings yet

- Instruction Book Manual de Instrucciones Livre D'InstructionsDocument79 pagesInstruction Book Manual de Instrucciones Livre D'InstructionsWilfrido RosadoNo ratings yet

- Music LP OrchestraDocument11 pagesMusic LP OrchestraCybi MethueneNo ratings yet

- UGCNETDEC AdmitCardDocument1 pageUGCNETDEC AdmitCardAkshay RajNo ratings yet

- Combustion Products From Ventilation Controlled Fires - Thesis PDFDocument321 pagesCombustion Products From Ventilation Controlled Fires - Thesis PDFYuri SanchezNo ratings yet

- Gen Bio 1 Le Week 1 - Quarter 2Document7 pagesGen Bio 1 Le Week 1 - Quarter 2Cassy Joy Rellama100% (1)

- Marquipt Mounting Systems FR SS LadDocument2 pagesMarquipt Mounting Systems FR SS LadAyhan ÇalışkanNo ratings yet

- UntitledDocument22 pagesUntitledMoniNo ratings yet

- Biology Online TextbookDocument2 pagesBiology Online TextbookMicaela DavisNo ratings yet

- Jeppview For Windows: General Information Communication Information General InformationDocument34 pagesJeppview For Windows: General Information Communication Information General InformationAviation WithvoiceNo ratings yet

- TWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100Document18 pagesTWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100PolygondotcomNo ratings yet

- Taylor & Francis Journals Standard Reference Style Guide: American Psychological Association, Seventh Edition (APA-7)Document36 pagesTaylor & Francis Journals Standard Reference Style Guide: American Psychological Association, Seventh Edition (APA-7)Yago PessoaNo ratings yet

- Sergiu Celibidache Concerts in JapanDocument2 pagesSergiu Celibidache Concerts in JapanpasuasafcoNo ratings yet

- Curriculum Vitae: EducationDocument4 pagesCurriculum Vitae: EducationHetav MehtaNo ratings yet

- ENVS 532: DR Assad Al-Thukair Associate ProfessorDocument16 pagesENVS 532: DR Assad Al-Thukair Associate ProfessorAbu Muhsin Al NgapakyNo ratings yet

- CGL PRE 2023 English All SetsDocument314 pagesCGL PRE 2023 English All Setskumarmohit0203No ratings yet

- Clsi Astnewsupdate January2020ddddddpmDocument15 pagesClsi Astnewsupdate January2020ddddddpmRenato DesideriNo ratings yet

- 1st Sem Final Exam SummaryDocument16 pages1st Sem Final Exam SummaryAbu YazanNo ratings yet

- Solid State MCQ & CsaDocument10 pagesSolid State MCQ & Csashivansh upadhyay100% (1)

- Ibm - R61i Vga ShareDocument100 pagesIbm - R61i Vga Shareحسن علي نوفلNo ratings yet

- Stevenson12e Preface PDFDocument31 pagesStevenson12e Preface PDFLukas OstjenNo ratings yet

- 1st Quarter Exam in Math9Document3 pages1st Quarter Exam in Math9Robert Jay Mejorada100% (4)

- Group Medical Insurance - 2020-21Document2 pagesGroup Medical Insurance - 2020-21Vilaz VijiNo ratings yet

- Macdonald - 2009 - The Development of Arabic As A Written Language PDFDocument26 pagesMacdonald - 2009 - The Development of Arabic As A Written Language PDFelreynol100% (1)

- Business Plan MNHS OlangoDocument7 pagesBusiness Plan MNHS OlangoJomar Romero BalmoresNo ratings yet