Professional Documents

Culture Documents

Safety Data Sheet For Acetone: Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet For Acetone: Lee Chang Yung Chemical Industry Corporation

Uploaded by

haris abdullahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Data Sheet For Acetone: Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet For Acetone: Lee Chang Yung Chemical Industry Corporation

Uploaded by

haris abdullahCopyright:

Available Formats

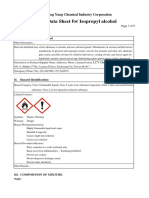

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 1 of 7

I. Identification

Chemicals name: ACETONE

Other Information: -

Relevant identified uses of the substance or mixture and uses advised against :Specification tests for Chemical products

(such as Methyl isobutyl ketone, Methyl isobutyl carbinol (MIBC); Methylmethacrylate); solvents such as paint,

lacquer, enamels, cellulose acetate textile solvent; cleaning and sterilizing of precision equipment; Potassium Iodide and

Potassium Permanganate solvents; Methylmethacrylate fiber deglazer; sulfurized rubber products.

Information on Producer/Supplier Name, Addresses, Phone: Linyuan Factory, LCY Chemical Corp /

NO.11, Shihhua 3rd Rd., Linyuan District, Kaohsiung City, Taiwan (R.O.C )

Emergency Phone / Fax: (07) 6419966-137 / (07) 6410537

II. Hazard Identification:

Hazard Category: Class 2 flammable liquids, Class 3 skin corrosion/irritation substance, Class 2 severe injury/eye

irritation materials, Class 2 hazardous inhalation substance.

Labeled Contents:

Symbols: Flame, Exclamation Point, Health hazard

Warning: Danger

Hazard Warning Information:

Highly flammable liquid and vapor

Produces light skin irritation

Produces eye irritation

May cause injuries if ingested and entered into the respiratory tract.

Hazard Prevention Measures:

Place container in a well-ventilated area.

Keep away from inflammables. – Smoking prohibited.

For contact with eyes, wash with large amount of water and then seek medical help.

Other Hazards: -

III. COMPOSITION OF MIXTURE

Single

English Name: ACETONE

Synonyms: Dimethyl Formaldehyde, Dimethylketal, Dimethyl Ketone, Ketone Propane, Beta-Ketopropane, Methyl

Ketone, 2-Propanone, Pyroacrtic Acid, Pyroacetic Ether

Chemical Abstracts Number (CAS No.): 00067-64-1

Percentage for Chemical Ingredient (%): 100

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 2 of 7

IV. First Aid Measures:

Emergency and First Aid Procedures:

Inhalation:

1. Remove the pollution source or the patient to a place with fresh air.

2. If discomfort persists, seek medical care immediately.

Skin Contact::

1. Use warm water to alleviate and wash the contaminated areas for 5 minutes or until the contaminants are

removed.

Eye Contact:

1. Immediately lift eyelids, use running warm water to wash contaminated eye(s) for 20 minutes or until the

contaminants are removed.

2. Prevent clean water from contacting the unaffected eye. 3. Get medical attention immediately.

Ingestion:

1. If the patient is losing consciousness, unconscious or in spasm, do not feed anything orally.

2. If the patient is conscious, let the patient rinse his/her mouth completely with water.

3. Do not induce vomiting. 4. Let the patient drink 240-300ml of water. 5. Seek medical care immediately.

Major Disease and Harm Effect: Concentration higher than 2000 ppm may induce sleepiness, nausea, vomit,

intoxication and dizziness.

First-Aid Personal Protection: Must wear Class C protective gear and perform emergency rescue in safe area.

Prompt to Doctor: If ingested accidentally, gastric lavage and active carbon should be administered.

V. Fire Fighting Measure:

Suitable Extinguishing Media: chemical powder, alcoholic foam and carbon dioxide

Special Exposure Hazards:

1. Liquid is extremely flammable and may be ignited at room temperature.

2. Vapor is heavier than air and may travel to far places and flashback from ignition sources.

3. Will accumulate in closed areas.

4. Containers in burning areas may rupture and explode.

5. Even diluted solution may ignite.

Special Extinguishing Procedure:

1. Retreat and extinguish the fire from a safe distance or a protected area. 2. Stay upwind to keep away from

hazardous vapor and toxic decomposition. 3. Any leakage should be stopped before extinguishing the fire. If the

leakage cannot be stopped and there is no immediate danger in the surrounding area, allow it to burn away. If the

leakage is not stopped before extinguishing the fire, the vapor and the air will form an explosive mixture and ignite

afterwards. 4. Separate materials that are not on fire and protect the personnel. 5. Move the container away from

the fire field under safe conditions. 6. Use water mist to cool the tanks or containers in exposed the fire field. 7.

The use of water mist to extinguish fire may be ineffective unless executed by fire fighters trained for extinguishing

flammable liquids. 8. If the leakage is not ignited, spray water mist to disperse vapor and protect the personnel

who try to stop the leakage. 9. A water spout is ineffective for extinguishing the fire. 10. For a big fire in a large

area, use the unmanned water mist stand or the automatic water fire monitor. 11. Retreat from the fire field and

allow the fire to burn out. 12. Stay away from the tanks. 13. When the safety valve alarm of the tank sounds or

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 3 of 7

the color changes due to fire, retreat immediately. 14. Personnel without special protective equipment should not

enter the fire field.

Special Protection Equipment: Fire fighters must wear air respirators, fire fighting coats, and protective gloves.

VI. Accidental Release Measures:

Personal Protection:

1. Restrict the access to the area till the polluted area is cleaned up completed. 2. Make sure the cleaning work is

performed by trained personnel. 3. The personnel should wear appropriate personal protective equipment.

Environmental Protection:

1. The air in the area should be ventilated and exchanged. 2. All flammable sources should be eliminated. 3.

Report the accident to the safety, health, and environmental protection authorities of the government.

Methods for Cleaning Up:

1. Do not come in contact with the released chemical. 2. Avoid the released chemical from entering the sewers,

drains, or sealed spaces. 3. Stop or reduce the leakage under safe conditions if possible. 4. Use sand, earth, or

other absorbents that do not react with the released chemical to block the leakage. 5. Small Quantity: Use an

absorbent that does not react with the released chemical to absorb. The polluted absorbent becomes as harmful as

the released chemical and should be placed in the appropriate container that is capped and labeled. Use water to

clean up the leakage area. The small release may be diluted with a large quantity of water. 6. Large Quantity:

Contact the fire fighting department, emergency response department, and the supplier for assistance.

VII. Handling and Storage:

Handling:

1. This substance is a highly flammable and toxic liquid. Therefore, personal protective equipment should be

utilized during disposal while the engineer control is operational. The staff should receive relevant trainings on the

risk and safe handling of this substance. 2. All flammable sources should be removed and kept away from heat

and incompatible substances. 3. The “Smoking Prohibited” sign should be present in the work area. 4. All tanks,

transfer containers and pipes must be grounded and in contact with bare metal. 5. When the operation is not

conducted in the sealed system, the connections between the operation container and the receiving transmission

equipment should be at the equivalent electric potential. 6. The empty tanks, containers, and lines may contain

harmful residues. Therefore, there should be no welding, cutting, drilling, or heating before they are cleaned. 7.

The tanks or containers may be filled with inert gas to reduce the risk of fire and explosion. 8. The ventilation

system or equipment that does not produce sparks used in the work area should be explosion-proof. 9. The aisles

and exits should be free from obstruction. 10. The installation of the system for detecting leakage and fire, the

appropriate fire-fighting system, or emergency operation equipment in the storage area and large quantity operation

area should be taken into consideration. 11. The formation of mist or vapor during the operation should be

avoided. The operation should be conducted in a well-ventilated area in the smallest quantity possible. The

operation area should be separated from the storage area. 12. Wear appropriate personal protective equipment

when necessary to avoid contact with this chemical substance or the polluted equipment. 13. Do not use with

incompatible chemicals (such as strong oxidants) in order to decrease the risks of fire and explosion. 14. Use

containers made from compatible materials. Do not spill during dispensing. 15. Do not use air or inert gas to

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 4 of 7

pressurize the liquid for the transport out of the container. 16. Unless the area is isolated with a fire-resistant

structure, do not conduct the handling operation in the storage area. 17. Use a certified flammable liquid storage

container and handling equipment. 18. Do not pour polluted liquid back to the original container. 19. The

containers should be labeled clearly. Keep the container fastened to avoid damage when not in use.

Storage:

1. The chemical should be stored in cool, dry, and well-ventilated area away from direct sunlight. Keep away from

heat sources, flammable sources, and incompatibles. 2. Consider the installation of spill and alarm devices in the

storage areas. 3. Storage facilities must be constructed using fireproof materials. 4. Use no-spark ventilation

system, approved anti-explosion equipment and safe electrical systems for the storage area. 5. The floor should be

construction with non-permeable materials to prevent absorption by the floor. 6. Set up slopes, doorsills or

furrows at doorways so that leaking substances are discharged to a safe place. 7. Label storage areas clearly with

no obstacles and only assigned or trained personnel are allowed to enter. 8. Separate the storage area from the

work area; stocks should stay away from lifts, construction objects, room exits or main passages. 9. There should

be adequate fire extinguishers and leakage cleaning equipment nearby the storage area. 10. Inspect the storage

containers regularly for damages or leakages. 11. Inspect all new containers to see if they are properly labeled and

without damage. 12. Limit the storage quantity. 13. Use storage containers made of compatible materials to

store the spilled or leaked substances. 14. Ground and potentially bond storage tanks with other equipment. 15.

Use anti-explosive refrigerators for small amount of storage. Empty tanks may still contain hazardous residues so

they should be sealed and stored separately. 16. Tanks used for storing inflammable liquids must be installed with

relief valve and vacuum relief valve. 17. Store under the temperature recommended by the chemical manufacturer

or supplier. If necessary, install a temperature detector alarm for warning if the temperature is too high or too low.

18. The storage of large quantities should be avoided. The chemical should be stored in the isolated fireproof

building. 19. The exhaust pipes of tanks should be installed with flame arresters. 20. The storage tanks should be

built on the ground level with the entire bottom sealed to prevent leakage. The liquid control dam able to hold the

entire volume should be present in the surrounding area.

VIII. Exposure Control / Personal Protection:

Engineering Control:

1. A separate and grounded ventilation system that will not produce sparks shall be applied.

2. Exhaust opening is connected directly outside the window.

3. Provide sufficient fresh air to replenish the air exhausted by the exhaust system.

Control Factor

TWA STEL CEILING BEI

750 ppm 937.5 ppm - 100mg/L

(Acetone in urine)

Personal Protection Equipment:

Respiratory Protection:

Below 2500ppm: Chemical filter cartridge type with organic vapor filter cartridge, powered air purifying type,

supplied air type, and self-contained breathing apparatus.

Unknown concentration: Positive-pressure self-contained respiratory apparatus, positive-pressure full air-supply

respiratory apparatus with positive-pressure self-contained respiratory apparatus.

Escape: Gas mask with organic vapor filter cartridge, life escape self-contained breathing apparatus.

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 5 of 7

Hand Protection: Impermeable gloves made from butyl rubber, Teflon, 4H, Barricade, Chemrel, Responder,

Trellchem and Tychem 10000 preferred.

Eye Protection: Anti-chemical splashing safety goggles and mask (lowest limit is 8 inches)

Skin & Body Protection: The above-mentioned one-piece protective rubber clothing, work boots, eye wash and quick

shower facilities.

Hygiene Procedures:

1. Polluted clothes should be removed as soon as the work is completed. The clothes should be worn or discarded only

after being washed. The washing staff should be informed of the harmful effects of the pollution. 2. Eating, drinking,

and smoking are strictly prohibited in the work area. 3. Wash hands thoroughly after handling the substance. 4.

Keep the work area clean.

IX. Physical and Chemical Properties / Characteristics:

Appearance: Colorless and transparent liquid Odor: Special sweet flavor, mint flavor

Odor threshold: 3.6-653ppm (detected), 33-699ppm (sensed) Melting point: -94.6℃

pH value: Boiling Point / Boiling Range: 56.2℃

Flammability (solid, gas): - Flash Point: -18℃

Decomposition Temperature: - Test Method: Close Cup

Spontaneous Temperature: 465 ℃ Exposure Limits: 2.5 ~ 12.8﹪

Vapor Pressure: 180 mmHg Vapor Density: 2

Specific Gravity: 0.791 Solubility in Water: Completely soluble

Log Kow: -0.24 Percent volatile: 5.6 (n-Butyl Acetate = 1)

X. Stability and Reactivity:

Stability: Stable under normal conditions

Special Conditions of Hazardous Reaction:

1. Acute reaction to oxidizer (such as oxide, nitrate, perchlorate), strong reducing agent, chlorinated solution and

alkaline mixture (such as chloroform and sodium hydroxide), increases the risk of fire and explosion. 2. Strong

reaction to potassium t-butoxide, hexachloromelamine, sulfur dichloride.

Conditions to Avoid: Sparks, fire, heat, ignition sources, long exposure to heat.

Incompatibility: 1. Oxidizer, chlorinated solution and alkaline mixture, potassium t-butoxide, hexachloromelamine,

sulfur dichloride and strong reducing agent.

Hazardous Decomposition Products: Heat decomposition produces carbon monoxide and carbon dioxide.

XI. Toxicological Information

Exposure route: inhalation, skin contact, eye contact, ingestion

Symptoms: Headache, weakness, tiredness, nausea, feelings of intoxication, vomiting, atrophy, unconsciousness,

defatting of the skin, dermatitis, disorientation

Acute Toxicity:

Skin: 1. Direct contact may cause mild irritation.

Inhalation: 1. No acute effect at low concentration. Slight irritation to nose and pharynx at high concentration

(about 1000ppm). 2. Concentration higher than 2000ppm may induce sleep, nausea, vomiting,

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 6 of 7

feeling of intoxication and dizziness. 3. Concentration higher than 10000ppm may induce

unconsciousness and death.

Ingestion: 1. Irritates pharynx, esophagus and stomach. 2. Symptoms for large amount of ingestion are the

same as for inhalation (such as headache, weakness, tiredness, etc.) 3. Aspiration into lungs may

produce fatal lung damage.

Eye: 1. High concentration vapor (1000ppm) can cause slight but short irritation. 2. The liquids are

severely irritating to the eyes.

LD50 (test animal, absorption route): 5800 mg/kg (rat, ingestion)

LC50 (test animal, absorption route): 50100 ppm/6H (rat, inhalation)

500mg/24H (rabbit, skin): causes slight irritation

20mg/24H (rabbit, eyes): causes medium level irritation.

Chronic:

1. Prolonged or repeated skin contact may cause defatting of the skin or dermatitis (dryness, irritation, redness

and cracking).

2. Daily exposure of 3 hours at 1000ppm concentration for 7 to 15 years will result in nose and pharynx

irritation, disorientation and weakness. 3. Exposure to acetone will increase the liver toxicity of chlorinated

solutions such as 1,1-dichloroethylene, 1,1,2-trichloroethane, carbonyl chloride, chloroform,

trichloroethylene, bromodichloroethylene, dibromochloropentadecane, etc.

31500ug/m3/24H (mammals, inhalation) affects fertility.

XII. Ecological Information:

Eco-toxicity: LC50 (Fish): 8300-40000mg/l/96H

EC50 (aquatic invertebrates): 10mg/l/48H (cyclops)

Bio-concentration Factor (BCF): 0.69

Durability and Degradability:

1. Although acetone biodegrades rapidly with or without the presence of oxygen, but under high concentration,

acetone is toxic to microorganisms.

2. When released into the air, it will react with the free oxygen radicals (half-life is about 22 days).

3. When released into water, this material is expected to readily biodegrade.

Half-life (air): 279~2790 hr

Half-life (water surface): 24~168 hr

Half-life (underground water): 48~336 hr

Half-life (soil): 24~168 hr

Biological Accumulation:

1. Will not accumulate; a large portion of the acetone will be discharged through respiration. A small amount of

acetone will oxidize to form carbon dioxide and discharged through respiration and urine.

Fluidity in the Soil: 1. When released into the soil, it is expected to readily biodegrade and quickly evaporate.

Other adverse effects: -

XIII. Disposal Information:

Disposal Information:

Lee Chang Yung Chemical Industry Corporation

Safety Data Sheet for Acetone

Page 7 of 7

1. Dispose according to related regulations.

2. Small amounts can be burned in an approved incinerator while large amounts can be sent to an approved

waste facility for disposal.

3. Waste substances must be kept in a safe container before they are disposed.

4. Substances with absorbed acetone can be buried in approved landfills.

XVI. Transport Information:

The United Nations Number (Un-No): 1090

UN Transport Name: Acetone

Transport Hazard Classification: Class 3 Flammable Liquids

Packaging Category: II

Marine Pollutant (Yes/No): No

Special Transport Way and Note: -

XV. Regulation Information:

Apply Regulation:

1. Enforcement Rules of the Occupational Safety and Health Act

2. Regulation of Labelling and Hazard Communication of Dangerous and Harmful Materials

3. Ordinance on Prevention of Organic Solvent Poisoning

4. Standards of Permissible Exposure Limits of Airborne Hazardous Substances in Workplace

5. Traffic Safety Regulations

6. Standards for the Storage, Clearance, and Disposal of Industrial Waste

7. Public Hazardous Materials and Flammable Pressurized Gases Establishment Standards and Safety Control

Regulations

XVI. Other Information:

Reference 1. CHEMINFO Database, CCINFO CD, 2005-2

2. RTECS Database, TOMES PLUS CD, Vol.63,2005

3. HSDB Database, TOMES PLUS CD, Vol.63,2005

4. ChemWatch Database, 2004-4

Name: Linyuan Factory, LCY Chemical Corp

Responsible

Department Address/Tel: NO.11, Shihhua 3rd Rd., Linyuan District, Kaohsiung City, Taiwan (R.O.C ) /

(07) 6419966-117

Prepared by Job title: Industrial Safety Engineer. Name(signature and seal): Cash Chuang

Date January 27, 2015

Note This SDS version is intended for reference only.

You might also like

- Harry Potter - VocabularyDocument11 pagesHarry Potter - VocabularyviniciusmdiasNo ratings yet

- MSDS-02590801 Asian Coal Tar EpoxyDocument13 pagesMSDS-02590801 Asian Coal Tar EpoxyPrashant RukmangadNo ratings yet

- Marketing Audit of HeinekenDocument13 pagesMarketing Audit of HeinekenDonthimall Sandeep Prabhu100% (1)

- Calcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanDocument2 pagesCalcium - Oxalic Acid - Technological Importance: F. Jacob, Munich-WeihenstephanGiorgi GhambashidzeNo ratings yet

- product-201197153041-EAC-MSDS-NEW ENGDocument9 pagesproduct-201197153041-EAC-MSDS-NEW ENGCandida AlmaNo ratings yet

- Alcohol MSDSDocument8 pagesAlcohol MSDSAjay KastureNo ratings yet

- Material Safety Data Sheet (MSDS) : SECTION 1: Identification of The Substance/Mixture and CompanyDocument9 pagesMaterial Safety Data Sheet (MSDS) : SECTION 1: Identification of The Substance/Mixture and CompanyAli BeetleNo ratings yet

- 5-Hojas de SeguridadDocument69 pages5-Hojas de SeguridadCamilo SernaNo ratings yet

- Msds LcoDocument9 pagesMsds LcoDeshanNo ratings yet

- SDS - Safety Data Sheet: 1. IdentificationDocument8 pagesSDS - Safety Data Sheet: 1. IdentificationAli El AliNo ratings yet

- Safety Data Sheet (SDS) : TOUGHNESS FINE C Shosekikako Co.,Ltd. 0076 Revised: March 1, 2021 Page.1/5Document5 pagesSafety Data Sheet (SDS) : TOUGHNESS FINE C Shosekikako Co.,Ltd. 0076 Revised: March 1, 2021 Page.1/5Bong CasirNo ratings yet

- MSDS - Monopropylene Glycol - Industrial - EngDocument11 pagesMSDS - Monopropylene Glycol - Industrial - Engamiller1987No ratings yet

- Safety Data Sheet (SDS) : 1. Identification of The Substance/Preparation and Company/UndertakingDocument6 pagesSafety Data Sheet (SDS) : 1. Identification of The Substance/Preparation and Company/UndertakingBong CasirNo ratings yet

- It Xylene MsdsDocument8 pagesIt Xylene MsdsHendriyana StNo ratings yet

- 6.1. MSDS Fine BondDocument4 pages6.1. MSDS Fine BondBong CasirNo ratings yet

- MSDS TolueneDocument11 pagesMSDS TolueneRoy JudeNo ratings yet

- 6.2. MSDS Toughness Fine ADocument4 pages6.2. MSDS Toughness Fine ABong CasirNo ratings yet

- MSDS Kan Epoxy ThinnerDocument6 pagesMSDS Kan Epoxy ThinnerHafiza UlfatNo ratings yet

- MSDS Kan PU ThinnerDocument6 pagesMSDS Kan PU ThinnerHafiza UlfatNo ratings yet

- A0200 Acetic Acid Glacial EngDocument5 pagesA0200 Acetic Acid Glacial EngWaqas RamayNo ratings yet

- Der 332Document9 pagesDer 332bd1972No ratings yet

- Safety Data Sheet (SDS) : TOUGHNESS FINE B Shosekikako Co.,Ltd. 0075 Revised: March 1, 2021 Page.1/4Document4 pagesSafety Data Sheet (SDS) : TOUGHNESS FINE B Shosekikako Co.,Ltd. 0075 Revised: March 1, 2021 Page.1/4Bong CasirNo ratings yet

- Methyl Ethyl Ketone MSDSDocument15 pagesMethyl Ethyl Ketone MSDSArjunNo ratings yet

- Material Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument9 pagesMaterial Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingEetu SatosalmiNo ratings yet

- Alvania EP GreaseDocument5 pagesAlvania EP Greasemingyu parkNo ratings yet

- MSDS: Iso-OctenesDocument7 pagesMSDS: Iso-OctenesHeavenL77No ratings yet

- MSDS-12620616 Ep HB CTGDocument11 pagesMSDS-12620616 Ep HB CTGPrashant RukmangadNo ratings yet

- FDS-jotamastic 87 ALU Comp ADocument7 pagesFDS-jotamastic 87 ALU Comp Amahmoud_allam3No ratings yet

- Bis A Epoxy ResinDocument12 pagesBis A Epoxy Resinraselche justNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document9 pagesMaterial Safety Data Sheet: Product and Company Identification 1Geovonni Almosthadme OsbourneNo ratings yet

- Material Safety Data Sheet: Toa Thinner # 21Document5 pagesMaterial Safety Data Sheet: Toa Thinner # 21ชินวิช แสงสักNo ratings yet

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Document5 pagesSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeNo ratings yet

- EVA Copolymer SDSDocument8 pagesEVA Copolymer SDSlobocernaNo ratings yet

- Material Safety Data Sheet MSDS L-QC320Document8 pagesMaterial Safety Data Sheet MSDS L-QC320Paulo Ricardo CasagrandaNo ratings yet

- SDS - Pilot II - Marine - Protective - English (Uk) - SingaporeDocument5 pagesSDS - Pilot II - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaNo ratings yet

- Material Safety Data Sheet: 1. IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. IdentificationMai PhuongNo ratings yet

- IT TOLUENE MSDS Intertrade SingaporeDocument7 pagesIT TOLUENE MSDS Intertrade SingaporeThupten Gedun Kelvin OngNo ratings yet

- Safety Data Sheet: Section 1 - Product and Company IdentificationDocument10 pagesSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloNo ratings yet

- SDS Methanol 31301 2016Document9 pagesSDS Methanol 31301 2016mariaalvarado54020No ratings yet

- Corena Oil PDocument5 pagesCorena Oil Pmingyu parkNo ratings yet

- SDS - Pioner Topcoat - Marine - Protective - English (Uk) - SingaporeDocument6 pagesSDS - Pioner Topcoat - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaNo ratings yet

- SDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFDocument4 pagesSDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFBNo ratings yet

- ZIC ATF-3 Material Safety Data SheetDocument9 pagesZIC ATF-3 Material Safety Data SheetJose Angel MalumbresNo ratings yet

- 6300-Weber - Kol SRK Safety Data Sheet: Saint-Gobain Weber Yapi Kim. San. Ve Tic. A.SDocument10 pages6300-Weber - Kol SRK Safety Data Sheet: Saint-Gobain Weber Yapi Kim. San. Ve Tic. A.SGökhan PanpaNo ratings yet

- 1107 Solvent No 1 1314174041Document8 pages1107 Solvent No 1 1314174041Renato AsNo ratings yet

- Msds Am 2cDocument5 pagesMsds Am 2cTony KhouryNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- 306Document6 pages306vinithaNo ratings yet

- SDS - Fenomastic Emulsion Semigloss - English (Uk) - Dubai PDFDocument5 pagesSDS - Fenomastic Emulsion Semigloss - English (Uk) - Dubai PDFBNo ratings yet

- 210 CatalystDocument5 pages210 CatalystViVek VermaNo ratings yet

- Safety Data Sheet (SDS) : TF CLOTH Shosekikako Co.,Ltd. 0079 Revised: March 1, 2021 Page.1/4Document4 pagesSafety Data Sheet (SDS) : TF CLOTH Shosekikako Co.,Ltd. 0079 Revised: March 1, 2021 Page.1/4Bong CasirNo ratings yet

- MSds 21961 Fenomastic Pure CL Emu SK (I) Euk inDocument6 pagesMSds 21961 Fenomastic Pure CL Emu SK (I) Euk inzayzanNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument12 pagesSafety Data Sheet: 1. IdentificationeadriesNo ratings yet

- HK Liquified Petroleum Gas 33970Document9 pagesHK Liquified Petroleum Gas 33970HungNo ratings yet

- Durathane Matt - Comp ADocument4 pagesDurathane Matt - Comp ABalasubramanian AnanthNo ratings yet

- Car Dip+Spray On+issue+2 1Document6 pagesCar Dip+Spray On+issue+2 1mxsportNo ratings yet

- MSDSUFC85Document8 pagesMSDSUFC85taghdirimNo ratings yet

- 1 - Identification of The Material and Supplier Marine Naval Fuel F76Document5 pages1 - Identification of The Material and Supplier Marine Naval Fuel F76Ashwani KumarNo ratings yet

- Elf Elfmatic G3 PlusDocument6 pagesElf Elfmatic G3 Plusben.altenberg44No ratings yet

- Guidelines For Open Plant StructuresDocument6 pagesGuidelines For Open Plant StructuresIndrawNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- After a Disaster: Information to Help You and Your Family RecoverFrom EverandAfter a Disaster: Information to Help You and Your Family RecoverNo ratings yet

- Test Pth5 SummaryDocument5 pagesTest Pth5 Summaryharis abdullahNo ratings yet

- CH18 - Fire Cause DeterminationDocument67 pagesCH18 - Fire Cause Determinationharis abdullahNo ratings yet

- Govpub C13Document108 pagesGovpub C13haris abdullahNo ratings yet

- Pelaksanaan Pembayaran Ganti Kerugian Dalam Asuransi Kebakaran Di PT Asuransi Umum Bumiputera Cabang PadangDocument17 pagesPelaksanaan Pembayaran Ganti Kerugian Dalam Asuransi Kebakaran Di PT Asuransi Umum Bumiputera Cabang Padangharis abdullahNo ratings yet

- Safety Data Sheet: Date of Issue: 04 April 2016Document6 pagesSafety Data Sheet: Date of Issue: 04 April 2016haris abdullahNo ratings yet

- The Study of Transport Category Aircraft Fire Safety Airworthiness Design PDFDocument5 pagesThe Study of Transport Category Aircraft Fire Safety Airworthiness Design PDFharis abdullahNo ratings yet

- How To Become A Pro Barista E BookDocument15 pagesHow To Become A Pro Barista E BookBivek MaharjanNo ratings yet

- Mixtures and Alligations - PPTDocument22 pagesMixtures and Alligations - PPTEvariste MigaboNo ratings yet

- Production of Transparent SoapsDocument4 pagesProduction of Transparent SoapsMahnoorNo ratings yet

- AWD Grenache GuideDocument41 pagesAWD Grenache GuideJesse CassNo ratings yet

- Lennox - Ella MilesDocument258 pagesLennox - Ella MilesNgwe Ywun TwetarNo ratings yet

- Hukka MenuDocument1 pageHukka Menuranjan988No ratings yet

- Dalmore 12 Years + Royal Sands Koh Rong: All InclusiveDocument6 pagesDalmore 12 Years + Royal Sands Koh Rong: All InclusiveChristian NavidaNo ratings yet

- 1° Ano Médio - Aula 2Document13 pages1° Ano Médio - Aula 2Teacher BrunaNo ratings yet

- Qualitative Tests For Preliminary Phytochemical Screening: An OverviewDocument6 pagesQualitative Tests For Preliminary Phytochemical Screening: An OverviewJaved KhanNo ratings yet

- Libbey 2015 GlasswareDocument162 pagesLibbey 2015 GlasswareTabletopJournalNo ratings yet

- Coca Cola Conversation LessonDocument3 pagesCoca Cola Conversation LessonHong Gia100% (2)

- Alkene DPPDocument20 pagesAlkene DPPKalyan ReddtNo ratings yet

- DR - Mohamad Issa Watfe Bar Operation Introduction and DefinitionDocument9 pagesDR - Mohamad Issa Watfe Bar Operation Introduction and DefinitionDanielNo ratings yet

- MC Wedding IvanDocument4 pagesMC Wedding IvanGito LiemNo ratings yet

- How To Fix A Run On Sentence and Comma SpliceDocument7 pagesHow To Fix A Run On Sentence and Comma SpliceAbeer Emad Awadeen 10CNo ratings yet

- Biotransformation of Spent Coffee Grounds by Fermentation WithDocument11 pagesBiotransformation of Spent Coffee Grounds by Fermentation WithDavi MouraNo ratings yet

- Constantes TermodinámicasDocument64 pagesConstantes TermodinámicasgerardoNo ratings yet

- Mohan Meakin ProjectDocument78 pagesMohan Meakin ProjectAmar Goel50% (2)

- Kikibees Full MenuDocument17 pagesKikibees Full MenudrkojoansongNo ratings yet

- Công Thức Thực HànhDocument10 pagesCông Thức Thực Hành8smvqdcspkNo ratings yet

- Task Sheet 5.3 - Present and Serve Food and Beverage Orders To Guests PDFDocument2 pagesTask Sheet 5.3 - Present and Serve Food and Beverage Orders To Guests PDFjosephine50% (2)

- DS - 8.4 The Alligation MethodDocument45 pagesDS - 8.4 The Alligation MethodLOLONo ratings yet

- Lindab Safe PDFDocument133 pagesLindab Safe PDFadigeto100% (1)

- Fdocuments - in Study The Rate of Fermentation of Fruits and Vegetables JuicesDocument9 pagesFdocuments - in Study The Rate of Fermentation of Fruits and Vegetables JuicesabinavNo ratings yet

- All About Cannabis Scavenger HuntDocument3 pagesAll About Cannabis Scavenger HuntRoshen SridharNo ratings yet

- Reflection Chart (Prenatal Period) 4 / 20 / 23 NAME: Asumbrado, Reymar C. Year and Section: BSED ENG - 2A Topic: Intro To Module 3Document3 pagesReflection Chart (Prenatal Period) 4 / 20 / 23 NAME: Asumbrado, Reymar C. Year and Section: BSED ENG - 2A Topic: Intro To Module 3Reymar AsumbradoNo ratings yet

- FF7R - The - Investigation - Unit - Within - The - Painting - ENG - TranslationDocument30 pagesFF7R - The - Investigation - Unit - Within - The - Painting - ENG - TranslationAndrew PageNo ratings yet