Professional Documents

Culture Documents

Assignment 1. - Probability and Statistics

Assignment 1. - Probability and Statistics

Uploaded by

Tejo NathOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 1. - Probability and Statistics

Assignment 1. - Probability and Statistics

Uploaded by

Tejo NathCopyright:

Available Formats

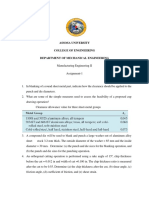

ME3011D MACHINE DESIGN I - 2021 winter

Assignment 1 - Probability and statistics

1. It has been observed from a sample of 200 bearing bushes that the internal diameters are

normally distributed with a mean of 30.010 mm and a standard deviation of 0.008 mm. The

upper and lower limits for the internal diameter, as specified by the designer, are 30.02 and

30.00 mm respectively. Calculate the percentage of rejected bushes.

2. The tolerance specified by the designer for the diameters of a transmission shaft is 25.000

± 0.025 mm. The shafts are machined on three different machines. It was observed from

the sample of shafts that the diameters are normally distributed with a standard deviation

of 0.015 mm for each of the three machines. However, the mean diameter of shafts

fabricated on the three machines is found to be 24.99, 25.00 and 25.01 mm respectively.

Determine the percentage of rejected shafts in each case and comment on the result.

3. The life of a ball bearing is a normally distributed random variable, with a mean of 10 000

h and a standard deviation of 500 h. The manufacturer of the bearings wants to give a

guarantee that 90% of the bearings will reach or exceed the rated life published in his

catalogue. What should be the rated life?

4. It is observed from a sample of 100 bolts produced on an automatic machine that their

diameters are normally distributed with a mean of 10.5 mm and a standard deviation of

0.02 mm. Determine the tolerances specified by the designer if five bolts are rejected.

5. A cantilever beam is made of plain carbon steel 45C8 having mean yield strength of 380

N/mm2 and a standard deviation of 50 N/mm2. It is subjected to a bending stress with a

mean of 250 N/mm2 and a standard deviation of 25 N/mm2.

Determine: (i) The reliability of the beam;

(ii) The average factor of safety; and

(iii) The minimum available factor of safety.

You might also like

- Forging HW at IUTDocument1 pageForging HW at IUTNabil Haidar100% (1)

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- Machine Design-II EME602 2012-13Document4 pagesMachine Design-II EME602 2012-13nitin_johriNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- Me1302 DmeDocument4 pagesMe1302 DmesumikannuNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayNo ratings yet

- Question Bank: Subject:Tool Engineering/Tool Design Q.No QuestionDocument3 pagesQuestion Bank: Subject:Tool Engineering/Tool Design Q.No QuestionhemendraNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Sample MSD PaperDocument2 pagesSample MSD PaperKylo Ren0% (1)

- Time: 3 Hours Total Marks: 100: B.Tech (Sem-V) Theory Examination 2019-20 Machine Design-IDocument3 pagesTime: 3 Hours Total Marks: 100: B.Tech (Sem-V) Theory Examination 2019-20 Machine Design-IAnup KashyapNo ratings yet

- Dme 2022 23 ExperimentsDocument34 pagesDme 2022 23 Experimentshagovef164No ratings yet

- C 954 Â " 98 QZK1NC1SRUQDocument4 pagesC 954 Â " 98 QZK1NC1SRUQSebastián RodríguezNo ratings yet

- Design of Machine Members: Part-ADocument4 pagesDesign of Machine Members: Part-ARkrishna ANo ratings yet

- 2Document4 pages2Shem YusoyaNo ratings yet

- Dome 6TH Sem. SP - 09Document7 pagesDome 6TH Sem. SP - 09neelesh singhNo ratings yet

- Design of Machine Elements Question Paper SampleDocument7 pagesDesign of Machine Elements Question Paper SampleK V SATHEESHKUMAR MECHNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Machine Element I Worksheet On U2Document2 pagesMachine Element I Worksheet On U2Wolelaw FikaduNo ratings yet

- Machine Element I Worksheet 2Document2 pagesMachine Element I Worksheet 2dagimawgchew777No ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- 510 Open ExamDocument17 pages510 Open Examariyamanjula2914100% (1)

- Practice Sheet 2Document2 pagesPractice Sheet 2Arshpreet SinghNo ratings yet

- FALLSEM2019-20 MEE2001 ELA VL2019201005431 Reference Material II 12-Jul-2019 Conventional TolerancingDocument22 pagesFALLSEM2019-20 MEE2001 ELA VL2019201005431 Reference Material II 12-Jul-2019 Conventional TolerancingNikhil VermaNo ratings yet

- Manufacturing Engineering-29 PDFDocument1 pageManufacturing Engineering-29 PDFSameerChauhanNo ratings yet

- Practice Sheet 2Document2 pagesPractice Sheet 2GUNJAN KHULLARNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological UniversityJaineshNo ratings yet

- Design of Machine Elements2Document14 pagesDesign of Machine Elements2Satwik PriyadarshiNo ratings yet

- PI1502 Assignment 2Document1 pagePI1502 Assignment 2Abhishek KumarNo ratings yet

- TE - 2019 - Design of Machine Elements PDFDocument4 pagesTE - 2019 - Design of Machine Elements PDFonkar nikamNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- 3.1 Keys and Couplings 1Document2 pages3.1 Keys and Couplings 1Edrian PentadoNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- MdId Gtu PaperDocument3 pagesMdId Gtu PaperhukNo ratings yet

- 0326 Me 2303 Design of Machine ElementsDocument3 pages0326 Me 2303 Design of Machine ElementsSaravanan MathiNo ratings yet

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Design of Machine Element-IIDocument53 pagesDesign of Machine Element-IIPramod R Bidve100% (1)

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- Design of Machine ElementsDocument3 pagesDesign of Machine ElementsHariharanAutoNo ratings yet

- Tutorial 2 (2023)Document1 pageTutorial 2 (2023)Dr. Aung Ko LattNo ratings yet

- Assignment 7221 MD-IIIDocument2 pagesAssignment 7221 MD-IIIkalikaNo ratings yet

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- Assosa University College of Engineering Department of Mechanical EngineeringDocument2 pagesAssosa University College of Engineering Department of Mechanical EngineeringKedir AddisuNo ratings yet

- Machine DesignDocument3 pagesMachine DesignSantosh Kumar SinghNo ratings yet

- 6mm To 18mmDocument15 pages6mm To 18mmMd.zubairNo ratings yet

- Tutorial No.6 DMEDocument1 pageTutorial No.6 DMEOnkarNo ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Design of Machine Elements Question Paper SampleDocument5 pagesDesign of Machine Elements Question Paper SampleK V SATHEESHKUMAR MECHNo ratings yet

- Lube Oil SystemDocument6 pagesLube Oil SystemTejo NathNo ratings yet

- Assignment 15 - A-Batch Balancing of Multi-Cylinder EngineDocument2 pagesAssignment 15 - A-Batch Balancing of Multi-Cylinder EngineTejo NathNo ratings yet

- Robotic Harvesting of Asparagus Using Machine Learning - B180129MEDocument28 pagesRobotic Harvesting of Asparagus Using Machine Learning - B180129METejo NathNo ratings yet

- Instagram Hack Online Password Easily 2 Minutes 300720144Document4 pagesInstagram Hack Online Password Easily 2 Minutes 300720144Tejo NathNo ratings yet

- Assignment 1 Static Force AnalysisDocument2 pagesAssignment 1 Static Force AnalysisTejo NathNo ratings yet

- Image Classification Teacher GuideDocument34 pagesImage Classification Teacher GuideTejo NathNo ratings yet

- Assignment 12 Approximate Expression For Turning MomentDocument1 pageAssignment 12 Approximate Expression For Turning MomentTejo NathNo ratings yet

- Image Classification Teacher GuideDocument34 pagesImage Classification Teacher GuideTejo NathNo ratings yet

- FM Notes PDFDocument64 pagesFM Notes PDFTejo NathNo ratings yet