Professional Documents

Culture Documents

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

Uploaded by

RisoSilvaCopyright:

Available Formats

You might also like

- 4K, 512 X 8 Bit: FN8126.2 Data Sheet March 16, 2006Document21 pages4K, 512 X 8 Bit: FN8126.2 Data Sheet March 16, 2006Angel LugoNo ratings yet

- AT25080A, 160A, 320A, 640A Rev04Document23 pagesAT25080A, 160A, 320A, 640A Rev04Bobby HancockNo ratings yet

- Ds5074a 00Document40 pagesDs5074a 00martin sembinelliNo ratings yet

- Nec 78k0 Kb2Document27 pagesNec 78k0 Kb2Anonymous pu1L9ZNo ratings yet

- Datasheet 28Document35 pagesDatasheet 28Eric ArcherNo ratings yet

- Z86e0412psc PDFDocument44 pagesZ86e0412psc PDFhectorsevillaNo ratings yet

- Synchronous Rectified MOSFET Driver With Pre-Biased Load Startup CapabilityDocument11 pagesSynchronous Rectified MOSFET Driver With Pre-Biased Load Startup CapabilityYogender KumarNo ratings yet

- Z86E0812SSCDocument44 pagesZ86E0812SSCmstrkoskiNo ratings yet

- DS8884B 01Document46 pagesDS8884B 01semar bypasNo ratings yet

- ISL62882HRTZDocument42 pagesISL62882HRTZAnderson PimentelNo ratings yet

- Atmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetDocument20 pagesAtmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetalaitsevNo ratings yet

- ISL62883 RenesasDocument37 pagesISL62883 Renesasanh_sao_dem_92No ratings yet

- LKS32MC05x 3P3N DS EN v1.88Document47 pagesLKS32MC05x 3P3N DS EN v1.88vishalkumarNo ratings yet

- P87C51RA2/RB2/RC2/RD2: 80C51 8-Bit Microcontroller FamilyDocument67 pagesP87C51RA2/RB2/RC2/RD2: 80C51 8-Bit Microcontroller FamilyAlbert YasnóNo ratings yet

- MDT10P57: 1. General DescriptionDocument13 pagesMDT10P57: 1. General DescriptionJuan Carlos Ramírez LeónNo ratings yet

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonNo ratings yet

- Two-Wire Serial Eeprom: FeaturesDocument19 pagesTwo-Wire Serial Eeprom: Featuresvladimir_p80No ratings yet

- 2M (256K 8/128K 16) BIT: Flash MemoryDocument49 pages2M (256K 8/128K 16) BIT: Flash MemoryEdson CostaNo ratings yet

- 3-Wire Serial Eeproms: FeaturesDocument18 pages3-Wire Serial Eeproms: FeaturesAriana ScheiderNo ratings yet

- En25qh64a EonDocument75 pagesEn25qh64a EonMarcelituz RojasNo ratings yet

- CXP82316 - I.C.Document20 pagesCXP82316 - I.C.Andre BaezNo ratings yet

- Two-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64ADocument22 pagesTwo-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64AmedNo ratings yet

- Atmel DatasheetDocument27 pagesAtmel DatasheetKhoa DangNo ratings yet

- 8-Bit Atmel Micro ControllerDocument40 pages8-Bit Atmel Micro ControllerSabita LangkamNo ratings yet

- At Mega 1280Document448 pagesAt Mega 1280Craciun SergiuNo ratings yet

- (BISS) TransistorsDocument12 pages(BISS) TransistorsMiloud ChouguiNo ratings yet

- Data SheetDocument37 pagesData SheetRenny Amalia PratiwiNo ratings yet

- At 25080Document21 pagesAt 25080sabNo ratings yet

- 25AA640A/25LC640A: 64K SPI Bus Serial EEPROMDocument36 pages25AA640A/25LC640A: 64K SPI Bus Serial EEPROMmarino246No ratings yet

- 8-Bit Microcontroller With 16K/ 32K Bytes Flash AT89C51RB2 AT89C51RC2Document127 pages8-Bit Microcontroller With 16K/ 32K Bytes Flash AT89C51RB2 AT89C51RC2MNPRAWINNo ratings yet

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pages24AA08/24LC08B: 8KI C Serial EEPROMjoseNo ratings yet

- PIC16F887Document338 pagesPIC16F887David BaronNo ratings yet

- Datasheet 24c01 EepromDocument26 pagesDatasheet 24c01 EepromItalo Vasquez LeonNo ratings yet

- At25f512a 844895Document19 pagesAt25f512a 844895mirage0706No ratings yet

- 24LC08 PDFDocument30 pages24LC08 PDFJaime BarrancoNo ratings yet

- 8-Bit Microcontroller With 1K Bytes Downloadable Flash AT90S1200 PreliminaryDocument7 pages8-Bit Microcontroller With 1K Bytes Downloadable Flash AT90S1200 PreliminaryRichard KrillNo ratings yet

- 8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesDocument137 pages8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesCarlos BaezNo ratings yet

- Three-Wire Serial Eeproms: FeaturesDocument21 pagesThree-Wire Serial Eeproms: FeaturesX'mix DreamerNo ratings yet

- Two-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64ADocument21 pagesTwo-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64Anordio2No ratings yet

- TL 3845Document29 pagesTL 3845Hisham MohamedNo ratings yet

- Slvs 038 IDocument28 pagesSlvs 038 Igabriel6276No ratings yet

- Tlx84X Current-Mode PWM Controllers: 1 Features 3 DescriptionDocument26 pagesTlx84X Current-Mode PWM Controllers: 1 Features 3 DescriptionAnonymous t9tLb3WgNo ratings yet

- R8C24 25 Flyer (24-003A)Document2 pagesR8C24 25 Flyer (24-003A)nagforuNo ratings yet

- Mcp320x 12-Bit AdcDocument34 pagesMcp320x 12-Bit AdcGeoFurrielNo ratings yet

- Xmc-Xm25qh64ahig C328461Document75 pagesXmc-Xm25qh64ahig C328461c4rl0slinuxNo ratings yet

- Xmc-Xm25qh128ahig C328463Document78 pagesXmc-Xm25qh128ahig C328463Manishkumar JethvaNo ratings yet

- Philips P89C51RD2 6Document52 pagesPhilips P89C51RD2 6api-3726520No ratings yet

- 8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesDocument136 pages8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesSorin AlexandruNo ratings yet

- lpc2104 2105 2106Document32 pageslpc2104 2105 2106B GowdaNo ratings yet

- At25128b 5eb PDFDocument22 pagesAt25128b 5eb PDFMurat BaybükeNo ratings yet

- ATmega2560 Doc2549Document448 pagesATmega2560 Doc2549Ship WrekNo ratings yet

- REN Isl8483e-85e DST 20030328Document15 pagesREN Isl8483e-85e DST 20030328Ercan CesurNo ratings yet

- 08 Bus CycleDocument40 pages08 Bus CycleMir4 BritoNo ratings yet

- CMOS 8-Bit Single Chip Microcomputer: CXP83408/83412/83416 CXP83409/83413/83417Document24 pagesCMOS 8-Bit Single Chip Microcomputer: CXP83408/83412/83416 CXP83409/83413/83417HerwinTorresNo ratings yet

- 8-Bit Microcontroller With 8K Bytes In-System Programmable Flash Atmega8535 Atmega8535L PreliminaryDocument19 pages8-Bit Microcontroller With 8K Bytes In-System Programmable Flash Atmega8535 Atmega8535L Preliminarymike_helplineNo ratings yet

- FSP-951T I56-6521 Fire SensorDocument57 pagesFSP-951T I56-6521 Fire SensorSandeep SNo ratings yet

- 2-Wire Serial EEPROM: FeaturesDocument19 pages2-Wire Serial EEPROM: FeaturesAgustin AndrokaitesNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

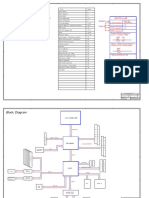

- 820-1540 (Project Q45B)Document74 pages820-1540 (Project Q45B)RisoSilvaNo ratings yet

- TroubleshootingDocument28 pagesTroubleshootingRisoSilvaNo ratings yet

- Schem, MLB, Pb15: Bom Options (In Common Parts)Document44 pagesSchem, MLB, Pb15: Bom Options (In Common Parts)RisoSilvaNo ratings yet

- SCHEM, MLB, PB17": Bom OptionsDocument44 pagesSCHEM, MLB, PB17": Bom OptionsRisoSilvaNo ratings yet

- ESQUEMA Ms-7529 (g31m3-v2) REV 1.1Document33 pagesESQUEMA Ms-7529 (g31m3-v2) REV 1.1RisoSilvaNo ratings yet

- Mosfet Substituto 13n03laDocument8 pagesMosfet Substituto 13n03laRisoSilvaNo ratings yet

- Mosfet Original P75N02LDGDocument3 pagesMosfet Original P75N02LDGRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 ATX: Cover Sheet Micro Star Restricted SecretDocument32 pagesMS-6728 ATX: Cover Sheet Micro Star Restricted SecretRisoSilvaNo ratings yet

- MS-6728 AtxDocument34 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- d9b19 Compal JBL00 LA-3801P - DELL E6400 Laptop SchematicsDocument66 pagesd9b19 Compal JBL00 LA-3801P - DELL E6400 Laptop SchematicsRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- Dell Latitude D510 SchematicsDocument46 pagesDell Latitude D510 SchematicsRisoSilvaNo ratings yet

- Msi ms-1682 r0b SchematicsDocument52 pagesMsi ms-1682 r0b SchematicsRisoSilvaNo ratings yet

- Model Name: GA-7VM400AMF: Sheet TitleDocument29 pagesModel Name: GA-7VM400AMF: Sheet TitleRisoSilvaNo ratings yet

- MS-16332 R0aDocument41 pagesMS-16332 R0aRisoSilvaNo ratings yet

- Model Name:Bbr20 La-1512: Brookdale MCHDocument44 pagesModel Name:Bbr20 La-1512: Brookdale MCHRisoSilvaNo ratings yet

- CPU Generation: Version 0BDocument33 pagesCPU Generation: Version 0BRisoSilvaNo ratings yet

- GA-8GEM800 Schematics: Sheet Title Sheet TitleDocument32 pagesGA-8GEM800 Schematics: Sheet Title Sheet TitleRisoSilvaNo ratings yet

- Debug 1214Document3 pagesDebug 1214Badii MaulanaNo ratings yet

- CMDBuild AdministratorManual ENG V240Document134 pagesCMDBuild AdministratorManual ENG V240jesusferre2No ratings yet

- Computer Basic TroubleshootingDocument5 pagesComputer Basic TroubleshootingAngel2106No ratings yet

- 9210 User Manual PDFDocument245 pages9210 User Manual PDFsapchaseNo ratings yet

- WiFi NVR Kits User Manual (For NVS001, 002, 004 009)Document10 pagesWiFi NVR Kits User Manual (For NVS001, 002, 004 009)Emanuel NicolaeNo ratings yet

- Remote Data Monitoring and Diagnostic Services: A Services Initiative by BHELDocument9 pagesRemote Data Monitoring and Diagnostic Services: A Services Initiative by BHELAravind ShankarNo ratings yet

- Magnetic DiskDocument15 pagesMagnetic DiskAmit CoolNo ratings yet

- MIT - Press.beowulf Cluster Computing With Windows (2002)Document475 pagesMIT - Press.beowulf Cluster Computing With Windows (2002)Johnnier Hernández RiveraNo ratings yet

- Essl Connection Diagram For AllDocument5 pagesEssl Connection Diagram For Allpushkar.mulayNo ratings yet

- Satyanarayan Katha in Tamil PDFDocument4 pagesSatyanarayan Katha in Tamil PDFSeshadri Rajan Iyer0% (1)

- 11g Dataguard EnhancementsDocument27 pages11g Dataguard EnhancementsPrintesh PatelNo ratings yet

- Blue ToothDocument100 pagesBlue ToothAlejo Mateo SfercoNo ratings yet

- Ibm FW Uefi D7e174b-3.20 Anyos 32-64Document7 pagesIbm FW Uefi D7e174b-3.20 Anyos 32-64Tiberiu ImbriscaNo ratings yet

- 0329 Mladost TuristDocument7 pages0329 Mladost TuristGuran MaricioNo ratings yet

- LogDocument23 pagesLogRebs - Not OfficialNo ratings yet

- AN 124 User Guide For FT PROGDocument43 pagesAN 124 User Guide For FT PROGodragosNo ratings yet

- Babel - A Glossary of Computer OrientedDocument69 pagesBabel - A Glossary of Computer OrientedMaria NichiforNo ratings yet

- Ai Scripts Release Notes 7.0R3.1Document22 pagesAi Scripts Release Notes 7.0R3.1WaqasMirzaNo ratings yet

- PIC18F97J60 FAMILY: 64/80/100-Pin High-Performance, 1-Mbit Flash Microcontrollers With EthernetDocument6 pagesPIC18F97J60 FAMILY: 64/80/100-Pin High-Performance, 1-Mbit Flash Microcontrollers With EthernetDESTROYER2020No ratings yet

- Business Computer PDFDocument3 pagesBusiness Computer PDFadom laryeaNo ratings yet

- Lab 2 REsultDocument7 pagesLab 2 REsultlallala4415No ratings yet

- 2024-02-20-Mikro Deney Föyü - İngDocument41 pages2024-02-20-Mikro Deney Föyü - İngefepar7812No ratings yet

- Linux Interview Questions On Boot Process and Other StuffDocument14 pagesLinux Interview Questions On Boot Process and Other Stuffgururaj_hebbarNo ratings yet

- FS1-2 Flash Storage System Help Desk Support Consultant CertificationDocument76 pagesFS1-2 Flash Storage System Help Desk Support Consultant CertificationSuhaimi MieNo ratings yet

- The Von Neumann Computer ModelDocument11 pagesThe Von Neumann Computer ModelJerome ScottNo ratings yet

- Compal LA-D101P r0.1Document53 pagesCompal LA-D101P r0.1vinuNo ratings yet

- LCD Television Service Manual: Chassis MSD6886Document61 pagesLCD Television Service Manual: Chassis MSD6886Marcelo MoreiraNo ratings yet

- OpenVZ, Xen, and KVM PDFDocument7 pagesOpenVZ, Xen, and KVM PDFSFNo ratings yet

- OpenCore Vanilla Desktop GuideDocument437 pagesOpenCore Vanilla Desktop GuideAndi 01No ratings yet

- S4 EN Manual V1.1Document87 pagesS4 EN Manual V1.1Menam EssamNo ratings yet

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

Uploaded by

RisoSilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

X5328, X5329 (Replaces X25328, X25329) : CPU Supervisor With 32kbit SPI EEPROM

Uploaded by

RisoSilvaCopyright:

Available Formats

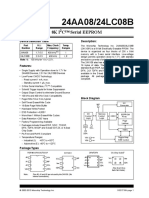

DATASHEET

X5328, X5329 (Replaces X25328, X25329) FN8132

CPU Supervisor with 32Kbit SPI EEPROM Rev 2.00

October 16, 2015

FEATURES DESCRIPTION

• Low VCC detection and reset assertion These devices combine three popular functions, Power-

—Five standard reset threshold voltages on Reset Control, Supply Voltage Supervision, and Block

—Re-program low VCC reset threshold voltage Lock Protect Serial EEPROM Memory in one package.

using special programming sequence This combination lowers system cost, reduces board

—Reset signal valid to VCC = 1V space requirements, and increases reliability.

• Long battery life with low power consumption

Applying power to the device activates the power-on

—<1µA max standby current

reset circuit which holds RESET/RESET active for a

—<400µA max active current during read

period of time. This allows the power supply and oscilla-

• 32Kbits of EEPROM

• Built-in inadvertent write protection tor to stabilize before the processor can execute code.

—Power-up/power-down protection circuitry The device’s low VCC detection circuitry protects the

—Protect 0, 1/4, 1/2 or all of EEPROM array with user’s system from low voltage conditions by holding

Block Lock™ protection RESET/RESET active when VCC falls below a mini-

—In circuit programmable ROM mode mum VCC trip point. RESET/RESET remains asserted

• 2MHz SPI interface modes (0,0 & 1,1) until VCC returns to proper operating level and stabi-

• Minimize EEPROM programming time lizes. Five industry standard VTRIP thresholds are

—32-byte page write mode available, however, Intersil’s unique circuits allow the

—Self-timed write cycle threshold to be reprogrammed to meet custom

—5ms write cycle time (typical) requirements or to fine-tune the threshold in applica-

• 2.7V to 5.5V and 4.5V to 5.5V power supply tions requiring higher precision.

operation

• Available packages

—14 Ld TSSOP, 8 Ld SOIC, 8 Ld PDIP

• Pb-free plus anneal available (RoHS compliant)

BLOCK DIAGRAM

WP Protect Logic

SI Data

Register Status

SO Register

Command

SCK Decode & 8Kbits

EEPROM Array

Control

CS Logic 8Kbits

16Kbits

Reset

Timebase

RESET/RESET

Power-on and

Low Voltage

VCC + Reset

Generation X5328 = RESET

VTRIP -

X5329 = RESET

FN8132 Rev 2.00 Page 1 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Ordering Information

VCC RANGE VTRIP TEMP PACKAGE

PART NUMBER PART MARKING (V) RANGE RANGE (°C) (RoHS Compliant)

RESET ACTIVE LOW

X5328PZ-4.5A (Note) (No longer available, recommended X5328P Z AL 4.5-5.5 4.5-4.75 0 to 70 8 Ld PDIP

replacement: X5328S8Z-4.5A)

X5328PIZ-4.5A (Note) (No longer available, recommended X5328P Z AM -40 to 85 8 Ld PDIP

replacement: X5328S8IZ-4.5A)

X5328S8Z-4.5A (Note) X5328 Z AL 0 to 70 8 Ld SOIC

X5328S8IZ-4.5A (Note) X5328 Z AM -40 to 85 8 Ld SOIC

X5328V14Z-4.5A (Note) X5328V Z AL 0 to 70 14 Ld TSSOP

X5328PZ (Note) (No longer available, recommended X5328P Z 4.5-5.5 4.25-4.5 0 to 70 8 Ld PDIP

replacement: X5328S8Z)

X5328PIZ (Note) (No longer available, recommended X5328P Z I -40 to 85 8 Ld PDIP

replacement: X5328S8IZ)

X5328S8Z* (Note) X5328 Z 0 to 70 8 Ld SOIC

X5328S8IZ* (Note) X5328 Z I -40 to 85 8 Ld SOIC

X5328PZ-2.7A (Note) (No longer available, recommended X5328P Z AN 2.7-5.5 2.85-3.0 0 to 70 8 Ld PDIP

replacement: X5328S8Z-2.7A)

X5328PIZ-2.7A (Note) (No longer available, recommended X5328P Z AP -40 to 85 8 Ld PDIP

replacement: X5328S8IZ-2.7A)

X5328S8Z-2.7A (Note) X5328 Z AN 0 to 70 8 Ld SOIC

X5328S8IZ-2.7A (Note) X5328 Z AP -40 to 85 8 Ld SOIC

X5328PZ-2.7 (Note) (No longer available, recommended X5328P Z F 2.7-5.5 2.55-2.7 0 to 70 8 Ld PDIP

replacement: X5328S8Z-2.7)

X5328PIZ-2.7 (Note) (No longer available, recommended X5328P Z G -40 to 85 8 Ld PDIP

replacement: X5328S8IZ-2.7)

X5328S8Z-2.7* (Note) X5328 Z F 0 to 70 8 Ld SOIC

X5328S8IZ-2.7* (Note) X5328 Z G -40 to 85 8 Ld SOIC

RESET ACTIVE HIGH

X5329S8Z-4.5A (Note) X5329 Z AL 4.5-5.5 4.5-4.75 0 to 70 8 Ld SOIC

X5329S8IZ-4.5A (Note) X5329 Z AM -40 to 85 8 Ld SOIC

X5329V14Z-4.5A (Note) X5329V Z AL 0 to 70 14 Ld TSSOP

X5329S8Z* (Note) X5329 Z 4.5-5.5 4.25-4.5 0 to 70 8 Ld SOIC

X5329S8IZ* (Note) X5329 Z I -40 to 85 8 Ld SOIC

X5329S8Z-2.7A (Note) X5329 Z AN 2.7-5.5 2.85-3.0 0 to 70 8 Ld SOIC

X5329S8IZ-2.7A (Note) (No longer available, recommended X5329 Z AP -40 to 85 8 Ld SOIC

replacement: X5329S8Z-2.7A)

X5329S8Z-2.7* (Note) X5329 Z F 2.7-5.5 2.55-2.7 0 to 70 8 Ld SOIC

X5329S8IZ-2.7* (Note) (No longer available, recommended X5329 Z G -40 to 85 8 Ld SOIC

replacement: X5329S8Z-2.7)

*Add “T1” suffix for tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

FN8132 Rev 2.00 Page 2 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

PIN DESCRIPTION

Pin Pin TS-

(SOIC/PDIP) SOP Name Function

1 1 CS Chip Select Input. CS HIGH, deselects the device and the SO output pin is at a

high impedance state. Unless a nonvolatile write cycle is underway, the device will

be in the standby power mode. CS LOW enables the device, placing it in the ac-

tive power mode. Prior to the start of any operation after power-up, a HIGH to

LOW transition on CS is required.

2 2 SO Serial Output. SO is a push/pull serial data output pin. A read cycle shifts data out

on this pin. The falling edge of the serial clock (SCK) clocks the data out.

5 8 SI Serial Input. SI is a serial data input pin. Input all opcodes, byte addresses, and

memory data on this pin. The rising edge of the serial clock (SCK) latches the input

data. Send all opcodes (Table 1), addresses and data MSB first.

6 9 SCK Serial Clock. The Serial Clock controls the serial bus timing for data input and out-

put. The rising edge of SCK latches in the opcode, address, or data bits present on

the SI pin. The falling edge of SCK changes the data output on the SO pin.

3 6 WP Write Protect. The WP pin works in conjunction with a nonvolatile WPEN bit to

“lock” the setting of the Watchdog Timer control and the memory write protect bits.

4 7 VSS Ground

8 14 VCC Supply Voltage

7 13 RESET/ Reset Output. RESET/RESET is an active LOW/HIGH, open drain output which

RESET goes active whenever VCC falls below the minimum VCC sense level. It will remain

active until VCC rises above the minimum VCC sense level for 200ms. RESET/RE-

SET goes active on power-up at about 1V and remains active for 200ms after the

power supply stabilizes.

3-5,10-12 NC No internal connections

PIN CONFIGURATION

14 Ld TSSOP

8 Ld SOIC/PDIP CS 1 14 VCC

1 8 VCC SO 2 13 RESET/RESET

CS

NC 3 12 NC

SO 2 7 RESET/RESET

X5328/29 NC 4 X5328/29 11 NC

WP 3 6 SCK NC 5 10 NC

VCC 4 5 SI WP SCK

6 9

VSS 7 8 SI

FN8132 Rev 2.00 Page 3 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

PRINCIPLES OF OPERATION Figure 1. Set VTRIP Voltage

Power-On Reset

Application of power to the X5328/X5329 activates a CS

Power-on Reset Circuit. This circuit goes active at about VP

1V and pulls the RESET/RESET pin active. This signal

SCK

prevents the system microprocessor from starting to

operate with insufficient voltage or prior to stabilization of VP

the oscillator. When VCC exceeds the device VTRIP

value for 200ms (nominal) the circuit releases SI

RESET/RESET, allowing the processor to begin execut-

ing code.

Resetting the VTRIP Voltage

Low Voltage Monitoring This procedure sets the VTRIP to a “native” voltage level.

During operation, the X5328/X5329 monitors the VCC For example, if the current VTRIP is 4.4V and the VTRIP is

level and asserts RESET/RESET if supply voltage falls reset, the new VTRIP is something less than 1.7V. This

below a preset minimum VTRIP. The RESET/RESET sig- procedure must be used to set the voltage to a lower

nal prevents the microprocessor from operating in a value.

power fail or brownout condition. The RESET/RESET

To reset the VTRIP voltage, apply a voltage between 2.7

signal remains active until the voltage drops below 1V. It

and 5.5V to the VCC pin. Tie the CS pin, the WP pin, and

also remains active until VCC returns and exceeds VTRIP

the SCK pin HIGH. RESET/RESET and SO pins are left

for 200ms.

unconnected. Then apply the programming voltage VP

to the SI pin ONLY and pulse CS LOW then HIGH.

VCC Threshold Reset Procedure

Remove VP and the sequence is complete.

The X5328/X5329 has a standard VCC threshold (VTRIP)

voltage. This value will not change over normal operat- Figure 2. Reset VTRIP Voltage

ing and storage conditions. However, in applications

where the standard VTRIP is not exactly right, or for

higher precision in the VTRIP value, the X5328/X5329

CS

threshold may be adjusted.

Setting the VTRIP Voltage SCK

VCC

This procedure sets the VTRIP to a higher voltage value.

For example, if the current VTRIP is 4.4V and the new VP

VTRIP is 4.6V, this procedure directly makes the change.

SI

If the new setting is lower than the current setting, then it

is necessary to reset the trip point before setting the new

value.

To set the new VTRIP voltage, apply the desired VTRIP

threshold to the VCC pin and tie the CS pin and the WP

pin HIGH. RESET/RESET and SO pins are left uncon-

nected. Then apply the programming voltage VP to both

SCK and SI and pulse CS LOW then HIGH. Remove VP

and the sequence is complete.

FN8132 Rev 2.00 Page 4 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Figure 3. VTRIP Programming Sequence Flow Chart

VTRIP Programming

Execute

Reset VTRIP

Sequence

Set VCC = VCC Applied =

Desired VTRIP

New VCC Applied = Execute New VCC Applied =

Old VCC Applied + Error Set VTRIP Old VCC Applied - Error

Sequence

Apply 5V to VCC Execute

Reset VTRIP

Sequence

Decrement VCC

(VCC = VCC - 10mV)

NO RESET pin

goes active?

YES

Error Emax Measured VTRIP - Error > Emax

Desired VTRIP

Error < Emax

DONE

Emax = Maximum Desired Error

Figure 4. Sample VTRIP Reset Circuit

VP

NC 4.7K

4.7K

RESET

1 8

NC

NC 2 7

X5328/29

VTRIP 3 6

Adj. + 4 5

Program

Reset VTRIP

10K 10K

Test VTRIP

Set VTRIP

FN8132 Rev 2.00 Page 5 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

SPI SERIAL MEMORY Write Enable Latch

The memory portion of the device is a CMOS Serial The device contains a Write Enable Latch. This latch

EEPROM array with Intersil’s block lock protection. The must be SET before a Write Operation is initiated. The

array is internally organized as x 8. The device features a WREN instruction will set the latch and the WRDI

Serial Peripheral Interface (SPI) and software protocol instruction will reset the latch (Figure 3). This latch is

allowing operation on a simple four-wire bus. automatically reset upon a power-up condition and after

the completion of a valid Write Cycle.

The device utilizes Intersil’s proprietary Direct Write™

cell, providing a minimum endurance of 100,000 cycles Status Register

and a minimum data retention of 100 years. The RDSR instruction provides access to the Status

The device is designed to interface directly with the syn- Register. The Status Register may be read at any time,

chronous Serial Peripheral Interface (SPI) of many pop- even during a Write Cycle. The Status Register is for-

ular microcontroller families. It contains an 8-bit matted as follows:

instruction register that is accessed via the SI input, with

data being clocked in on the rising edge of SCK. CS 7 6 5 4 3 2 1 0

must be LOW during the entire operation. WPEN FLB 1* 1* BL1 BL0 WEL WIP

All instructions (Table 1), addresses and data are trans- *Bits (5,4) should be written as ‘1’ only.

ferred MSB first. Data input on the SI line is latched on The Write-In-Progress (WIP) bit is a volatile, read only

the first rising edge of SCK after CS goes LOW. Data is bit and indicates whether the device is busy with an

output on the SO line by the falling edge of SCK. SCK is internal nonvolatile write operation. The WIP bit is read

static, allowing the user to stop the clock and then start it using the RDSR instruction. When set to a “1”, a nonvol-

again to resume operations where left off. atile write operation is in progress. When set to a “0”, no

write is in progress.

Table 1. Instruction Set

Instruction Name Instruction Format* Operation

WREN 0000 0110 Set the Write Enable Latch (Enable Write Operations)

SFLB 0000 0000 Set Flag Bit

WRDI/RFLB 0000 0100 Reset the Write Enable Latch/Reset Flag Bit

RSDR 0000 0101 Read Status Register

WRSR 0000 0001 Write Status Register (Block Lock, WPEN & Flag Bits)

READ 0000 0011 Read Data from Memory Array Beginning at Selected Address

WRITE 0000 0010 Write Data to Memory Array Beginning at Selected Address

Note: *Instructions are shown MSB in leftmost position. Instructions are transferred MSB first.

Table 2. Block Protect Matrix

WREN CMD Status Register Device Pin Block Block Status Register

WPEN, BL0, BL1,

WEL WPEN WP# Protected Block Unprotected Block WD0, WD1

0 X X Protected Protected Protected

1 1 0 Protected Writable Protected

1 0 X Protected Writable Writable

1 X 1 Protected Writable Writable

FN8132 Rev 2.00 Page 6 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

The Write Enable Latch (WEL) bit indicates the Status of In Circuit Programmable ROM Mode

the Write Enable Latch. When WEL = 1, the latch is set This mechanism protects the block lock and Watchdog

HIGH and when WEL = 0 the latch is reset LOW. The bits from inadvertent corruption.

WEL bit is a volatile, read only bit. It can be set by the

WREN instruction and can be reset by the WRDS In the locked state (Programmable ROM Mode) the WP pin

instruction. is LOW and the nonvolatile bit WPEN is “1”. This mode

disables nonvolatile writes to the device’s Status Register.

The block lock bits, BL0 and BL1, set the level of block

lock protection. These nonvolatile bits are programmed Setting the WP pin LOW while WPEN is a “1” while an

using the WRSR instruction and allow the user to protect internal write cycle to the Status Register is in progress

one quarter, one half, all or none of the EEPROM array. will not stop this write operation, but the operation dis-

Any portion of the array that is block lock protected can ables subsequent write attempts to the Status Register.

be read but not written. It will remain protected until the

When WP is HIGH, all functions, including nonvolatile

BL bits are altered to disable block lock protection of that

writes to the Status Register operate normally.

portion of memory.

Setting the WPEN bit in the Status Register to “0” blocks

Status Register Bits Array Addresses Protected the WP pin function, allowing writes to the Status Register

BL1 BL0 X5328/X5329 when WP is HIGH or LOW. Setting the WPEN bit to “1”

0 0 None while the WP pin is LOW activates the Programmable

ROM mode, thus requiring a change in the WP pin prior to

0 1 $0C00-$0FFF subsequent Status Register changes. This allows manu-

1 0 $0800-$0FFF facturing to install the device in a system with WP pin

1 1 $0000-$0FFF grounded and still be able to program the Status Register.

Manufacturing can then load Configuration data, manu-

The FLAG bit shows the status of a volatile latch that can facturing time and other parameters into the EEPROM,

be set and reset by the system using the SFLB and RFLB then set the portion of memory to be protected by setting

instructions. The Flag bit is automatically reset upon the block lock bits, and finally set the “OTP mode” by set-

power-up. ting the WPEN bit. Data changes now require a hardware

change.

The nonvolatile WPEN bit is programmed using the

WRSR instruction. This bit works in conjunction with the

WP pin to provide an In-Circuit Programmable ROM func-

tion (Table 2). WP is LOW and WPEN bit programmed

HIGH disables all Status Register Write Operations.

Figure 5. Read EEPROM Array Sequence

CS

0 1 2 3 4 5 6 7 8 9 10 20 21 22 23 24 25 26 27 28 29 30

SCK

Instruction 16 Bit Address

SI 15 14 13 3 2 1 0

Data Out

High Impedance

SO 7 6 5 4 3 2 1 0

MSB

FN8132 Rev 2.00 Page 7 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Read Sequence For the Page Write Operation (byte or page write) to be

When reading from the EEPROM memory array, CS is completed, CS can only be brought HIGH after bit 0 of

first pulled low to select the device. The 8-bit READ the last data byte to be written is clocked in. If it is

instruction is transmitted to the device, followed by the brought HIGH at any other time, the write operation will

16-bit address. After the READ opcode and address are not be completed (Figure 4).

sent, the data stored in the memory at the selected To write to the Status Register, the WRSR instruction is

address is shifted out on the SO line. The data stored in followed by the data to be written (Figure 5). Data bits 0

memory at the next address can be read sequentially by and 1 must be “0”.

continuing to provide clock pulses. The address is auto-

matically incremented to the next higher address after While the write is in progress following a Status Register

each byte of data is shifted out. When the highest or EEPROM Sequence, the Status Register may be

address is reached, the address counter rolls over to read to check the WIP bit. During this time the WIP bit

address $0000 allowing the read cycle to be continued will be high.

indefinitely. The read operation is terminated by taking

CS high. Refer to the Read EEPROM Array Sequence OPERATIONAL NOTES

(Figure 1). The device powers-up in the following state:

To read the Status Register, the CS line is first pulled low – The device is in the low power standby state.

to select the device followed by the 8-bit RDSR instruc-

tion. After the RDSR opcode is sent, the contents of the – A HIGH to LOW transition on CS is required to enter

Status Register are shifted out on the SO line. Refer to an active state and receive an instruction.

the Read Status Register Sequence (Figure 2). – SO pin is high impedance.

– The Write Enable Latch is reset.

Write Sequence

– The Flag Bit is reset.

Prior to any attempt to write data into the device, the

“Write Enable” Latch (WEL) must first be set by issuing – Reset Signal is active for tPURST.

the WREN instruction (Figure 3). CS is first taken LOW,

then the WREN instruction is clocked into the device. Data Protection

After all eight bits of the instruction are transmitted, CS The following circuitry has been included to prevent

must then be taken HIGH. If the user continues the Write inadvertent writes:

Operation without taking CS HIGH after issuing the

WREN instruction, the Write Operation will be ignored. – A WREN instruction must be issued to set the Write

Enable Latch.

To write data to the EEPROM memory array, the user

– CS must come HIGH at the proper clock count in order

then issues the WRITE instruction followed by the 16-bit

to start a nonvolatile write cycle.

address and then the data to be written. Any unused

address bits are specified to be “0’s”. The WRITE opera-

tion minimally takes 32 clocks. CS must go low and

remain low for the duration of the operation. If the

address counter reaches the end of a page and the

clock continues, the counter will roll back to the first

address of the page and overwrite any data that may

have been previously written.

FN8132 Rev 2.00 Page 8 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Figure 6. Read Status Register Sequence

CS

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

SCK

Instruction

SI

Data Out

High Impedance

SO 7 6 5 4 3 2 1 0

MSB

Figure 7. Write Enable Latch Sequence

CS

0 1 2 3 4 5 6 7

SCK

SI

High Impedance

SO

Figure 8. Write Sequence

CS

0 1 2 3 4 5 6 7 8 9 10 20 21 22 23 24 25 26 27 28 29 30 31

SCK

Instruction 16 Bit Address Data Byte 1

SI 15 14 13 3 2 1 0 7 6 5 4 3 2 1 0

CS

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

SCK

Data Byte 2 Data Byte 3 Data Byte N

SI 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 6 5 4 3 2 1 0

FN8132 Rev 2.00 Page 9 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Figure 9. Status Register Write Sequence

CS

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

SCK

Instruction Data Byte

SI 7 6 5 4 3 2 1 0

High Impedance

SO

SYMBOL TABLE

WAVEFORM INPUTS OUTPUTS

Must be Will be

steady steady

May change Will change

from LOW from LOW

to HIGH to HIGH

May change Will change

from HIGH from HIGH

to LOW to LOW

Don’t Care: Changing:

Changes State Not

Allowed Known

N/A Center Line

is High

Impedance

FN8132 Rev 2.00 Page 10 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

ABSOLUTE MAXIMUM RATINGS COMMENT

Temperature under bias .................... -65°C to +135°C Stresses above those listed under “Absolute Maximum

Storage temperature ........................ -65°C to +150°C Ratings” may cause permanent damage to the device.

Voltage on any pin with This is a stress rating only; functional operation of the

respect to VSS ...................................... -1.0V to +7V device (at these or any other conditions above those

D.C. output current ............................................... 5mA listed in the operational sections of this specification) is

Lead temperature (soldering, 10s) .................... 300°C not implied. Exposure to absolute maximum rating condi-

tions for extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

Temperature Min. Max. Voltage Option Supply Voltage

Commercial 0°C 70°C -2.7 or -2.7A 2.7V to 5.5V

Industrial -40°C +85°C BLank or -4.5A 4.5V-5.5V

D.C. OPERATING CHARACTERISTICS (Over the recommended operating conditions unless otherwise specified.)

Limits

Symbol Parameter Min. Typ. Max. Unit Test Conditions

ICC1 VCC Write Current (Active) 5 mA SCK = VCC x 0.1/VCC x 0.9 @ 2MHz,

SO = Open

ICC2 VCC Read Current (Active) 0.4 mA SCK = VCC x 0.1/VCC x 0.9 @ 2MHz,

SO = Open

ISB VCC Standby Current 1 µA CS = VCC, VIN = VSS or VCC,

VCC = 5.5V

ILI Input Leakage Current 0.1 10 µA VIN = VSS to VCC

ILO Output Leakage Current 0.1 10 µA VOUT = VSS to VCC

VIL(1) Input LOW Voltage -0.5 VCC x 0.3 V

VIH(1) Input HIGH Voltage VCC x 0.7 VCC + 0.5 V

VOL1 Output LOW Voltage 0.4 V VCC > 3.3V, IOL = 2.1mA

VOL2 Output LOW Voltage 0.4 V 2V < VCC 3.3V, IOL = 1mA

VOL3 Output LOW Voltage 0.4 V VCC 2V, IOL = 0.5mA

VOH1 Output HIGH Voltage VCC - 0.8 V VCC > 3.3V, IOH = -1.0mA

VOH2 Output HIGH Voltage VCC - 0.4 V 2V < VCC 3.3V, IOH = -0.4mA

VOH3 Output HIGH Voltage VCC - 0.2 V VCC 2V, IOH = -0.25mA

VOLS Reset Output LOW Voltage 0.4 V IOL = 1mA

CAPACITANCE TA = +25°C, f = 1MHz, VCC = 5V

Symbol Test Max. Unit Conditions

COUT (2) Output Capacitance (SO, RESET, RESET) 8 pF VOUT = 0V

CIN (2) Input Capacitance (SCK, SI, CS, WP) 6 pF VIN = 0V

Notes: (1) VIL min. and VIH max. are for reference only and are not tested.

(2) This parameter is periodically sampled and not 100% tested.

FN8132 Rev 2.00 Page 11 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

EQUIVALENT A.C. LOAD CIRCUIT AT 5V VCC A.C. TEST CONDITIONS

Input pulse levels VCC x 0.1 to VCC x 0.9

5V 5V

Input rise and fall times 10ns

2.06k 4.6k Input and output timing level VCC x0.5

Output RESET/RESET

3.03k 100pF 30pF

A.C. CHARACTERISTICS (Over recommended operating conditions, unless otherwise specified)

Serial Input Timing

2.7-5.5V

Symbol Parameter Min. Max. Unit

fSCK Clock Frequency 0 2 MHz

tCYC Cycle Time 500 ns

tLEAD CS Lead Time 250 ns

tLAG CS Lag Time 250 ns

tWH Clock HIGH Time 200 ns

tWL Clock LOW Time 250 ns

tSU Data Setup Time 50 ns

tH Data Hold Time 50 ns

tRI(3) Input Rise Time 100 ns

tFI(3) Input Fall Time 100 ns

tCS CS Deselect Time 500 ns

tWC(4) Write Cycle Time 10 ms

FN8132 Rev 2.00 Page 12 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Serial Input Timing

tCS

CS

tLEAD tLAG

SCK

tSU tH tRI tFI

SI MSB IN LSB IN

High Impedance

SO

Serial Output Timing

2.7-5.5V

Symbol Parameter Min. Max. Unit

fSCK Clock Frequency 0 2 MHz

tDIS Output Disable Time 250 ns

tV Output Valid from Clock Low 250 ns

tHO Output Hold Time 0 ns

tRO (3) Output Rise Time 100 ns

tFO (3) Output Fall Time 100 ns

Notes: (3) This parameter is periodically sampled and not 100% tested.

(4) tWC is the time from the rising edge of CS after a valid write sequence has been sent to the end of the self-timed internal nonvolatile

write cycle.

Serial Output Timing

CS

tCYC tWH tLAG

SCK

tV tHO tWL tDIS

SO MSB Out MSB–1 Out LSB Out

ADDR

SI

LSB IN

FN8132 Rev 2.00 Page 13 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Power-Up and Power-Down Timing

VTRIP VTRIP

VCC tPURST

0 Volts

tPURST tF

tR tRPD

RESET (X5328)

RESET (X5329)

RESET Output Timing

Symbol Parameter Min. Typ. Max. Unit

VTRIP Reset Trip Point Voltage, X5328-4.5A, X5328-4.5A 4.5 4.63 4.75

Reset Trip Point Voltage, X5328, X5329 4.25 4.38 4.5

V

Reset Trip Point Voltage, X5328-2.7A, X5329-2.7A 2.85 2.93 3.0

Reset Trip Point Voltage, X5328-2.7, X5329-2.7 2.55 2.63 2.7

VTH VTRIP Hysteresis (HIGH to LOW vs. LOW to HIGH VTRIP voltage) 20 mV

tPURST Power-up Reset Time Out 100 200 280 ms

tRPD (5) VCC Detect to Reset/Output 500 ns

tF (5) VCC Fall Time 100 µs

tR (5) VCC Rise Time 100 µs

VRVALID Reset Valid VCC 1 V

Note: (5) This parameter is periodically sampled and not 100% tested.

FN8132 Rev 2.00 Page 14 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

VTRIP Set Conditions

tTHD

VCC VTRIP

tTSU

tRP

tVPS tP tVPH

CS tVPO

tVPS tVPH

VP

SCK

VP tVPO

SI

VTRIP Reset Conditions

VCC*

tRP

tVPS tP tVP1

CS tVPS tVPO

tVPH

VCC

SCK

VP tVPO

SI

*VCC > Programmed VTRIP

FN8132 Rev 2.00 Page 15 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

VTRIP Programming Specifications VCC = 1.7-5.5V; Temperature = 0°C to 70°C

Parameter Description Min. Max. Unit

tVPS SCK VTRIP Program Voltage Setup time 1 µs

tVPH SCK VTRIP Program Voltage Hold time 1 µs

tP VTRIP Program Pulse Width 1 µs

tTSU VTRIP Level Setup time 10 µs

tTHD VTRIP Level Hold (stable) time 10 ms

tWC VTRIP Write Cycle Time 10 ms

tRP VTRIP Program Cycle Recovery Period (Between successive programming cycles) 10 ms

tVPO SCK VTRIP Program Voltage Off time before next cycle 0 ms

VP Programming Voltage 15 18 V

VTRAN VTRIP Programed Voltage Range 1.7 5.0 V

Vta1 Initial VTRIP Program Voltage accuracy (VCC applied-VTRIP) (Programmed at 25°C.) -0.1 +0.4 V

Vta2 Subsequent VTRIP Program Voltage accuracy [(VCC applied-Vta1)-VTRIP] -25 +25 mV

(Programmed at 25°C.)

Vtr VTRIP Program Voltage repeatability (Successive program operations.) (programmed at -25 +25 mV

25°C)

Vtv VTRIP Program variation after programming (0-75°C). (programmed at 25°C) -25 +25 mV

VTRIP programming parameters are periodically sampled and are not 100% tested.

FN8132 Rev 2.00 Page 16 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

TYPICAL PERFORMANCE

VCC Supply Current vs. Temperature (ISB) tPURST vs. Temperature

2 205

200

195

190

Time (ms)

185

Isb (µA)

1 (VCC = 3V, 5V) 180

175

170

165

160

0 -40 25 90

-40C 25C 90C Degrees °C

Temp°C

VTRIP vs. Temperature (programmed at 25°C)

5.025

VTRIP = 5V

5.000

4.975

3.525

VTRIP = 3.5V

Voltage

3.500

3.475

2.525

VTRIP = 2.5V

2.500

2.475

0 25 85

Temperature

FN8132 Rev 2.00 Page 17 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Revision History

The revision history provided is for informational purposes only and is believed to be accurate, but not warranted. Please go to the web to make

sure that you have the latest revision.

DATE REVISION CHANGE

October 16, 2015 FN8132.2 Updated the Ordering Information table on page 2.

Added Revision History and About Intersil sections.

Replaced all Package Outline drawings with the most recent versions.

About Intersil

Intersil Corporation is a leading provider of innovative power management and precision analog solutions. The company's products

address some of the largest markets within the industrial and infrastructure, mobile computing and high-end consumer markets.

For the most updated datasheet, application notes, related documentation and related parts, please see the respective product

information page found at www.intersil.com.

You may report errors or suggestions for improving this datasheet by visiting www.intersil.com/ask.

Reliability reports are also available from our website at www.intersil.com/support.

© Copyright Intersil Americas LLC 2005-2015. All Rights Reserved.

All trademarks and registered trademarks are the property of their respective owners.

For additional products, see www.intersil.com/en/products.html

Intersil products are manufactured, assembled and tested utilizing ISO9001 quality systems as noted

in the quality certifications found at www.intersil.com/en/support/qualandreliability.html

Intersil products are sold by description only. Intersil may modify the circuit design and/or specifications of products at any time without notice, provided that such

modification does not, in Intersil's sole judgment, affect the form, fit or function of the product. Accordingly, the reader is cautioned to verify that datasheets are

current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. However, no responsibility is assumed by Intersil or its

subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

FN8132 Rev 2.00 Page 18 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Package Outline Drawing

M8.15E

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

Rev 0, 08/09

4

4.90 ± 0.10 A

DETAIL "A" 0.22 ± 0.03

6.0 ± 0.20

3.90 ± 0.10

PIN NO.1

ID MARK

(0.35) x 45°

4° ± 4°

0.43 ± 0.076

1.27

0.25 M C A B

SIDE VIEW “B”

TOP VIEW

1.75 MAX

1.45 ± 0.1

0.25

GAUGE PLANE

C

0.175 ± 0.075 SEATING PLANE

0.10 C

SIDE VIEW “A

0.63 ±0.23

DETAIL "A"

(1.27) (0.60)

NOTES:

(1.50)

1. Dimensions are in millimeters.

Dimensions in ( ) for Reference Only.

2. Dimensioning and tolerancing conform to AMSE Y14.5m-1994.

(5.40) 3. Unless otherwise specified, tolerance : Decimal ± 0.05

4. Dimension does not include interlead flash or protrusions.

Interlead flash or protrusions shall not exceed 0.25mm per side.

5. The pin #1 identifier may be either a mold or mark feature.

6. Reference to JEDEC MS-012.

TYPICAL RECOMMENDED LAND PATTERN

FN8132 Rev 2.00 Page 19 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Plastic Dual-In-Line Packages (PDIP)

D E N

PIN #1

A2 A INDEX

E1

SEATING

PLANE c

L

A1

eA 1 2 N/2

NOTE 5

e b eB b2

MDP0031

PLASTIC DUAL-IN-LINE PACKAGE

INCHES

SYMBOL PDIP8 PDIP14 PDIP16 PDIP18 PDIP20 TOLERANCE NOTES

A 0.210 0.210 0.210 0.210 0.210 MAX

A1 0.015 0.015 0.015 0.015 0.015 MIN

A2 0.130 0.130 0.130 0.130 0.130 ±0.005

b 0.018 0.018 0.018 0.018 0.018 ±0.002

b2 0.060 0.060 0.060 0.060 0.060 +0.010/-0.015

c 0.010 0.010 0.010 0.010 0.010 +0.004/-0.002

D 0.375 0.750 0.750 0.890 1.020 ±0.010 1

E 0.310 0.310 0.310 0.310 0.310 +0.015/-0.010

E1 0.250 0.250 0.250 0.250 0.250 ±0.005 2

e 0.100 0.100 0.100 0.100 0.100 Basic

eA 0.300 0.300 0.300 0.300 0.300 Basic

eB 0.345 0.345 0.345 0.345 0.345 ±0.025

L 0.125 0.125 0.125 0.125 0.125 ±0.010

N 8 14 16 18 20 Reference

Rev. C 2/07

NOTES:

1. Plastic or metal protrusions of 0.010” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions E and eA are measured with the leads constrained perpendicular to the seating plane.

4. Dimension eB is measured with the lead tips unconstrained.

5. 8 and 16 lead packages have half end-leads as shown.

FN8132 Rev 2.00 Page 20 of 21

October 16, 2015

X5328, X5329 (Replaces X25328, X25329)

Package Outline Drawing

M14.173

14 LEAD THIN SHRINK SMALL OUTLINE PACKAGE (TSSOP)

Rev 3, 10/09

A

1 3

5.00 ±0.10

14 8 SEE

DETAIL "X"

6.40

PIN #1

4.40 ±0.10 I.D. MARK

2 3

0.20 C B A 1 7

0.65 B 0.09-0.20

TOP VIEW END VIEW

1.00 REF

H 0.05

C

0.90 +0.15/-0.10

1.20 MAX

SEATING GAUGE

PLANE PLANE 0.25

0.25 +0.05/-0.06 5

0.10 C 0.05 MIN 0°-8°

0.10 CBA

0.15 MAX 0.60 ±0.15

SIDE VIEW DETAIL "X"

(1.45)

NOTES:

1. Dimension does not include mold flash, protrusions or gate burrs.

(5.65)

Mold flash, protrusions or gate burrs shall not exceed 0.15 per side.

2. Dimension does not include interlead flash or protrusion. Interlead

flash or protrusion shall not exceed 0.25 per side.

3. Dimensions are measured at datum plane H.

4. Dimensioning and tolerancing per ASME Y14.5M-1994.

5. Dimension does not include dambar protrusion. Allowable protrusion

shall be 0.80mm total in excess of dimension at maximum material

condition. Minimum space between protrusion and adjacent lead is 0.07mm.

(0.65 TYP) (0.35 TYP) 6. Dimension in ( ) are for reference only.

7. Conforms to JEDEC MO-153, variation AB-1.

TYPICAL RECOMMENDED LAND PATTERN

FN8132 Rev 2.00 Page 21 of 21

October 16, 2015

You might also like

- 4K, 512 X 8 Bit: FN8126.2 Data Sheet March 16, 2006Document21 pages4K, 512 X 8 Bit: FN8126.2 Data Sheet March 16, 2006Angel LugoNo ratings yet

- AT25080A, 160A, 320A, 640A Rev04Document23 pagesAT25080A, 160A, 320A, 640A Rev04Bobby HancockNo ratings yet

- Ds5074a 00Document40 pagesDs5074a 00martin sembinelliNo ratings yet

- Nec 78k0 Kb2Document27 pagesNec 78k0 Kb2Anonymous pu1L9ZNo ratings yet

- Datasheet 28Document35 pagesDatasheet 28Eric ArcherNo ratings yet

- Z86e0412psc PDFDocument44 pagesZ86e0412psc PDFhectorsevillaNo ratings yet

- Synchronous Rectified MOSFET Driver With Pre-Biased Load Startup CapabilityDocument11 pagesSynchronous Rectified MOSFET Driver With Pre-Biased Load Startup CapabilityYogender KumarNo ratings yet

- Z86E0812SSCDocument44 pagesZ86E0812SSCmstrkoskiNo ratings yet

- DS8884B 01Document46 pagesDS8884B 01semar bypasNo ratings yet

- ISL62882HRTZDocument42 pagesISL62882HRTZAnderson PimentelNo ratings yet

- Atmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetDocument20 pagesAtmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetalaitsevNo ratings yet

- ISL62883 RenesasDocument37 pagesISL62883 Renesasanh_sao_dem_92No ratings yet

- LKS32MC05x 3P3N DS EN v1.88Document47 pagesLKS32MC05x 3P3N DS EN v1.88vishalkumarNo ratings yet

- P87C51RA2/RB2/RC2/RD2: 80C51 8-Bit Microcontroller FamilyDocument67 pagesP87C51RA2/RB2/RC2/RD2: 80C51 8-Bit Microcontroller FamilyAlbert YasnóNo ratings yet

- MDT10P57: 1. General DescriptionDocument13 pagesMDT10P57: 1. General DescriptionJuan Carlos Ramírez LeónNo ratings yet

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonNo ratings yet

- Two-Wire Serial Eeprom: FeaturesDocument19 pagesTwo-Wire Serial Eeprom: Featuresvladimir_p80No ratings yet

- 2M (256K 8/128K 16) BIT: Flash MemoryDocument49 pages2M (256K 8/128K 16) BIT: Flash MemoryEdson CostaNo ratings yet

- 3-Wire Serial Eeproms: FeaturesDocument18 pages3-Wire Serial Eeproms: FeaturesAriana ScheiderNo ratings yet

- En25qh64a EonDocument75 pagesEn25qh64a EonMarcelituz RojasNo ratings yet

- CXP82316 - I.C.Document20 pagesCXP82316 - I.C.Andre BaezNo ratings yet

- Two-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64ADocument22 pagesTwo-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64AmedNo ratings yet

- Atmel DatasheetDocument27 pagesAtmel DatasheetKhoa DangNo ratings yet

- 8-Bit Atmel Micro ControllerDocument40 pages8-Bit Atmel Micro ControllerSabita LangkamNo ratings yet

- At Mega 1280Document448 pagesAt Mega 1280Craciun SergiuNo ratings yet

- (BISS) TransistorsDocument12 pages(BISS) TransistorsMiloud ChouguiNo ratings yet

- Data SheetDocument37 pagesData SheetRenny Amalia PratiwiNo ratings yet

- At 25080Document21 pagesAt 25080sabNo ratings yet

- 25AA640A/25LC640A: 64K SPI Bus Serial EEPROMDocument36 pages25AA640A/25LC640A: 64K SPI Bus Serial EEPROMmarino246No ratings yet

- 8-Bit Microcontroller With 16K/ 32K Bytes Flash AT89C51RB2 AT89C51RC2Document127 pages8-Bit Microcontroller With 16K/ 32K Bytes Flash AT89C51RB2 AT89C51RC2MNPRAWINNo ratings yet

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pages24AA08/24LC08B: 8KI C Serial EEPROMjoseNo ratings yet

- PIC16F887Document338 pagesPIC16F887David BaronNo ratings yet

- Datasheet 24c01 EepromDocument26 pagesDatasheet 24c01 EepromItalo Vasquez LeonNo ratings yet

- At25f512a 844895Document19 pagesAt25f512a 844895mirage0706No ratings yet

- 24LC08 PDFDocument30 pages24LC08 PDFJaime BarrancoNo ratings yet

- 8-Bit Microcontroller With 1K Bytes Downloadable Flash AT90S1200 PreliminaryDocument7 pages8-Bit Microcontroller With 1K Bytes Downloadable Flash AT90S1200 PreliminaryRichard KrillNo ratings yet

- 8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesDocument137 pages8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesCarlos BaezNo ratings yet

- Three-Wire Serial Eeproms: FeaturesDocument21 pagesThree-Wire Serial Eeproms: FeaturesX'mix DreamerNo ratings yet

- Two-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64ADocument21 pagesTwo-Wire Serial EEPROM 32K (4096 X 8) 64K (8192 X 8) AT24C32A AT24C64Anordio2No ratings yet

- TL 3845Document29 pagesTL 3845Hisham MohamedNo ratings yet

- Slvs 038 IDocument28 pagesSlvs 038 Igabriel6276No ratings yet

- Tlx84X Current-Mode PWM Controllers: 1 Features 3 DescriptionDocument26 pagesTlx84X Current-Mode PWM Controllers: 1 Features 3 DescriptionAnonymous t9tLb3WgNo ratings yet

- R8C24 25 Flyer (24-003A)Document2 pagesR8C24 25 Flyer (24-003A)nagforuNo ratings yet

- Mcp320x 12-Bit AdcDocument34 pagesMcp320x 12-Bit AdcGeoFurrielNo ratings yet

- Xmc-Xm25qh64ahig C328461Document75 pagesXmc-Xm25qh64ahig C328461c4rl0slinuxNo ratings yet

- Xmc-Xm25qh128ahig C328463Document78 pagesXmc-Xm25qh128ahig C328463Manishkumar JethvaNo ratings yet

- Philips P89C51RD2 6Document52 pagesPhilips P89C51RD2 6api-3726520No ratings yet

- 8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesDocument136 pages8-Bit Flash Microcontroller AT89C51RD2 AT89C51ED2: FeaturesSorin AlexandruNo ratings yet

- lpc2104 2105 2106Document32 pageslpc2104 2105 2106B GowdaNo ratings yet

- At25128b 5eb PDFDocument22 pagesAt25128b 5eb PDFMurat BaybükeNo ratings yet

- ATmega2560 Doc2549Document448 pagesATmega2560 Doc2549Ship WrekNo ratings yet

- REN Isl8483e-85e DST 20030328Document15 pagesREN Isl8483e-85e DST 20030328Ercan CesurNo ratings yet

- 08 Bus CycleDocument40 pages08 Bus CycleMir4 BritoNo ratings yet

- CMOS 8-Bit Single Chip Microcomputer: CXP83408/83412/83416 CXP83409/83413/83417Document24 pagesCMOS 8-Bit Single Chip Microcomputer: CXP83408/83412/83416 CXP83409/83413/83417HerwinTorresNo ratings yet

- 8-Bit Microcontroller With 8K Bytes In-System Programmable Flash Atmega8535 Atmega8535L PreliminaryDocument19 pages8-Bit Microcontroller With 8K Bytes In-System Programmable Flash Atmega8535 Atmega8535L Preliminarymike_helplineNo ratings yet

- FSP-951T I56-6521 Fire SensorDocument57 pagesFSP-951T I56-6521 Fire SensorSandeep SNo ratings yet

- 2-Wire Serial EEPROM: FeaturesDocument19 pages2-Wire Serial EEPROM: FeaturesAgustin AndrokaitesNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- 820-1540 (Project Q45B)Document74 pages820-1540 (Project Q45B)RisoSilvaNo ratings yet

- TroubleshootingDocument28 pagesTroubleshootingRisoSilvaNo ratings yet

- Schem, MLB, Pb15: Bom Options (In Common Parts)Document44 pagesSchem, MLB, Pb15: Bom Options (In Common Parts)RisoSilvaNo ratings yet

- SCHEM, MLB, PB17": Bom OptionsDocument44 pagesSCHEM, MLB, PB17": Bom OptionsRisoSilvaNo ratings yet

- ESQUEMA Ms-7529 (g31m3-v2) REV 1.1Document33 pagesESQUEMA Ms-7529 (g31m3-v2) REV 1.1RisoSilvaNo ratings yet

- Mosfet Substituto 13n03laDocument8 pagesMosfet Substituto 13n03laRisoSilvaNo ratings yet

- Mosfet Original P75N02LDGDocument3 pagesMosfet Original P75N02LDGRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 ATX: Cover Sheet Micro Star Restricted SecretDocument32 pagesMS-6728 ATX: Cover Sheet Micro Star Restricted SecretRisoSilvaNo ratings yet

- MS-6728 AtxDocument34 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- d9b19 Compal JBL00 LA-3801P - DELL E6400 Laptop SchematicsDocument66 pagesd9b19 Compal JBL00 LA-3801P - DELL E6400 Laptop SchematicsRisoSilvaNo ratings yet

- MS-6728 AtxDocument33 pagesMS-6728 AtxRisoSilvaNo ratings yet

- Dell Latitude D510 SchematicsDocument46 pagesDell Latitude D510 SchematicsRisoSilvaNo ratings yet

- Msi ms-1682 r0b SchematicsDocument52 pagesMsi ms-1682 r0b SchematicsRisoSilvaNo ratings yet

- Model Name: GA-7VM400AMF: Sheet TitleDocument29 pagesModel Name: GA-7VM400AMF: Sheet TitleRisoSilvaNo ratings yet

- MS-16332 R0aDocument41 pagesMS-16332 R0aRisoSilvaNo ratings yet

- Model Name:Bbr20 La-1512: Brookdale MCHDocument44 pagesModel Name:Bbr20 La-1512: Brookdale MCHRisoSilvaNo ratings yet

- CPU Generation: Version 0BDocument33 pagesCPU Generation: Version 0BRisoSilvaNo ratings yet

- GA-8GEM800 Schematics: Sheet Title Sheet TitleDocument32 pagesGA-8GEM800 Schematics: Sheet Title Sheet TitleRisoSilvaNo ratings yet

- Debug 1214Document3 pagesDebug 1214Badii MaulanaNo ratings yet

- CMDBuild AdministratorManual ENG V240Document134 pagesCMDBuild AdministratorManual ENG V240jesusferre2No ratings yet

- Computer Basic TroubleshootingDocument5 pagesComputer Basic TroubleshootingAngel2106No ratings yet

- 9210 User Manual PDFDocument245 pages9210 User Manual PDFsapchaseNo ratings yet

- WiFi NVR Kits User Manual (For NVS001, 002, 004 009)Document10 pagesWiFi NVR Kits User Manual (For NVS001, 002, 004 009)Emanuel NicolaeNo ratings yet

- Remote Data Monitoring and Diagnostic Services: A Services Initiative by BHELDocument9 pagesRemote Data Monitoring and Diagnostic Services: A Services Initiative by BHELAravind ShankarNo ratings yet

- Magnetic DiskDocument15 pagesMagnetic DiskAmit CoolNo ratings yet

- MIT - Press.beowulf Cluster Computing With Windows (2002)Document475 pagesMIT - Press.beowulf Cluster Computing With Windows (2002)Johnnier Hernández RiveraNo ratings yet

- Essl Connection Diagram For AllDocument5 pagesEssl Connection Diagram For Allpushkar.mulayNo ratings yet

- Satyanarayan Katha in Tamil PDFDocument4 pagesSatyanarayan Katha in Tamil PDFSeshadri Rajan Iyer0% (1)

- 11g Dataguard EnhancementsDocument27 pages11g Dataguard EnhancementsPrintesh PatelNo ratings yet

- Blue ToothDocument100 pagesBlue ToothAlejo Mateo SfercoNo ratings yet

- Ibm FW Uefi D7e174b-3.20 Anyos 32-64Document7 pagesIbm FW Uefi D7e174b-3.20 Anyos 32-64Tiberiu ImbriscaNo ratings yet

- 0329 Mladost TuristDocument7 pages0329 Mladost TuristGuran MaricioNo ratings yet

- LogDocument23 pagesLogRebs - Not OfficialNo ratings yet

- AN 124 User Guide For FT PROGDocument43 pagesAN 124 User Guide For FT PROGodragosNo ratings yet

- Babel - A Glossary of Computer OrientedDocument69 pagesBabel - A Glossary of Computer OrientedMaria NichiforNo ratings yet

- Ai Scripts Release Notes 7.0R3.1Document22 pagesAi Scripts Release Notes 7.0R3.1WaqasMirzaNo ratings yet

- PIC18F97J60 FAMILY: 64/80/100-Pin High-Performance, 1-Mbit Flash Microcontrollers With EthernetDocument6 pagesPIC18F97J60 FAMILY: 64/80/100-Pin High-Performance, 1-Mbit Flash Microcontrollers With EthernetDESTROYER2020No ratings yet

- Business Computer PDFDocument3 pagesBusiness Computer PDFadom laryeaNo ratings yet

- Lab 2 REsultDocument7 pagesLab 2 REsultlallala4415No ratings yet

- 2024-02-20-Mikro Deney Föyü - İngDocument41 pages2024-02-20-Mikro Deney Föyü - İngefepar7812No ratings yet

- Linux Interview Questions On Boot Process and Other StuffDocument14 pagesLinux Interview Questions On Boot Process and Other Stuffgururaj_hebbarNo ratings yet

- FS1-2 Flash Storage System Help Desk Support Consultant CertificationDocument76 pagesFS1-2 Flash Storage System Help Desk Support Consultant CertificationSuhaimi MieNo ratings yet

- The Von Neumann Computer ModelDocument11 pagesThe Von Neumann Computer ModelJerome ScottNo ratings yet

- Compal LA-D101P r0.1Document53 pagesCompal LA-D101P r0.1vinuNo ratings yet

- LCD Television Service Manual: Chassis MSD6886Document61 pagesLCD Television Service Manual: Chassis MSD6886Marcelo MoreiraNo ratings yet

- OpenVZ, Xen, and KVM PDFDocument7 pagesOpenVZ, Xen, and KVM PDFSFNo ratings yet

- OpenCore Vanilla Desktop GuideDocument437 pagesOpenCore Vanilla Desktop GuideAndi 01No ratings yet

- S4 EN Manual V1.1Document87 pagesS4 EN Manual V1.1Menam EssamNo ratings yet