Professional Documents

Culture Documents

546669-09 Intermediate Kit MMPX 403

546669-09 Intermediate Kit MMPX 403

Uploaded by

Alexander0 ratings0% found this document useful (0 votes)

105 views3 pages546669-09 Intermediate Kit MMPX 403

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document546669-09 Intermediate Kit MMPX 403

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

105 views3 pages546669-09 Intermediate Kit MMPX 403

546669-09 Intermediate Kit MMPX 403

Uploaded by

Alexander546669-09 Intermediate Kit MMPX 403

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

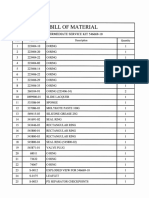

BILL OF MATERIAL

INTERMEDIATE SERVICE K!

223404-22, 1

223404-82, 2

223406-14 =

223406-22 1

223406-29, 1

223406-35 O RING 1

260104-91 O RING (223406-34) 2

1899900-01

SLIDE LACQUER

535586-04

537086-03

539474-03

541691-01

543446-02

545800-01

SPONGE

MOLYKOTE PASTE 100G

SILICONE GREASE 25G

SEAL RING

RECTANGULAR RING

RECTANGULAR RING

545800-03

545800-04

RECTANGULAR RING

SEAL RING (545800-02)

545871-01

68011

VALVE PLUG

ORING

73632

74067

ORING

ORING

EXPLODED VIEW FOR 546669-09

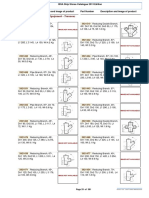

PX SEPARATOR CHECKPOINTS

LEAFLET.

Intermediate service kit 546669-09

14

Note: The information included in this leaflet does not replace Information in Service Manuals,

delivered with machine. For Your safety please study Service manual before any service

Inlet pipe and paring disc

‘Screw the inlet pipe

counterclockwisetleft hand

Inspection for corrosion/eracks

Evidence of corrosion should be checked and

rectified each time the separator is

dismounted.

If corrosion exceeds 1 mm.

bbeen found, do not co

separator,

Pits and spots forming ines may indicate

cracks under the surface.

Polish corrosion marks to prevent further

damage.

Replace the parts if corrosion is suspected as

the streneth can be affected.

PX-type SEPARATOR CHECKPOINTS

Height position of lower paring dise

Adjusting ofthe |

lower paring dise

depends on

machine type.

See technical

Manual

Individual

Z

Valve plugs

in contact with valve plugs. Poor sealing

between the valve plugs on the operating slide

‘and bowl body may prevent complete closing

Cf the bowl. Always replace only complete set

(of plugs. Remove any marks and lime deposits

with fine grain emery cloth,

Paring disc device

impact marks on

thread and guide

and lock ring can

Clean the water channels in

paring disc device

Paring disc height position

The height position of

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heatpac CBM: Component DescriptionDocument28 pagesHeatpac CBM: Component DescriptionAlexanderNo ratings yet

- Efficient, Economical: BOLL Automatic FilterDocument7 pagesEfficient, Economical: BOLL Automatic FilterAlexanderNo ratings yet

- Spare Parts Kits en 2014Document12 pagesSpare Parts Kits en 2014AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть91Document2 pagesISSA2013Ed CabinStores v100 Часть91AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть11Document2 pagesISSA2013Ed CabinStores v100 Часть11AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть19Document2 pagesISSA2013Ed CabinStores v100 Часть19AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть18Document2 pagesISSA2013Ed CabinStores v100 Часть18AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть17Document2 pagesISSA2013Ed CabinStores v100 Часть17AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть13Document2 pagesISSA2013Ed CabinStores v100 Часть13AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть16Document2 pagesISSA2013Ed CabinStores v100 Часть16AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть14Document2 pagesISSA2013Ed CabinStores v100 Часть14AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть15Document2 pagesISSA2013Ed CabinStores v100 Часть15AlexanderNo ratings yet

- Non-Contacting Two-Channel Speed Sensor Type FA11 With Brass Screw-In ThreadDocument14 pagesNon-Contacting Two-Channel Speed Sensor Type FA11 With Brass Screw-In ThreadAlexanderNo ratings yet

- Thermostatic Valve For LT Water: Wärtsilä 32 Spare Parts List 196-001Document1 pageThermostatic Valve For LT Water: Wärtsilä 32 Spare Parts List 196-001Alexander100% (1)

- Limit-Value Switch For Temperature Thermistor Input (NTC)Document2 pagesLimit-Value Switch For Temperature Thermistor Input (NTC)AlexanderNo ratings yet

- ISSA2013Ed CabinStores v100 Часть10Document2 pagesISSA2013Ed CabinStores v100 Часть10AlexanderNo ratings yet

- Burgess Limit Switches 705Document1 pageBurgess Limit Switches 705AlexanderNo ratings yet

- Micro Switch™ Limit Switches Line Guide: FeaturesDocument6 pagesMicro Switch™ Limit Switches Line Guide: FeaturesAlexanderNo ratings yet

- Snap-Action Microswitches - Standard Metal M9/C9: CharacteristicsDocument3 pagesSnap-Action Microswitches - Standard Metal M9/C9: CharacteristicsAlexanderNo ratings yet

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Burgess m2 v3Document14 pagesBurgess m2 v3AlexanderNo ratings yet

- ST173 174 Speed Pick UpDocument1 pageST173 174 Speed Pick UpAlexanderNo ratings yet

- 546670-07 Major Service Kit MMPX 403 - 404Document4 pages546670-07 Major Service Kit MMPX 403 - 404AlexanderNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- 546669-10 Intermediate Kit For P615Document4 pages546669-10 Intermediate Kit For P615AlexanderNo ratings yet

- Upgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesDocument2 pagesUpgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesAlexanderNo ratings yet

- 546669-05 Intermediate Kit MMPX 304Document3 pages546669-05 Intermediate Kit MMPX 304AlexanderNo ratings yet

- 546670-08 Major Service Kit MMPX 403 - 404Document2 pages546670-08 Major Service Kit MMPX 403 - 404AlexanderNo ratings yet

- 1 Hzslvwrqulqjvhwviru:Luwvlol 9 DVDHQJLQHVDocument2 pages1 Hzslvwrqulqjvhwviru:Luwvlol 9 DVDHQJLQHVAlexanderNo ratings yet