Professional Documents

Culture Documents

44AD0600-0000-E.04-01A4-A4 - Datasheet For LV Induction Motor

44AD0600-0000-E.04-01A4-A4 - Datasheet For LV Induction Motor

Uploaded by

Avinash ShuklaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

44AD0600-0000-E.04-01A4-A4 - Datasheet For LV Induction Motor

44AD0600-0000-E.04-01A4-A4 - Datasheet For LV Induction Motor

Uploaded by

Avinash ShuklaCopyright:

Available Formats

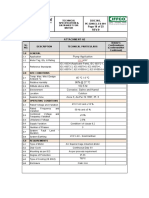

DOC. NO. 44AD0600-0000/E.

04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

PART - A : SPECIFIC REQUIREMENTS

1 APPLICABLE SPECIFICATION & STANDARD : 44 AD0600-00/E.02/001A/A4, IEC 60034 AND OTHER NATIONAL /

EQUIVALENT INTERNATIONAL STANDARDS

2 EQUIPMENT / DRIVEN MACHINE TAG NO. :

2.1 MOTOR TAG NO. :

3 QUANTITY :

4 CLIMATIC CONDITIONS

4.1 DESIGN AMBIENT TEMPERATURE 50 ° C

4.1a SITE AMBIENT TEMPERATURE RANGE:MIN. TO MAX. 4 ° C MINIMUM 46.7 ° C MAXIMUM

4.2 ALTITUDE ( ABOVE MSL ) < 1000 MTRS

4.3 RELATIVE HUMIDITY 89 % MAX

4.4 ANNUAL RAINFALL 428 MM/ DAY (MAX).

4.5 ENVIRONMENT DUSTY/TROPICAL/CORROSIVE / HAZARDOUS

4.6 AREA CLASSIFICATION i) UNCLASSIFIED SAFE / ZONE 1 / ZONE 2

ii) GAS GROUP OF ENCLOSURE : I / IIA / IIB / IIC AS

iii) TEMPERATURE CLASS : T1 / T2 / T3 / T4 / T5 / T6 PER

iv) Dusty- ZONE 21 / ZONE 22 PACKAGE

v) Dust Group III - III A / III B / III C RFQ

4.7 LOCATION INDOOR / OUTDOOR

4.8 SEISMIC LEVEL ZONE-IV AS PER IS1893

5 SYSTEM PARTICULARS

5.1 SYSTEM VOLTAGE , FREQUENCY , PHASES 415 V, 50 Hz, 3Ph.

5.2 VOLTAGE VARIATION ± 10 %

5.3 FREQUENCY VARIATION ±5 %

5.4 COMBINED VOLTAGE FREQUENCY VARIATION 10 %

5.5 3 PHASE SYMMETRICAL FAULT LEVEL AT MOTOR 50 kA FOR 0.25 SECS

TERMINALS

5.6 GROUNDING SOLID / NGR/ GROUNDING TRANSFORMERS

5.7 EARTH FAULT LEVEL 50 kA

6 DRIVEN MACHINE DATA

6.1 DRIVEN MACHINE TYPE PUMP / FAN / COMPRESSOR /AGITATOR

6.2 DRIVEN MACHINE REF. NO.

6.3 DRIVEN MACHINE DATASHEET REF. NO.

ENCLOSED / NOT ENCLOSED, DOC. NO. (DETAILS AS REQUIRED SHALL BE BY

6.4 DRIVEN MACHINE SPEED V/S TORQUE CURVE REF. NO.

MECHANICAL PACKAGE VENDOR)

2

6.5 DRIVEN EQUIPMENT INERTIA (GD /4)

7 MOTOR TYPE & RATING

7.1 TYPE

7.2 STANDARD OR ENERGY EFFICIENT MOTOR ENERGY EFFICIENT - IE3 (MINIMUM) (REFER NOTE 16.7)

7.3 DUTY - S1 / S2/ S3 / S4 / S5/ S6 /S7 / S8/ S9/ S10 BY PACKAGE VENDOR BASED ON APPLICATION.

7.4 SERVICE FACTOR 1.0

7.5 CLASS OF INSULATION CLASS ' F ' WITH TEMPERATURE RISE LIMITED TO CLASS 'B'

7.6 RATED SPEED ( SYN.) AT RATED FREQ. & VOLTAGE (TO MATCH WITH THE DRIVEN EQUIPMENT)

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

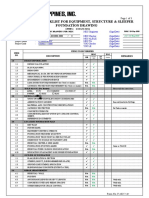

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

PART - A : SPECIFIC REQUIREMENTS ( CONTD...)

7 MOTOR TYPE & RATING (CONTD...)

7.7 SPEED VARIATION REQUIRED / NOT REQUIRED (BASED ON APPLICATION / PROCESS REQUIREMENT)

7.7.1 IF REQUIRED BY VARIABLE SPEED AC DRIVE / MULTISPEED BY CHANGE OF MOTOR CONNECTION (NA)

7.7.2 SPEED RANGE MAX. & MIN. BY MECHANICAL PACKAGE VENDOR BASED ON APPLICATION / PROCESS REQUIREMENT (NA)

7.7.3 DRIVE CONTROL CONSTANT TORQUE / VARIABLE TORQUE / CONSTANT HP (NA)

(BY MECHANICAL PACKAGE VENDOR BASED ON APPLICATION / PROCESS REQUIREMENT)

7.7.4 TACHOMETER WITH MOTOR REQUIRED YES / NO

7.8 WINDING TREATMENT SEE NOTE 16.3

7.9 GUARANTEED TEMP. RISE AT MIN. SPEED ---

WITH VSD APPLICATION DEGREE C

7.10 STARTING METHOD DOL / VSD UPTO kW / STAR DELTA kW/ SOFT STARTER

7.11 STARTING PERFORMANCE TO MATCH WITH THE DRIVEN EQUIPMENT FOR THE REQUIRED STARTING CONDITION

7.12 SHAFT EXTENSION STANDARD/ MM

7.13 EARTH TERMINALS TWO NOS. EXTERNAL

7.14 DIRECTION OF ROTATION BI-DIRECTIONAL / UNIDIRECTIONAL : AS PER DRIVEN EQUIPMENT REQUIREMENT

7.15 GREASING ARRANGEMENT GREASE NIPPLES WITH GREASE RELIEF VALVE/PLUG

7.16 MAIN NAME PLATE STAINLESS STEEL

7.17 AUXILIARY NAME PLATE REQUIRED / NOT REQUIRED

7.18 TYPE OF COUPLING * DIRECT / BELT-PULLY COUPLED (TO MATCH WITH DRIVEN EQPT.)

7.19 BED PLATE / SOLE PLATE REQUIRED / NOT REQUIRED(BY PACKAGE VENDOR)

8 ENCLOSURE

8.1 TYPE OF PROTECTION INDUSTRIAL / Ex 'd' / Ex 'eb' / Ex 'ec'

( W.R.T. TO AREA CLASSIFICATION ) REFER NOTE 16.5, 16.6

8.2 DEGREE OF PROTECTION OF ENCLOSURE IP 55 (MINIMUM)

8.3 TYPE OF MOUNTING AS PER DRIVEN EQUIPMENT

8.4 TYPE OF COOLING TEFC (IC411) / TETV (IC511) / CACA (IC611)

8.5 DATA FOR COOLING MEDIUM

8.6 PAINTING

- TYPE EPOXY

- SHADE 632

-- CORROSION CATEGORY AS PER ISO/EN 12944 PART 2 C3M

9 TERMINAL BOX ( SUITABLE FOR SPECIFIED

CABLE SIZE / TYPE )

9.1 TERMINAL Nos. SEE NOTE 16.24

9.2 SIZE OF TERMINALS SUITABLE FOR CABLE SIZE SPECIFIED, ELSE SEPARATE POWER JB SHALL BE

PROVIDED BY SUCCESSFUL BIDDER. JB (IF NECESSARY) SHALL BE CERTIFIED FOR

CLASSIFIED AREA AS PER PACKAGE RFQ.

(CABLE SIZE SHALL BE INFORMED TO SUCCESSFUL BIDDER)

9.3 LOCATION OF TERMINAL BOX SEEN FROM RHS / LHS / TOP

NON DRIVEN END

9.4 SEPARATE TERMINAL BOX FOR SPACE HEATER REQUIRED / NOT REQUIRED WHEREVER APPLICABLE RHS/LHS (FOR 55 KW AND ABOVE RATING)

9.5 SEPARATE TERMINAL BOX FOR PTC THERMISTORS REQUIRED / NOT REQUIRED WHEREVER APPLICABLE RHS/LHS

9.6 SEPARATE TERMINAL BOX FOR RTDs REQUIRED / NOT REQUIRED WHEREVER APPLICABLE RHS/LHS NA

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

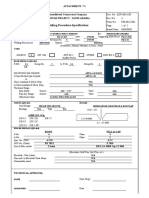

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

PART - A : SPECIFIC REQUIREMENTS ( CONTD...)

10 INSPECTION FINAL

TESTS -- ROUTINE TESTS SHALL BE WITNESSED

-- TYPE TESTS SHALL / SHALL NOT BE WITNESSED ( SUBJECT TO APPROVAL

OF TYPE TEST CERTIFICATES )

11 SPECIAL REQUIREMENTS :

11.1 ANTICONDENSATION HEATERS FOR 55kW & ABOVE

11.2 TEMP.DETECTORS -PTC THERMISTORS REQUIRED / NOT REQUIRED

(REQUIRED FOR VSD DRIVEN MOTORS, 75kW & ABOVE DOL MOTORS AND MOTORS

BASED ON SPECIFIC APPLICATION RELATED TO AREA CLASSIFICATION)

11.3 TEMP.DETECTORS FOR WINDINGS - RTDs REQUIRED / NOT REQUIRED

11.4 TEMP. DETECTORS FOR BEARINGS- BTDs REQUIRED / NOT REQUIRED

11.5 VOLTAGE RATING OF SPACE HEATER 240 V SINGLE PHASE 50 Hz

11.6 COMBINED TESTING OF MOTOR WITH YES / NO REFER NOTE 16.18a (NA)

VSD @ MANUFACTURER'S WORK REQUIRED

11.7 MOTOR SUITABLE FOR REACCELERATION YES / NO REFER NOTE 16.14

IN CASE OF LOSS OF VOLTAGE

12 CABLES

BASED ON FIRM MOTOR RATING BY SUCCESSFUL

POWER CABLE TYPE & SIZE A2XFY / LATER SQ.MM

BIDDER

SPACE HEATER CABLE TYPE & SIZE 2XWY / 3C X 4

THERMISTOR CABLE TYPE & SIZE 2P X 1.5 sq. mm. (IF REQUIRED)

RTD CABLE TYPE & SIZE

CABLE LUGS -- TYPE TINNED COPPER

INDUSTRIAL / FLAMEPROOF DOUBLE COMPRESSION GLANDS TO BE SUPPLIED BY PACKAGE

CABLE GLANDS -- TYPE

VENDOR

CABLE ENTRY THREAD TYPE IMPERIAL (ET THREAD) / METRIC

13 HEAT RUN TEST REQUIRED YES / NO REFER VQP / ITP

14 DRAWINGS, DATA & TEST CERTIFICATES

i) DATA SHEET

ii) GA DRAWING OF MOTOR

iii) GA DRAWING OF TERMINAL BOX FOR MOTOR, SPACE HEATER AND THERMISTOR / RTD.

iv) T-S CURVES AT 75 %, 100 % & 110 % VOLTAGE SUPERIMPOSED WITH T/S

CURVE OF DRIVEN EQUIPMENT

v) STARTING CURRENT -TIME CURVES AT 75 %, 100 % & 110 % VOLTAGE.

vi) STARTING CURRENT -SPEED CURVES AT 75 %, 100 % & 110 % VOLTAGE.

vii) THERMAL WITHSTAND CURVE ( HOT & COLD ) AT 75 %,

100 % & 110 % VOLTAGE.

viii) NEGATIVE SEQUENCE CURRENT CURVE.

ix) CALCULATION FOR ACCELERATION TIME AT 75% VOLTAGE.

x) EFFICIENCY, POWER FACTOR, CURRENT, SLIP v/s LOAD CURVES.

15 APPROVAL , INSPECTION & TESTING AS PER ITP/ VQP ENCLOSED

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

16 NOTES & ADDITIONAL REQUIREMENTS (THESE ARE STANDARD NOTES AND SHALL BE MODIFIED AS PER PROJECT REQUIREMENT)

16.1 OFFERED MOTOR TERMINAL BOX SHALL BE SUITABLE FOR REQUIRED SIZE AND NUMBER OF CABLE TERMINATIONS AND FAULT LEVEL SHALL BE SUITABLE

FOR 50KA FOR 0.25 SECS.

16.2 NOISE LEVEL SHALL BE LESS THAN 85dBA AT DISTANCE OF 1M AT NO LOAD.

16.3 MOTOR WINDING SHALL BE SUITABLE FOR CORROSIVE ATMOSPHERE WITH EPOXY GEL TREATMENT ON WINDING OVERHANG.

16.4 SOLID STUD TERMINAL PLATE SHALL BE PROVIDED IN OFFERED MOTOR.

16.5 MOTOR SELECTION FOR CLASSIFIED AREAS:

ZONE 1, DOL STARTING Ex "d"

ZONE 1, VSD DRIVEN Ex "d"

ZONE 2, DOL Ex "d" / Ex"eb"/Ex"ec"

ZONE 2, VSD DRIVEN Ex "d"

- ALL ELECTRIC MOTORS FOR AGITATORS / MIXERS AND METERING PUMPS HANDLING FLAMMABLE MATERIAL SHALL BE FLAMEPROOF TYPE (EX

"d") IRRESPECTIVE OF THE AREA BEING CLASSIFIED AS ZONE 2 OR ZONE 1.

- FOR ZONE 2 AREA (DOL STARTING) EX "ec" MOTORS SHALL BE USED UNLESS ANY OTHER TYPE SPECIFIED BY LICENSER OR FREQUENT START /

STOP REQUIREMENTS ARE ENVISAGED WHERE EX "d" MOTORS SHALL BE USED.

- FOR ZONE 2 AREAS, MOTORS WITH RATING ABOVE 100 KW AND UPTO 160 KW HAVING AVERAGE STARTING FREQUENCY MORE THAN 1 PER

WEEK, EX "d" MOTORS SHALL BE USED.

- ALL ELECTRICAL EQUIPMENT INSIDE THE PROCESS UNITS SHALL BE AS A MINIMUM SUITABLE FOR ZONE-2 IRRESPECTIVE OF AREA BEING SAFE.

16.6 HAZARDOUS AREA MOTORS MANUFACTURED IN INDIA SHALL HAVE A VALID TYPE TEST CERTIFICATE FROM CIMFR (FORMERLY CMRI) / ERTL AND VALID

APPROVAL CERTIFICATE FROM PESO (FORMERLY CCOE). MOTORS MANUFACTURED OUT OF INDIA SHALL HAVE VALID ATEX TEST CERTIFICATE WITH

VALID LATEST APPROVAL CERTIFICATE FROM PESO.

16.6a TYPE TEST CERTIFICATES FOR AN EXACTLY IDENTICAL DESIGN OF OFFERED EQUIPMENT SHALL BE FURNISHED. TYPE TEST REPORTS SHALL NOT BE

MORE THAN 5 YEARS OLD AT THE TIME OF LOI. IN CASE, TYPE TESTS HAVE NOT BEEN CONDUCTED DURING LAST 5 YEARS, BIDDER SHALL

DEMONSTRATE WITH ALL NECESSARY SUPPORTING DOCUMENTS (NO CHANGE IN DESIGN / STANDARDS/ CODES) FOR NOT CONDUCTING THE TYPE

TESTS OR ELSE BIDDER SHALL CONDUCT TYPE TESTS ON THE OFFERED DESIGN OF EQUIPMENT BEFORE DISPATCH WITHOUT ANY COST AND

DELIVERY IMPACT.

16.7 THE EFFICIENCY OF MOTOR SHALL BE IE3 AS PER IEC 60034-30. THE METHOD OF DETERMINING EFFICIENCY SHALL BE IN LINE WITH IEC 60034-2-1/IS

15999 PART 2 SECTION 1.

16.8 THE STARTING CURRENT OF THE MOTOR SHALL BE AS PER IEC 60034-30.

16.9 MOTORS UP TO AND INCLUDING 200 FRAMES SHALL BE PROVIDED WITH SEALED BEARINGS. MOTORS OF 225 FRAMES AND ABOVE SHALL BE

PROVIDED WITH BEARINGS HAVING ON-LINE GREASING ARRANGEMENT.

16.10 MOTOR BEARING LIFE SHALL BE L10 IN EXCESS OF 40,000 HRS UNDER THE WORST CASE OPERATING CONDITIONS

16.11 ALL CLASSIFIED AREA MOTORS SHALL BE DISPATCHED WITH CERTIFIED METALLIC PLUG.

16.12 SEPARATE EARTHING STUD / ARRANGEMENT SHALL BE PROVIDED INSIDE MOTOR TERMINAL BOX.

16.13 Ex "ec" MOTORS SHALL BE PROVIDED WITH CI FAN.

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

16 NOTES & ADDITIONAL REQUIREMENTS (CONTD.)

16.14 IN CASE MOTOR HAS TO BE SUITABLE FOR REACCELERATION, IN THAT CASE MOTOR VENDOR SHALL FURNISH THE TRANSIENT TORQUE VERSUS

TIME CURVE TO THE MECHANICAL DRIVEN EQUIPMENT VENDOR. MOTOR VENDOR SHALL ALSO FURNISH TRANSIENT TORQUE VERSUS TIME

CURVE FOR 3 PHASE FAULT CONDITION. MECHANICAL DRIVEN EQUIPMENT VENDOR SHALL ENSURE THAT DRIVEN EQUIPMENT SHAFT AND

COUPLING ARE DESIGNED TO WITHSTAND TRANSIENT TORQUES AS PER CURVES FURNISHED BY MOTOR VENDOR.

16.15 MOTOR SHALL BE SUITABLE FOR STARTING UNDER SPECIFIED LOAD CONDITIONS WITH 75% OF THE RATED VOLTAGE AT THE MOTOR TERMINALS.

16.16 MOTORS SHALL BE DESIGNED TO ALLOW THREE CONSECUTIVE STARTS FROM COLD CONDITION, TWO CONSECUTIVE STARTS FROM HOT

CONDITION AND FOUR UNIFORMLY DISTRIBUTED STARTS IN ONE HOUR.

16.17 MOTOR HOT WITHSTAND TIME AT 100% VOLTAGE SHALL BE 2.5 SECS MORE THAN THE STARTING TIME OF MOTOR AT 100% VOLTAGE.

16.18 LV MOTORS FOR USE WITH VSDs SHALL BE PROVIDED WITH INSULATED BEARINGS ON BOTH THE DRIVE AND NON-DRIVE ENDS WHERE

SHAFT VOLTAGE IS MORE THAN " 500mV PEAK".

16.18a VSD DRIVEN MOTORS IN ZONE 2 HAZARDOUS AREA SHALL BE Ex "d". VSD DRIVEN Ex "d" MOTORS FOR HAZARDOUS AREA APPLICATION SHALL HAVE

VALID TYPE TEST CERTIFICATE FOR COMBINED TESTING (MOTOR WITH VSD). VSD DRIVEN Ex "eb" MOTORS FOR ZONE 2 HAZARDOUS AREA SHALL BE

TYPE TESTED AS UNIT WITH VSD. FOR Ex "eb" MOTORS, PROVISION OF TRIPPING THE MOTOR IN CASE THE TEMPERATURE EXCEEDS PERMISSIBLE

LIMIT.

16.18b VSD DRIVEN MOTOR INSULATION SHALL BE DESIGNED TO ACCEPT THE APPLIED VOLTAGE WAVE FORM, WITHIN THE Ypeak and dv/dt LIMITS AS

PER IEC-61800-2.

16.19 MOTOR CASING SHALL BE PROVIDED WITH A SUITABLE DRAIN FOR REMOVAL OF CONDENSED MOISTURE EXCEPT IN CASE OF FLAMEPROOF

MOTORS (TYPE EX "d")

16.20 ROTORS SHALL BE CAPABLE OF WITHSTANDING 1.2 TIMES RATED SPEED FOR 60 SEC. WITHOUT DAMAGE.

16.21 PTC 130C THERMISTOR SHALL BE USED IN CASE OF MOTORS FOR WHICH INSULATION IS CLASS F WITH TEMPERATURE RISE LIMITED TO CLASS B.

16.22 ANY DEVIATION TO THE DATASHEET REQUIREMENT SHALL BE INFORMED TO THE CONSULTANT / CLIENT & WILL BE PERMITTED IF APPROVED BY

CONSULTANT / CLIENT.

16.23 SLEEVE OR ANTI-FRICTION TYPE BEARINGS SHALL BE USED. VERTICAL MOTORS SHALL HAVE THRUST BEARINGS.

16.24 ALL LV MOTORS RATED UPTO & INCLUDING 2.2KW SHALL BE WITH STAR CONNECTED. MOTORS ABOVE 2.2KW SHALL BE DELTA CONNECTED

WINDING.

16.25 TERMINAL BOX OF THE MOTOR SHALL BE SUITABLE FOR ROTATION BY 90°

16.26 VSD OPERATED MOTORS SHALL BE DESIGNED TO WITHSTAND VOLTAGE SPIKES FOR AT LEAST 1 SEC.

16.27 MOTORS SHALL BE PROVIDED WITH A SINGLE SHAFT EXTENSION WITH KEY-WAY AND FULL KEY. MOTOR SHAFT SHALL BE SIZED TO WITHSTAND

THE WORST CASE TORQUE DEVELOPED DURING REACCELERATION / SHORT CIRCUIT CASES / AUTO CUT IN MOTOR CONDITIONS.

16.28 THE FIRST ACTUAL CRITICAL SPEED OF STIFF ROTORS SHALL NOT BE LOWER THAN 125 % OF THE SYNCHRONOUS SPEED. FOR FLEXIBLE

ROTORS THIS SHALL BE BETWEEN 60 % AND 80 % OF THE SYNCHRONOUS SPEED; THE SECOND ACTUAL CRITICAL SPEED SHALL BE ABOVE

125% OF THE SYNCHRONOUS SPEED.

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

PART - B : PERFORMANCE PARTICULARS.

( TO BE FURNISHED BY MANUFACTURER)

THE PARTICULARS MARKED WITH ASTERISK ( * ) SHALL BE GUARANTEED , SUBJECT TO THE TOLERANCE

RATED PARAMETERS

1 MAKE / CATALOGUE NO.

2 ENCLOSURE WITH HAZARDOUS AREA CLASSIFICATION

3 RATED OUTPUT AT DESIGN AMBIENT TEMPERATURE kW

4 SERVICE FACTOR

5 FULL LOAD CURRENT A

6 ACCELERATION TIME TO RATED SPEED WITH RATED SEC.

LOAD AT 100% VOLTAGE & 75% VOLTAGE

FRAME SIZE, WEIGHT OF MOTOR & WEIGHT OF ROTOR

7

IN KGs

OUTLINE DIMENSION DWG NO. & OVERALL DIMENSION

8

(LXBXH)

9 MOUNTING HORIZONTAL/VERTICAL

10 RATED SPEED AT RATED FREQUENCY & VOLTAGE RPM

11 FULL LOAD SLIP IN %

12 LOCKED ROTOR CURRENT AT 100% VOLTAGE IN % OF %

FULL LOAD CURRENT

13 POWER FACTOR OF STARTING CURRENT WITH %

FULL VOLTAGE

14 TEMPERATURE RISE OVER DESIGN AMBIENT °C

TEMPERATURE AT FULL LOAD

15 NO LOAD CURRENT A

STARTING TORQUE (LOCKED ROTOR TORQUE) AT 75%

16 N-M

& 100% VOLTAGE

17 FULL LOAD TORQUE AT 75% & 100% VOLTAGE N-M

18 BREAK DOWN OR PULL OUT TORQUE N-M

19 PULL UP TORQUE N-M

20 EFFICIENCY : 50 % LOAD %

: 75 % LOAD %

: 100 % LOAD %

21 POWER FACTOR : 50 % LOAD

: 75 % LOAD

: 100 % LOAD

22 NO. OF PERMISSIBLE SUCCESSIVE D.O.L. STARTS

WITH MOTOR IN ' HOT ' / 'COLD' CONDITION

23 SAFE STALL TIME WITH MOTOR IN ' HOT ' CONDITION

AT 75% AND 100% VOLTAGE

24 NO. OF DOL STARTS PER HOUR WITH ALLOWABLE

MINIMUM INTERVAL BETWEEN STARTS

25 DETAILS OF RATING OF SPACE HEATERS

26 STATOR WINDING CONNECTION

27 INERTIA OF MOTOR (GD² /4)

28 INERTIA OF LOAD (GD² /4)

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

DOC. NO. 44AD0600-0000/E.04/01A4/A4

DATA SHEET FOR REQN. NO. 44AD0600-00-ER.37-0013-A

LV INDUCTION MOTOR SHEET OF

(AIR FIN COOLERS: 2060-EA-002,2072-EA-002)

APPD. BY KT

PROJECT NO 44AD0600 CHKD. BY KT

PROJECT LOCATION Gujarat, India PRPD. BY SS

Consultancy Services for

PROJECT TITLE DATE 18-Feb-20

Revamp of LAB Plant

CLIENT IOCL REV. 0 1 2

PART - B : PERFORMANCE PARTICULARS (CONTD….)

( TO BE FURNISHED BY MANUFACTURER)

THE PARTICULARS MARKED WITH ASTERISK ( * ) SHALL BE GUARANTEED , SUBJECT TO THE TOLERANCE

29 DETAILS OF EMBEDDED DETECTOR

29.1 TYPE

29.2 NO. & LOCATION

29.3 MATERIAL

29.4 RESISTANCE VALUE

30 HEATING UP TIME (tE) IN CASE OF INCREASED

SAFETY MOTORS

31 BEARINGS DE BEARING NDE BEARING

31.1 BEARING TYPE

31.2 MAKE

31.3 MODEL NO.

31.4 CLEARANCE

31.5 BEARING LIFE

31.6 INSULATED YES/NO YES/NO

31.7 GREASED FOR LIFE TIME YES/NO YES/NO

31.8 GREASE TYPE

32 LUBRICATION

32.1 INTERVAL OF LUBRICATION

32.2 TYPE OF LUBRICATION

32.3 RECOMMENDED LUBRICANT

32.4 QUANITY OF LUBRICANT

33 COOLING

34 MOTOR TERMINAL BOX FAULT RATING _ kA for _ Second

35 VIBRATIONS mm PER SECOND

36 NOISE LEVEL dB(A)

37 SUITABLE FOR OPERATION FOR VSD FROM RPM TO RPM

37.1 VARIABLE SPEED

37.2 CONSTANT TORQUE

37.3 VOLTAGE WITHSTAND PEAK kV peak for micro-seconds

38 GUARANTEED LOSSES - kW

38.1 IRON LOSS

38.2 COPPER LOSS

38.3 FRICTION,WINDAGE & STRAY LOSSES

39 ROTOR DETAILS

39.1 ROTOR END FLOAT Min. / Max. mm

39.2 ROTOR END PLAY mm

39.3 ROTOR AIR GAP mm

40 TEST CERTIFICATE BY CIMFR /PESO /BIS ENCLOSED /NOT ENCLOSED

VENDOR TO ENCLOSE BOTH CIMFR (CMRI) AND PESO

(CCOE)

* - VENDOR TO SPECIFY

APPLICABLE STANDARD SPECIFICATION : 44 AD0600-00/E.02/001A/A4

Copyright 2018, Jacobs Engineering group Inc.

44AD0600-0000-E.04-01A4-A4

You might also like

- Ford 5000 Parts CatalogueDocument8 pagesFord 5000 Parts Cataloguemaogomo1256No ratings yet

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- Caterpillar 745 3F6 Electrical SchematicDocument27 pagesCaterpillar 745 3F6 Electrical SchematicAnonymous q8z9k6a100% (2)

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htikeNo ratings yet

- Volume 1 - Bogie Maintenance ManualDocument276 pagesVolume 1 - Bogie Maintenance ManualManjunath AithalNo ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- Technical Specification of 315-2500 KVA Distribution TransformerDocument51 pagesTechnical Specification of 315-2500 KVA Distribution Transformertsraj1083% (6)

- Table-1 Scope of Work Supply (MR For ACHE)Document6 pagesTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaNo ratings yet

- VM Motori 2105,3105,4105 CatalogueDocument2 pagesVM Motori 2105,3105,4105 CatalogueYann Van OsselaerNo ratings yet

- Cummins 6bta5.9-G2 So10941 Parts CatalogueDocument10 pagesCummins 6bta5.9-G2 So10941 Parts CatalogueChen Caroline50% (2)

- Data Sheet For Indutstrial and Flame Proof Local Control StationDocument2 pagesData Sheet For Indutstrial and Flame Proof Local Control StationAvinash ShuklaNo ratings yet

- Technical Specification & Datasheet For Motor PE-3208-EL-ES-001Document7 pagesTechnical Specification & Datasheet For Motor PE-3208-EL-ES-001Akhil JainNo ratings yet

- Shaftmounted Gearedmotors: Technical CatalogueDocument235 pagesShaftmounted Gearedmotors: Technical CatalogueEdgarNo ratings yet

- T183-I-Ss-039 - Datasheet For Ups MDB PanelDocument8 pagesT183-I-Ss-039 - Datasheet For Ups MDB PanelTejendra TambeNo ratings yet

- 4.3 Exhaust Silencer DatasheetDocument4 pages4.3 Exhaust Silencer Datasheetabuya3kubmNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- Breather Valve 50 NBDocument2 pagesBreather Valve 50 NBdumb2471817No ratings yet

- Technical Catalogue S Iec Atex en Rev2 PDFDocument125 pagesTechnical Catalogue S Iec Atex en Rev2 PDFTeguh TirtayasaNo ratings yet

- API Motor Data Sheet Temp LetDocument6 pagesAPI Motor Data Sheet Temp LetkhalidNo ratings yet

- PCA1080DXBKNJ1DSA00 04.17.18 CompressedDocument70 pagesPCA1080DXBKNJ1DSA00 04.17.18 CompressedAtilaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- APMR52300G1YDocument2 pagesAPMR52300G1YazzamijNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- "Specific" Use and Maintenance Manual: (Translation of The Original Manual)Document16 pages"Specific" Use and Maintenance Manual: (Translation of The Original Manual)Tina Manousi0% (1)

- Service Water TankDocument58 pagesService Water TankRanu Januar100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Package-08 TR (R1)Document2 pagesPackage-08 TR (R1)Antony Prashanth OliveraNo ratings yet

- C120-2 Misc Drawing Checklist - IFC0 - SignedDocument3 pagesC120-2 Misc Drawing Checklist - IFC0 - SignedMary DenizeNo ratings yet

- Specification Synchronous Generator: For FinalDocument32 pagesSpecification Synchronous Generator: For Final1121986jedNo ratings yet

- 34 TRF 20-11-2019Document54 pages34 TRF 20-11-2019abhi6784No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- 1416 MC MDS V 104 - Rev.0Document5 pages1416 MC MDS V 104 - Rev.0KrunalNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Tata Consulting Engineers Limited: Data Sheet B Emergency Diesel Generator Upto 2000 KvaDocument7 pagesTata Consulting Engineers Limited: Data Sheet B Emergency Diesel Generator Upto 2000 KvaRohit GoyalNo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- Index: Sheet 1 of 29 REV 01Document26 pagesIndex: Sheet 1 of 29 REV 01Ayush ChoudharyNo ratings yet

- TPL 1044 34570 VM SC 2809 R3Document36 pagesTPL 1044 34570 VM SC 2809 R3m 418No ratings yet

- Firing, NOx 0042005Document78 pagesFiring, NOx 0042005JKKNo ratings yet

- QPE002342 - Technical BidDocument136 pagesQPE002342 - Technical BidMuhammed TamerNo ratings yet

- Performacen Dl250aDocument22 pagesPerformacen Dl250aRoger FederNo ratings yet

- Date SheetsDocument3 pagesDate SheetsAnıl ÖztürkNo ratings yet

- Centrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorDocument2 pagesCentrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorJuan José Grajeda AguayoNo ratings yet

- QE301122-01-R2-Serba MahirDocument6 pagesQE301122-01-R2-Serba MahirHussin YasinNo ratings yet

- TPL 1044 34570 VM DS 2817 R3Document29 pagesTPL 1044 34570 VM DS 2817 R3m 418No ratings yet

- Shaft Mounted MotovarioDocument152 pagesShaft Mounted MotovarioFery FebryantoNo ratings yet

- Ot ValidationDocument3 pagesOt ValidationRajdip ChaudhariNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- 02-SOP of FD Fan.Document11 pages02-SOP of FD Fan.Mithun Singh Rajput100% (2)

- ROX000405521AB - Process Data Sheet MPFMDocument17 pagesROX000405521AB - Process Data Sheet MPFMKAABECHE SlimaneNo ratings yet

- 01 - 4 Test Report For Power Transformer 1Document7 pages01 - 4 Test Report For Power Transformer 1PUSHPARAJ MAURYANo ratings yet

- 5kva 20 Kva Dist - Transformer Spec Uploaded Website 2711Document40 pages5kva 20 Kva Dist - Transformer Spec Uploaded Website 2711atul raiNo ratings yet

- CCA ControllerDocument2 pagesCCA ControllerRendy MechanicNo ratings yet

- SP - DS LSDocument5 pagesSP - DS LSsakhr fahdNo ratings yet

- Ns2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data SheetDocument19 pagesNs2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data Sheettrong ngoc PhanNo ratings yet

- TDC 550 ManualDocument11 pagesTDC 550 ManualMapohoNo ratings yet

- 25-200-Kva pdf01 06 2017Document49 pages25-200-Kva pdf01 06 2017mangesh lavateNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- 附件2 海水篩濾器之篩濾器及馬達數據規格表Document3 pages附件2 海水篩濾器之篩濾器及馬達數據規格表駱建澄No ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- All-Digital Frequency Synthesizer in Deep-Submicron CMOSFrom EverandAll-Digital Frequency Synthesizer in Deep-Submicron CMOSNo ratings yet

- Specification Att - 3-4 - A642-000-16-54-TS-0001 Spec For Equip Noise LimitDocument5 pagesSpecification Att - 3-4 - A642-000-16-54-TS-0001 Spec For Equip Noise LimitAvinash ShuklaNo ratings yet

- Data Sheet - 2 Att - 1-2 - Motor Data Sheet For MV Squirrel Cage Induction MotorDocument1 pageData Sheet - 2 Att - 1-2 - Motor Data Sheet For MV Squirrel Cage Induction MotorAvinash ShuklaNo ratings yet

- 44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorDocument8 pages44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorAvinash ShuklaNo ratings yet

- Specification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitDocument4 pagesSpecification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitAvinash ShuklaNo ratings yet

- Engineering Design Basis (Static Equipment) (EPC-2 / EPC-3)Document19 pagesEngineering Design Basis (Static Equipment) (EPC-2 / EPC-3)Avinash ShuklaNo ratings yet

- Data Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Document2 pagesData Sheet - 1 Att - 1-1 - Process DS For E-301 To 328ABCD Air Heaters For STV GW Loop - Modified R1 - 20160919 (Only Unit Revised)Avinash ShuklaNo ratings yet

- Specification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsDocument15 pagesSpecification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsAvinash ShuklaNo ratings yet

- Specification Att - 3-19 - 6-51-0038 20rev 202 - Spec For MV Variable Frequency Drive SystemDocument15 pagesSpecification Att - 3-19 - 6-51-0038 20rev 202 - Spec For MV Variable Frequency Drive SystemAvinash ShuklaNo ratings yet

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocument15 pages6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- 44AD0600-00-E.01-0104-A3 - Rev 0 - Terminal Block Diagram For Local Control StationDocument4 pages44AD0600-00-E.01-0104-A3 - Rev 0 - Terminal Block Diagram For Local Control StationAvinash ShuklaNo ratings yet

- Data Sheet For Indutstrial and Flame Proof Local Control StationDocument2 pagesData Sheet For Indutstrial and Flame Proof Local Control StationAvinash ShuklaNo ratings yet

- 44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSDocument5 pages44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSAvinash ShuklaNo ratings yet

- Ergo Plast Pvt. LTD.: Manufactured byDocument4 pagesErgo Plast Pvt. LTD.: Manufactured byAvinash ShuklaNo ratings yet

- 44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTDocument6 pages44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- 44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONDocument51 pages44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONAvinash ShuklaNo ratings yet

- TechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XDocument78 pagesTechnicalspecificationsofheatexchangeralongwithSOI 20200314062818.362 XAvinash ShuklaNo ratings yet

- 44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESDocument5 pages44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESAvinash ShuklaNo ratings yet

- 44AC9100-000-V.02-0124-A4 - Rev B - STANDARD FOR ANCHOR BOLTSDocument16 pages44AC9100-000-V.02-0124-A4 - Rev B - STANDARD FOR ANCHOR BOLTSAvinash ShuklaNo ratings yet

- Viscosity of OilsDocument4 pagesViscosity of OilsJa Phe TiNo ratings yet

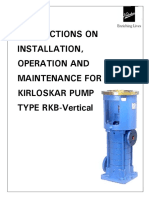

- Kirloskar Pump InstallationDocument34 pagesKirloskar Pump Installationmksingh_22No ratings yet

- DRIVESHAFTSDocument53 pagesDRIVESHAFTSDejan DžonićNo ratings yet

- InstallingHot StartrelayDocument5 pagesInstallingHot StartrelayjuanNo ratings yet

- Remove and Install Crankshaft Main BearingsDocument4 pagesRemove and Install Crankshaft Main BearingsMayumi Lizarme BuezoNo ratings yet

- Woodward TG Actuators 04045Document44 pagesWoodward TG Actuators 04045Jose Luis Castro Aguilar100% (1)

- Servo MotorsDocument27 pagesServo Motorsc_archana100% (1)

- Weber Carburetor Troubleshooting Guide: Operating ConditionsDocument8 pagesWeber Carburetor Troubleshooting Guide: Operating ConditionsRyan Hadi WicaksonoNo ratings yet

- View All Callouts: Function Isolation ToolsDocument37 pagesView All Callouts: Function Isolation ToolsTechnicien CheikhnaNo ratings yet

- Derale CatalogDocument32 pagesDerale CatalogЙордан ВасилевNo ratings yet

- Electric/ Electron Discharge Machining Lab ManualDocument8 pagesElectric/ Electron Discharge Machining Lab ManualDamodara MadhukarNo ratings yet

- 04 4000SP Ops MANUALDocument32 pages04 4000SP Ops MANUALjorge_t_71No ratings yet

- Piston and Connecting Rod Assembly TopicsDocument1 pagePiston and Connecting Rod Assembly TopicsgandhiramNo ratings yet

- Section II - h1 Engine SystemDocument57 pagesSection II - h1 Engine SystemraphaelsantanasouzaNo ratings yet

- Annex C - Price List - BidibidiDocument23 pagesAnnex C - Price List - Bidibidiemmanuelkitakufe1No ratings yet

- On Cooldown For Gas Turbine - Automation & Control Engineering ForumDocument1 pageOn Cooldown For Gas Turbine - Automation & Control Engineering ForumnboulegrouneNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Esquema 994DDocument4 pagesEsquema 994DEdnardo DutraNo ratings yet

- C002A-Propylene Compressor LLFDocument1 pageC002A-Propylene Compressor LLFPwan KhuranaNo ratings yet

- All PistonDocument5 pagesAll PistonyewlimNo ratings yet

- Owner'S Manual: Air - Cooled Diesel Engine Generator SetDocument23 pagesOwner'S Manual: Air - Cooled Diesel Engine Generator SetJoeNo ratings yet

- Ajax DPC 2804 Oampm Manual PDF FreeDocument185 pagesAjax DPC 2804 Oampm Manual PDF Freebassam.amir14296No ratings yet

- Operator'S Manual: 110 Series Leveling System HWH Lever-ControlledDocument15 pagesOperator'S Manual: 110 Series Leveling System HWH Lever-ControlledRussell ElrodNo ratings yet

- Martillo Perforador 23000Document6 pagesMartillo Perforador 23000jose sierraNo ratings yet

- Tech Data-Advanza Slim Glass Door Chiller&FreezerDocument2 pagesTech Data-Advanza Slim Glass Door Chiller&FreezerĐình QuangNo ratings yet