Professional Documents

Culture Documents

10na - Training - Flypartsguy - 8.2018

10na - Training - Flypartsguy - 8.2018

Uploaded by

Kurd SkorvskiCopyright:

Available Formats

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- 2.0L VCDi LNP DIESEL ENGINE MANUAL PDFDocument933 pages2.0L VCDi LNP DIESEL ENGINE MANUAL PDFLeonid BekermanNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- The Ultimate Guide To DynamoDocument10 pagesThe Ultimate Guide To DynamoAwes SewsaNo ratings yet

- Attention: 6R140 Installation GuideDocument4 pagesAttention: 6R140 Installation GuideAlex Maceira GraterolNo ratings yet

- Manual Chipeadora 18XP (059-119)Document61 pagesManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNo ratings yet

- Jonsered 49SP ManualDocument8 pagesJonsered 49SP ManualBlackbenellieSBE1No ratings yet

- Carburator - Ideal ProblemDocument4 pagesCarburator - Ideal ProblemfuggaNo ratings yet

- Ecom Driver Installation ManualDocument11 pagesEcom Driver Installation ManualKurd SkorvskiNo ratings yet

- K-12 School Presentation PDFDocument28 pagesK-12 School Presentation PDFDinabandhu PatraNo ratings yet

- Principles of TeachingDocument172 pagesPrinciples of Teachingjenniferespanol78% (9)

- SAP CRM Tech DRAFT (Tables, Relationships)Document15 pagesSAP CRM Tech DRAFT (Tables, Relationships)korramatta77100% (7)

- 13ta - TrainingDocument17 pages13ta - TrainingKurd SkorvskiNo ratings yet

- Gasoline Engine Owners Maunal For H2I2Document16 pagesGasoline Engine Owners Maunal For H2I2antNo ratings yet

- Wp06 Training MaterialDocument17 pagesWp06 Training MaterialKurd SkorvskiNo ratings yet

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Mitsubishi EnginesDocument31 pagesMitsubishi EnginesRickNo ratings yet

- Kf22Qt Sec4 FRDDocument21 pagesKf22Qt Sec4 FRDMauro PerezNo ratings yet

- FX-375 ServiceDocument21 pagesFX-375 ServiceMauro PerezNo ratings yet

- Operation Manual For Wp4g95e221 EngineDocument28 pagesOperation Manual For Wp4g95e221 EngineCarlos Astudillo VargasNo ratings yet

- MaintenanceInformation 4CylVeradoDocument27 pagesMaintenanceInformation 4CylVeradocombaheeNo ratings yet

- Before Operation & MaintenanceDocument7 pagesBefore Operation & MaintenanceTech CIMNo ratings yet

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- 94-Rvf400rr HRC ManualDocument13 pages94-Rvf400rr HRC ManualhungkuenNo ratings yet

- Manual Canrig 06Document8 pagesManual Canrig 06sertecs polNo ratings yet

- Manual de Taller CF150 PDFDocument190 pagesManual de Taller CF150 PDFMotorcycles Workshop Amigos PulsarNo ratings yet

- CRRCPro GF45IDocument8 pagesCRRCPro GF45IJulio CesarNo ratings yet

- Intervalos de ManutençãoDocument3 pagesIntervalos de ManutençãoOzan MedeirosNo ratings yet

- Installation ManualDocument6 pagesInstallation ManualBEARNo ratings yet

- Maintenance Program For HFO Diesel EngineDocument11 pagesMaintenance Program For HFO Diesel EngineUmit CengNo ratings yet

- Maintenance For Landking WP10 Euro III Diesel EnginesDocument67 pagesMaintenance For Landking WP10 Euro III Diesel EnginesClaudio Curbelo100% (1)

- WM 370235 Checking and Topping Up ATF (Clutch Fluid)Document4 pagesWM 370235 Checking and Topping Up ATF (Clutch Fluid)AlessandroMoreniNo ratings yet

- Owner'S General Engine: Manual GasolineDocument72 pagesOwner'S General Engine: Manual GasolineFrançois CantinNo ratings yet

- B Series Valve AdjustmentDocument5 pagesB Series Valve Adjustmentsasa oljacaNo ratings yet

- MaintenanceInformation OptiMaxDocument20 pagesMaintenanceInformation OptiMaxcombaheeNo ratings yet

- 31733030Document28 pages31733030sunthron somchaiNo ratings yet

- Lycoming Reciprocating Engine Break-In and Oil ConsumptionDocument7 pagesLycoming Reciprocating Engine Break-In and Oil ConsumptionChristian Enrique Casique PajarNo ratings yet

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- ZD30 Engine Fault ListDocument61 pagesZD30 Engine Fault Listlocario1No ratings yet

- 2011 Maintenance Manual of Zoomlion Mixer(中英文)Document16 pages2011 Maintenance Manual of Zoomlion Mixer(中英文)Freddy AndresNo ratings yet

- LC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakDocument29 pagesLC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakCarloss CastroNo ratings yet

- Model 66500A-66510A - Air Hydraulic Floor Jack ManualDocument8 pagesModel 66500A-66510A - Air Hydraulic Floor Jack ManualAlain DefoeNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Karcher G 2400 HHDocument13 pagesKarcher G 2400 HHpandem123No ratings yet

- Manual Soplador Ametek 505Document14 pagesManual Soplador Ametek 505Carlos Mario Lopez CabreraNo ratings yet

- Manual Motor Crrcpro26iDocument8 pagesManual Motor Crrcpro26ieduardo_albornoz_5No ratings yet

- On-Vehicle InspectionDocument5 pagesOn-Vehicle InspectionEdson CRNo ratings yet

- EngineDocument2,543 pagesEngineAlexis Yureni Rodriguez RojasNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Weichai Wp6g125e23Document64 pagesWeichai Wp6g125e23Maria PazNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- SECTION 2-General Maintanance PDFDocument18 pagesSECTION 2-General Maintanance PDFDidin Delgado0% (1)

- 6D105 Series O&M ManualDocument49 pages6D105 Series O&M Manualjobin joyNo ratings yet

- e-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDocument2 pagese-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDimas PrasetyoNo ratings yet

- ER-96-5-12 - Chain Drive SystemDocument11 pagesER-96-5-12 - Chain Drive SystemSebei ChakibNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Important Information: Section 1B - MaintenanceDocument17 pagesImportant Information: Section 1B - MaintenanceDr. Centelha Mecânica NaúticaNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- 1 - Titan Owners Manual For End UsersDocument24 pages1 - Titan Owners Manual For End Userschristian vergaray gonzalesNo ratings yet

- Carburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesDocument32 pagesCarburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesJoseNo ratings yet

- Manual PDS55S - 5B2 - E1 - (2) (39600 - 78420)Document22 pagesManual PDS55S - 5B2 - E1 - (2) (39600 - 78420)singoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- All - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Document183 pagesAll - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- 6ta - Parts - Flypartsguy - Com - 3.2019Document98 pages6ta - Parts - Flypartsguy - Com - 3.2019Kurd SkorvskiNo ratings yet

- Weichai Murphy Control Panel Combined Operation Manual - 20200103Document65 pagesWeichai Murphy Control Panel Combined Operation Manual - 20200103Kurd SkorvskiNo ratings yet

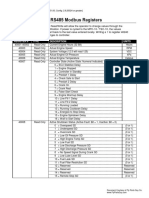

- Mpc-10 & Tec-10 Modbus Map 2.28.2019Document6 pagesMpc-10 & Tec-10 Modbus Map 2.28.2019Kurd SkorvskiNo ratings yet

- Mpc-10 Installation Manual - 00-02-0938Document15 pagesMpc-10 Installation Manual - 00-02-0938Kurd SkorvskiNo ratings yet

- Tec-10 Installation Manual 20180223Document12 pagesTec-10 Installation Manual 20180223Kurd SkorvskiNo ratings yet

- Murphy Configuration and Installation ManualDocument10 pagesMurphy Configuration and Installation ManualKurd SkorvskiNo ratings yet

- Mpc-10 & Tec-10 Setup For A Mechanical EngineDocument1 pageMpc-10 & Tec-10 Setup For A Mechanical EngineKurd SkorvskiNo ratings yet

- Wp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoDocument8 pagesWp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- 13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Document84 pages13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Kurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP13GTA, Bi-FuelDocument110 pagesParts Manual: Gas Engine Models: WP13GTA, Bi-FuelKurd Skorvski100% (2)

- 13ta - TrainingDocument17 pages13ta - TrainingKurd SkorvskiNo ratings yet

- Document Courtesy of Fly Parts Guy CoDocument5 pagesDocument Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- Wp13Gta Installation and Application ManualDocument25 pagesWp13Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- 10ta - Data Sheet - Flypartsguy - Com - 8.2018Document8 pages10ta - Data Sheet - Flypartsguy - Com - 8.2018Kurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP13Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP13Kurd SkorvskiNo ratings yet

- Wp10Gta Installation and Application ManualDocument27 pagesWp10Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP10GTA, Bi-FuelDocument112 pagesParts Manual: Gas Engine Models: WP10GTA, Bi-FuelKurd Skorvski100% (1)

- 10ta - Brochure - Flypartsguy - Com - 8.2019Document5 pages10ta - Brochure - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP10GNA, Bi-FuelDocument114 pagesParts Manual: Gas Engine Models: WP10GNA, Bi-FuelKurd SkorvskiNo ratings yet

- 10na - Assembly - Flypartsguy 4.2018Document106 pages10na - Assembly - Flypartsguy 4.2018Kurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP10Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP10Kurd SkorvskiNo ratings yet

- Assembly & Disassembly Manual: Gas Engine Model: WP10GTADocument111 pagesAssembly & Disassembly Manual: Gas Engine Model: WP10GTAKurd SkorvskiNo ratings yet

- Wp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGDocument26 pagesWp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGKurd SkorvskiNo ratings yet

- 6ta - Assembly & Disassembly - 2018Document90 pages6ta - Assembly & Disassembly - 2018Kurd SkorvskiNo ratings yet

- 12 BytesDocument9 pages12 BytesAlinfa1No ratings yet

- BIOLOGY XI CHAP 1 Question-556227Document4 pagesBIOLOGY XI CHAP 1 Question-556227Arti ThokchomNo ratings yet

- Lesson Exemplar Eng6Document3 pagesLesson Exemplar Eng6Angelo Jude Cobacha100% (1)

- Mill Series Training Manual Haas CNC Mill OperatorDocument81 pagesMill Series Training Manual Haas CNC Mill OperatorDamir PrstenkovNo ratings yet

- Solar System Travel BrochureDocument4 pagesSolar System Travel BrochureTatheer AbbasNo ratings yet

- Childhood SchizophreniaDocument14 pagesChildhood SchizophreniaAnalia WriterNo ratings yet

- Developing A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enDocument68 pagesDeveloping A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enLean ZechNo ratings yet

- STVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivityDocument9 pagesSTVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivitySun Shine OalnacarasNo ratings yet

- BRC V9 - ArDocument180 pagesBRC V9 - Ars.salah07100% (1)

- Unit 2 Definition of Knowledge and Its Basic AssumptionsDocument9 pagesUnit 2 Definition of Knowledge and Its Basic AssumptionssubhayudanNo ratings yet

- HOW TO... : Why Is Egg Turning Important?Document7 pagesHOW TO... : Why Is Egg Turning Important?Anusha NairNo ratings yet

- Presentations For Tensor CategoriesDocument34 pagesPresentations For Tensor CategoriesEstadistica EPSONo ratings yet

- Bala MuruganDocument6 pagesBala MuruganBala Murugan100% (1)

- Chapter 4 Force and Newtons Laws of MotionDocument23 pagesChapter 4 Force and Newtons Laws of MotionQassem MohaidatNo ratings yet

- Urooj CV For TeachingDocument1 pageUrooj CV For TeachingUrooj ShamsNo ratings yet

- Permeability of Granular Soils (Constant Head) : Standard Test Method ForDocument5 pagesPermeability of Granular Soils (Constant Head) : Standard Test Method ForEdwardNo ratings yet

- Evidence Based Dentistry - A Review: January 2014Document5 pagesEvidence Based Dentistry - A Review: January 2014Sitta Dea ViastiyaNo ratings yet

- Digital Skills: Where Universities MatterDocument12 pagesDigital Skills: Where Universities MatterSean Hooeks0% (1)

- Grade 5 - Arts ActivitiesDocument7 pagesGrade 5 - Arts ActivitiesMarcus Sayson DabonNo ratings yet

- Noted Academic Researcher DR Kannan Vishwanath To Address On Open Innovation at The VI Economic ForumDocument3 pagesNoted Academic Researcher DR Kannan Vishwanath To Address On Open Innovation at The VI Economic ForumDr Kannan VishwanathNo ratings yet

- ISTA 6-AMAZON Packaging Test Solutions (PDFDrive)Document38 pagesISTA 6-AMAZON Packaging Test Solutions (PDFDrive)Ghenal RiveraNo ratings yet

- Exp2 MotionDocument2 pagesExp2 Motiondcsvn131930No ratings yet

- GeeCee VenturesDocument1 pageGeeCee VenturesNaveen kishore100% (1)

- W Ork Ing Sci Ent Ifica LlyDocument30 pagesW Ork Ing Sci Ent Ifica Llyイクラご飯.No ratings yet

- Multiple Intelligences - 8 Ways of Being SmartDocument2 pagesMultiple Intelligences - 8 Ways of Being SmartImpulsive collector100% (2)

- Emotional Intelligence PresentationDocument10 pagesEmotional Intelligence Presentationshubhrawad1996No ratings yet

10na - Training - Flypartsguy - 8.2018

10na - Training - Flypartsguy - 8.2018

Uploaded by

Kurd SkorvskiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10na - Training - Flypartsguy - 8.2018

10na - Training - Flypartsguy - 8.2018

Uploaded by

Kurd SkorvskiCopyright:

Available Formats

WP10 Gas Engine

Key point of maintenance and assembly

Aug 2018

Document Courtesy of Fly Parts Guy Co. 1

www.FlyPartsGuy.com

CONTENTS

1. Maintenance

2. Key point of assembly

Document Courtesy of Fly Parts Guy Co. 2

www.FlyPartsGuy.com

1.Maintenance—Specification of fuel, lubricating oil and coolant

• Natural Gas: at least 70% methane by volume or have a

Fuel heating value of 950-1100 BTUs per standard cubic foot

• LPG: minimum of 90% propane, maximum of 5% propylene,

and maximum 5% of other gases

• Recommends using a straight weight or multi-weight low ash

content oil specifically formulated for Natural Gas Engines.

Oil • Specific weight depends on operating temperatures: (10W-

30 : -25 to 30℃), (15W-40 : -20 to 40℃), (20W-50 : -15 to

45℃)

• API No. CH-4 or above are also recommended.

• recommends using a 50/50 mixture of fully formulated

Coolant Ethylene Glycol or fully formulated Propylene Glycol coolant

and distilled water

Document Courtesy of Fly Parts Guy Co. 3

www.FlyPartsGuy.com

1.Maintenance—Maintenance schedule

Non-emergency

Document Courtesy of Fly Parts Guy Co. 4

www.FlyPartsGuy.com

1.Maintenance—Maintenance schedule

Emergency

Document Courtesy of Fly Parts Guy Co. 5

www.FlyPartsGuy.com

1.Maintenance—Daily check

1.Check engine oil level 3. Check operation conditions

❖ Check hoses, clamps, pipes for loose

connection or leak.

❖ Check connectors for loose connection.

❖ Check harness for cut, short, corrosion

or abrasions.

❖ Check belt for loose or fraying.

❖ Assure battery voltage is ≥12v each.

2.Check coolant level

4. Check oil pressure

Oil Pressure

Idle PSI KPa

Min 19 ≥130

Rated Speed

Min 50 350

Max 84 580

Caution : Never remove radiator

or top tank cap when coolant is

hot!

Document Courtesy of Fly Parts Guy Co. 6

www.FlyPartsGuy.com

1.Maintenance—Replace lubricating oil and oil filter element

Engine model Oil refill volume Material details

27~30L (7.1~7.9 Gal)

WP10 2 filter elements and 2 O-rings

Recheck dipstick

Replace oil filter element:

1. Drain oil completely.

2. Remove oil filters by the filter wrench and

remove O-rings.

3. Install new filter and O-ring by hand.(Apply a

thin coat of motor oil to o- ring before

installing)

4. Tighten filter until the rubber gasket contacts

base. Tighten additional 3/4 to 1 turn to seal..

5. Fill new oil and run engine for 5 minutes,

check for leaks.

Document Courtesy of Fly Parts Guy Co. 7

www.FlyPartsGuy.com

1.Maintenance—Adjust valve lash

TDC mark

Valve lash (cold)

intake 0.5mm

1.The first piston is on the “TDC” of compression stroke exhaust 0.8mm

Fan #1@TDC INT EXH INT EXH INT EXH Flywheel

side (COMPRESSION STROKE) 1 1 2 3 4 5 side

2.The number six piston is on the “TDC” of compression stroke

Fan EXH INT EXH INT INT EXH #6@TDC Flywheel

side 2 3 4 5 6 6 (COMPRESSION STROKE) side

Document Courtesy of Fly Parts Guy Co. 8

www.FlyPartsGuy.com

CONTENTS

1. Maintenance

2. Key point of assembly

Document Courtesy of Fly Parts Guy Co. 9

www.FlyPartsGuy.com

2. Key point of assembly—Gear timing

1.Rotate the crankshaft to the TDC of first and sixth cylinder.

2.Rotate the camshaft and install the timing gear when the scale mark in timing

gear and “OT” scale mark in gear housing are aligning.

NOTE: Camshaft timing fastening bolts: Apply tighten

glue and tight to 45~45Nm.

1.Crankshaft gear 2.Intermediate gear

3.Camshaft gear 5.Signal generator gear

6.Oil pump intermediate gear

7.Oil pump gear

Document Courtesy of Fly Parts Guy Co. 10

www.FlyPartsGuy.com

2. Key point of assembly—Intermediate gear

Install intermediate gear:

1. The “V” mark should face to front (out side).

2. Bolts: Apply tighten glue and tight to (60±5)Nm, turn 90°, reach to

100~120Nm at the same time.

“V” mark

Document Courtesy of Fly Parts Guy Co. 11

www.FlyPartsGuy.com

2. Key point of assembly—Signal generator

1. Rotate the crankshaft to “OT” mark, make sure the first piston is on the top

dead center of compression stroke.

2. Install the signal generator and adjust angle of the fluted disc until its TDC mark

points at the center of the phase sensor and the predetermined ignition angle is

reached.

3. Tighten the locknut (80~100N·m) on the signal generator fluted disc.

Note: the correct value of the gap between the fluted disc and sensor is 0.8~1.5mm

1th piston@ TDC of Fluted disc TDC mark points at the

compression stroke center of phase sensor.

Document Courtesy of Fly Parts Guy Co. 12

www.FlyPartsGuy.com

2. Key point of assembly—Connecting rod and piston

Key points:

1. The connecting rod oblique split are back to the piston notch.

2. The piston notch and oil nozzle should be in the same direction when install

the connect rod and piston combinations.

3. The torque of connecting rod bolt is :120N·m + (90±5°), (Reach 170 to

250N·m at the same time)

NOTE: 1.The connecting rod bolts can’t be re-used.

2. The opening mouth of piston rings should not overlap.

Piston

notch 1.The oblique split

are back to the

piston notch.

2. The piston notch

should be in the

same direction with

oil nozzle

Adjust the angle of piston

rings to make sure the

opening not overlap.

Document Courtesy of Fly Parts Guy Co. 13

www.FlyPartsGuy.com

2. Key point of assembly—Main bearing bolt

Main bearing bolts:

The first time 80Nm, the second time 250Nm. Required sequence of

tightening as below

Note: the oil groove on the thrust plate should face to crankshaft.

Document Courtesy of Fly Parts Guy Co. 14

www.FlyPartsGuy.com

2. Key point of assembly—Cylinder head bolts

Cylinder head bolts and nuts:

1. Align the cylinder head with the cylinder block. Apply a proper amount of clean lubricating oil to the

threads and pressure-bearing surfaces of shoulders of the main bolts of cylinder head and the

shouldered nuts. Install the main bolts to the cylinder head. Install the clamping blocks and nuts to

the auxiliary bolts of cylinder head.

2. Tighten the main bolts and nuts of auxiliary bolts of cylinder head to the torque of (30~50) Nm.

3. Tap the clamping blocks so that they descend in place.

4. Tighten the nuts of auxiliary bolts in the sequence to the torque of 100N·m.

5. Tighten the main bolts in the sequence to the torque of 200N·m.

6. Tighten the nuts of auxiliary bolts in the sequence by 90º. Then make marks on the nuts.

7. Tighten the main bolts in the sequence by 90º. Then make marks on the bolts.

8. Tighten the nuts of auxiliary bolts in the sequence by another 90º to the torque of (120~160) Nm.

9. Tighten the main bolts in the sequence by another 90º to the torque of (240~340) Nm.

10. The cylinder head bolts and nuts shall be tightened according to the order given by Illustration

below, in which, those numbering 1-21 are nuts of auxiliary bolt, while those numbering 22-45 are

main bolts of cylinder head

Document Courtesy of Fly Parts Guy Co. 15

www.FlyPartsGuy.com

2. Key point of assembly—Flywheel housing

Flywheel housing bolts:

1. Apply the lubricating oil on the contact surface and thread of bolts.

2. Tighten torque: 100~140Nm and tighten sequence as below.

Document Courtesy of Fly Parts Guy Co. 16

www.FlyPartsGuy.com

2. Key point of assembly—

Engine Fastener Torque Specifications

Tightening torque (N·m) + further turned Permissible times of

Fastener’s Name Bolt Specification

angle (°) repeat used

The first time 80N·m, the second time

Main bearing M18-10.9 2

250~280N·m (See illustration13)

120N·m + (90±5°), (Reach 170 to 250N·m at

Connecting rod M14x1.5-12.9 0

the same time)

200N·m +2x (90±5°), required sequence of

Cylinder head M16-12.9 tightening (See illustration14), (Reach 240 to 3

340N.m at the same time)

60N·m +2x(90±5°), (Reach 230 to 280N·m at

Flywheel M14x1.5 2

the same time)

Flywheel housing 110 to 140N·m 2

Camshaft gear M8-12.9 40 to 45N·m

Exhaust manifold M10 50 to 70N·m 2

Intake manifold M10 45+5N.m -

Damper M10-10.9 65 to 70N·m -

Spark-plug M14x1.25 (25 to 28) N·m -

UEGO sensor M18x1.5 40N.m±5N·m -

Water temperature

M14x1.5 25N.m±5N·m -

sensor

Document Courtesy of Fly Parts Guy Co. 17

www.FlyPartsGuy.com

Document Courtesy of Fly Parts Guy Co. 18

www.FlyPartsGuy.com

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- 2.0L VCDi LNP DIESEL ENGINE MANUAL PDFDocument933 pages2.0L VCDi LNP DIESEL ENGINE MANUAL PDFLeonid BekermanNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- The Ultimate Guide To DynamoDocument10 pagesThe Ultimate Guide To DynamoAwes SewsaNo ratings yet

- Attention: 6R140 Installation GuideDocument4 pagesAttention: 6R140 Installation GuideAlex Maceira GraterolNo ratings yet

- Manual Chipeadora 18XP (059-119)Document61 pagesManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNo ratings yet

- Jonsered 49SP ManualDocument8 pagesJonsered 49SP ManualBlackbenellieSBE1No ratings yet

- Carburator - Ideal ProblemDocument4 pagesCarburator - Ideal ProblemfuggaNo ratings yet

- Ecom Driver Installation ManualDocument11 pagesEcom Driver Installation ManualKurd SkorvskiNo ratings yet

- K-12 School Presentation PDFDocument28 pagesK-12 School Presentation PDFDinabandhu PatraNo ratings yet

- Principles of TeachingDocument172 pagesPrinciples of Teachingjenniferespanol78% (9)

- SAP CRM Tech DRAFT (Tables, Relationships)Document15 pagesSAP CRM Tech DRAFT (Tables, Relationships)korramatta77100% (7)

- 13ta - TrainingDocument17 pages13ta - TrainingKurd SkorvskiNo ratings yet

- Gasoline Engine Owners Maunal For H2I2Document16 pagesGasoline Engine Owners Maunal For H2I2antNo ratings yet

- Wp06 Training MaterialDocument17 pagesWp06 Training MaterialKurd SkorvskiNo ratings yet

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Mitsubishi EnginesDocument31 pagesMitsubishi EnginesRickNo ratings yet

- Kf22Qt Sec4 FRDDocument21 pagesKf22Qt Sec4 FRDMauro PerezNo ratings yet

- FX-375 ServiceDocument21 pagesFX-375 ServiceMauro PerezNo ratings yet

- Operation Manual For Wp4g95e221 EngineDocument28 pagesOperation Manual For Wp4g95e221 EngineCarlos Astudillo VargasNo ratings yet

- MaintenanceInformation 4CylVeradoDocument27 pagesMaintenanceInformation 4CylVeradocombaheeNo ratings yet

- Before Operation & MaintenanceDocument7 pagesBefore Operation & MaintenanceTech CIMNo ratings yet

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- 94-Rvf400rr HRC ManualDocument13 pages94-Rvf400rr HRC ManualhungkuenNo ratings yet

- Manual Canrig 06Document8 pagesManual Canrig 06sertecs polNo ratings yet

- Manual de Taller CF150 PDFDocument190 pagesManual de Taller CF150 PDFMotorcycles Workshop Amigos PulsarNo ratings yet

- CRRCPro GF45IDocument8 pagesCRRCPro GF45IJulio CesarNo ratings yet

- Intervalos de ManutençãoDocument3 pagesIntervalos de ManutençãoOzan MedeirosNo ratings yet

- Installation ManualDocument6 pagesInstallation ManualBEARNo ratings yet

- Maintenance Program For HFO Diesel EngineDocument11 pagesMaintenance Program For HFO Diesel EngineUmit CengNo ratings yet

- Maintenance For Landking WP10 Euro III Diesel EnginesDocument67 pagesMaintenance For Landking WP10 Euro III Diesel EnginesClaudio Curbelo100% (1)

- WM 370235 Checking and Topping Up ATF (Clutch Fluid)Document4 pagesWM 370235 Checking and Topping Up ATF (Clutch Fluid)AlessandroMoreniNo ratings yet

- Owner'S General Engine: Manual GasolineDocument72 pagesOwner'S General Engine: Manual GasolineFrançois CantinNo ratings yet

- B Series Valve AdjustmentDocument5 pagesB Series Valve Adjustmentsasa oljacaNo ratings yet

- MaintenanceInformation OptiMaxDocument20 pagesMaintenanceInformation OptiMaxcombaheeNo ratings yet

- 31733030Document28 pages31733030sunthron somchaiNo ratings yet

- Lycoming Reciprocating Engine Break-In and Oil ConsumptionDocument7 pagesLycoming Reciprocating Engine Break-In and Oil ConsumptionChristian Enrique Casique PajarNo ratings yet

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- ZD30 Engine Fault ListDocument61 pagesZD30 Engine Fault Listlocario1No ratings yet

- 2011 Maintenance Manual of Zoomlion Mixer(中英文)Document16 pages2011 Maintenance Manual of Zoomlion Mixer(中英文)Freddy AndresNo ratings yet

- LC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakDocument29 pagesLC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakCarloss CastroNo ratings yet

- Model 66500A-66510A - Air Hydraulic Floor Jack ManualDocument8 pagesModel 66500A-66510A - Air Hydraulic Floor Jack ManualAlain DefoeNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Karcher G 2400 HHDocument13 pagesKarcher G 2400 HHpandem123No ratings yet

- Manual Soplador Ametek 505Document14 pagesManual Soplador Ametek 505Carlos Mario Lopez CabreraNo ratings yet

- Manual Motor Crrcpro26iDocument8 pagesManual Motor Crrcpro26ieduardo_albornoz_5No ratings yet

- On-Vehicle InspectionDocument5 pagesOn-Vehicle InspectionEdson CRNo ratings yet

- EngineDocument2,543 pagesEngineAlexis Yureni Rodriguez RojasNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Weichai Wp6g125e23Document64 pagesWeichai Wp6g125e23Maria PazNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- SECTION 2-General Maintanance PDFDocument18 pagesSECTION 2-General Maintanance PDFDidin Delgado0% (1)

- 6D105 Series O&M ManualDocument49 pages6D105 Series O&M Manualjobin joyNo ratings yet

- e-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDocument2 pagese-QD Series Generator Set Models Mdkau, Mdkav, MDKBG, Mdkaw, Mdkaz, MDKBD, Mdkbe, MDKBFDimas PrasetyoNo ratings yet

- ER-96-5-12 - Chain Drive SystemDocument11 pagesER-96-5-12 - Chain Drive SystemSebei ChakibNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Important Information: Section 1B - MaintenanceDocument17 pagesImportant Information: Section 1B - MaintenanceDr. Centelha Mecânica NaúticaNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- 1 - Titan Owners Manual For End UsersDocument24 pages1 - Titan Owners Manual For End Userschristian vergaray gonzalesNo ratings yet

- Carburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesDocument32 pagesCarburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesJoseNo ratings yet

- Manual PDS55S - 5B2 - E1 - (2) (39600 - 78420)Document22 pagesManual PDS55S - 5B2 - E1 - (2) (39600 - 78420)singoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- All - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Document183 pagesAll - Troubleshooting & Diagnostic Manual - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- 6ta - Parts - Flypartsguy - Com - 3.2019Document98 pages6ta - Parts - Flypartsguy - Com - 3.2019Kurd SkorvskiNo ratings yet

- Weichai Murphy Control Panel Combined Operation Manual - 20200103Document65 pagesWeichai Murphy Control Panel Combined Operation Manual - 20200103Kurd SkorvskiNo ratings yet

- Mpc-10 & Tec-10 Modbus Map 2.28.2019Document6 pagesMpc-10 & Tec-10 Modbus Map 2.28.2019Kurd SkorvskiNo ratings yet

- Mpc-10 Installation Manual - 00-02-0938Document15 pagesMpc-10 Installation Manual - 00-02-0938Kurd SkorvskiNo ratings yet

- Tec-10 Installation Manual 20180223Document12 pagesTec-10 Installation Manual 20180223Kurd SkorvskiNo ratings yet

- Murphy Configuration and Installation ManualDocument10 pagesMurphy Configuration and Installation ManualKurd SkorvskiNo ratings yet

- Mpc-10 & Tec-10 Setup For A Mechanical EngineDocument1 pageMpc-10 & Tec-10 Setup For A Mechanical EngineKurd SkorvskiNo ratings yet

- Wp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoDocument8 pagesWp13Gta 12.5 L: Document Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- 13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Document84 pages13ta - Assembly & Disassembly - Flypartsguy - Com - 1.2018Kurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP13GTA, Bi-FuelDocument110 pagesParts Manual: Gas Engine Models: WP13GTA, Bi-FuelKurd Skorvski100% (2)

- 13ta - TrainingDocument17 pages13ta - TrainingKurd SkorvskiNo ratings yet

- Document Courtesy of Fly Parts Guy CoDocument5 pagesDocument Courtesy of Fly Parts Guy CoKurd SkorvskiNo ratings yet

- Wp13Gta Installation and Application ManualDocument25 pagesWp13Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- 10ta - Data Sheet - Flypartsguy - Com - 8.2018Document8 pages10ta - Data Sheet - Flypartsguy - Com - 8.2018Kurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP13Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP13Kurd SkorvskiNo ratings yet

- Wp10Gta Installation and Application ManualDocument27 pagesWp10Gta Installation and Application ManualKurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP10GTA, Bi-FuelDocument112 pagesParts Manual: Gas Engine Models: WP10GTA, Bi-FuelKurd Skorvski100% (1)

- 10ta - Brochure - Flypartsguy - Com - 8.2019Document5 pages10ta - Brochure - Flypartsguy - Com - 8.2019Kurd SkorvskiNo ratings yet

- Parts Manual: Gas Engine Models: WP10GNA, Bi-FuelDocument114 pagesParts Manual: Gas Engine Models: WP10GNA, Bi-FuelKurd SkorvskiNo ratings yet

- 10na - Assembly - Flypartsguy 4.2018Document106 pages10na - Assembly - Flypartsguy 4.2018Kurd SkorvskiNo ratings yet

- Operation and Maintenance Manual: Gas Engine Model: WP10Document33 pagesOperation and Maintenance Manual: Gas Engine Model: WP10Kurd SkorvskiNo ratings yet

- Assembly & Disassembly Manual: Gas Engine Model: WP10GTADocument111 pagesAssembly & Disassembly Manual: Gas Engine Model: WP10GTAKurd SkorvskiNo ratings yet

- Wp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGDocument26 pagesWp10Na Installation and Application Manual: Emission-Related Installation Instructions For Wp10Gna Engine NG, LPG & VPGKurd SkorvskiNo ratings yet

- 6ta - Assembly & Disassembly - 2018Document90 pages6ta - Assembly & Disassembly - 2018Kurd SkorvskiNo ratings yet

- 12 BytesDocument9 pages12 BytesAlinfa1No ratings yet

- BIOLOGY XI CHAP 1 Question-556227Document4 pagesBIOLOGY XI CHAP 1 Question-556227Arti ThokchomNo ratings yet

- Lesson Exemplar Eng6Document3 pagesLesson Exemplar Eng6Angelo Jude Cobacha100% (1)

- Mill Series Training Manual Haas CNC Mill OperatorDocument81 pagesMill Series Training Manual Haas CNC Mill OperatorDamir PrstenkovNo ratings yet

- Solar System Travel BrochureDocument4 pagesSolar System Travel BrochureTatheer AbbasNo ratings yet

- Childhood SchizophreniaDocument14 pagesChildhood SchizophreniaAnalia WriterNo ratings yet

- Developing A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enDocument68 pagesDeveloping A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enLean ZechNo ratings yet

- STVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivityDocument9 pagesSTVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivitySun Shine OalnacarasNo ratings yet

- BRC V9 - ArDocument180 pagesBRC V9 - Ars.salah07100% (1)

- Unit 2 Definition of Knowledge and Its Basic AssumptionsDocument9 pagesUnit 2 Definition of Knowledge and Its Basic AssumptionssubhayudanNo ratings yet

- HOW TO... : Why Is Egg Turning Important?Document7 pagesHOW TO... : Why Is Egg Turning Important?Anusha NairNo ratings yet

- Presentations For Tensor CategoriesDocument34 pagesPresentations For Tensor CategoriesEstadistica EPSONo ratings yet

- Bala MuruganDocument6 pagesBala MuruganBala Murugan100% (1)

- Chapter 4 Force and Newtons Laws of MotionDocument23 pagesChapter 4 Force and Newtons Laws of MotionQassem MohaidatNo ratings yet

- Urooj CV For TeachingDocument1 pageUrooj CV For TeachingUrooj ShamsNo ratings yet

- Permeability of Granular Soils (Constant Head) : Standard Test Method ForDocument5 pagesPermeability of Granular Soils (Constant Head) : Standard Test Method ForEdwardNo ratings yet

- Evidence Based Dentistry - A Review: January 2014Document5 pagesEvidence Based Dentistry - A Review: January 2014Sitta Dea ViastiyaNo ratings yet

- Digital Skills: Where Universities MatterDocument12 pagesDigital Skills: Where Universities MatterSean Hooeks0% (1)

- Grade 5 - Arts ActivitiesDocument7 pagesGrade 5 - Arts ActivitiesMarcus Sayson DabonNo ratings yet

- Noted Academic Researcher DR Kannan Vishwanath To Address On Open Innovation at The VI Economic ForumDocument3 pagesNoted Academic Researcher DR Kannan Vishwanath To Address On Open Innovation at The VI Economic ForumDr Kannan VishwanathNo ratings yet

- ISTA 6-AMAZON Packaging Test Solutions (PDFDrive)Document38 pagesISTA 6-AMAZON Packaging Test Solutions (PDFDrive)Ghenal RiveraNo ratings yet

- Exp2 MotionDocument2 pagesExp2 Motiondcsvn131930No ratings yet

- GeeCee VenturesDocument1 pageGeeCee VenturesNaveen kishore100% (1)

- W Ork Ing Sci Ent Ifica LlyDocument30 pagesW Ork Ing Sci Ent Ifica Llyイクラご飯.No ratings yet

- Multiple Intelligences - 8 Ways of Being SmartDocument2 pagesMultiple Intelligences - 8 Ways of Being SmartImpulsive collector100% (2)

- Emotional Intelligence PresentationDocument10 pagesEmotional Intelligence Presentationshubhrawad1996No ratings yet