Professional Documents

Culture Documents

3 4point Bend Flexural Testing Application Note

3 4point Bend Flexural Testing Application Note

Uploaded by

Pankaj MunjalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 4point Bend Flexural Testing Application Note

3 4point Bend Flexural Testing Application Note

Uploaded by

Pankaj MunjalCopyright:

Available Formats

3 and 4 Point Flexural Testing

Application Note

With ever increasing demand for high quality and The rising popularity of human interface devices such as

reliable electronic components and materials, flexural touch screens means that everyday devices such as mobile

tests have become an important test method in phones are subjected to many cycles of flexing during

both the manufacturing process and research and normal use. As a result manufacturers are committed

development to define a material’s ability to resist to ensuring products do not fail within their planned

deformation under load. A component’s or material’s lifetime and of guaranteeing performance across a

flexural strength provides critical insight into the range of usage scenarios. In order to achieve this, the

modulus of elasticity in bending, flexural stress and manufacturing and quality control processes need to be

flexural strain. optimised by testing the performance of the material or

product.

Bend testing of final assembly

3 and 4 Point Flexural Testing Application Note

Test Methods

Flexural tests simulate stresses of tensile and compression on a specimen, such as PCB or final assembly. The physical response

behaviour of the PCB or assembly is then monitored. Two common methods to test flexural strength involve destructive and non

destructive testing.

Destructive tests involve applying a uniform force on a

PCB or assembly until it fails and recording the maximum

force required as well as the distance displaced.

Non-destructive tests involve applying a uniform force up

to a specified limit and recording the displacement and

ensuring the PCB and assembly can tolerate the

specified force.

Cyclical and fatigue testing, where specified force-displacement

and force-time waveforms can be executed. This test method

enables different strain rates to be induced onto a sample over

a period of time, allowing analysis of cycles to failure as well as

force-displacement and force-time characteristics to

be determined.

The Nordson DAGE Solution

The Nordson DAGE 4000Plus tester provides the ability to

perform 3 and 4 point flexure tests. A combination of fixtures

as well as bespoke test solutions conform to a range of

international standards including; ASTM D790 and D672, IPC Push/pull 50kg with 3 point bend jig

TM-650, IEC 61189-2:TM20 and ISO 14125.

3 point flexure test Bespoke tests

The 3 point flexure fixture produces its peak stress at the Specimen testing provides one aspect of flexural strength

specimen mid-point with reduced stress elsewhere. properties. Materials and substrates may go through several

This stress localisation is ideal for testing for specific phases, such as heat reflow, before a complete product is

isolation of stress on a component or material. produced. These steps can reduce the flexural strength

of a product.

4 point flexure test

The 4 point flexure fixture produces peak stresses along an Nordson DAGE provides bespoke test solutions which cater for

extended region of the specimen hence exposing a larger unique properties and designs in order to aid end product testing.

length of the specimen with more potential for defects This provides a clear flexural strength of the end product.

and flaws to be highlighted.

Please contact Nordson DAGE for further information.

Application Note 3 and 4 Point Flexural Testing

Software: Typical example of test

The Nordson DAGE Paragon™ flexure test software features an easy to PCB and SMT technology are constantly facing new challenges

use interface allowing minimum test setup time, enabling the following in packaging and substrate design, where a typical product such as

material characteristics to be determined: a mobile phone will undergo many types of mechanical strain and

shock. Flexural testing has to be performed in order to determine

Flexural strength: defined as the materials or assemblies ability

how the product will react under force or changing forces such as

to resist deformation under load. Measured at the moment

bending or flexing.

of rupture where the highest stress is experienced within

the material. It is also important to determine the flexural properties of

the product so that the design is within the desired tolerance.

Stress-strain properties: the relationship between stress and strain. Cyclical and fatigue testing determine how long the product can

Usually represented graphically. From this graph the following sustain certain forces before failure and hence allow correct design

properties can be determined: of product.

• Flexural offset yield strength

A flexural test would allow a range of characteristics to be

• Tangent modulus of elasticity

determined of a PCB, including maximum force to failure,

• Secant modulus of elasticity

cycles and time to failure, flexural strength and flexural strain.

Flexural stress These characteristics can help determine the quality of a bare

Flexural stress at break PCB material or final assembly in order to deduce quality and

Stress at given strain reliability which was not previously possible on a bond test

Flexural strain platform.

Chord modulus

Nordson DAGE provides a complete solution for 3 point and 4

In addition, the Paragon flexure test software allows bespoke cyclic

point testing which coupled with the cyclic and fatigue software

testing for custom test procedures, user defined cyclic patterns and

capabilities provides for a robust, reliable and repeatable test for

selectable load range and speeds. Destructive and non-destructive

research and development, test and inspection as well as process

tests are also featured. These custom test features allow for the

control.

determination of fail points of components or materials.

The Nordson DAGEe 4 point bend jig utilises an additional

displacement sensor to measure midspan deflection of a sample

under test accurately to 50um, this is achieved with a Baumer

laser displacement sensor.

4 Point bend Jig

3 and 4 Point Flexural Testing Application Note

For more information,

Paragon™ Software Data Manipulation please contact your

Flexible Analysis and Data can be manipulated in a number Nordson DAGE regional office

Reporting of ways: or speak with your

Nordson DAGE representative,

ODBC compatibility (locally or via a

Data Analysis all of which are listed on

network link)

Paragon provides an incredibly flexible

www.nordsondage.com.

RS232 including a fixed field option

analysis suite suitable for the most

CSV file format availability Americas

demanding of applications +1 510 683 3930 Phone

including: Copy results to the clip board to paste sales@nordsondage.com Email

directly into Microsoft Excel or save direct

On-board statistics and Statistical China

to Excel or Word +86 512 6665 2008 Phone

Process Control (SPC) package complete

sales.ch@nordsondage.com Email

with histogram distribution curves

(mean and current samples)

Third Party Statistical

Germany

Process Control (SPC) +49 7021 950690 Phone

Force trend analysis (with box whisker

Paragon can be configured to output results sales.de@nordsondage.com Email

and optional mini histogram on the same chart)

into industry leading SPC packages. Japan

Grade pareto

+81 432 995851 Phone

These packages are directly available from,

Loop height trend analysis sales.jp@nordsondage.com Email

and supported by, the manufacturer.

Force/time displacement curves South East Asia

+65 655 27533 Phone

Exporting Results sales.sg@nordsondage.com Email

All combined with a powerful statistical

Test results can be saved directly to Microsoft®

results display, for mean, maximum and United Kingdom

Excel and Word as well as Adobe® Acrobat, +44 1296 317800 Phone

minimum range, standard deviation,

while graphs can be exported in common globalsales@nordsondage.com Email

mean – 3s, Cpk and Cp.

picture formats, such as .jpg, .tif and .bmp.

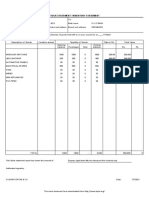

Flexural test results analysis

Nordson DAGE +44(0)1296 317800 Copyright © Nordson DAGE

25 Faraday Road www.nordsondage.com AP-BT-34PGT-201011.

Rabans Lane Industrial Area

Aylesbury, Buckinghamshire HP19 8RY, UK

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Stock Statement Format For Bank LoanDocument1 pageStock Statement Format For Bank Loanpsycho Neha40% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- H-05Document11 pagesH-05lincoln9003198No ratings yet

- 1474Document10 pages1474طه اللوذعيNo ratings yet

- Iso 1817 1999 FR en PDFDocument8 pagesIso 1817 1999 FR en PDFطه اللوذعي0% (1)

- ADMET FF-T Bend Fixture 50kN-100kN PDFDocument1 pageADMET FF-T Bend Fixture 50kN-100kN PDFطه اللوذعيNo ratings yet

- Sasmo CementDocument11 pagesSasmo Cementطه اللوذعيNo ratings yet

- Syrians StandardsDocument157 pagesSyrians Standardsطه اللوذعي100% (5)

- g223 Compression PlatensDocument1 pageg223 Compression Platensطه اللوذعيNo ratings yet

- Mastertop P10 TDSDocument2 pagesMastertop P10 TDSطه اللوذعيNo ratings yet

- Complete Materials Testing List EngDocument10 pagesComplete Materials Testing List Engطه اللوذعيNo ratings yet

- High Early Strength Cement - PdsDocument1 pageHigh Early Strength Cement - Pdsطه اللوذعيNo ratings yet

- Tensile TestDocument3 pagesTensile Testطه اللوذعيNo ratings yet

- Ten Guidelines For Standards EngineersDocument3 pagesTen Guidelines For Standards Engineersطه اللوذعيNo ratings yet

- Simplified Design Procedure For Blast Resistant GlazingDocument4 pagesSimplified Design Procedure For Blast Resistant Glazingطه اللوذعيNo ratings yet

- 2 PileDocument4 pages2 Pileطه اللوذعيNo ratings yet

- .In Cert TestequipmentDocument3 pages.In Cert Testequipmentsunilkumarpatel55No ratings yet

- Solution: C1 Example. Concentrated Load Under A BearingDocument3 pagesSolution: C1 Example. Concentrated Load Under A Bearingطه اللوذعيNo ratings yet

- 63 CalibrationEquipment E EmailDocument14 pages63 CalibrationEquipment E Emailطه اللوذعيNo ratings yet

- Lynyrd Skynyrd - Steve Gaines Equipment HistoryDocument10 pagesLynyrd Skynyrd - Steve Gaines Equipment HistorySean88% (8)

- OTC-24958 MEIDP Owen Fracture Zone CrossingDocument16 pagesOTC-24958 MEIDP Owen Fracture Zone CrossingFrds123No ratings yet

- FB-1 - Beam Detector Specification PDFDocument1 pageFB-1 - Beam Detector Specification PDFRafiq MagdyNo ratings yet

- Babar Abbasi C VDocument10 pagesBabar Abbasi C VmimrantajNo ratings yet

- Design of Sensor Less Sliding-Mode BLDC Motor Speed Regulator Using Class of Uncertain Takagi-Sugeno Nonlinear SystemsDocument5 pagesDesign of Sensor Less Sliding-Mode BLDC Motor Speed Regulator Using Class of Uncertain Takagi-Sugeno Nonlinear SystemsijcnesNo ratings yet

- The Tangents Drawn at The Ends ofDocument6 pagesThe Tangents Drawn at The Ends ofpjojibabu100% (2)

- If emDocument13 pagesIf emglassw380No ratings yet

- Fundamental Financial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument36 pagesFundamental Financial Accounting Concepts 9th Edition Edmonds Solutions Manualalicenhan5bzm2z100% (33)

- Greenboro Polychem PVT LTDDocument57 pagesGreenboro Polychem PVT LTDMehdi MadaniNo ratings yet

- Gear Box Catalogue PDFDocument7 pagesGear Box Catalogue PDFPiyush Anand100% (2)

- Catalogue of Industrial Laundry EquipmentDocument8 pagesCatalogue of Industrial Laundry EquipmentTrung TrịnhNo ratings yet

- AVO Analysis Guide PDFDocument89 pagesAVO Analysis Guide PDFceciliaNo ratings yet

- Aqualisa Quartz Simply A Better ShowerDocument12 pagesAqualisa Quartz Simply A Better ShowerPranjal SinghNo ratings yet

- DLL - Science 6 - Q2 - W2Document5 pagesDLL - Science 6 - Q2 - W2Geoffrey Tolentino-Unida100% (1)

- What Is Pure Substance?: Pure Substances Are Substances That Are Made Up of Only One Kind ofDocument3 pagesWhat Is Pure Substance?: Pure Substances Are Substances That Are Made Up of Only One Kind ofNi Made FebrianiNo ratings yet

- Corporate Briefing Notes - EPCL-1Document4 pagesCorporate Briefing Notes - EPCL-1Abdullah CheemaNo ratings yet

- UEFA B - Technical InformationDocument85 pagesUEFA B - Technical InformationILO 007No ratings yet

- Exp#05 M.inshal Fa18 Bme 022Document5 pagesExp#05 M.inshal Fa18 Bme 022Muhammad inshalNo ratings yet

- 1a209 Manual PDFDocument2 pages1a209 Manual PDFbayu edityaNo ratings yet

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Document8 pagesWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNo ratings yet

- 81161i Piattaforme 04-2018 EngDocument20 pages81161i Piattaforme 04-2018 EngEvandro Amaral RodriguesNo ratings yet

- Dyna 86l 8086 P Training Development System With LCD PDFDocument1 pageDyna 86l 8086 P Training Development System With LCD PDFSoluchanNo ratings yet

- Interior Design & Renovation Guide For Singapore Home OwnersDocument11 pagesInterior Design & Renovation Guide For Singapore Home OwnersPeter TanNo ratings yet

- Lesley Nair Thematic Summary of All You ZombiesDocument3 pagesLesley Nair Thematic Summary of All You Zombiesnair1904No ratings yet

- Design and Performance Analysis of 2Document24 pagesDesign and Performance Analysis of 2Dilip Kumar100% (1)

- FFODocument12 pagesFFOzahab007No ratings yet

- Re29150 - 2005-07 - DBETBXDocument12 pagesRe29150 - 2005-07 - DBETBXCarlos AugustoNo ratings yet

- CTEO Chapter II B Chemistry and 10 Clinker FactsDocument43 pagesCTEO Chapter II B Chemistry and 10 Clinker FactsFranciscoCorreaJara100% (2)