Professional Documents

Culture Documents

Yerp Design Manual Engineering Verification Checklist

Yerp Design Manual Engineering Verification Checklist

Uploaded by

ZeshanCopyright:

Available Formats

You might also like

- Fh601d Fh641d Fh680d Fh721d Kawasaki Service Repair Manual 99924206002Document114 pagesFh601d Fh641d Fh680d Fh721d Kawasaki Service Repair Manual 99924206002ljimun100% (1)

- Electrical Wiring SimplifiedDocument118 pagesElectrical Wiring Simplifiedplayontime100% (4)

- Principles of Mine Haul Road Design and Construction v5 Sep 2015 RJTs.28192929Document156 pagesPrinciples of Mine Haul Road Design and Construction v5 Sep 2015 RJTs.28192929Marc Flu100% (1)

- Exercise Questions For Section VIII Div.Document13 pagesExercise Questions For Section VIII Div.Karthikeyan Nadarajan100% (1)

- API 510 - Pressure Vessel (Exam Review and Preparation)Document4 pagesAPI 510 - Pressure Vessel (Exam Review and Preparation)solrac4371No ratings yet

- Tanks - Addition of Shell Nozzles by Hot TappingDocument2 pagesTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzNo ratings yet

- Gap Analysis in Healthcare TemplateDocument2 pagesGap Analysis in Healthcare TemplateZeshanNo ratings yet

- Sil Manual PDFDocument44 pagesSil Manual PDFDerbel WalidNo ratings yet

- Sample of Weld Map (Shop DWG)Document1 pageSample of Weld Map (Shop DWG)Septian Firdaus100% (2)

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87No ratings yet

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaNo ratings yet

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- 510 CalshDocument2 pages510 CalshMurugananthamParamasivamNo ratings yet

- Inspection DishendDocument5 pagesInspection DishendVarun MalhotraNo ratings yet

- Storage Tank Weld JointsDocument16 pagesStorage Tank Weld JointsDilip Varadharajan100% (1)

- Welding Questionarie & Ans.Document6 pagesWelding Questionarie & Ans.Deepak DineshNo ratings yet

- 19 - Weld Fit Up Inspection Employee TrainingDocument10 pages19 - Weld Fit Up Inspection Employee TrainingManoj KumarNo ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- ASME CODE Section VIII Div 1 Vs Div 2 Design FactorDocument7 pagesASME CODE Section VIII Div 1 Vs Div 2 Design FactorsarvannnNo ratings yet

- API Tank Estimate SheetDocument3 pagesAPI Tank Estimate SheetKjunwolf100% (1)

- API 650 12th Edition 2013 - NDT RequirementDocument1 pageAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Telltale HoleDocument3 pagesTelltale HoleAMALENDU PAULNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- Pressure Vessel Design CheckDocument2 pagesPressure Vessel Design CheckAnonymous ByTIbr100% (1)

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Hydro Test Loop File Index FormatDocument22 pagesHydro Test Loop File Index FormatHema NandhNo ratings yet

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocument6 pagesAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- API Repair ProcedureDocument1 pageAPI Repair ProcedurejacquesmayolNo ratings yet

- Interview Ques & Ans - KNPCDocument8 pagesInterview Ques & Ans - KNPCStephen RajNo ratings yet

- Fabrication and Inspection of PV and Columns PPMAIDocument47 pagesFabrication and Inspection of PV and Columns PPMAIguruj3057640% (1)

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Procedure Fabrikasi TankiDocument10 pagesProcedure Fabrikasi TankiMuhammad Yunus NurdinNo ratings yet

- Devlopment of SurfacesDocument17 pagesDevlopment of SurfacesBalajee Mech100% (5)

- Pipe Fitting Weight ChartDocument1 pagePipe Fitting Weight Chartab5918590No ratings yet

- Final Exam (Closed Book) : Answer SheetDocument13 pagesFinal Exam (Closed Book) : Answer SheetDAMIAN ALEJANDRO100% (1)

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- Pneumatic Test Procedure For SeagullDocument4 pagesPneumatic Test Procedure For SeagullDarkvaderNo ratings yet

- API - 650 Check List Tank InspectionDocument5 pagesAPI - 650 Check List Tank InspectionMijanur RahmanNo ratings yet

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- Tube To Tubesheet Weld Joint Design & Welding Qualifications MicroDocument21 pagesTube To Tubesheet Weld Joint Design & Welding Qualifications MicroSiva baalanNo ratings yet

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument76 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsgopidhanNo ratings yet

- API 650 PoıntsDocument4 pagesAPI 650 PoıntsSamet BelliNo ratings yet

- ITP Pressure VesselDocument2 pagesITP Pressure Vesselnafismuhammad1007No ratings yet

- General Specification For Welding and Weld Inspection EIL PDFDocument19 pagesGeneral Specification For Welding and Weld Inspection EIL PDFValesh MonisNo ratings yet

- Tubes Expansion ProcedureDocument3 pagesTubes Expansion Procedurefizanlamin100% (1)

- Storage Tank (API 650) - Home Welding & InspectionDocument34 pagesStorage Tank (API 650) - Home Welding & InspectionHussain AliNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- Welding Inspector Interview ReviewDocument5 pagesWelding Inspector Interview ReviewLuttpiNo ratings yet

- Volume-2 Api510 ExamDocument119 pagesVolume-2 Api510 ExamMohammad Danish100% (2)

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak0% (1)

- Codes StandardsDocument61 pagesCodes Standardshrk100No ratings yet

- Inspection and Test Plan For Pressure Vessel Repair, Modification, AlterationDocument5 pagesInspection and Test Plan For Pressure Vessel Repair, Modification, AlterationMuhammed Abo-Fandood50% (2)

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- Tank GADocument1 pageTank GASubramanian100% (1)

- GTS, PTS & Technical Data Sheet of Pakaldul H.E.projectDocument121 pagesGTS, PTS & Technical Data Sheet of Pakaldul H.E.projectSujeet Kumar50% (2)

- Steel Frame Design Manual: Italian NTC 2008Document96 pagesSteel Frame Design Manual: Italian NTC 2008Haytham ZaghloulNo ratings yet

- Yard Readiness Verification Check List BP2-YRV-002.Document5 pagesYard Readiness Verification Check List BP2-YRV-002.DHANEESH VELLILAPULLINo ratings yet

- ADA402914Document66 pagesADA402914PhalgunaNo ratings yet

- Department of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionDocument14 pagesDepartment of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionAbed samadsureyft7vewyrNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- HSE TerminologyDocument6 pagesHSE TerminologyZeshanNo ratings yet

- Failure of Secondary Reformer RefractoryDocument27 pagesFailure of Secondary Reformer RefractoryZeshanNo ratings yet

- Free Intro Template by PowerPoint SchoolDocument2 pagesFree Intro Template by PowerPoint SchoolZeshanNo ratings yet

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- General Weld Inspection - RT Requirement For NP Const.Document2 pagesGeneral Weld Inspection - RT Requirement For NP Const.ZeshanNo ratings yet

- Rubber Mateiral Chemical Resitivity ChartDocument18 pagesRubber Mateiral Chemical Resitivity ChartZeshanNo ratings yet

- Process Safety Management of Highly Hazardous Chemicals: Nancy J BetheaDocument55 pagesProcess Safety Management of Highly Hazardous Chemicals: Nancy J BetheaZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Market Gap Analysis TemplateDocument2 pagesMarket Gap Analysis TemplateZeshanNo ratings yet

- Gas Piping Best Practices Chris WolfeDocument11 pagesGas Piping Best Practices Chris WolfeZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Holdsworth Funnels REH 92 Sample PDFDocument6 pagesHoldsworth Funnels REH 92 Sample PDFMarcos RamirezNo ratings yet

- Plastic Waste On A Bituminous PavementDocument2 pagesPlastic Waste On A Bituminous PavementJess AguigamNo ratings yet

- Compact Integrated Power SteeringDocument21 pagesCompact Integrated Power SteeringTihomir MarkovicNo ratings yet

- Is 8406 1993 PDFDocument12 pagesIs 8406 1993 PDFSiddharth GuptaNo ratings yet

- Understanding Sarbanes OxleyDocument11 pagesUnderstanding Sarbanes OxleyrangoonroudyNo ratings yet

- SM 9 The - Guide - Case - Studies PDFDocument130 pagesSM 9 The - Guide - Case - Studies PDFJuan AlayoNo ratings yet

- Booklet On New Line OpeningDocument136 pagesBooklet On New Line OpeningRVNLPKG6B VBL-GTLMNo ratings yet

- P141 OrderForm - v32 - 082019Document11 pagesP141 OrderForm - v32 - 082019Kuenley TiNy OndeNo ratings yet

- Ericsson CommandsDocument8 pagesEricsson Commandsmahado100% (1)

- 5G The Microwave Perspective PDFDocument4 pages5G The Microwave Perspective PDFMuhammad JamilNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- SP231A/232A/233A/310A/312A Enhanced RS-232 Line Drivers/ReceiversDocument8 pagesSP231A/232A/233A/310A/312A Enhanced RS-232 Line Drivers/ReceiversAlejandra MariñoNo ratings yet

- Iecex Certificate of ConformityDocument7 pagesIecex Certificate of ConformityycjpaulNo ratings yet

- IMS VulnerabilitiesDocument9 pagesIMS Vulnerabilitiesprog_man_0101No ratings yet

- Upright and Pendent Intermediate Level SprinklerDocument6 pagesUpright and Pendent Intermediate Level SprinklerAhrian BenaNo ratings yet

- Avaya CDR FormatDocument5 pagesAvaya CDR FormatkhatriasifNo ratings yet

- Emi-Ucp4 6Document105 pagesEmi-Ucp4 6Fazrul IzwanNo ratings yet

- Printrinix S809Document4 pagesPrintrinix S809vinod yadavNo ratings yet

- LTE Technical Paper. VoLTE Feature Parameter DescriptionDocument13 pagesLTE Technical Paper. VoLTE Feature Parameter DescriptionZiya2009No ratings yet

- Metal Enclosed Switchgear in Plant Medium VoltageDocument4 pagesMetal Enclosed Switchgear in Plant Medium VoltagejuevesNo ratings yet

- OEL Maintenance Manual: B401/B411L6/B431L6Document184 pagesOEL Maintenance Manual: B401/B411L6/B431L6ALİ RIZA YILDIZNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationdudepapNo ratings yet

- TP-Link TL - WR740N WR741ND PDFDocument9 pagesTP-Link TL - WR740N WR741ND PDFnormalmannNo ratings yet

- Grundfosliterature 5235944 PDFDocument324 pagesGrundfosliterature 5235944 PDFĐạt TrầnNo ratings yet

- Draft Product Vision BoardDocument1 pageDraft Product Vision BoardJohn PatlolNo ratings yet

- 6657 Bom Photo-2011-7-8Document38 pages6657 Bom Photo-2011-7-8Damir SmigalovicNo ratings yet

Yerp Design Manual Engineering Verification Checklist

Yerp Design Manual Engineering Verification Checklist

Uploaded by

ZeshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yerp Design Manual Engineering Verification Checklist

Yerp Design Manual Engineering Verification Checklist

Uploaded by

ZeshanCopyright:

Available Formats

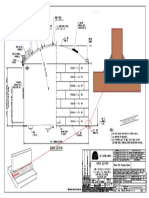

YERP DESIGN MANUAL

ENGINEERING VERIFICATION CHECKLIST

Discipline: Fixed Equipment

Activity: Pressure Vessel Checklist Document Number:

Checklist No.: Revision:

Accepted

Action Description Results Yes No

01 Have all given conditions been considered in the design/specification

of each item? This includes normal operating, startup/shutdown,

regeneration, auto-refrigeration, upset and design conditions.

(reference documents: Vessel Design Data and Connection

Summary, Project Design Data)

02 Has the Minimum Design Metal Temperature (MDMT) been

established/specified?

03 For items in cyclic service, do designs and details meet the

requirements of YERP-SAES-D-001?

04 For ASME Section VllI-Div. 2 vessels, have the items on the attached

Division 2 Checklist been included in the data sheet?

05 Has the User Design Specification (UDS) been established in

accordance with ASME Section VllI-Div. 2 paragraph 2.2.2?

06 Has the manufacturer complied with the provisions of the UDS?

07 Have post weld heat treatment requirements been appropriately

specified, especially for items in amine or caustic services? (reference

documents: Materials of Construction, ASME code, YERP standards

& specs)

08 Have columns been designed for aerodynamic vibration in

accordance with YERP-32-SAMSS-004?

09 Have lifting/tailing lugs been properly designed and specified? Have

columns been checked for structural integrity during their erection lift?

10 Have the proper caution notes been specified on drawings of

equipment that is required to be pneumatically tested?

11 Have the effects of external loads, such as those caused by piping or

attached equipment, been considered in the local and overall item

design? (reference documents: piping mechanical load values)

12 Do all ladders/cages, stairways and platforms meet the requirements

of OSHA (or other appropriate governing regulation) and the YERP

structural steel standards?

13 For items in hydrogen service, have proper details, metallurgy, and

weld requirements been specified to prevent hydrogen embrittlement,

entrapment and blistering (reference documents: Materials of

Construction)?

14 Have process fluids been reviewed to determine if the “lethal" or

Page 1 of 3 Date: 05/28/21

YERP DESIGN MANUAL

ENGINEERING VERIFICATION CHECKLIST

"Class M" requirements of ASME or ANSI apply?

Comments:

This section is only to be completed during Quality Assessments

Accepted

Rejected Completed by: Date:

(clarify above) (YERP PMT Quality Representative)

Page 2 of 3 Date: 05/28/21

YERP DESIGN MANUAL

ENGINEERING VERIFICATION CHECKLIST

ASME Section VIII, Division 2 Checklist

Part: Check: Code Par. Comments

Lengths 4.3.12.2.(f) See also Nomenclature

Cones Check both sides of seam

Nozzle to Seam Spacing 4.3.12.2.(f)

including shell side.

Trunnion Welding to Shell 4.2.5.6 Trunnion second choice

Lug Pad Thickness (required) 4.2.5.6 Lifting lug is last choice

Continuous AD-900(c)(1) Required always

Welds Required close to

Penetration Welding AD-911; AD-912

discontinuities

Hydrotest Stress 8.2

Spacing 4.5.13, Fig. 4.5.11

Spacing of Small Nozzles 4.5.13, Fig. 4.5.11

Nozzles

Standard Lenape will not

Forging Details Part 4 & Part 5

work

4.15.4, Fig. 4.2.4

Skirts Attachment 4.15.7, Fig 4.15.8

Includes all clips, etc. And

Attachments Welding to Shell 4.2.5.6, Fig 4.2.2 & Fig 4.2.3

clear discontinuities

2.2.2 (f)

Pads Fatigue 4.1.1.4 Do not use pads if possible.

5.5.2.

Fig. 4.2.2, Fig. 4.2.3

Std. Dwgs. Welding & Details Fig. 4.2.4, Fig 4.15.7

Fig. 4.15.8

Page 3 of 3 Date: 05/28/21

You might also like

- Fh601d Fh641d Fh680d Fh721d Kawasaki Service Repair Manual 99924206002Document114 pagesFh601d Fh641d Fh680d Fh721d Kawasaki Service Repair Manual 99924206002ljimun100% (1)

- Electrical Wiring SimplifiedDocument118 pagesElectrical Wiring Simplifiedplayontime100% (4)

- Principles of Mine Haul Road Design and Construction v5 Sep 2015 RJTs.28192929Document156 pagesPrinciples of Mine Haul Road Design and Construction v5 Sep 2015 RJTs.28192929Marc Flu100% (1)

- Exercise Questions For Section VIII Div.Document13 pagesExercise Questions For Section VIII Div.Karthikeyan Nadarajan100% (1)

- API 510 - Pressure Vessel (Exam Review and Preparation)Document4 pagesAPI 510 - Pressure Vessel (Exam Review and Preparation)solrac4371No ratings yet

- Tanks - Addition of Shell Nozzles by Hot TappingDocument2 pagesTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzNo ratings yet

- Gap Analysis in Healthcare TemplateDocument2 pagesGap Analysis in Healthcare TemplateZeshanNo ratings yet

- Sil Manual PDFDocument44 pagesSil Manual PDFDerbel WalidNo ratings yet

- Sample of Weld Map (Shop DWG)Document1 pageSample of Weld Map (Shop DWG)Septian Firdaus100% (2)

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87No ratings yet

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaNo ratings yet

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- 510 CalshDocument2 pages510 CalshMurugananthamParamasivamNo ratings yet

- Inspection DishendDocument5 pagesInspection DishendVarun MalhotraNo ratings yet

- Storage Tank Weld JointsDocument16 pagesStorage Tank Weld JointsDilip Varadharajan100% (1)

- Welding Questionarie & Ans.Document6 pagesWelding Questionarie & Ans.Deepak DineshNo ratings yet

- 19 - Weld Fit Up Inspection Employee TrainingDocument10 pages19 - Weld Fit Up Inspection Employee TrainingManoj KumarNo ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- ASME CODE Section VIII Div 1 Vs Div 2 Design FactorDocument7 pagesASME CODE Section VIII Div 1 Vs Div 2 Design FactorsarvannnNo ratings yet

- API Tank Estimate SheetDocument3 pagesAPI Tank Estimate SheetKjunwolf100% (1)

- API 650 12th Edition 2013 - NDT RequirementDocument1 pageAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Telltale HoleDocument3 pagesTelltale HoleAMALENDU PAULNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- Pressure Vessel Design CheckDocument2 pagesPressure Vessel Design CheckAnonymous ByTIbr100% (1)

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Hydro Test Loop File Index FormatDocument22 pagesHydro Test Loop File Index FormatHema NandhNo ratings yet

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocument6 pagesAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- API Repair ProcedureDocument1 pageAPI Repair ProcedurejacquesmayolNo ratings yet

- Interview Ques & Ans - KNPCDocument8 pagesInterview Ques & Ans - KNPCStephen RajNo ratings yet

- Fabrication and Inspection of PV and Columns PPMAIDocument47 pagesFabrication and Inspection of PV and Columns PPMAIguruj3057640% (1)

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Procedure Fabrikasi TankiDocument10 pagesProcedure Fabrikasi TankiMuhammad Yunus NurdinNo ratings yet

- Devlopment of SurfacesDocument17 pagesDevlopment of SurfacesBalajee Mech100% (5)

- Pipe Fitting Weight ChartDocument1 pagePipe Fitting Weight Chartab5918590No ratings yet

- Final Exam (Closed Book) : Answer SheetDocument13 pagesFinal Exam (Closed Book) : Answer SheetDAMIAN ALEJANDRO100% (1)

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- Pneumatic Test Procedure For SeagullDocument4 pagesPneumatic Test Procedure For SeagullDarkvaderNo ratings yet

- API - 650 Check List Tank InspectionDocument5 pagesAPI - 650 Check List Tank InspectionMijanur RahmanNo ratings yet

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- Tube To Tubesheet Weld Joint Design & Welding Qualifications MicroDocument21 pagesTube To Tubesheet Weld Joint Design & Welding Qualifications MicroSiva baalanNo ratings yet

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument76 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsgopidhanNo ratings yet

- API 650 PoıntsDocument4 pagesAPI 650 PoıntsSamet BelliNo ratings yet

- ITP Pressure VesselDocument2 pagesITP Pressure Vesselnafismuhammad1007No ratings yet

- General Specification For Welding and Weld Inspection EIL PDFDocument19 pagesGeneral Specification For Welding and Weld Inspection EIL PDFValesh MonisNo ratings yet

- Tubes Expansion ProcedureDocument3 pagesTubes Expansion Procedurefizanlamin100% (1)

- Storage Tank (API 650) - Home Welding & InspectionDocument34 pagesStorage Tank (API 650) - Home Welding & InspectionHussain AliNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- Welding Inspector Interview ReviewDocument5 pagesWelding Inspector Interview ReviewLuttpiNo ratings yet

- Volume-2 Api510 ExamDocument119 pagesVolume-2 Api510 ExamMohammad Danish100% (2)

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak0% (1)

- Codes StandardsDocument61 pagesCodes Standardshrk100No ratings yet

- Inspection and Test Plan For Pressure Vessel Repair, Modification, AlterationDocument5 pagesInspection and Test Plan For Pressure Vessel Repair, Modification, AlterationMuhammed Abo-Fandood50% (2)

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- Tank GADocument1 pageTank GASubramanian100% (1)

- GTS, PTS & Technical Data Sheet of Pakaldul H.E.projectDocument121 pagesGTS, PTS & Technical Data Sheet of Pakaldul H.E.projectSujeet Kumar50% (2)

- Steel Frame Design Manual: Italian NTC 2008Document96 pagesSteel Frame Design Manual: Italian NTC 2008Haytham ZaghloulNo ratings yet

- Yard Readiness Verification Check List BP2-YRV-002.Document5 pagesYard Readiness Verification Check List BP2-YRV-002.DHANEESH VELLILAPULLINo ratings yet

- ADA402914Document66 pagesADA402914PhalgunaNo ratings yet

- Department of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionDocument14 pagesDepartment of Defense Standard Practice Chromium Plating, Low Embrittlement, Electro-DepositionAbed samadsureyft7vewyrNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- HSE TerminologyDocument6 pagesHSE TerminologyZeshanNo ratings yet

- Failure of Secondary Reformer RefractoryDocument27 pagesFailure of Secondary Reformer RefractoryZeshanNo ratings yet

- Free Intro Template by PowerPoint SchoolDocument2 pagesFree Intro Template by PowerPoint SchoolZeshanNo ratings yet

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- General Weld Inspection - RT Requirement For NP Const.Document2 pagesGeneral Weld Inspection - RT Requirement For NP Const.ZeshanNo ratings yet

- Rubber Mateiral Chemical Resitivity ChartDocument18 pagesRubber Mateiral Chemical Resitivity ChartZeshanNo ratings yet

- Process Safety Management of Highly Hazardous Chemicals: Nancy J BetheaDocument55 pagesProcess Safety Management of Highly Hazardous Chemicals: Nancy J BetheaZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Market Gap Analysis TemplateDocument2 pagesMarket Gap Analysis TemplateZeshanNo ratings yet

- Gas Piping Best Practices Chris WolfeDocument11 pagesGas Piping Best Practices Chris WolfeZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument2 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Holdsworth Funnels REH 92 Sample PDFDocument6 pagesHoldsworth Funnels REH 92 Sample PDFMarcos RamirezNo ratings yet

- Plastic Waste On A Bituminous PavementDocument2 pagesPlastic Waste On A Bituminous PavementJess AguigamNo ratings yet

- Compact Integrated Power SteeringDocument21 pagesCompact Integrated Power SteeringTihomir MarkovicNo ratings yet

- Is 8406 1993 PDFDocument12 pagesIs 8406 1993 PDFSiddharth GuptaNo ratings yet

- Understanding Sarbanes OxleyDocument11 pagesUnderstanding Sarbanes OxleyrangoonroudyNo ratings yet

- SM 9 The - Guide - Case - Studies PDFDocument130 pagesSM 9 The - Guide - Case - Studies PDFJuan AlayoNo ratings yet

- Booklet On New Line OpeningDocument136 pagesBooklet On New Line OpeningRVNLPKG6B VBL-GTLMNo ratings yet

- P141 OrderForm - v32 - 082019Document11 pagesP141 OrderForm - v32 - 082019Kuenley TiNy OndeNo ratings yet

- Ericsson CommandsDocument8 pagesEricsson Commandsmahado100% (1)

- 5G The Microwave Perspective PDFDocument4 pages5G The Microwave Perspective PDFMuhammad JamilNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- SP231A/232A/233A/310A/312A Enhanced RS-232 Line Drivers/ReceiversDocument8 pagesSP231A/232A/233A/310A/312A Enhanced RS-232 Line Drivers/ReceiversAlejandra MariñoNo ratings yet

- Iecex Certificate of ConformityDocument7 pagesIecex Certificate of ConformityycjpaulNo ratings yet

- IMS VulnerabilitiesDocument9 pagesIMS Vulnerabilitiesprog_man_0101No ratings yet

- Upright and Pendent Intermediate Level SprinklerDocument6 pagesUpright and Pendent Intermediate Level SprinklerAhrian BenaNo ratings yet

- Avaya CDR FormatDocument5 pagesAvaya CDR FormatkhatriasifNo ratings yet

- Emi-Ucp4 6Document105 pagesEmi-Ucp4 6Fazrul IzwanNo ratings yet

- Printrinix S809Document4 pagesPrintrinix S809vinod yadavNo ratings yet

- LTE Technical Paper. VoLTE Feature Parameter DescriptionDocument13 pagesLTE Technical Paper. VoLTE Feature Parameter DescriptionZiya2009No ratings yet

- Metal Enclosed Switchgear in Plant Medium VoltageDocument4 pagesMetal Enclosed Switchgear in Plant Medium VoltagejuevesNo ratings yet

- OEL Maintenance Manual: B401/B411L6/B431L6Document184 pagesOEL Maintenance Manual: B401/B411L6/B431L6ALİ RIZA YILDIZNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationdudepapNo ratings yet

- TP-Link TL - WR740N WR741ND PDFDocument9 pagesTP-Link TL - WR740N WR741ND PDFnormalmannNo ratings yet

- Grundfosliterature 5235944 PDFDocument324 pagesGrundfosliterature 5235944 PDFĐạt TrầnNo ratings yet

- Draft Product Vision BoardDocument1 pageDraft Product Vision BoardJohn PatlolNo ratings yet

- 6657 Bom Photo-2011-7-8Document38 pages6657 Bom Photo-2011-7-8Damir SmigalovicNo ratings yet