Professional Documents

Culture Documents

CMT Programm Spd18a-07 - 3

CMT Programm Spd18a-07 - 3

Uploaded by

nabiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMT Programm Spd18a-07 - 3

CMT Programm Spd18a-07 - 3

Uploaded by

nabiCopyright:

Available Formats

Well Cementing Proposal

CUSTOMER: SOUTH PARS PROJECT PHASES17&18

CASING TYPE: 10 3/4"- 9 5/8” Casing

WELL NAME: SPD18A-07

n al

Fi

RIG: COSL FORCE

______________________________________

Proposal Date: 09- August - 2011

Pasdaran St, Ahvaz, Iran

South Pars Project Phases 17 &18 Tel: +98-912-820-5670 Fax: +98-611-4144945

E-Mail:areza_soltanil@Yahoo.com

Subject: Proposal for the cementing of 10 3/4"- 9 5/8" Casing for the

SPD18A-07

Dear Sirs,

In response to your request, we are proposing a plan for the cementing of

10 3/4"-9 5/8" Casing for the SPD18A-07 the volumes include an excess

volume of 30% for lead slurry and 30 % for the tail slurry. It is planned to

pump 576 bbl of lead slurry at 12.5 ppg, 115 bbl of tail slurry at 15.8 ppg

and displacement with the Sea Water.

We hope that the information presented here will meet your approval. If you

wish to discuss this proposal further, please feel free to call us.

Sincerely,

al

A.Reza.Soltani

Head of Cementing Programming Engineering Dep.

NIDC

n

Fi

Pasdaran St, Ahvaz, Iran

South Pars Project Phases 17 &18 Tel: +98-912-820-5670 Fax: +98-611-4144945

E-Mail:areza_soltanil@Yahoo.com

Static well security

n al

3,500

Fi

Note : lead slurry 12.5 PPG , Tail slurry at 15.8 PPG , Spacer slurry at 12 PPG

Pasdaran St, Ahvaz, Iran

South Pars Project Phases 17 &18 Tel: +98-912-820-5670 Fax: +98-611-4144945 E-Mail:areza_soltanil@Yahoo.com

Cementing Procedure:

Top Plug and Bottom Plug Method

While running in hole 10 3/4″- 9 5/8″ casing:

1- Clean up tanks and prepare chemicals for mixing fluid.

2- Fill tanks with mixing water for mixing fluids (Lead & Tail).

3- 5 hours before reaching casing shoe start mixing Lead & Tail cement

additives.

4- After casing running, make up Cement Head and load Bottom plug,

connect cement line.

5- Perform a Pre-Job safety Meeting with all personnel involved on the

operation as well as the client representative.

6- Ensure communication between DOS Cementer and Rig floor.

7- Test cements line W/ 4000 psi.

8- Mix and Pump 50 BBLS Spacer@ 12 PPG

9- Drop bottom plug and install top plug in the cement head.

10- Mix and pump 576 BBLS lead cement slurry @ 12.5 PPG.

11- Mix and pump 115 BBLS tail cement slurry @ 15.8 PPG.

12- Release top plug.

al

13- Pump 10 BBLS Drill water behind the plug.

14- Switch to mud pump and start displacement with the Sea water.

15- Bump the plug, bleed off pressure and check for float shoe.

n

Important Notes and Considerations:

Fi

1- Slurry Volume has been calculated based on 30 % Excess on open hole

annular volume on Tail Slurry.

2- Slurry Volume has been calculated based on 30 % Excess on open hole

annular volume on Lead Slurry.

3- Dead volume rate is not considered in calculation.

Pasdaran St, Ahvaz, Iran

South Pars Project Phases 17 &18 Tel: +98-912-820-5670 Fax: +98-611-4144945

E-Mail:areza_soltanil@Yahoo.com

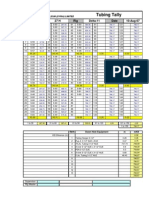

Rig: Cosl Force

Well:SPD 18-07

Dana Oil Services 9 5/8" CEMENT JOB. Date: August 2011

Cement&Mixing Water for Lead Slurry:

Cement Type: UCC"G"

Mix Water Source: Drill water

T.O.Lead@ 0 m 0 FT Slurry Density: 12.5 PPG 1.5 kg/L

Slurry Yield: 2.13 cuft/sk

Mixing Water Required: 11.92 gal/sk

Total Mixing Fluid Required: 12.35 gal/sk

Lead Cement Additives:

Bentonite 2.50% bwoc(PH) 4203.6 LB

FLC-DA 9 0.70% bwoc(PH) 1177.0 LB

300 m 984.3 CFR-DA 3 0.05% bwoc(PH) 84.1 LB

10 3/4"Csg55lb/ft@ CR-DA 4 0.15% bwoc(PH) 252.2 LB

Microblock 0.25 gal/sk 447.2 GAL

DF-DA 3 0.012 gal/sk 21.5 GAL

Volumes:Lead cuft/ft cuft m3 bbls Depth

Open hole& 9 5/8" 0.3132 1202.82 34.06 214.2 3840.4 FT

Excess: 30% 360.845 10.22 64.27

9 5/8"&13 3/8"Csg: 0.3354 1459.74 41.34 260 4352.2 FT

10 3/4"&13 3/8"Csg: 0.2105 207.195 5.867 36.9 984.3 FT

Excess: 0% 0 0 0

Total Volume : 3230.6 91.48 575.4 575.4 BBLS

bbls cuft m3

Dead Vol. 80.0 449.2 12.7

Sacks of lead Cement:

1516.7 Sacks 142571 Lbs 64.8 MT

13 3/8"Shoe@ 1626.5 m 5336.5 FT 1788.8 Sacks(total) 168145 Lbs 76.4 MT

Water Requirement: Mixing Fluid

430.5 Barrels 446.0 Barrels

al

507.7 bbls(total) 526.0 BBL(total)

9 5/8"csg 47 lb/ft

Cement&Mixing Water for Tail Slurry:

Cement Type: UCC"G"

n

Mix Water Source: Drill Water

Slurry Density: 15.8 PPG 1.9 kg/L

Slurry Yield: 1.15

Fi

12 1/4"Open hole 40%Ex cuft/sk

Mixing Water Required: 4.6 gal/sk

Total Mixing Fluid Required: 5.0 gal/sk

Tail Cement Additives:

Paragas 0.40 gal/sk 493.3 Gal

CFR-DA 3 0.30% bwoc(PH) 347.8 LB

T.O.T CMT@ 2797 m 9177 FT CR-DA 4 0.30% bwoc(PH) 347.8 LB

DF-DA 3 0.01 gal/sk 12.3 GAL

Volumes:Tail cuft/ft cuft m3 bbls Depth

Open hole& 9 5/8": 0.3132 462.4 13.1 82.4 1476.5 FT

12 1/4'' Cap 0.8185 8.1 0.2 1.4 9.8

Excess: 30% 141.1 4.0 25.1

9 5/8"Cap.: 0.411 33.7 1.0 6.0 82.0 FT

Float Collar@ 3222 m 10571 ft Total Volume : 645.3 18.3 114.9 114.9 BBLS

bbls cuft m3

Dead Vol: 80 449.2 12.72

Sacks of Tail Cement:

561.2 Sacks 52749 Lbs 23.9 MT

1233.2 Sacks(total) 115917 Lbs 52.6 MT

Float Shoe@ 3247 m 10653 ft Water Requirement: Mixing Fluid

61.5 Barrels 66.8 Barrels

T.D@ 3250 m 10663 ft 135.1 bbls(total) 146.8 BBL(total)

Total Cement&Chemicals Required:

Cement 195320.4 LBS 88.6 MT

Bentonite 4203.6 LBS 42.0 Sacks

10 3/4" 984.3 0.082 FLC-DA 9 1177.0 LBS 21.4 Sacks

9 5/8" 9587.1 0.073 CR-DA 4 600.0 LBS 10.9 Sacks

CFR-DA 3 431.8 LBS 8.6 Sacks

Displ 780.6 bbl DF-DA 3 33.8 GAL 6.8 Cans

Paragas 493.3 GAL 16.4 drums

Microblock 447.2 GAL 8.1 drums

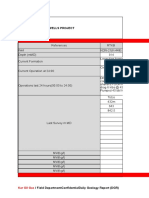

Dana Oil Services

Cement Test Report

Project No: SPP 17,18 Well: SPD 18-07 Date: August 2011

Company: NIDC Field: SOUTH PARS(17&18)

Well Depth: (MD): 3250 m 10663 ft Job Type : Casing

Job Purpose: Spacer 500E for 9 5/8'' Casing Rig: Cosl Force

Cementing Additives Conc. Cement and Mixing Water

Additive # 1 Drill water 35.4 gal/bbl

Additive # 2 E-DA 500 9.5 lb./bbl Mix Water Source: Drill water

Additive # 3 Barite 196 lb./bbl Spacer Density: (12 PPG) 1.44 Kg/L

Additive # 4 Musol 0.5 gal/bbl

Additive # 5 PA -DA 5 0.2 gal/bbl

Temperature BHST: 121 oC BHCT: 66.7 oC

Temperature BHST: 251 oF BHCT: 152 oF Temperature Gradient: 1.6 oF / 100 ft

API Schedule: Heat up time: min Final Pressure : kPa

API Free Fluid: cc % Free Fluid @ 45o: cc %

o

API Fluid Loss: cc/30 min @ F and 1000 Psi

al

o

Consistency @ : 0 5 20 min @: F

Bc:

n

Rheology Data Gel

Temp. Fan Readings ( RPM) lbs/100ft2 n' K' PV YP

Fi

o n' 2

F 600 300 200 100 6 3 10 sec 10 min lb-sec /ft CP lbs/100ft2

80 36 24 19 14 6 5 0.4992 0.0097 15 9

Pump Time (Bc): Hrs:min Thickening Time (Bc): Hrs:min

Compressive Strength:

H2O Analysis: Chlorides: mg/liter:

PH = Prehydrated DB = Dry Blended % bwoc = % by weight of cement % bwow = % by weight of water

Note:

Remarks:

DOS Cementing & Lab Engineers: Esmaeel Asgharnia,Babak Valiollahi

Notice: The above test report is a preliminary report and is for information and reference only and the content is

limited to the sample described. Dana Oil Services will not be liable for any loss or damage, regardless of

cause, including any act or omission of Dana Oil Services, resulting from the use thereof.

Dana Oil Services

9 5/8"CEMENT JOB.

Chemical Description:

1) FLC-DA 9=Fluid Loss Controller

2) CFR-DA 3=Friction Reducer

3)CR-DA 4 =Cement Retarder

4) DF-DA 3 =Defoamer

5) Microblock =Extender

6) Paragas = Gas Migration

Mixing Procedure For Lead Slurry:

To be Prehydrated in Mixing Water in Mud Pit

1) Mixing Water : Drill Water=507.7 bbls

2) Bentonite= 4203.6 Ibs

3) FLC-DA 9=Fluid Loss Controller= 1177 Ibs

4) Microblock =Extender= 447.2 Gal

5) CFR-DA 3=Friction Reducer= 84.1 Ibs

6) CR-DA 4 = Cement Retarder= 252.2 Ibs

7) DF-DA 3 =Defoamer= 21.5 Gal

To be Mixed on Cement Unit

8) Dry Cement= 64.8 MT

Mixing Procedure For Tail Slurry:

To be Prehydrated in Mixing Water in Mud Pit

1) Mixing Water : Fresh Water=135.1 bbls

al

2) Paragas = Gas Migration= 493.3 Gal

3) CFR-DA 3=Friction Reducer= 347.8 Ibs

4) CR-DA 4 = Cement Retarder= 347.8 Ibs

5) DF-DA 3 =Defoamer= 12.3 Gal

n

To be Mixed on Cement Unit

Fi

6) Dry Cement= 23.9 MT

Dana Oil Services

Cement Test Report

Project No: SPP 17,18 Well: SPD 18-07 Date: August 2011

Company: NIDC Field: SOUTH PARS(17&18)

Well Depth: (MD): 3250 m 10663 ft Job Type : Casing

Job Purpose: 10 3/4"- 9 5/8"Casing Lead Rig: Cosl Force

Cementing Additives Conc. Units Cement and Mixing Water

Bentonite 2.5 % bwoc (DB)

PH) Cement Type: UCC''G''

FLC-DA 9 0.75 %bwoc (PH) Mix Water Source: Drill Water

Microblock 0.25 gal/sk Slurry Density: (12.5 PPG) 1.5 kg/L

CFR-DA 3 0.05 % bwoc (DB)

PH) Slurry Yield: 2.13 cuft/sk

CR-DA 4 0.15 % bwoc (DB)

PH) Mixing Water Required: 11.92 gal/sk

DF-DA 3 0.02 gal/sk

Total Mixing Fluid Required: 12.35 gal/sk

Temperature BHST: 124 oC BHCT: 68.9 oC

Temperature BHST: 256 oF BHCT: 156 oF Temperature Gradient: 1.6 oF / 100 ft

API Schedule: Heat up time: min Final Pressure : kPa

al

API Free Fluid: cc 1.0 % Free Fluid @ 45o : cc %

o

API Fluid Loss: cc/30 min @ 152 F and 1000 Psi

n

o

Consistency @ : 0 5 20 min @: F

Fi

Bc:

Rheology Data Gel

Temp. Fan Readings ( RPM) lbs/100ft2 n' K' PV YP

o n' 2

F 600 300 200 100 6 3 10 sec 10 min lb-sec /ft CP lbs/100ft2

80 39 19 15 9 5 3 0.6863 0.0029 15 5

Pumping time 50(BC): Hrs:Min 70(BC): 6:52 Hrs:Min 100(BC): Hrs:Min

o

Compressive Strength: 700 Psi in 24 Hrs @ 256 F and 1000 psi

Water Analysis: Chlorides: mg/liter

PH: Prehydrated DB: Dry Blended % bwoc: % by weight of cement % bwow: % by weight of water

Note: Calc based on 94 lbs sack of dry cement.

Remarks: Water Sample received from Rig:Cosl Force @ July-2011

DOS Cementing & Lab Engineers: Esmaeel Asgharnia,Babak Valiollahi

Notice: The above test report is a preliminary report and is for information and reference only and the content is

limited to the sample described. Dana Oil Services will not be liable for any loss or damage, regardless of

cause, including any act or omission of Dana Oil Services, resulting from the use thereof.

Dana Oil Services

Cement Test Report

Project No: SPP 17,18 Well: SPD 18-07 Date: August 2010

Company: NIDC Field: SOUTH PARS(17&18)

Well Depth: (MD): 3250 m 10663 ft Job Type : Casing

Job Purpose: 10 3/4" - 9 5/8"casing Tail Rig: Cosl Force

Cementing Additives Conc. Units Cement and Mixing Water

Paragas 0.4 gal/sk Cement Type: UCC''G''

CFR -DA 3 0.3 % bwoc (PH) Mix Water Source: Drill Water

CR-DA 4 0.3 % bwoc (PH) Slurry Density: (15.8 PPG) 1.9 kg/L

DF -DA 3 0.01 gal/sk Slurry Yield: ( 0.764 Lit/kg) 1.15 cuft/sk

Mixing Water Required: 4.6 gal/sk

Total Mixing Fluid Required: 5.0 gal/sk

Temperature BHST: 105 oC BHCT: 68.9 oC

Temperature BHST: 221 oF BHCT: 156 oF Temperature Gradient: 1.6 oF / 100 ft

API Schedule: Heat up time: min Final Pressure : kPa

API Free Fluid: cc 0% Free Fluid @ 45o : cc %

al

o

API Fluid Loss: cc/30 min @ F and 1000 Psi

o

n

Consistency @ : 0 5 20 min @: F

Bc:

Fi

Rheology Data Gel

Temp. Fan Readings ( RPM) lbs/100ft2 n' K' PV YP

o n' 2

F 600 300 200 100 6 3 10 sec 10 min lb-sec /ft CP lbs/100ft2

80 195 109 76 42 4 3 0.8667 0.0052 100 9

2 1

Pumping time 50(BC): Hrs:Min 70(BC): 4:25 Hrs:Min 100(BC): Hrs:Min

o

Compressive Strength: 1500 Psi in 8 Hrs @ 221 F and 1000 psi

o

3100 Psi in 12 Hrs @ 221 F and 1000 psi

o

4800 Psi in 24 Hrs @ 221 F and 1000 psi

Water Analysis: Chlorides: mg/liter

PH: Prehydrated DB: Dry Blended % bwoc: % by weight of cement % bwow: % by weight of water

Note: Calc based on 94 lbs sack of dry cement.

Remarks: Water Sample received from Rig:Cosl Force @ July-2011

DOS Cementing & Lab Engineers: Esmaeel Asgharnia,Babak Valiollahi

Notice: The above test report is a preliminary report and is for information and reference only and the content is

limited to the sample described. Dana Oil Services will not be liable for any loss or damage, regardless of

cause, including any act or omission of Dana Oil Services, resulting from the use thereof.

You might also like

- Group 80 - CONFIGURATION DIAGRAMS - Mitsubishi Outlander III - Wiring DiagramsDocument16 pagesGroup 80 - CONFIGURATION DIAGRAMS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- Wellhead - Manual S2100559Document47 pagesWellhead - Manual S2100559Parag PadoleNo ratings yet

- Haber-Bosch WorksheetDocument3 pagesHaber-Bosch Worksheetapi-283989564No ratings yet

- Cementing Program For The 13 38 Inch CasingDocument40 pagesCementing Program For The 13 38 Inch CasingMarvin OmañaNo ratings yet

- NLOG GS PUB 1387 Cementing EOWRDocument61 pagesNLOG GS PUB 1387 Cementing EOWRWilson WanNo ratings yet

- Casing ModuleDocument12 pagesCasing ModuleFarahKhanJamaliNo ratings yet

- Tech Drilling Cementing CalculationsDocument0 pagesTech Drilling Cementing Calculationsadvantage025No ratings yet

- Wl&fe Unit-4Document40 pagesWl&fe Unit-4Paul AjithNo ratings yet

- Fishing Operations Checklist Basic StepsDocument1 pageFishing Operations Checklist Basic StepsaungwinnaingNo ratings yet

- Petroleum Production Technology Tutorial.4 Packer and Tubing Load CalculationDocument3 pagesPetroleum Production Technology Tutorial.4 Packer and Tubing Load CalculationGrant HosieNo ratings yet

- Santos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3Document13 pagesSantos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3TonyNo ratings yet

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- Herunefer W 13Document3 pagesHerunefer W 13Islam AtifNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- 9.625 Inter-Prod 53.5 PPFDocument17 pages9.625 Inter-Prod 53.5 PPFAnonymous XbmoAFtINo ratings yet

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiNo ratings yet

- Appendix-25 Sole-2 Wireline ReportDocument8 pagesAppendix-25 Sole-2 Wireline ReportAustinNo ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Well Kick Data: Sheet No. 2Document2 pagesWell Kick Data: Sheet No. 2Raul Dolo QuinonesNo ratings yet

- 05 Trip Sheet - IPM - QuartzDocument7 pages05 Trip Sheet - IPM - QuartzRebarNo ratings yet

- Well DataDocument5 pagesWell Datamohamed elshemyNo ratings yet

- Pump Fit/Lot Weight Up Equivalent Circulating DensityDocument100 pagesPump Fit/Lot Weight Up Equivalent Circulating DensityGustavo Javier FloresNo ratings yet

- Da13 DDR N1 13991116 143 0Document3 pagesDa13 DDR N1 13991116 143 0Hamed NazariNo ratings yet

- Pre Recorded Imformation: Davis Family 1-42Document10 pagesPre Recorded Imformation: Davis Family 1-42scrbdgharaviNo ratings yet

- Inflow Test Negative Test 1717362618Document7 pagesInflow Test Negative Test 1717362618saif khudhairNo ratings yet

- GAME PLAN RTTS RBP Wellhead WorkDocument1 pageGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNo ratings yet

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiNo ratings yet

- Kadanwari Well Integrity Test ProgramDocument28 pagesKadanwari Well Integrity Test ProgramsalmanNo ratings yet

- Efficient Process Restores Flow To Sand - and Liquid-Loaded Well in Ameland Island - BJ Techline MagazineDocument28 pagesEfficient Process Restores Flow To Sand - and Liquid-Loaded Well in Ameland Island - BJ Techline MagazineManuel S. NavarroNo ratings yet

- 2008 Workover and Completion Practice TestDocument14 pages2008 Workover and Completion Practice TestWaOne PrabowoNo ratings yet

- TCP-DST-01 String Diagram Rajian-07 PDFDocument1 pageTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNo ratings yet

- Pipe Body Performance PropertiesDocument118 pagesPipe Body Performance Propertieshamid nobakhtNo ratings yet

- Analysis of An Annular Pressure Buildup Failure During Drill AheadDocument6 pagesAnalysis of An Annular Pressure Buildup Failure During Drill AheadJulian OlarteNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Casing Cutting Procedure - WFDDocument5 pagesCasing Cutting Procedure - WFDprateek132106No ratings yet

- 4c - Primary Cementing ChecklistDocument2 pages4c - Primary Cementing ChecklistSiti Maisarah Riana PutriNo ratings yet

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74100% (1)

- Tubing Tally: Delta-11 Well 27 H Rig Date 10-Aug-07Document1 pageTubing Tally: Delta-11 Well 27 H Rig Date 10-Aug-07Saer OklaNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- Spe62752 Viscous Pill InfoDocument1 pageSpe62752 Viscous Pill InfoAkkassin AbdullayevNo ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Manifold ValvesDocument3 pagesManifold ValvesberrouiNo ratings yet

- Liner Cementing GuidelinesDocument2 pagesLiner Cementing GuidelineszapspazNo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- Torque and Drag Mini-Series Episode 6 of 8Document35 pagesTorque and Drag Mini-Series Episode 6 of 8Gilbert OmittaNo ratings yet

- KARAM-10 Perforation ProgramDocument7 pagesKARAM-10 Perforation ProgramAhmed AliNo ratings yet

- Running Procedure 5Document2 pagesRunning Procedure 5Pesireron RoberthNo ratings yet

- Da13 DDR N1 13991115 142 0Document3 pagesDa13 DDR N1 13991115 142 0Hamed NazariNo ratings yet

- Dilution: 3 ExperimentDocument10 pagesDilution: 3 ExperimenthamaNo ratings yet

- Da13 DDR N1 13991122 149 0Document3 pagesDa13 DDR N1 13991122 149 0Hamed NazariNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Kick Tolerance2Document4 pagesKick Tolerance2fisco4rilNo ratings yet

- PillsDocument4 pagesPillsbestman82No ratings yet

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- Reverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesDocument5 pagesReverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesRMolina65No ratings yet

- SD-24P Bit Record 2Document1 pageSD-24P Bit Record 2Them Bui XuanNo ratings yet

- Pickering 1-18 Intermediate: Inner CSNGDocument1 pagePickering 1-18 Intermediate: Inner CSNGscrbdgharaviNo ratings yet

- 450 Final SolutionsDocument14 pages450 Final SolutionsWilliam Williams100% (2)

- Chapter 4-CDocument15 pagesChapter 4-CMahrouz MadoNo ratings yet

- Annexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFDocument7 pagesAnnexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFMehdi NorouziNo ratings yet

- Practices Manual Running Conductor CasingDocument2 pagesPractices Manual Running Conductor Casingciucalata88No ratings yet

- BUCS-144W Drilling Instruction For 16in Hole&13.375in CSGDocument2 pagesBUCS-144W Drilling Instruction For 16in Hole&13.375in CSGnabiNo ratings yet

- 20in Casing TallyDocument1 page20in Casing TallynabiNo ratings yet

- SPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationDocument6 pagesSPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationnabiNo ratings yet

- 19-MPD As Well controlGOM-doneDocument6 pages19-MPD As Well controlGOM-donenabiNo ratings yet

- Drilling Instruction For 26in Hole&20in CSGDocument2 pagesDrilling Instruction For 26in Hole&20in CSGnabiNo ratings yet

- SPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WayDocument10 pagesSPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WaynabiNo ratings yet

- Journal Pre-Proof: Process Safety and Environmental ProtectionDocument32 pagesJournal Pre-Proof: Process Safety and Environmental ProtectionnabiNo ratings yet

- IPTC-21407-MS Handling High-Intensity Brine Influxes Using Flow-While-Drilling FWD Techniques in A Salt Formation in Chinarevskoye FieldDocument15 pagesIPTC-21407-MS Handling High-Intensity Brine Influxes Using Flow-While-Drilling FWD Techniques in A Salt Formation in Chinarevskoye FieldnabiNo ratings yet

- Ocean Engineering: A B A A B A B A B A BDocument5 pagesOcean Engineering: A B A A B A B A B A BnabiNo ratings yet

- Managed Pressure Drilling Systems: Guide For Classification and Certification ofDocument37 pagesManaged Pressure Drilling Systems: Guide For Classification and Certification ofnabiNo ratings yet

- Completion ComponentsDocument28 pagesCompletion ComponentsnabiNo ratings yet

- EC-Drill Eliminates Effect of Equivalent Circulating DensityDocument3 pagesEC-Drill Eliminates Effect of Equivalent Circulating DensitynabiNo ratings yet

- 9 5-8'' - CMT Programme SPD18A-07 (12.5 PPG)Document1 page9 5-8'' - CMT Programme SPD18A-07 (12.5 PPG)nabiNo ratings yet

- 13.375 CSG tALLY - DL-15Document3 pages13.375 CSG tALLY - DL-15nabiNo ratings yet

- Completion Design and EngineeringDocument92 pagesCompletion Design and EngineeringnabiNo ratings yet

- PIPE Tally Sheet 7'' Liner kB2Document10 pagesPIPE Tally Sheet 7'' Liner kB2nabiNo ratings yet

- 1 - Classification of CasingDocument68 pages1 - Classification of CasingnabiNo ratings yet

- Terminology and FormlaeDocument7 pagesTerminology and FormlaenabiNo ratings yet

- Comp Tally W.P#14Document3 pagesComp Tally W.P#14nabiNo ratings yet

- Wob RPM GPM PDFDocument1 pageWob RPM GPM PDFnabiNo ratings yet

- Chapter 17 Absorption Refrigeration ExercisesDocument2 pagesChapter 17 Absorption Refrigeration ExercisesAndrew PantaleonNo ratings yet

- Experiment (7) : Flow Under Sluice GateDocument4 pagesExperiment (7) : Flow Under Sluice GateBatool Al-kharabshehNo ratings yet

- Mosd 10page PDFDocument15 pagesMosd 10page PDFOriginalo Versiona100% (3)

- CHE 217 Lab 4Document10 pagesCHE 217 Lab 4igor_silva02No ratings yet

- History of CalendarDocument2 pagesHistory of CalendarMuhammad Muhammad AliNo ratings yet

- Journal of Management Science & Engineering Research - Vol.5, Iss.1 March 2022Document80 pagesJournal of Management Science & Engineering Research - Vol.5, Iss.1 March 2022Bilingual PublishingNo ratings yet

- Athena Users1 PDFDocument436 pagesAthena Users1 PDFAnonymous eWMnRr70qNo ratings yet

- Oteco Inc. 3" Reset Relief Valve 3 1/16"-10,000 PSI FLANGE INLET & OUTLET Installation & Maintenance Manual PART NO. 130384Document12 pagesOteco Inc. 3" Reset Relief Valve 3 1/16"-10,000 PSI FLANGE INLET & OUTLET Installation & Maintenance Manual PART NO. 130384VRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- Freshman Mathimatics Unit 1 Part 2Document11 pagesFreshman Mathimatics Unit 1 Part 2future tubeNo ratings yet

- Sleep and Wake UpDocument3 pagesSleep and Wake UpAlekzanfulNo ratings yet

- International Economics 4th Edition Feenstra Test Bank 1Document48 pagesInternational Economics 4th Edition Feenstra Test Bank 1steven100% (42)

- TransformationDocument10 pagesTransformationzex007No ratings yet

- A Survey On Nongeostationary Satellite Systems The Communication PerspectiveDocument32 pagesA Survey On Nongeostationary Satellite Systems The Communication PerspectiveSwattic GhoseNo ratings yet

- 1st Formative Test in PPGDocument1 page1st Formative Test in PPGJacinth HeridaNo ratings yet

- Article: ZootaxaDocument14 pagesArticle: ZootaxaSabrina Nur Fitri 2004125073No ratings yet

- Ancon 25-14 Restraint SystemDocument2 pagesAncon 25-14 Restraint SystemabudabeejajaNo ratings yet

- Wolves of Isle Royale Case StudyDocument3 pagesWolves of Isle Royale Case Study66dancelNo ratings yet

- Numerical Descriptive Techniques (6 Hours)Document89 pagesNumerical Descriptive Techniques (6 Hours)Kato AkikoNo ratings yet

- Criminal 2016 XixDocument3 pagesCriminal 2016 XixTenshi FukuiNo ratings yet

- Finals TheoriesDocument25 pagesFinals TheoriesQui Lea ChinNo ratings yet

- Hyper Local Supply ChainDocument3 pagesHyper Local Supply ChainAishwarya MathurNo ratings yet

- ch5 CPU SchedulingDocument72 pagesch5 CPU SchedulingIlham HafizNo ratings yet

- Have Space To Grow: With Password Protection Data SheetDocument2 pagesHave Space To Grow: With Password Protection Data SheetMuhammad Usama SheikhNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- Stand On ZanzibarDocument12 pagesStand On ZanzibarMacmillan Publishers2% (354)

- Micromaster 430Document118 pagesMicromaster 430Alwyn GeorgeNo ratings yet

- Epson E2h Scara RobotsDocument2 pagesEpson E2h Scara RobotsmaciasrobNo ratings yet

- PC-12 NG PowerPoint Presentation - 220523 - 081602Document1,163 pagesPC-12 NG PowerPoint Presentation - 220523 - 081602Manuel CarteNo ratings yet