Professional Documents

Culture Documents

Preview WR

Preview WR

Uploaded by

Shaiju NarayananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preview WR

Preview WR

Uploaded by

Shaiju NarayananCopyright:

Available Formats

WIRE ROPE WR–1

Introduction Definition

The drilling line is a machine. It is an assembly of precision Drilling lines and wire lines are known as and are used inter-

parts, each can move independently, requires lubrication, is changeably with the term “wire rope”. Reference to all three

static until an external force is applied and it transmits energy. of these terms will be prevalent throughout this manual.

The information that follows will guide you in the selection, Wire rope is an intricate network of close tolerance, precision

care and use of drilling lines. Instructions are included for made steel wires, much on the order of a machine, where

attaching wire rope clips, socketing wire rope, seizing wire each part has a job to do. Each part must work in a perfect

rope, etc. relationship with the other part for the rope to properly func-

tion. Proper care and handling is mandatory to receive the

To keep the wire line costs at a minimum, the rig crews and

highest service at the highest level of safety.

all levels of operations management should know how to ob-

tain maximum safe life from the drilling line. The following is

basic to that objective. Nomenclature

Wire rope comprises just three parts—core, strand and wire

A. Select the proper size and type line to meet the

(Figure WR-1).

requirements.

B. Care for the line to prevent damage. Become familiar with each part; it is surprising how many

C. Compute the service obtained from the line in times a “wire” is reported to be a “strand”.

Ton-Miles.

Each of the components are detailed later in this manual.

D. Choose a cut-off program that best suits your

Wire rope is described and identified with numerals and ab-

conditions and follow it carefully. This will greatly

breviations. It is important to understand these terms and

increase the service obtained from the line.

to relate them to the wire rope specified within our industry.

When a new line is received, the reel number, make and

The following is an example description of a rotary drilling

description of the line should be recorded on the daily

line; the identifying terms are translated and explained

drilling report.

individually.

The ton-mile service should be computed daily and a record

5,000 ft × 1 in. 6×19 S-IWRC EIP SZ (RR) PRF

kept so cut-offs can be made after a proper interval of service.

5,000 ft = Length of wire rope, ft

1 in. = Nominal diameter of wire rope, in.

6 = Number of outer strands per wire rope

19 = Number of wires per outer strand

S = Seale outer strand wire pattern

Core

IWRC = Independent wire rope core

Strand

Wire EIP = Extra improved plow steel

SZ (RR) = Right regular lay

PRF = Preformed strands

This translates to a 5,000 ft length of 1 in. diameter, 6-strand

rope with 19 wires in each strand laid in a Seale pattern (S).

The strands of the rope are laid around an Independent Wire

Rope Core. The strength grade of the rope is Extra Improved

Plow Steel (EIP). The strands are laid in a Right Regular Lay

(SZ or RR) pattern and are preformed (PRF) in a helical shape

Rope prior to closing the rope.

Sizes and constructions diameter

Diameter measurements are correct only when made across

the “crowns” of the rope strands so that the true diameter is

the widest diameter of the rope. Always rotate the caliper

on the rope—or rotate the rope inside the caliper to take the

measurement.

Figure WR-1: Anatomy of wire rope, showing core, Always measure the diameter of any rope at its widest

strand and wire, which comprise the rope.

point by turning the caliper on the rope. Measurements for

IADC Drilling Manual Copyright © 2015

WR–2 WIRE ROPE

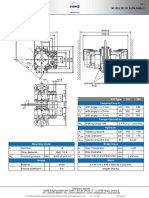

Table WR-2: The number of strands and number of

wires per strand determine a rope's classification.

1 2

Classification Number of Wires per strand

strands

6×7 6 7

6×19 6 16 through 26

Correct 6×36 6 27 through 49

8×19 8 16 through 26

Wire rope differs in the number of strands and the number

1 2

and pattern of wires per strand. Most common wire rope

constructions are grouped into four standard classifications

based on the number of strands and wires per strand, as

shown in Table WR-2.

Within each classification there are specific rope construc-

Incorrect tions. For example, in the 6×19 class, some of the rope con-

structions are 6×25 FW (filler wire), 6×119 S (Seale) and

Figure WR-2: Wire diameter measurement. 6×26 WS (Warrington Seale).

Characteristics, such as fatigue resistance and resistance to

abrasion, are directly affected by the design of strands. As

a general rule, a strand made up of a few large wires will

diameter shall be taken on a straight portion of the rope at be more abrasion-resistant and less fatigue-resistant than

two positions spaced at least three feet apart. Two diame- a strand of the same size made up of many smaller wires.

ters shall be measured at each position at right angles from

each other. The average of these four measurements shall Basic strand constructions

be the reported diameter.

Most ropes are manufactured larger than the nominal diam- Single layer

eter. When first placed in operation, strands of new unused

rope will “seat in” and “pull down” from its original diame-

ter. Therefore, measurements recorded for future reference

and comparison should be taken after the rope has been in

service for a short period of time. See Table WR-1 for rope

diameter vs. tolerances.

Table WR-1: Rope diameter vs. tolerance. Figure WR-3: Example of a single-layer strand.

Rope Steel wire ropes Steel wire ropes

The “Single Layer Principle” is the basis of this strand con-

Diameter with IWRC with fiber core

struction. The most common example is a single wire center

Inches

Tolerance (percent) Tolerance (percent) with six wires laid around it. It is called a 7-wire (1–6) strand

(Figure WR-3).

UNDER OVER UNDER OVER

d < 3/16 0 8 0 9 Filler wire

3/16 ≤ d < 1/4 0 7 0 9 This construction has two layers of the same-sized wires

around a center wire, with the inner layer having half the num-

1/4 ≤ d < 3/8 0 6 0 8

ber of wires as the outer layer. Small filler wires, equal in num-

3/8 and larger 0 5 0 7 ber to the inner layer, are laid in the valleys of the inner layer.

IADC Drilling Manual Copyright © 2015

WIRE ROPE WR–3

Combined patterns

When a strand is formed in a single operation using two or

more of the foregoing constructions, it is referred to as a

“combined pattern”. Beginning from the center wire, the first

two layers constitute a Seale pattern. The third layer, with

two different wire sizes is a Warrington pattern. The fourth

layer of the same diameter wires forms a Seale pattern.

Figure WR-4: Filler wire has two layers of the

same-sized wires around a center wire. This is a

25 filler wire (1-6-6f-12) strand.

Seale

The Seale construction has two layers of wires around a

center wire with the same number of wires in each layer. All

wires in each layer are the same diameter and the strand

Figure WR-7: Strands formed in a single operations using two or

is designed so that the larger outer wires rest in the valleys

more of the foregoing constructions is called a “combined pattern.”

between the smaller inner wires. Above is 49 Seal Warrington Seale (1-8-8-(8+8)-16) strand.

Preforming

Preforming is a process by which strands are helically

formed into the shape they will assume in the finished rope.

Preforming improves fatigue resistance, ease of handling, and

resistance to kinking in a rope by equalizing the load among

the strands and among the individual wires of strands.

When a preformed rope is cut, the end does not unlay. If strands

are unlayed from the rope, they retain their helical shape. When

Figure WR-5: Seale construction features two layers of wires

around a center wire, with the same number of wires in a non-performed rope is cut, it will open up or "broom" unless

each layer. This example is 19 Seale (1-9-9) strand. the end has been secured (seized) before cutting.

The superior qualities of preformed ropes result from wires

Warrington and strands being “at rest” in the rope which minimizes in-

ternal stresses within the rope. Because wires and strands

The Warrington construction has 2 layers of wires. The in-

are free to move and slide in relation to each other when the

ner layer is a single size of wire and the outer layer has two

rope bends, the rope can adjust more easily while operating

diameters of wire, alternating large and small. The larger

on sheaves or drums. Unless otherwise indicated in the rope

outer-layer wires rest in the valleys and the smaller ones on

description, ropes are preformed.

the crowns of the inner layer.

Figure WR-8: Right lay, regular lay.

Lay

The first element in describing Lay is the DIRECTION of

Figure WR-6: Warrington construction features two layers strands lay in the rope—Right or Left. When you look along

of wires. The inner is a single size wire, and the outer has a rope, strands of a Right Lay rope spiral to the right. Left Lay

two wire diameters, alternating large and small. Drawing is rope spirals to the left.

of 19 Warrington (1-6-(6+6) strand.

IADC Drilling Manual Copyright © 2015

WR–4 WIRE ROPE

The second element in describing lay is the relationship be- The grade of rope refers to the strength of a new unused

tween the direction the strands lay in the rope and direction wire rope. Standard 6 strand EEIP ropes within the same

the wires lay in the strands. classification and having an IWRC have a nominal strength

about 10% higher than EIP ropes.

In Regular Lay, wires are laid opposite the direction the

strands lay in the rope. In appearance, the wires in Regular Galvanized ropes are those in which the individual wires

Lay are parallel to the axis of the rope. have had a zinc coating applied to their surface to provide

increased corrosion resistance. The proper grade of rope to

The second element in describing lay is the relationship be-

use depends on the specific characteristics of the application.

tween the direction the strands lay in the rope and direction

the wires lay in the strands.

Cores

In Regular Lay, wires are laid opposite the direction the

The primary purpose of a core in wire rope is to provide a

strands lay in the rope. In appearance, the wires in Regular

foundation or support for the strands. Approximately 7 ½%

Lay are parallel to the axis of the rope.

of the nominal strength of a 6-strand IWRC rope is attribut-

ed to the core.

Wire rope cores are usually one of three types (Figure WR-

12). The first, fiber core (top) is either of natural fiber, such as

sisal or man-made fiber, such as polypropylene. The second,

independent wire rope core (center) is literally an indepen-

dent wire rope called IWRC. Finally, strand core (bottom) is

Figure WR-9: Left lay, regular lay.

a strand composed of wires.

In Lang Lay, wires are laid the same direction as the strands lay in

the rope and the wires appear to cross the rope axis at an angle.

Figure WR-10: Right lay, lang lay.

The third element in describing lay is that one rope lay is the

length along the rope axis which one strand uses to make

one complete helix around the core.

Figure WR-12: Examples of rope cores (from top)—fiber core (FC);

independent wire rope core, center; strand core, bottom.

Table WR-3: Lay designations.

Lay type Preferred Other

designations designations

One Rope Lay Right hand ordinary lay RR, sZ RHOL, RRL

Left hand ordinary lay LL, zS LHOL, LRL

Figure WR-11: One rope lay.

Right hand langs lay RL, zZ RHLL, RLL

Left hand langs lay LL, sS LHLL, LLL

Grades Right hand alternate lay RA, aZ RHAL, RAL

Today the greatest portion of all wire rope is made in two Left hand alternate lay LA, aS LHAL, LAL

grades: Extra Improved Plow Steel (EIP) and Extra Extra

Improved Plow Steel (EEIP)

IADC Drilling Manual Copyright © 2015

WIRE ROPE WR–5

Table WR-4: Typical sizes and constructions of wire rope for oilfield service.

Service and well depth Wire rope inches Wire rope description

Rod & Tubing Pull Lines

Shallow ½ to 3/4 incl. 6×26 WS or 6×31 WS

Intermediate 3/4, 7/8 RRL or LRL IPS,EIP or EEIP, IWRC

Deep 7/8 to 11/8 incl.

Rod Hanger Lines 1/4 6×19, RRL, IPS, FC

Sand Lines

Shallow 1/4 to ½ incl.

Intermediate ½, 9/16 6×7 or 5×7 or 5×7 Swaged Bright or Galv.2, RRL IPS, FC

Deep 9/16, 5/8

Drilling Lines—Cable Tool (Drilling & Cleanout)

Shallow 5/8, 3/4

Intermediate 3/4, 7/8 6×21 FW, RRL or LRL, PS or IPS, FC

Deep 7/8, 1

Casing Lines—Cable Tool

Shallow 3/4, 7/8

Intermediate 7/8, 1 6×25 FW, RRL, IPS, FC or IWRC

Deep 1, 1 1/8 6x25 FW, RRL, IPS or ElP, IWRC

Drilling Line—Coring and Slim-Hole Rotary Rigs

Shallow 7/8, 1 6×26 WS, RRL, IPS or EIP, IWRC

Intermediate 1, 1 1/8 6×19 S or 6×26 WS, RRL, EIP or EEIP, IWRC

May have compacted strands or be plastic impregnated.

Drilling Lines—Large Rotary Rigs

Shallow 1, 1 1/8 6×19 S or 6×21 S or 6×26WS, RRL, EIP or EEIP, IWRC.

May have compacted strands or be plastic impregnated

Deep 1 1/4 to 2 incl.

5/8 to 7/8 incl. 6×26 WS or 6×31 WS, RRL, IPS EIP or EEIP, IWRC

Winch Lines—Heavy Duty

7/8 to 1 1/8 incl. 6×36 WS, PF, RRL, IPS EIP or EEIP, IWRC

Horsehead Pumping—Unit Lines

Shallow ½ to 1 1/8 incl.4 6×19 Class or 6×36 Class or 19×7, IPS, FC or IWRC

Intermediate 5/8 to 1 1/8 incl.3 6×19 Class or 6×36 Class, IPS, FC or IWRC

7/8 to 2 3/4 incl. 6×19 Class, Bright or GaIv., RRL, ElP or EEIP, IWRC

Offshore Anchorage Lines 1 3/8 to 4 3/4 incl. 6×36 Class, Bright or GaIv., RRL, ElP or EEIP, IWRC

3 3/4 to 4 3/4 incl. 6×61 Class, Bright or GaIv., RRL, ElP or EEIP, IWRC

Mast Raising Lines5 1 3/8 and smaller 6×19 Class, RRL, EIP or EEIP, IWRC

1 ½ and larger 6×36 Class, RRL, EIP or EEIP, IWRC

Guideline Tensioner Line 3/4 6×25 FW, RRL, IPS or EIP, IWRC

6×36 WS or 6×41 WS or 6×41 SFW or

6×49 SWS, RRL, IPS or EIP, IWRC or

Riser Tensioner Lines 1 ½ and larger

8×36 class RL IWRC

May have compacted strands and/or be plastic impregnated.

Abbreviations

WS Warrington Seale IPS Improved Plow Steel RRL Right Lay

S Seale ElPS Extra Improved Plow Steel LRL Left Lay

FW Filler-Wire PRF Preformed FC Fiber Core

PS Plow Steel NPF Non-preformed IWRC Independent Wire Rope Core

2

Bright wire sand lines are regularly finished; galvanized finish is sometimes required.

3

Applies to pumping units having one piece of wire rope looped over an ear on the horsehead and both ends fastened to a

polished rod yoke.

4

Applies to pumping units having two vertical lines (parallel) with sockets at both ends of each line.

5

See API Spec. 4E – Specification for Drilling and Well Servicing Structures.

IADC Drilling Manual Copyright © 2015

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Komatsu Pc75uu 2 Shop ManualDocument20 pagesKomatsu Pc75uu 2 Shop Manualthomas100% (61)

- Komatsu Wheel Loaders WA450 3 Shop Manual PDFDocument789 pagesKomatsu Wheel Loaders WA450 3 Shop Manual PDFNelson Conselho100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- VDiff TheTradClimbersGuideToProblemSolving E Book June2019 PDFDocument157 pagesVDiff TheTradClimbersGuideToProblemSolving E Book June2019 PDFMichał SzymusiakNo ratings yet

- Safety Audit Checklist - Stringing ActivityDocument3 pagesSafety Audit Checklist - Stringing ActivitysAuRaBh100% (1)

- DTM Brochure-webVersionDocument8 pagesDTM Brochure-webVersionShaiju NarayananNo ratings yet

- Iron Ore Water AbsorbationDocument7 pagesIron Ore Water AbsorbationShaiju NarayananNo ratings yet

- International Standard: Steel Wire Ropes - Standard DesignationsDocument3 pagesInternational Standard: Steel Wire Ropes - Standard DesignationsShaiju NarayananNo ratings yet

- PEMA Practical Observations - Rail Mounted Crane InterfacesDocument26 pagesPEMA Practical Observations - Rail Mounted Crane InterfacesShaiju Narayanan100% (1)

- T120 ManualDocument47 pagesT120 ManualShaiju NarayananNo ratings yet

- Model No. Gs5000 125Mm Straight GrinderDocument3 pagesModel No. Gs5000 125Mm Straight GrinderShaiju NarayananNo ratings yet

- Wirelock Technical Data ManualDocument17 pagesWirelock Technical Data ManualShaiju NarayananNo ratings yet

- LCC Docs 12144732 v1 Gantry Crane PfsDocument2 pagesLCC Docs 12144732 v1 Gantry Crane PfsShaiju NarayananNo ratings yet

- Calliper Brake SHI 251 & 252Document19 pagesCalliper Brake SHI 251 & 252Shaiju NarayananNo ratings yet

- RTT-IND-004 Rev. 6 (SC4000 Cement) 011020 JFODocument11 pagesRTT-IND-004 Rev. 6 (SC4000 Cement) 011020 JFOShaiju NarayananNo ratings yet

- Machine Shop Policies and Procedures Rev 7-14-15Document44 pagesMachine Shop Policies and Procedures Rev 7-14-15Shaiju NarayananNo ratings yet

- Safety Data Sheet: Tip Top Hardener E40Document10 pagesSafety Data Sheet: Tip Top Hardener E40Shaiju NarayananNo ratings yet

- Kiswire - NeptuneDocument8 pagesKiswire - NeptunealphadingNo ratings yet

- Objective: Develop Current and Future Value Stream Maps of Any Process in AnyDocument8 pagesObjective: Develop Current and Future Value Stream Maps of Any Process in AnyRaja ShafaatNo ratings yet

- Appendix A Inspection Checklists: (210-VI-NEH, Amend. 59, November 2011)Document40 pagesAppendix A Inspection Checklists: (210-VI-NEH, Amend. 59, November 2011)kian hongNo ratings yet

- LMDB-1 Dimensional DatabookDocument20 pagesLMDB-1 Dimensional DatabookHarshadNo ratings yet

- Gangway and Accommodation LaddersDocument3 pagesGangway and Accommodation Laddersminakshi tiwari100% (1)

- Wire Rope InspectionDocument0 pagesWire Rope InspectionAnonymous alQXB11EgQNo ratings yet

- West Coast Wire Rope IWRC PDFDocument157 pagesWest Coast Wire Rope IWRC PDFjesusgameboyNo ratings yet

- WSHi - Vehicular Safety at Work in SingaporeDocument17 pagesWSHi - Vehicular Safety at Work in SingaporeThupten Gedun Kelvin Ong100% (1)

- Tutorial - Traditional Game ActivityDocument2 pagesTutorial - Traditional Game Activitylim0157No ratings yet

- Marine TechDocument28 pagesMarine TechMichael OwingsNo ratings yet

- US DoD Shelf Life of Rubbers H695D-2CDocument43 pagesUS DoD Shelf Life of Rubbers H695D-2CJim Haig100% (1)

- Is.6594.2001 - SS Wire Rope PDFDocument20 pagesIs.6594.2001 - SS Wire Rope PDFpalani.djpNo ratings yet

- Homework Ropes & Knots: Section A: Key TermDocument13 pagesHomework Ropes & Knots: Section A: Key TermJoey KirklandNo ratings yet

- Adm Traction PDFDocument10 pagesAdm Traction PDFbitha p bNo ratings yet

- BISOMAC210-1000 REV 6Document49 pagesBISOMAC210-1000 REV 6joseNo ratings yet

- Crane Ropes - Usha Martin 1Document18 pagesCrane Ropes - Usha Martin 1Sanjeeb SinhaNo ratings yet

- 08 Hoisting WinchingDocument35 pages08 Hoisting WinchingAndrés RiosNo ratings yet

- Is 6594Document17 pagesIs 6594rajmarathiNo ratings yet

- Ingersoll Rand CatalogDocument76 pagesIngersoll Rand CatalogG100% (1)

- Lift Schedule of Tender SpecificationDocument33 pagesLift Schedule of Tender Specificationchia yeewahNo ratings yet

- Mooring of Ships - Forces (Document168 pagesMooring of Ships - Forces (shakirhamid6687100% (5)

- Mooring AnchooringDocument10 pagesMooring AnchooringLuffy KingNo ratings yet

- Rigging TechniquesDocument27 pagesRigging TechniquesDeepak ShettyNo ratings yet

- 8-Strand Class I Eye Splice: Getting StartedDocument3 pages8-Strand Class I Eye Splice: Getting StartedJose Manuel Vicedo MateosNo ratings yet

- Thern Full Line CatalogDocument96 pagesThern Full Line CatalogMena Fran Ja0% (1)

- WAHSA TGN07 Reference Information For Work at Height PDFDocument18 pagesWAHSA TGN07 Reference Information For Work at Height PDFAnupam GhoshNo ratings yet