Professional Documents

Culture Documents

General POlymers® 3745 - Top Coat

General POlymers® 3745 - Top Coat

Uploaded by

Mohindra PersadCopyright:

Available Formats

You might also like

- Techno-Economic Assessment About Sodium ChlorateDocument3 pagesTechno-Economic Assessment About Sodium ChlorateIntratec SolutionsNo ratings yet

- Resuflor 3746Document2 pagesResuflor 3746Jhose BonillaNo ratings yet

- 4685 POLYCOTE SW Ficha TecnicaDocument2 pages4685 POLYCOTE SW Ficha TecnicaGenesis Alejandra Mancilla CaniuNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- Protective & Marine Coatings: General Polymers 3479Document2 pagesProtective & Marine Coatings: General Polymers 3479Post MaloneeNo ratings yet

- Zerust AxxaCoat90 TechnicalDataSheet RevD2Document3 pagesZerust AxxaCoat90 TechnicalDataSheet RevD2ccorp0089No ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- E-Bond T526 Technical Data Sheet-1Document5 pagesE-Bond T526 Technical Data Sheet-1fatemeh.ahmadkhaniNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Devran 201: Cat. # 201B0245/201C0300Document2 pagesDevran 201: Cat. # 201B0245/201C0300Mohamed NouzerNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Protective & Marine Coatings: General Polymers 3746Document2 pagesProtective & Marine Coatings: General Polymers 3746Efrain Israel Arroyo AlaniaNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- DS 066 Epilux 84 ClearDocument2 pagesDS 066 Epilux 84 ClearShodhan M AminNo ratings yet

- Product Data Sheet: Topaz Matt Emulsion 588MEDocument2 pagesProduct Data Sheet: Topaz Matt Emulsion 588MEJoseph DarwinNo ratings yet

- Ideal Color80 Tec EngDocument2 pagesIdeal Color80 Tec EngPedroNo ratings yet

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- PEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-PrimerDocument2 pagesPEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-Primersarcozy922No ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- 400 UkDocument4 pages400 UkAhmed IbrahimNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Sealbond 218 P Pressure Injection EpoxyDocument1 pageSealbond 218 P Pressure Injection EpoxyLeoven Jef Suzara Lorin0% (1)

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Ficha GP3477 Epoxy Water EmulsionDocument2 pagesFicha GP3477 Epoxy Water EmulsionMarina AvNo ratings yet

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Jazeera Floor Coating 400Document3 pagesJazeera Floor Coating 400Ahmad BougeisNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetYuvaraj NithyanandamNo ratings yet

- Durapol Coating For Amines EtcDocument2 pagesDurapol Coating For Amines EtckermadaxNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- List of Periodic Checks Life Saving & Fire Fighting EquipmentDocument5 pagesList of Periodic Checks Life Saving & Fire Fighting EquipmentSandro CheNo ratings yet

- G.R. No. 198501 Kestrel Shipping Inc. v. MunarDocument12 pagesG.R. No. 198501 Kestrel Shipping Inc. v. MunarJa RuNo ratings yet

- TDS - RHEOSPERSE™ S 300 - en - WWDocument1 pageTDS - RHEOSPERSE™ S 300 - en - WWUlaş ÇuğuNo ratings yet

- 150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6Document59 pages150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6K68G-Trần Hải HàNo ratings yet

- Lysosome PresentationDocument5 pagesLysosome Presentationapi-241502402No ratings yet

- Mental Ability and Intellectual Tests: Comprehensive ListDocument9 pagesMental Ability and Intellectual Tests: Comprehensive ListzylfielNo ratings yet

- University of Rajasthan Admit CardDocument2 pagesUniversity of Rajasthan Admit CardYugal RamnaniNo ratings yet

- Cleanskin K SDS PDFDocument5 pagesCleanskin K SDS PDFIris BetancourtNo ratings yet

- Compressor PresentationDocument24 pagesCompressor PresentationPrashant Kumar mishraNo ratings yet

- Yield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessDocument9 pagesYield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessAMAANINo ratings yet

- Contract of ServiceDocument2 pagesContract of ServiceAnonymous 03JIPKRkNo ratings yet

- Physical Activity Scale For The Elderly Pase .4Document6 pagesPhysical Activity Scale For The Elderly Pase .4Erna UtamiNo ratings yet

- Flow Control Valves: 1 DescriptionDocument6 pagesFlow Control Valves: 1 Descriptionnotitle91No ratings yet

- Disturbance in Sensory PerceptionDocument48 pagesDisturbance in Sensory PerceptionKristine Louise JavierNo ratings yet

- 27 3310 01 Ecosmooth Rice Husk Cosmetic PowderDocument2 pages27 3310 01 Ecosmooth Rice Husk Cosmetic PowderJdNo ratings yet

- EE - exam.PowerSystem - Feb 2 2015-2Document3 pagesEE - exam.PowerSystem - Feb 2 2015-2giophilipNo ratings yet

- Fitness Test Score CardDocument1 pageFitness Test Score CardLloydNo ratings yet

- Huawei BoostLi ESM-48100B1 Datasheet (3U) A - (20190228) PDFDocument2 pagesHuawei BoostLi ESM-48100B1 Datasheet (3U) A - (20190228) PDFDiego Rocha100% (2)

- Data Sheet Buffer Tank 60-BT-01 - Rev0.1Document4 pagesData Sheet Buffer Tank 60-BT-01 - Rev0.1bandithaguru6338No ratings yet

- Manual Termometro BraumDocument25 pagesManual Termometro BraumJose Alberto IzquielNo ratings yet

- Power Your Signal: Antenna SpecificationsDocument4 pagesPower Your Signal: Antenna SpecificationsДмитрийNo ratings yet

- Specimen Cover Letters and Job Application LettersDocument4 pagesSpecimen Cover Letters and Job Application LettersVthree YsNo ratings yet

- S Listing Ui Group Eae26ab3f22c4787 2603 125516 DefaultDocument16 pagesS Listing Ui Group Eae26ab3f22c4787 2603 125516 DefaulthcghealthcureNo ratings yet

- Bomb Calorimeter TheoryDocument2 pagesBomb Calorimeter TheoryTub Pitthayuth33% (3)

- Paediatrica Indonesiana: Original ArticleDocument8 pagesPaediatrica Indonesiana: Original ArticleNuaimatul Hani'ahNo ratings yet

- Isgot Receive Nitrogen - TO BE POSTED IN CCRDocument1 pageIsgot Receive Nitrogen - TO BE POSTED IN CCRsonerNo ratings yet

- PyinkadoDocument7 pagesPyinkadoNay Win SheinNo ratings yet

- Products EznsT100InstallGuideRev4Document12 pagesProducts EznsT100InstallGuideRev4Nguyen Sy LuuNo ratings yet

- Operation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20Document64 pagesOperation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20hungstampNo ratings yet

General POlymers® 3745 - Top Coat

General POlymers® 3745 - Top Coat

Uploaded by

Mohindra PersadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General POlymers® 3745 - Top Coat

General POlymers® 3745 - Top Coat

Uploaded by

Mohindra PersadCopyright:

Available Formats

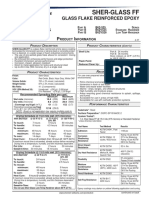

Protective General POlymers® 3745

& SELF-LEVELING EPOXY

Marine

P A GP3745 S

Coatings

art eries

P B GP3745B01 S H art tandard ardener

P B GP3745B02 F C H art ast ure ardener

Revised: September 23, 2014

Product Description Product Characteristics (Cont'd)

GENERAL POLYMERS 3745 SELF-LEVELING EPOXY is a

two-component, recoatable epoxy and binder resin. It may be Drying Schedule @ 10.0 mils (250 microns) wet:

used directly over primed substrates, or as a gloss seal coat over @ 55ºF (13ºC) @ 72°F(22°C) @ 95°F(35°C)

decorative slurry and mortar systems. GENERAL POLYMERS 3745 Standard Hardener: 50% RH

Self-Leveling Epoxy is extemely hard wearing, chemical resistant, To touch: 16-24 hours 6-12 hours 4-8 hours

impact and abrasion resistant.

To recoat:

Advantages minimum 24 hours 8 hours 6 hours

• Impact and abrasion resistant maximum 48 hours 24 hours 24 hours

• Durable, easy to clean Foot traffic: 48 hours 24 hours 18 hours

• Chemical resistant Heavy traffic: 96 hours 72 hours 60 hours

• Suitable for use in USDA inspected facilities Full cure: 7 days 7 days 7 days

• Available with an antimicrobial agent

If maximum recoat time is exceeded, abrade surface before recoating.

• Fast cure hardener available

• Tint bases can be tinted using Maxitoner @ 50% tint strength Drying time is temperature, humidity, and film thickness dependent.

Pot Life: 60 minutes 40 minutes 20 minutes

Typical Uses gallon mass

GENERAL POLYMERS 3745 SELF-LEVELING EPOXY should be Drying Schedule @ 10.0 mils (250 microns) wet:

used in areas where maintenance of a high performance, aestheti-

cally appealing and chemical resistant epoxy system is required. @ 72°F (22°C)

GENERAL POLYMERS 3745 Self-Leveling Epoxy is suited for use Fast Cure Hardener:

in clean rooms, laboratories, workshops, light assembly areas. To touch: 4 hours

Suitable for use in the Mining & Minerals Industry. To recoat: 8 hours minimum

Limitations minimum: 24 hours maximum

Foot traffic: 10-12 hours

• Slab on grade requires vapor/moisture barrier.

• Substrate must be structurally sound, dry and free of bond Heavy traffic: 24-48 hours

inhibiting contaminants. Full cure: 7 days

• During installation and initial cure cycle substrate and If maximum recoat time is exceeded, abrade surface before recoating.

ambient air temperature must be at a minimum of 50°F Drying time is temperature, humidity, and film thickness dependent.

(10°C). Substrate temperature must be at least 5°F (3ºC)

above the dew point (for lower temperature installation Pot Life: gallon mass 25 minutes @ 72°F (22°C)

contact the Technical Service Department). Shelf Life: Part A: 18 months, unopened

• Maximum dry surface temperature not to exceed 160°F Part B (Standard): 12 months, unopened

(71°C). Part B (Fast Cure): 18 months, unopened

Store indoors at 40°F (4.5°C) to 100°F (38°C)

• Strictly adhere to published coverage rates.

• Apply clear at only 10-15 mils (250-375 microns) maximum

per coat. Performance Characteristics

• Do NOT use fast cure hardener with tint bases.

Test Name Test Method Results

Surface Preparation Abrasion ASTM D4060, 100 mg loss

Resistance CS17 wheel, 1000

Proper inspection and preparation of the substrate to receive cycles

resinous material is critical. Read and follow the “Instructions for Adhesion ACI 503R 300 psi concrete failure

Concrete Surface Preparation” (Form G-1) for complete details.

Flammability Self-extinguishing over

Product Characteristics concrete

Flexural Strength ASTM D 790 ~12,400 psi

Finish: Gloss

Hardness, Shore D ASTM D 2240 80

Color: Clear, Standard Colors Impact Resistance MIL-D-3134J Direct, inch pound greater

Wide range of colors possible than 160, passes;

Reverse, inch pound

Volume Solids: 98% ± 2%, mixed greater than 80, passes

Weight Solids: 98% ± 2%, mixed Flame Spread Index 20;

ASTME84/

Surface Burning* Smoke Development

Mix Ratio: 2:1 NFPA 255 Index 90

VOC (EPA Method 24): <100 g/L ; 0.83 lb/gal, mixed Tensile Strength ASTM D 638 ~6,000 psi

Recommended Spreading Rate per coat: *GENERAL POLYMERS 3477 at 1.5 mils (40 microns) DFT topcoated with

Minimum Maximum GENERAL POLYMERS 3745 at 17.5 mils (438 microns) DFT

Wet mils (microns): 6.0 (150) 30.0 (750)

Coverage sq ft/gal (m2/L): 266 (6.8) 50 (1.3)

www.sherwin-williams.com/protective continued on back

Protective General POlymers® 3745

& SELF-LEVELING EPOXY

Marine

P A GP3745 S

Coatings

art eries

P B GP3745B01 S H art tandard ardener

P B GP3745B02 F C H art ast ure ardener

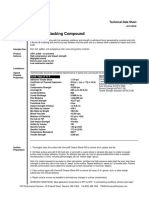

Revised: September 23, 2014 Product Information

Storage / Application Chemical Resistance

• MATERIAL DELIVERY AND STORAGE For comprehensive chemical resistance information, consult the

Chemical Resistant Guide and contact the Technical Service

Store materials in accordance instructions, with seals and labels Department.

intact and legible. Keep resins, hardeners, and solvents separated

from each other and away from sources of ignition. 18 months

shelf life is expected for products stored between 40°F (4.5°C) - Cleanup

100°F (38°C). Clean up mixing and application equipment immediately after use.

Use toluene or xylene. Observe all fire and health precautions when

• APPLICATION INSTRUCTIONS handling or storing solvents.

1. Premix 3745A (resin) using a low speed drill and Jiffy blade.

Mix for one minute and until uniform, exercising caution not to Safety

introduce air into the material. Refer to the MSDS sheet before use.

2. Add 2 parts 3745A (resin) to 1 part 3745B (hardener) by volume. Published technical data and instructions are subject to change

Mix with low speed drill and Jiffy blade for three minutes and until without notice. Contact your Sherwin-Williams representative

uniform. To insure proper system cure and performance, strictly for additional technical data and instructions.

follow mix ratio recommendations.

3. Apply 3745 using a squeegee or trowel and back roll with a 3/8" Maintenance

nap roller at a spread rate of 50-160 square feet per gallon (1.3- Occasional inspection of the installed material and spot repair can

4.0 meters squared per liter) to yield 10-30 mils (250-750 microns) prolong system life. For specific information, contact the Technical

WFT making sure of uniform coverage. Take care not to puddle Service Department.

materials and insure even coverage.

4. Allow to cure 24 hours minimum before opening to traffic and Shipping

72 hours before water exposure.

• Destinations East of the Rocky Mountains are shipped F.O.B.

Cincinnati, Ohio.

Note: Epoxy materials will appear to be cured and “dry to touch” prior

to full chemical cross linking. Allow epoxy to cure a minimum of 3 days • Destinations West of the Rocky Mountains are shipped F.O.B.

prior to exposure to water or other chemicals for best performance. Victorville, California.

For specific information relating to international shipments, contact

your local sales representative.

Ordering Information Disclaimer

The information and recommendations set forth in this Product Data Sheet are

based upon tests conducted by or on behalf of The Sherwin-Williams Company.

Packaging: Such information and recommendations set forth herein are subject to change and

Part A: 1 gallon (3.79L) pertain to the product offered at the time of publication. Consult your Sherwin-

Williams representative to obtain the most recent Product Data Information and

3.3 gallon (12.5L) and Application Bulletin.

5 gallon (18.9L) containers

Part B: 0.5 gallon (1.89L) Warranty

1.67 gallon (6.31L) and

The Sherwin-Williams Company warrants our products to be free of manufactur-

5 gallon (18.9L) containers ing defects in accord with applicable Sherwin-Williams quality control procedures.

Liability for products proven defective, if any, is limited to replacement of the defec-

tive product or the refund of the purchase price paid for the defective product as

Weight: 10.3 ± 0.2 lb/gal; 1.23 Kg/L determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

mixed, may vary by color OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED,

STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

You might also like

- Techno-Economic Assessment About Sodium ChlorateDocument3 pagesTechno-Economic Assessment About Sodium ChlorateIntratec SolutionsNo ratings yet

- Resuflor 3746Document2 pagesResuflor 3746Jhose BonillaNo ratings yet

- 4685 POLYCOTE SW Ficha TecnicaDocument2 pages4685 POLYCOTE SW Ficha TecnicaGenesis Alejandra Mancilla CaniuNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- Protective & Marine Coatings: General Polymers 3479Document2 pagesProtective & Marine Coatings: General Polymers 3479Post MaloneeNo ratings yet

- Zerust AxxaCoat90 TechnicalDataSheet RevD2Document3 pagesZerust AxxaCoat90 TechnicalDataSheet RevD2ccorp0089No ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- E-Bond T526 Technical Data Sheet-1Document5 pagesE-Bond T526 Technical Data Sheet-1fatemeh.ahmadkhaniNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Devran 201: Cat. # 201B0245/201C0300Document2 pagesDevran 201: Cat. # 201B0245/201C0300Mohamed NouzerNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Protective & Marine Coatings: General Polymers 3746Document2 pagesProtective & Marine Coatings: General Polymers 3746Efrain Israel Arroyo AlaniaNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- DS 066 Epilux 84 ClearDocument2 pagesDS 066 Epilux 84 ClearShodhan M AminNo ratings yet

- Product Data Sheet: Topaz Matt Emulsion 588MEDocument2 pagesProduct Data Sheet: Topaz Matt Emulsion 588MEJoseph DarwinNo ratings yet

- Ideal Color80 Tec EngDocument2 pagesIdeal Color80 Tec EngPedroNo ratings yet

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- PEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-PrimerDocument2 pagesPEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-Primersarcozy922No ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- 400 UkDocument4 pages400 UkAhmed IbrahimNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Sealbond 218 P Pressure Injection EpoxyDocument1 pageSealbond 218 P Pressure Injection EpoxyLeoven Jef Suzara Lorin0% (1)

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Ficha GP3477 Epoxy Water EmulsionDocument2 pagesFicha GP3477 Epoxy Water EmulsionMarina AvNo ratings yet

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Jazeera Floor Coating 400Document3 pagesJazeera Floor Coating 400Ahmad BougeisNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetYuvaraj NithyanandamNo ratings yet

- Durapol Coating For Amines EtcDocument2 pagesDurapol Coating For Amines EtckermadaxNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- List of Periodic Checks Life Saving & Fire Fighting EquipmentDocument5 pagesList of Periodic Checks Life Saving & Fire Fighting EquipmentSandro CheNo ratings yet

- G.R. No. 198501 Kestrel Shipping Inc. v. MunarDocument12 pagesG.R. No. 198501 Kestrel Shipping Inc. v. MunarJa RuNo ratings yet

- TDS - RHEOSPERSE™ S 300 - en - WWDocument1 pageTDS - RHEOSPERSE™ S 300 - en - WWUlaş ÇuğuNo ratings yet

- 150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6Document59 pages150 de Thi Hoc Sinh Gioi Tieng Anh Lop 6K68G-Trần Hải HàNo ratings yet

- Lysosome PresentationDocument5 pagesLysosome Presentationapi-241502402No ratings yet

- Mental Ability and Intellectual Tests: Comprehensive ListDocument9 pagesMental Ability and Intellectual Tests: Comprehensive ListzylfielNo ratings yet

- University of Rajasthan Admit CardDocument2 pagesUniversity of Rajasthan Admit CardYugal RamnaniNo ratings yet

- Cleanskin K SDS PDFDocument5 pagesCleanskin K SDS PDFIris BetancourtNo ratings yet

- Compressor PresentationDocument24 pagesCompressor PresentationPrashant Kumar mishraNo ratings yet

- Yield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessDocument9 pagesYield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessAMAANINo ratings yet

- Contract of ServiceDocument2 pagesContract of ServiceAnonymous 03JIPKRkNo ratings yet

- Physical Activity Scale For The Elderly Pase .4Document6 pagesPhysical Activity Scale For The Elderly Pase .4Erna UtamiNo ratings yet

- Flow Control Valves: 1 DescriptionDocument6 pagesFlow Control Valves: 1 Descriptionnotitle91No ratings yet

- Disturbance in Sensory PerceptionDocument48 pagesDisturbance in Sensory PerceptionKristine Louise JavierNo ratings yet

- 27 3310 01 Ecosmooth Rice Husk Cosmetic PowderDocument2 pages27 3310 01 Ecosmooth Rice Husk Cosmetic PowderJdNo ratings yet

- EE - exam.PowerSystem - Feb 2 2015-2Document3 pagesEE - exam.PowerSystem - Feb 2 2015-2giophilipNo ratings yet

- Fitness Test Score CardDocument1 pageFitness Test Score CardLloydNo ratings yet

- Huawei BoostLi ESM-48100B1 Datasheet (3U) A - (20190228) PDFDocument2 pagesHuawei BoostLi ESM-48100B1 Datasheet (3U) A - (20190228) PDFDiego Rocha100% (2)

- Data Sheet Buffer Tank 60-BT-01 - Rev0.1Document4 pagesData Sheet Buffer Tank 60-BT-01 - Rev0.1bandithaguru6338No ratings yet

- Manual Termometro BraumDocument25 pagesManual Termometro BraumJose Alberto IzquielNo ratings yet

- Power Your Signal: Antenna SpecificationsDocument4 pagesPower Your Signal: Antenna SpecificationsДмитрийNo ratings yet

- Specimen Cover Letters and Job Application LettersDocument4 pagesSpecimen Cover Letters and Job Application LettersVthree YsNo ratings yet

- S Listing Ui Group Eae26ab3f22c4787 2603 125516 DefaultDocument16 pagesS Listing Ui Group Eae26ab3f22c4787 2603 125516 DefaulthcghealthcureNo ratings yet

- Bomb Calorimeter TheoryDocument2 pagesBomb Calorimeter TheoryTub Pitthayuth33% (3)

- Paediatrica Indonesiana: Original ArticleDocument8 pagesPaediatrica Indonesiana: Original ArticleNuaimatul Hani'ahNo ratings yet

- Isgot Receive Nitrogen - TO BE POSTED IN CCRDocument1 pageIsgot Receive Nitrogen - TO BE POSTED IN CCRsonerNo ratings yet

- PyinkadoDocument7 pagesPyinkadoNay Win SheinNo ratings yet

- Products EznsT100InstallGuideRev4Document12 pagesProducts EznsT100InstallGuideRev4Nguyen Sy LuuNo ratings yet

- Operation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20Document64 pagesOperation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20hungstampNo ratings yet