Professional Documents

Culture Documents

US5562405

US5562405

Uploaded by

Vyacheslav0 ratings0% found this document useful (0 votes)

2 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

2 views7 pagesUS5562405

US5562405

Uploaded by

VyacheslavCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

United States Patent 15)

0 080 8

1) Patent Number: 5,562,405

Ryall 14s] Date of Patent: Oct. 8, 1996

[54] MULTISTAGE AXIAL FLOW PUMPS AND 0236165 9/1987 Earopean Pat. Off

COMPRESSORS 0475920 5/1992. Earopean Pat. OF.

0368160 3/1932 United Kingdom

(75] lnventor: Michael L, Ryall, Killearn, Scotland 512487 9/1939 United Kingdom

315469 12/1939 Unied Kingdom

Sn ae eee cece 44319 10/1950 United Kingdom

(73] Assignee: Weir Pumps Limited, Glasgow, 616371 7/1952 United Kingdom

= 682188 6/1953. United Kingdom

743475 1/1986 United Kingdom

[21] Appl. No.: 401,413 766812 /1957 United Kingdom

. 19736 4/1968 United Kingdom

(22] Filed: Mar. 9, 1998 14712224197) United Kingdom

(30] Foreign Application Priority Data ceniamadia nse

Mar, 10, 1994 [GB] United Kingdom 19404653 OTHER PUBLICATIONS

et. 21,1994 (GB} United Kingdom “vn

21, 1984 [GB] United Kingdos 9421259 poseidon Multiphase Technology”, World Pumps, No. 319,

(51) Int ~ ssn » FO4D 3100 pp. 16-17, Oxford.

(52) US. Ch nnn 415772; 415/199,3; 415/221

[58] Field of Search ve 415/71, 72, 199.2, Primary Examiner—Bdward K. Look

“s157199,3, 221, 220 Assistant Examiner—Michae! S. Lee

‘Attomey, Agent, or Firm—Young, & Basile

(56) References Cited

U.S. PATENT DOCUMENTS Cul ABSTRACT

[A multistage axial flow pump or compressor comprises

lates cue surname i oe es co

3442220 5/1969 Mottram etal _ 41572 ai (16) is arranged to impart whirl in one direction,

101975 Stom while the stator (20) is arranged to impart whirl in the

@1977 Sloan opposite direction. This arrangement is useful in providing

31978. Dawson .. 415221 comparatively high stage pressures for a given rotor tip

4830584 5/1989. Mohn velocity with relatively low rotar vane hydraulic loadings.

5222863 6/1993 Jones ‘The arrangement is also useful in pumping multiphase

3425617 6/1995 Tera. aism2 aids

FOREIGN PATENT DOCUMENTS

1/1983 European Pat. Of.

‘0080251

Iss

Sat

25 Claims, 3 Drawing Sheets

10

ISSO

5,562,405

U.S. Patent

U.S. Patent Oct. 8, 1996 Sheet 2 of 3 5,562,405

— /

Stator Vanes:

Asal path of \ N=Bst

Fluid Through OS QO, 22

The Machine

US. Patent Oct. 8, 1996 Sheet 3 of 3 5,562,405

5,562,405

1

‘MULTISTAGE AXIAL FLOW PUMPS AND

‘COMPRESSORS

FIELD OF THE INVENTION

‘This invention relates to pumps and compressors, and in

particular to multistage axial flow pumps and compressors,

BACKGROUND OF THE INVENTION

‘The invention has application in multistage pamps suit

able for pumping a range of fluids, both liquids and gases,

Dut also offers particular advantages in relation 10 axial

pumps for use in pumping multiphase uids as may be

encountered in oil and gas exploration and production. Both

the general and multiphase applications of the invention are

described herein

Im existing mulkistage fluid pumps and compressors,

whether of the centrifugal, mixed flow or axial flow type, an

increase in fluid pressure is achieved in each stage by: an

impeller, which imparts both whirl to the fuid and increases

its pressure; and a diffuser or volute, which reduces the

absolute velocity of the luid and increases the fluid pressure

further by the partial conversion of fluid velocity energy into

pressure energy. In general, an objective in the design of

these machines is that at the flow rate at which the hydraulic

efficiency is a maximum that is, the design duty flow, a

substantial amount of fuid difusion takes place in the volute

or bladed stators.

In onder to achieve relatively high stage pressures it is

generally necessary to employ centrifugal or mixed flow

pumps. It is among the objects of one aspect of the present

invention to provide a multistage axial flow pump which

will provide a performance comparable with, or better than,

multistage centrifugal or mixed flow pump, at a lower

‘manufacturing cost.

In many oil fields the fluid which is extracted from a

hydrocarbon reservoir is a mixture of gas and liquid phases.

During the pumping of such fluid, particularly at lower

pressures, the gas phase tends t0 separate from the liquid

phase, this problem being particularly acute within pump

stages. In a conventional axial pump the gas phase tends to

accumulate around the axis of the pump and to flow back

along the pump axis.

‘Such conventional pumps typically comprise a cylindrical

casing within which is mounted a rotatable shaft. An axial

flow impeller, which may have a cylindrical ora conical hub,

is mounted on the shaft directly upstream of a stationary

diffuser. The impeller adds energy to the fuid while the

diffuser reduces the absolute velocity of the fluid and

increases the fluid pressure. The diffuser also serves to

‘minimise the whirl velocity of the uid atthe diffuser outlet,

and provides for substantially axial uid ow from the stage.

Due to the whirl imparted to the uid by the impeller,

separation of the gas and liquid phases towards the hub of,

both impeller and diffuser within the pump stages limits the

gas-handling capability of such pumps. Accordingly, it is

among the objects of another aspect ofthe present invention

to provide a pump for mulkiphase fluids in which the gas

phase remains substantially entrained within the liquid

phase, thereby enhancing the ability of the pump to handle

Targe gas fractions in the total uid flow.

SUMMARY OF THE INVENTION

According to one aspect of the present invention there is

provided a multistage axial flow pump or compressor com-

0

15

30

3s

45

50

ss

2

prising at least one stage including a rotor for imparting

Whirl in one direction and a stator for imparting whirl in the

opposite direction,

According to another aspect of the present invention there

is provided a method of pumping or compressing a fluid

utiising a multistage pump or compressor including the

sieps: imparting whiel to the fuid in a first rotor; and then,

imparting whic to the fuid in the opposite direction ina first,

stator,

‘The present invention has application in both pumps and

compressors however, in the interest of brevity, the descrip-

tion mainly refers to pumps.

Inuuse, it has been found that pumps made in accordance

‘with the' invention are capable of providing comparatively

high stage pressures for a given rotor tip velocity with

relatively low rotor vane hydraulic loadings. Thus, it is

possible to produce axial flow pumps and compressors

according to the invention with equivalent or better perfor-

‘mance than centrifugal and mixed flow pumps, and such

axial flow pumps are likely to be significantly less expensive

{to produce than comparable centrifugal or mixed flow

equivalents.

‘The configuration of the rotor and stator is such that the

axial length per stage of pumps in accordance with the

invention may be less than equivalent conventional axial

flow, mixed flow and centrifugal machines, such that the

invention allows construction of pumps and compressors

with relatively short, stiff and rugged shafts and compact

lightweight rotor assemblies.

Preferably, the pump rotor has a cylindrical hub, and

rotates within a cylindrical housing.

Preferably also, the stator is configured to produce litle or

no diffusion, to maximise the efficiency of the whirl reversal

process, and such that, at or near the design duty flow, the

fluid is discharged from the stator with an absolute velocity

which has substantially the same axial component as the

fluid entering the stator, and has a whirl component of

velocity which is substantially the same as the whisl com-

ponent entering the stator, but in the opposite rotational

direction. Thus, the absolute velocity of the fluid passing

through the stator is maintained substantially constant dur

ing the whisl reversal process, the stator vanes effectively

acting as a cascade bend,

Conveniently, means for diffusion of the fluid is provided

after the last purap stage, for example by providing a bladed

diffuser or volute,

Preferably also, the rotor of a second pump stage is

arranged to impart a whirl component in the same direction

as the direction of rotation of the rotor of the frst stage.

According to a further aspect of the present invention

there is provided an axial flow pump for use in pumping a

‘multiphase fluid, the pump comprising at least one stage

having a rotor for imparting whirl in one direction and a

stator for imparting whirl in the opposite direction to main-

tain entrainment of the gas phase of the uid within the

liguid phase.

‘Compared to conventional pump stage arrangements, in

which the whirl induced in the fluid is likely to be unidi-

rectional, the maximum whiel velocity attained in the stage

is considerably lower, thus reducing the centrifugal forces

acting on the fluid and which tend to separate the phases.

‘Also, the arrangement of the invention avoids the fuid being

subject 10 a continuous centrifuging effect. The changes in

direction of whirl also tend to induce re-entrainment of any

{885 that has nevertheless separated from the liguid phase.

5,562,405

3

Preferably, sad at least one stage includes two stators, one

upstream and downstream of the rotor, the stators inducing

whirl in one direction and the rotor inducing whit! in the

opposite direction,

‘The stage may be arranged such that the pressure rise

across the stage is predominately achieved in the roto, the

stator serving solely or predominately to change the direc:

tion of whirl of the Nuid. Alternatively, the stator may act as

a diffuser. In the former arrangement the rotor may be

mounted on a parallel cylindrical hub, to produce purely

axial flow, while in the latter arrangement the rotor may be

mounted on a conical hub,

Preferably also, the rotor is in the form of an impeller

‘mounted on a rotating shaft. Most preferably, the stator is

‘mounted to the casing which defines the outer wall of the

pump stage,

Preferably also, the stator is formed of a plurality of

radially extending blades or vanes. Most preferably, the

stator downstream of the rotor has bull-nosed vanes that is

vanes with a blunt, rounded leading edge, capable of toler-

ating a wide range of flow incidence angles at the bull-nosed

leading edges. Preferably also, the profile of the vanes is

such as 10 provide substantially constant passage width

between the vanes.

BRIEF DESCRIPTION OF THE DRAWINGS

‘These and other aspects of the present invention will now

be described, by way of example, with reference to the

accompanying drawings, in which:

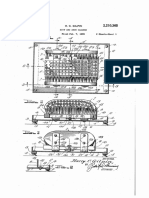

FIG. 1 i a cut-away view of a stage of a mulkistage axial

pump in accordance with a preferred embodiment of the

present invention;

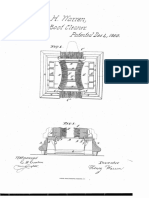

FIG. 2s a somewhat schematic representation ofthe uid

path through a stator, a rotor and a further stator of a

‘multistage pump in accordance with an embodiment of the

present iavention;

FIG. 3is a velocity diagram of fuid passing through the

rotor and the stator of the pump of FIG. 1; and

FIG. 4 is a somewhat schematic representation of the

passage a multiphase fluid through the stator, rotor and a

further stator of a multistage pump in accordance with a

further embodiment of the present invention.

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENTS

Reference is first made to FIG. 1 of the drawings, which

illustrates one stage of 2 multistage axial pump in accor-

dance with an embodiment of the present invention. The

pump slage 10 is located within a cylindrical casing 12

which contains a central driving shaft 14. rotor 16 is linked

to the driving shaft 1d via a cylindrical hub 18. Downstream

Of the rotor 16 is a stator 20 having blades 22 which are

fixedly mounted within, brazed to, or cast integral with the

casing 12, Tho stator blades 22 aro generally similar to the

rotor blades of an axial flow impulse type steam turbine, and

effectively act as cascade bends,

In use, the rotor 16, which in this example is rotated in a

clockwise direction, induces clockwise whirl in the fuid,

which is then reversed by the stator 20, The flow of fluid

through the stage 10 is illustrated in greater detail in FIG. 2

of the drawings, which shows a section of the pump stage

10, including three blades 24 of a first stator 26 and three

blades 22 of a second stator 20, the rotor 16 being located

‘therebetween. Considering first the path of the fuid from the

x0

8

45

0

ss

@

6

4

rotor 16 to the downstream stator 20, the Suid whirl is

generated by the rotor blade camber and/or incidence, and

the uid is discharged from the rotor with an absolute

velocity (V,,) which has both an axial component and a

‘whirl component in the direction of rotation of the rotor. The

fluid then flows into the passages between the stator blades

22, in which, atthe design point, litle or no diffusion takes

place, the function of the stator 20 being predominantly to

tum the fluid such that it is discharged from the stator with

an absolute velocity (V,.) which has: the same (or nearly the

same) axial component; and a whir! component which i the

same (or nearly the same) as the whirl component entering

the stator, but in the opposite direction. As may be seen from

the velocity diagram shown in FIG, 3 of the drawings, the

absolute velocity ofthe uid passing through the stator vane

passages (Vy Vyq) is maintained substantially constant

during this whiel direction reversal process.

The fluid, with an absolute velocity component contrary

to the direction of rotation ofthe rotor 16, then flows into the

‘passages between the rotor vanes of the next rotor stage (not

shown), and the wit! generation in that rotor then turns the

flow such that on exit from the second rotor stage the fluid

hhas a whirl component in the same direction as the direction

of rotation of the rotor.

‘Thus, as is evident from the Figures, the function of

altemate rotors and stators is simply to impart positive and

negative whin, respectively, wo the uid. The passage cross

sectional arca in the stator is advantageously kept constant,

or slightly convergent divergent, io maximize the efficiency

of the whirl reversal process in the stators. While little or no

diffusion of the fluid flow takes place in the stator vane

passages between successive rotors, it is preferable that

some provision for fluid diffusion is made after the last

stage, for example by providing a bladed diffuser or volute,

as is well known to those of skill in the ar.

In such a multistage fluid machine, the first pump stage

can be designed with or without provision to create fluid

‘his in a diection contrary to rotor rotation upstream of the

first stage rotor, depending upon the net positive suction

head requirements at the first stage. FIG. 2 illustrates the

situation where an upstream stator 26 is provided to impart

Whirl upstream of the rotor 16

thas been found that pumps designed as described above

may provide comparatively high stage pressures for a given

rotor tip velocity, with relatively low rotor vane hydraulic

loadings. It is thus practicable to design multistage axial

flow pumps and compressors which can compete favorably

‘on performance and economic terms with centrifugal and

mixed flow pumps. There is considerable flexibility in pump

design available, so that headl/flow and powesiflow charac-

teristics may be selected to suit particular applications and

system requirements. Further, using the above-described

rotor and stator configuration, axial length per stage is less

than with the equivalent conventional axial low and mixed

flow machines, allowing the manufacture of pumps and

compressors with stiff, rigged shafts and rotor assemblies.

Reference is now made to FIG. 4 of the drawings, which

illustrates a section of a pump stage 30, similar to that

described above with reference to FIG. 2, being utilised to

pomp a multiphase fuid

FIG. 3 illustrates three blades $0 of a first upstream stator

‘51 and three blades 38 ofa second downstream stator 40, the

{impeller or rotor 36 being located therebetween. The Figure

also illustrate the process of separation and re-entrainment

that occurs as a multiphase fluid passes through the pump

stage.

5,562,405

5

As mentioned above with reference to the frs-described

embodiment, it will be noted that the passage cross-section

‘between the stator blades $0, 38 is substantially constant

such that the stators 51, 40 do not diffuse the fuid. It will

also be noted that the stator blades 50, 38 are bulled-nosed

and thus less sensitive to the incidence angle of fluid lowing

into the stators.

AAs the fluid flows between the stator blades $0, and is

subject to a first change in whirl direction, a degree of

separation may occur in the low pressure area S6 along the

trailing edge of each blade 50, However, the separated gas,

phase is re-entrained with the liquid phase on encountering

the leading edges of the rotor blades 55, which induce whirl

in the opposite direction. As the fuid passes through the

rotor, a certain degree of separation may take place in the

low pressure area $8 along the front face of the trailing edge

‘of each rotor blade $5. On passing from the rotor and into

the stator 40 and separated gas phase is re-entrained within

the liquid phase, asthe whirl direction is changed once more.

(On the fluid flowing from the stator 40 there isthe possiblity

ff some separation occurring in the low pressure area 60

along the trailing edge of each stator blade 38.

Thus, it will be seen that, although an inevitable degree of

separation does take place as the fluid passes through the

pump stage, any significant separation ofthe phases tends to

be followed by re-entrainment. In addition, the changes in

whic velocity direction as the fluid flows through the stage

results in the maximum whirl velocity attained in the stage

being considerably lower than in a conventional axial pump

configuration, thus reducing the centrifugal forces acting on

the fluid and which tend t0 separate the phases. Also, the

cchanges in whirl velocity direction avoids the fuid being

subject to a continuous centrifuging effect

It will be clear to those of skill in the art that the

above-described embodiments are merely exemplary of the

present invention and that various modifications and

improvements may be made thereto, without departing from

the scope of the invention, for example the illustrated

‘embodiments feature machines with a cylindrical hub and a

cylindrical casing, and for certain applications the same

general flow principles may be incorporated into pumps or

‘compressors with conical hubs and/or conical casings.

claim:

1. An axial flow pump for use in pumping a multiphase

‘uid, the pump comprising at least one stage having 2 rotor

for imparting whiel in one direction and two stators for

‘imparting whirl in the opposite direction to maintain entrain-

ment of the gas pase of the fluid within the liquid phase,

fone stator being upstream of the rotor and the other stator

being downstream of the rotor.

2. The pump of claim 1, wherein the rotor has a cylindrical

hub and rotates within a cylindrical housing,

3. The pump of claim 1, wherein means for diffusion of

the fluid is provided after the last pump stage

4. The pump of claim 1, wherein said at least one stage

includes two stators, one upstream and one downstream of

the rotor, the rotor arranged to induce whirl in one direction

and the stators arranged to induce whirl in the opposite

direction,

5. The pump of claim 1, wherein the rotor is in the form

‘of an impeller mounted on a rotatable shaft

6. The pump of claim 1, wherein a stator is provided

downstream of the roior and has bull-nosed vanes capable of

tolerating a wide range of flow incidence angles.

17. The pump of claim 1, wherein the rotor is in the form

of a series of impellers mounted on a rotatable shat.

8. The pump of claim 1, wherein the rotor has 2 fluid flow

coefficient of less than 0.4

20

25

30

33

0

50

©

6

9. The pump of claim 8, wherein the rotor has afuid flow

coetficient of between 0.15 and 0.25.

10. A mulistage axial low pump or compressor compris-

{ng at least one stage including a rotor for imparting whirl in

one direction and an inter-stage stator for imparting whirl in

the opposite direction and having a plurality of vanes

Gefining curved arcuate passages therebetween, the cross-

sectional area of each passage being substantially constant

along the whole length of the curved arc of each passage

whereby the stator produces litle or no diffusion.

11. The pump of claim 10, wherein the rotor has a

cylindrical hub and rotates within a cylindrical housing.

12, The pump of claim 10, wherein the stator is configured

such that, at or near the design duty flow, the Mid is

discharged from the stator with an absolute velocity which

has substantially the same axial component as the fluid

entering the stator, and has a whiel component of velocity

‘which is substantially the same as the whit! component

centering the stator, but in the opposite rotational direction

13, The pump of claim 10, wherein means for diffusion of

the Muid is provided after the last pump stage.

14. The pump of ciaim 10, wherein the rotor of a second

‘pump stage is arranged to impart a whit] component in the

‘same direction as the direction of rotation of the rotor of the

first stage

15. The pump of claim 10, wherein said at least one stage

includes two stators, one upstream and one downstream of

the rotor, the rotor arranged to induce whic in one direction

and the stators arranged to induce whirl in the opposite

direction.

16. The pump of claim 10, wherein the rotor is inthe form

of an impeller mounted on a rotatable shaft.

17. The pump of claim 10, wherein the stator is mounted

1 the casing which defines the outer wall of the pump stage.

18. Tho pump of claim 10, wherein a stator is provided

downstream of the rotor and has bull-nosed vanes capable of

tolerating a wide range of flow incidence angles.

19. The pump of claim 10, wherein the stator is configured

such that, at or near the design duty flow, the fuid is

discharged from the stator with an absolute velocity which

hhas substantially the same axial component as the fluid

centering the stator, and has a whirl component of velocity

which is substantially the same as the whirl component

centering the stator, but in the opposite rotational direction.

20, The pump of claim 10, wherein the rotor is in the form

of a series of impellers mounted on a rotatable shaft

21. The pump of claim 10, wherein the stator is formed of

a plurality of radially extending blades or vanes.

22, The pump of claim 10, wherein the stator bas bull-

nosed vanes capable of tolerating a wide range of ow

incidence angles.

23. The pump of claim 10, wherein the rotor has a fluid

ow coefficient of less than 0.4

24. The pamp of claim 23, wherein the rotor has a fluid

low cocficient of between 0.15 and 0.25.

25, A method of pumping or compressing a fluid wilizing

1 multistage axial pump or compressor, the method includ

‘ng the steps of: imparting whirl to the Suid in a first rotor;

and then imparting whirl to the fluid inthe opposite direction

in a frst stator with litle or not diffusion such that, at or near

the design duty flow, the fluid is discharged from the stator

‘with an absolute velocity with has substantially the same

axial component as the uid entering the stator, and has a

whirl component of velocity which is substantially the same

as the whirl component entering the stator, but in the

opposite rotational direction,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SZAZ2%: Itz ZiiDocument4 pagesSZAZ2%: Itz ZiiVyacheslavNo ratings yet

- G: Evvvvv: OfessiaDocument5 pagesG: Evvvvv: OfessiaVyacheslavNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- United States Patent: (45) Date of Patent: Mar - 3, 2020Document15 pagesUnited States Patent: (45) Date of Patent: Mar - 3, 2020VyacheslavNo ratings yet

- G. E. V.On Hoff Mann.: Patented Nov, 8, 1921Document2 pagesG. E. V.On Hoff Mann.: Patented Nov, 8, 1921VyacheslavNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0172488 A1Document7 pagesPatent Application Publication (10) Pub. No.: US 2003/0172488 A1VyacheslavNo ratings yet

- 3.22. RT by His Diarney: Kitnessgs. Inv JitorDocument3 pages3.22. RT by His Diarney: Kitnessgs. Inv JitorVyacheslavNo ratings yet

- No. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22Document3 pagesNo. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22VyacheslavNo ratings yet

- HPW Oversiktsbrosjyre M. PT-logoDocument1 pageHPW Oversiktsbrosjyre M. PT-logoVyacheslavNo ratings yet

- No. 303,845. Patented Aug. 19, 1884.: C. W. HarrisDocument4 pagesNo. 303,845. Patented Aug. 19, 1884.: C. W. HarrisVyacheslavNo ratings yet

- 70? 3/2869. Azézéz Z24, /360.: Over %y VaultDocument2 pages70? 3/2869. Azézéz Z24, /360.: Over %y VaultVyacheslavNo ratings yet

- Us 20100329892Document14 pagesUs 20100329892VyacheslavNo ratings yet