Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsUs 20080292407

Us 20080292407

Uploaded by

VyacheslavCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SZAZ2%: Itz ZiiDocument4 pagesSZAZ2%: Itz ZiiVyacheslavNo ratings yet

- G: Evvvvv: OfessiaDocument5 pagesG: Evvvvv: OfessiaVyacheslavNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- United States Patent: (45) Date of Patent: Mar - 3, 2020Document15 pagesUnited States Patent: (45) Date of Patent: Mar - 3, 2020VyacheslavNo ratings yet

- G. E. V.On Hoff Mann.: Patented Nov, 8, 1921Document2 pagesG. E. V.On Hoff Mann.: Patented Nov, 8, 1921VyacheslavNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0172488 A1Document7 pagesPatent Application Publication (10) Pub. No.: US 2003/0172488 A1VyacheslavNo ratings yet

- 3.22. RT by His Diarney: Kitnessgs. Inv JitorDocument3 pages3.22. RT by His Diarney: Kitnessgs. Inv JitorVyacheslavNo ratings yet

- No. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22Document3 pagesNo. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22VyacheslavNo ratings yet

- HPW Oversiktsbrosjyre M. PT-logoDocument1 pageHPW Oversiktsbrosjyre M. PT-logoVyacheslavNo ratings yet

- No. 303,845. Patented Aug. 19, 1884.: C. W. HarrisDocument4 pagesNo. 303,845. Patented Aug. 19, 1884.: C. W. HarrisVyacheslavNo ratings yet

- 70? 3/2869. Azézéz Z24, /360.: Over %y VaultDocument2 pages70? 3/2869. Azézéz Z24, /360.: Over %y VaultVyacheslavNo ratings yet

- Us 20100329892Document14 pagesUs 20100329892VyacheslavNo ratings yet

Us 20080292407

Us 20080292407

Uploaded by

Vyacheslav0 ratings0% found this document useful (0 votes)

3 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

3 views6 pagesUs 20080292407

Us 20080292407

Uploaded by

VyacheslavCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

"US 200802!

cu») United States

2) Patent Application Publication — co) Pub. No.: US 2008/0292407 AL

Jonker et al.

(54) SYSTEM AND METHOD FOR INS

FOUNDATION ELEMENTS,

ALLING

(76) Inventors: Geert Jonker, Bussum (NL): Artis

Van Duljvenboden, Ktwijk Aan

Zee (NL)

GREENBERG TRAURIG, LLP

200 PARK AVE., PO. BOX 677

FLORHAM PARK, NJ 07932 (US)

(21) Appl. No. 11913,133,

(2) PCT Tiled May 3, 2006

(43) Pub, Date Nov. 27, 2008

(86) PCT No PCTIBP2006(062006

$371 OU.

@,@)Dae: May 8, 2008

G0) Foreign Application Pri

005

ity Data

May3,

ey 051037133

Publication Classification

(1) Incl

EOD 710 (2006.01)

(52) US.CL 405/228

6 ABSTRACT

Te invention pertains to a system (1) for installing founda

tion elements, such as ples or conductors (2), in a sub-sea

‘round formation (3), comprising a hydraulic driver (and a

power comerter (9) for generating hydraulic pressure in a

Enydraulc uid forthe diver (8). The driver (8) and the con-

verter (9) are aclapted to fit inside dhe Foundation elements (2).

4

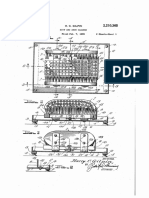

Patent Application Publication Nov. 27, 2008 Sheet 1 of 2 US 2008/0292407 AI

js

Patent Application Publication Nov. 27, 2008 Sheet 2 of 2

26

B—

Fig.2

US 2008/0292407 AI

US 2008/0292407 AI

SYSTEM AND METHOD FOR INSTALLING

FOUNDATION ELEMENTS,

10001} The invention pertains to a system for installing

‘oundation elements, suchas piles or conductors, in subsea

‘round formation, comprising a hydraulic driver anda power

‘converter for penerating hydraulic pressure in a hydraulic

{uid forthe driver. The iavention also relates to a method of

installing foundation element

[0002] "U.S, Pat, No, 4,964,473 relates to a method for

driving a hyde suhmerged too, whereby the hydraulic

pressure energy is generated ina submerged power converter

AAs explained in US. Pat, No. 4,964,473, uch a method was

the ar, ie, from the Netherlands patent

3240, which corresponds to US. Pat. No

{0003}

pile diver to which an clectcaly driven hymulic power

‘The latter document discloses hydraulically driven

Unit is attached in which electric power is converted into

hydraulic power. Feoding this power converter occurs by

supplying electric energy by electric cables to the power

‘converter ffom a generator located above water ashore, or on

4 ship or on a work platform. In the same way other sub

‘merged tools are driven, suchas drilling tools, sampling appa

ratuses and tools for working at or inspecting submarine

10008) The electrical cables are uncoled from a reel on

‘deck o follow the power converter lowered below the water

For work ships with ther restricted deck space and hoisting

‘capacity suchlike reels with eables and diesel-electric power

units are wery aggravating,

10005] Further, with an increase of the depth on which has

tobe worked, extension ofthe electric cables is lost impos:

sible or very complicated, because in most cases these are

‘combines cables lor eleetical power, electrical signals and

supply. These cables moreover ae rather heavy, costly and

vlaerable

10006] |The invention underlying U.S. Pat. No. 4.964.473

sims to provide a method as well asa device for driving 2

hydraulic submerge tool with whieh these problems can be

solved nan easy way. According o U.S. Pat. No. 4,964,473,

this object is obtained by driving the converter with pres

surised surounding water, which, after the enengy transfer, is

‘exhausted into the surrounding Water. Herewith a simple

drive is obtained whereby no retum conduct is necessary.

Especially with drilfing ships in which high-pressure sea

‘water pumps arealready present andin which thedeling pipe

‘composed of sections also ean be used for transporting the

pressurised sca water. this method will ive a considerable

‘cost redtion, wheres the working depth may be very large,

[0007] _Ttisanobjectof the present invention to improverthe

system according to the opening paragraph,

10008] To this end, the system according to the present

‘vention i characterised i tat the driver and the converter

are adapted to fit inside the foundation elements

[0009] This system enables so-called “pile toe driving”

‘without the need for an umbilical between the converter and

the driver,

10010] Typically, hydraulic pile drivers are connected to @

tank fora hydraulic fs and comprise a hydrauliceylinder,&

piston accommodated in the hydraulic cylinder, an impact

‘weight connected tothe piston, high and low-pressure ace

rmulators, a valve system for alterately connecting, the

Nov. 27, 2008

hydraulic eylinder (othe high and low-pressure aecumul-

tors, and conduits for operatively connecting these compo-

‘ents in a manner known in ise

[011] Ie is preferred thot the tank is mounted on or inte-

arated with thoconvercerIisalso preferred that theeylinder,

piston, accumulators, and the valvesystem are mounted on oF

Sntograted with the converter to form a converter drive unit

[0012] By integratingoneor more components of thedever

‘with the converter, preferably most orall components except

forthe impact weight, handling of the system is simplified, a

housing forthe weight may be omitted andlor tolerances and

shape of the weight become less erie

0013} To farther separate the weight from the converter

‘rive unit, iis prefered thatthe weight is comnected to the

piston by means ofa flexible element, such as a cable, chain

‘ortelescopie member, and preferably a shock absorber.

[0014] The invention further relates toa method of istall-

‘ng hollow foundation eloments, such as piles or conductors,

‘na sub-sea ground formation, by means ofa hydraulic driver

anda power converte for generating hydraulic pressure in a

hnydraulic fluid for the driver, which method comprises the

steps of (inna paticular order)

[0018] mounting the driver inside a foundation clement

‘and, typically subsequently, mounting the eonverter inside

the foundation element, and

[0016] lowering the foundation clement, the driver and the

power converter froma vessel, seh a an drilling platform oF

Ship, preferably by means ofa drill string.

[0017] It is profered that an energy’ transfering uid, in

particular water taken from the surroundings ofthe drilling

platform or ship, is fed to the convertor through the dill

string

[018] Its noted that WO 2004/051004 discloses a “pile-

riving apparatus comprising pile, ashoetip coupled toatoe

‘ofthe pile anda dil string disposed within he pile. The dell

String comprises gripping device eoupling the drill string to

the pile aad a hammer deployed into the ile such that the

‘hammers capable of transmitting force tothe shoe tp.” The

‘hammer receves fd (© generate the force, used to drive the

she tp, and controlling signals via an umbilical.

019} Further, U.S. Pat. No. 6.626.248 discloses a

“method fordeving adrive pipe into asub-Sea formation, said

‘method comprising: accelerating at east one mass relative to

the deive pipe, wherein the atleast one mass is aecelerated

‘within the drive pipe; transferring energy from the ecceler

ated atleast one mass tothe dive pipe: Suspending the drive

pipe froma dil string; and isolating [by means ofa “running

ool" the drill sting from the transfered energy from the

accelerated a least one mas

[0020]. ‘The invention will nose be explained in more detil

‘ith eference tothe figures, which show a preferred embod

‘ment ofthe system accorting to the present invention.

[0021] FIG. 1 schematically shows a system according 10

the present invention suspended from drilling platform by

‘means ofa drill ting.

[0022] FIG. 2 isan enlarge view of the system shown in

FIG.1.

[0023] It is noted thatthe drawings are not necessarily to

scale and tat details, which ate not required for understand.

ing the present invention, may have been omitted

[0024] The Figures show a system 1 for installing founda-

tion elements, such a tubular piles or conductors 2, in a

seabed 3, sespended from a drilling platform 4 hy means of =

cable, a reinforced umbilical or, preferably, a drill ting,

US 2008/0292407 AI

10025] In this example, the foundation element is so-

called conductor pipe 2, -e.a hollow metal tube, which typ

‘ally as length ina range from 50 to 125 m or even up 10

250m Gin deep Water) anda diameter ina range from 7010 100

‘em, for instance 30 0 36 inch, Nea its bottom, the conductor

Pipe? is provided with adrve shoe 6anda toe driveussembly,

steel plate ora solid stee! anvil.

10026] The system 1 comprises a hydraulic driver 8 and a

power converter 9 for generating hydraulic pressure in a

hydraulic uid and supplying the same to the dever 8, whieh

boll fit inside the conductor pipe 2

[0027] -Thedriver8 comprises a tank 10 for hydraulic Nu,

such as hydraulic oil or (seawater optionally including

appropriate additives, a hydraulic cylinder 11, a piston 12

reciprocatingly accommodated in the hydraulic eylindet 1,

high and low-pressureaccumulators 13,14, avalve system 18

for alterotely connecting the hydraulic cylinder 11 10 the

high and low-pressure secumultors 13, 14, a volume com

pensator (not shown), typically a piston compensator, for

‘compensating fhicttations of the volume of hydra iin

the tank 10 (esulting from the movements ofthe piston 12),

and an impact weight 17. Further, an acceleration chamber 16

is positioned above the piston 12 and connected tothe valve

system 1S.

10028] Inaccondance witha preferred aspect ofthe present

Svention, the impact weight 17 has been separated from the

‘ther components 10-18 ofthe dever 8 ad has been adapted

to reciprocate inside the conductor pipe 2. The impact weight

17 comprises a plurality of guides 18, preferably mounted

slong the circumference ofthe impact weight 17 and at least

‘aC oF near its upper and lower ends. The guides 18 abu the

‘inner wall of the foundation element 2 and are preferably

made ofa synthetic material, such as HDPE, ora metal, sueh

ts brass. The guides IN eliminate nearly all wear on the

impact weight 17 and allow the weight 17 t work at inclina-

10029] The impact weight 17 is connected tothe ower end

‘ofthe piston 12 by means ofa flexible element 19,e.2. steel

‘able, and a shock absorber 20

10030] The converter 9 is preferably a uid pressure con-

verter comprising a so-called mud motor 24 a Mid inlet 22

‘connected fo the cil string , such that a fluid, in particular

seawater taken from the surroundings of the dling platform

44-canbe fod through the dil string 5 tothe converter 9, and

‘pump 28 connected the high-pressoreaccuimulator Land

the valve system 15, Further, conduits 24,28 are provided to

‘connect the low-pressure accumulator 14 tothe tank 10 and

the pump 23 tothe tank 10 and the high-pressure aceumulator

13, respectively.

10031] |The mud motor 21, ex. 2 Moyno 962N3460 or a

21288625 ex Roper pumps is known in tel and comprises

‘8 power section, connected, via the fluid inlet 22, to the dill,

string 8, a tansmission, and an output shalt connected to the

pump 23,

10032] In an alternative embodiment (oot shown), mostly

suitable for foundation elements having a lange diameter, the

‘converter comprises one or more work eyinders, which each

by means ofa Mating piston are divided ina space filed with

pressurised water and a space filled with a hydnalie work

medium, switching means being provided which are set

‘ated each time that a floating piston reaches the end of its

work stroke, by reason of which at each work eylinder the

space which can be filled with pressurised water altematly is

‘connected either to a feed conduit of pressurised water,

Nov. 27, 2008

particular the dil string 8, o oa fee exhaust (aot shown),

‘ach work eylinder atthe side ofthe hydraulic work medusa

being connected © the pressure conduit 28 running to the

high-pressure accumulator 13. With this relatively simple

vice, a practically loss free energy conversion is realize

Funluer deus on this type of converter canbe found in US.

Pat, No. 4,964,473, which is incorporated herein by refer

[0033] In the preferred embodiment shown in the Figures,

the tank, cylinder, piston, accumlators, and valve system

hha been integrated with the converter fo form a converter

river unit 26. An expandable ring, for instance so-called

packer 27, ora gripper has been attached about the czcum-

ference ofthe wit 26, eg, halfway or at both the upper and

Jower ends ofthe unit 26, to temporarily secure the unit 2610

the inner wall of the foundation element 2. Optionally, the

sing 27 andthe anvil 7 provide ar ght seals, in which case

water below the unit 26 can be replaced by e.g. air ths

reducing the resistance on the impact weight 17 during recip-

‘cating movement inside the foundation element 2

[0034] The conductor pipe 2 is installa in the seabed 3, by

Jowering the conductor pipe 2 from the platform 4 into the

sa, mounting the impact weight 17 and the converter driver

‘uit 26 inside the pipe 2 attaching the converter diver u

‘the dilsring, securing the latter agains the inner wall of the

pipe 2, eg. by expanding the ring 27 andlor connecting the

pipe 2 to the dell sting $ by means of (W)ROV diseonnect-

able slings, lowering the assembly thus obtained from the

tilling platform 4 by means ofthe dil string 8, and pos

‘ioning the condvetor pipe 2 on the seabed 3.

[0035] The operating eyele begins with an upward move-

‘ment involving the iting ofthe piston 12 and the impact

‘Weight 17, A first valve (within the valve system 15) ia the

high-pressure line (2) is opened snd a second valve in the

relum line (24) is closed, Once a preset siroke has boca

‘eachied, the fist valve is closed and the socand valve pened,

allowing the impact weight 17 wo sta its dawavard move.

‘ment. In this example, the flexible element 19 is sufficiently

short to enable the piston 1210 abut and hence accelerate the

impact weight 17 during downward movement by connecting

the chamber 16 above the piston 12 to the high-pressure line,

aiving the impact weight 17 total seceleration of up to 2 2

‘This reduces the actual stoke required andinereasesthe bow

rate. At impact the weight strikes the anvil7 and the pipe 2 is

riven into the seabed 3

[0036] From the above examples it willbe clear tht sys-

fem according to the invention enables so-called “pile toe

driving” without the need for an umbilical Between the eon-

verter and the driver Purler, by integrating one or more

components of the diver with th converter, preferably most

forall components exeept for the impact Weight, handling of

the system is simplified, a housing for the weight may’ be

‘omitted and/or tolerances and shape of the weight become

less erties

[0037] The invention is not restricted to the abovede-

sod embodiments, which ean be varied in a number of

‘ways within the scope of the claims. or instance, the impact

‘weight (17) may be rigidly connected to the piston (12). The

smeans (27) fr securing the converter driver unit the inner

‘wall of the foundation element ean be employed to absor®

torque generate in the converter, thus reducing or even pre-

venting torque inthe drill string

[038] Also, the converter may comprise two or more

‘Pumps, ez Wo main pumps driven in opposite direeto

US 2008/0292407 AI

(oan, ducing torque) and a pump for diving a jet for

removing obstacles in the way ofthe impact weight.

10039] "Further, the converter andl driver can be configured

‘separate units, preferably connected by «exible element

‘and suitable conduits forthe hydra ful andor each pro>

Vided with a means for securing the same to the inner wall of

the foundation clement

1. System (1) for installing foundation elements, such as

piles or conductors (2), in a sub-sea ground formation (3),

‘comprising & hydmulc diver (8) and a power converter (9)

Jor generating hydraulic pressure ina hydraulic Mui forthe

driver (8) characterisedin thatthe driver(®) and theconverter

(0) are adapted to fit inside the foundation elements (2).

2. System (1) according o elas 1, comprising a tank (10)

{ora hydraulie Mud, whieh tank (10) is mounted on or inte-

rated withthe converter (9),

3, System (1) acconiing to claim 1 or 2, comprising a

hydraulic eylinder (11), a piston (12) accommodated in the

hydraulic eylinder (11), high and low-pressure secumultors

(13.14), and a valve system (18) fr alternately connecting

theirydrauiceylinder(11) tothe high and low-pressure acew-

mulators (13, 14), wherein the eylinder (11), piston (12),

accumulators (13, 14), and valve system (18) aremounted on

‘or integrated with the converter (9; 26),

4 System (1)according to any anc the preceding claims

‘comprising an impact weight (17) adapted to reciprocate

inside a foundation element (2) and preferably to abut the

‘nger yall ofthe foundation element 2), which impact weight

(17) is connected to the piston (11) by means of a fexible

element (19).

8, System (1) according toany one ofthe preceding claims,

‘comprising an acceleration compartment located above the

Piston (11) andior communicating with chamber (16) above

the piston (11).

6. System (1) according to any one ofthe preceding claims

wherein the driver (8) and/or the converter (9; 26) comprises

‘ameans for securing the driver (8) and/or the converter 9:16)

‘and any components integrated therewith to de inner wall of

the foundation clement 2).

Nov. 27, 2008

7. Systea (1) aocording to any one ofthe preceding els

wherein the converter (9; 26), preferably a fluid pressure

converter comprises a Mud inlet adapted to be connected toa

rill string (8), sueh that a fluid can be fed through the dil

string (S) tothe converter (9; 26)

8, Method of installing hollow foundation elements, such

aspiles or conductors 2), na sub-sea ground formation (3)

by icons ofa hydaalc driver (8) and a power comverter (9)

{or generating hydraulic pressure ina hydraulic uid forthe

river (8), which method comprises the steps of

‘mounting the driver (8) andthe converter (9:26) inside the

foundation elemeat (2).

lowering the foundation element (2), the diver (8), andthe

power converter (9) from a vessel (4).

9. Method according to claim 8, wherein the converter (9

26) and any components integrated therewith is lowered by

‘means of drill string 8).

10, Method according to claim 9, wherein sn enengy trans-

‘ering, id s Fed tothe converter (9; 26) through the dil

string (8).

11, Method aecording o any one of claims 8-10, wherein

te driver (8) and the power converter (9) re positioned and

preferably scoured inside the foundation clement (2) before

Jowering the foundation element (2), the driver (8), and the

power converter (9) tothe formation (3)

12, Method aecording to any one of claims 8-11, wherein

the converter (9; 26) and elemens integrated therewith are

secured to the inner wall of the foundation clement (2)

13, Method aecording to any one of claims 8-12, wherein

water below the converter (9; 26) is replaced by a gs, thus

reducing the resistance on the impact weight (17) during

‘eiprocating movement inside the foundation element (2).

14. Method! according o any one of claims 8-13, whorcin

the impact weight (17). during reciprocating movement, is

agided hy the inner wall ofthe foundation clement (2,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SZAZ2%: Itz ZiiDocument4 pagesSZAZ2%: Itz ZiiVyacheslavNo ratings yet

- G: Evvvvv: OfessiaDocument5 pagesG: Evvvvv: OfessiaVyacheslavNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- United States Patent: (45) Date of Patent: Mar - 3, 2020Document15 pagesUnited States Patent: (45) Date of Patent: Mar - 3, 2020VyacheslavNo ratings yet

- G. E. V.On Hoff Mann.: Patented Nov, 8, 1921Document2 pagesG. E. V.On Hoff Mann.: Patented Nov, 8, 1921VyacheslavNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0172488 A1Document7 pagesPatent Application Publication (10) Pub. No.: US 2003/0172488 A1VyacheslavNo ratings yet

- 3.22. RT by His Diarney: Kitnessgs. Inv JitorDocument3 pages3.22. RT by His Diarney: Kitnessgs. Inv JitorVyacheslavNo ratings yet

- No. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22Document3 pagesNo. 530,707. Patented Deo. 11, 1894.: Ce (E2A Aste) - 22VyacheslavNo ratings yet

- HPW Oversiktsbrosjyre M. PT-logoDocument1 pageHPW Oversiktsbrosjyre M. PT-logoVyacheslavNo ratings yet

- No. 303,845. Patented Aug. 19, 1884.: C. W. HarrisDocument4 pagesNo. 303,845. Patented Aug. 19, 1884.: C. W. HarrisVyacheslavNo ratings yet

- 70? 3/2869. Azézéz Z24, /360.: Over %y VaultDocument2 pages70? 3/2869. Azézéz Z24, /360.: Over %y VaultVyacheslavNo ratings yet

- Us 20100329892Document14 pagesUs 20100329892VyacheslavNo ratings yet