Professional Documents

Culture Documents

69 - RA For Installation of Fire Fighting Piping in Confined Space

69 - RA For Installation of Fire Fighting Piping in Confined Space

Uploaded by

UMUTCopyright:

Available Formats

You might also like

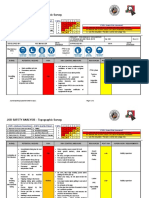

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Ansi A 10.8 2001 PDFDocument107 pagesAnsi A 10.8 2001 PDFCompetencias Bureau Veritas100% (2)

- SCAFFOLDING Method Statement Fv2Document4 pagesSCAFFOLDING Method Statement Fv2blackwellkid100% (1)

- Cuplok Scaffold System: User GuideDocument11 pagesCuplok Scaffold System: User Guideezzularab100% (1)

- Piling Works, Pile Head Cutting and Trimming at Pipe BridgeDocument28 pagesPiling Works, Pile Head Cutting and Trimming at Pipe BridgeAlif Shahril100% (1)

- General Principal and Concept of Occupational Safety & Health and Environment (OSHE)Document79 pagesGeneral Principal and Concept of Occupational Safety & Health and Environment (OSHE)aimamNo ratings yet

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- 4.2 Safety Data sheet-FEVICOL AC DUCT KING DUCT SELEANT-3278Document3 pages4.2 Safety Data sheet-FEVICOL AC DUCT KING DUCT SELEANT-3278UMUTNo ratings yet

- CG8 - 18 Preparation of QuotationsDocument2 pagesCG8 - 18 Preparation of QuotationsArdamitNo ratings yet

- Doka Automotif Climbing FormworkDocument32 pagesDoka Automotif Climbing FormworkRafa Rahmat FaddisNo ratings yet

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (2)

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Risk Assessment For Excavation and BackfillingDocument5 pagesRisk Assessment For Excavation and BackfillingBulent AkNo ratings yet

- Safe Work Method Statement (SWMS)Document5 pagesSafe Work Method Statement (SWMS)CK TangNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- Risk and ContingencyDocument34 pagesRisk and ContingencyMary Ingrid Arellano RabulanNo ratings yet

- Excavation ChecklistDocument4 pagesExcavation ChecklistCINQO HSENo ratings yet

- Change Risk Assessment TemplateDocument12 pagesChange Risk Assessment TemplateAlvaro Duviel AldanaNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)contrax8No ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- RAID Register - SapphireDocument11 pagesRAID Register - SapphireMuhammadMuzammalJamilNo ratings yet

- Change Risk Assessment TemplateDocument10 pagesChange Risk Assessment TemplatePhụng LêNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- Safe Work Method SWMS 30jun17Document2 pagesSafe Work Method SWMS 30jun17professional accountantsNo ratings yet

- Nosaexecutivereport040713 4191Document8 pagesNosaexecutivereport040713 4191Marius BuysNo ratings yet

- Generic Risk Assessment Rescues From Tunnels and Underground StructuresDocument5 pagesGeneric Risk Assessment Rescues From Tunnels and Underground Structurestumelo makgabutlaneNo ratings yet

- Risk ManagementDocument5 pagesRisk ManagementmominNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- 215 Using of P.P.E.Document10 pages215 Using of P.P.E.grantNo ratings yet

- 334 - Manual Handling of GRP PipingDocument7 pages334 - Manual Handling of GRP Pipingcontrax8No ratings yet

- 330 - Element 5.02 Using of Stanley Knife (EPCM)Document8 pages330 - Element 5.02 Using of Stanley Knife (EPCM)grantNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- RA For Block WorkDocument4 pagesRA For Block WorkMd.Imtayaj AhmadNo ratings yet

- 210 On and Off Loading of Vehicles and TrucksDocument15 pages210 On and Off Loading of Vehicles and TrucksgrantNo ratings yet

- Cable Tray InstallationDocument3 pagesCable Tray InstallationIzzy TudtudNo ratings yet

- QUALITY RISK ASSESMENT BlankDocument3 pagesQUALITY RISK ASSESMENT BlankAlbert NajjarNo ratings yet

- Block Work Risk AssessmentDocument4 pagesBlock Work Risk Assessmentabdelghafour megaacheNo ratings yet

- Department of Social Welfare and Development Integrity Management Committee Name of Office/Agency/Division/UnitDocument10 pagesDepartment of Social Welfare and Development Integrity Management Committee Name of Office/Agency/Division/UnitNELSON NISPEROSNo ratings yet

- IG2 - SOP For Risk Assessment 3SLSADocument14 pagesIG2 - SOP For Risk Assessment 3SLSAMahbub KhanNo ratings yet

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- F-025 TCM Incident Investigation Report Form Rev A3Document4 pagesF-025 TCM Incident Investigation Report Form Rev A3Mohammed AbdulNo ratings yet

- 331 - Element 5.02.17 Handling and Storage of HCS and Flammable LiquidDocument8 pages331 - Element 5.02.17 Handling and Storage of HCS and Flammable LiquidgrantNo ratings yet

- Sample Use: ExcavationDocument4 pagesSample Use: ExcavationMd FahadNo ratings yet

- 2-HEMP-Hazards and Effects ManagementDocument17 pages2-HEMP-Hazards and Effects ManagementShahid IqbalNo ratings yet

- 11 - Commission Inspection ModeDocument10 pages11 - Commission Inspection Modeyoen_anNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- EMS Risk RegisterDocument5 pagesEMS Risk RegistermominNo ratings yet

- Jigcc-Abd - A05-Hs-Ra - 01Document13 pagesJigcc-Abd - A05-Hs-Ra - 01Shovon khanNo ratings yet

- Job Hazard Analysis (JHA) : Feb 5 2021 HTS Engineering MT Dennis - THESL RoomDocument3 pagesJob Hazard Analysis (JHA) : Feb 5 2021 HTS Engineering MT Dennis - THESL RoomCharity KingNo ratings yet

- RA For ROAD WORKS - EXCAVATION AND PIPES INSTALLATIONDocument14 pagesRA For ROAD WORKS - EXCAVATION AND PIPES INSTALLATIONLawrence adeleke OmisakinNo ratings yet

- APP J Risk RegisterDocument1 pageAPP J Risk Register--No ratings yet

- Adac Asgtc 2018 Ra 07 Hot WorkDocument3 pagesAdac Asgtc 2018 Ra 07 Hot Workabubakrelsaid90No ratings yet

- Msra IneltecDocument23 pagesMsra IneltecAmit BhattNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- 212 Using of Portable Electrical EquipmentDocument12 pages212 Using of Portable Electrical EquipmentgrantNo ratings yet

- SFC Doc1Document25 pagesSFC Doc1Don Rulas MosotiNo ratings yet

- RA - The AtelierDocument45 pagesRA - The AtelierMd ShahinNo ratings yet

- Engineering Change Request: Oil & Gas Development Company LimitedDocument4 pagesEngineering Change Request: Oil & Gas Development Company LimitedSyed Mustafa HussainNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Total Risk Management Kingdom DrillingDocument15 pagesTotal Risk Management Kingdom Drillingbengam100% (3)

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- Accelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsFrom EverandAccelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsNo ratings yet

- Job Safety Analysis (JSA) : Sl. No. Department Equipment Location Job DescriptionDocument1 pageJob Safety Analysis (JSA) : Sl. No. Department Equipment Location Job DescriptionUMUTNo ratings yet

- COVID-19 Prevention & Protection Plan: New PTA Complex ProjectDocument15 pagesCOVID-19 Prevention & Protection Plan: New PTA Complex ProjectUMUTNo ratings yet

- JSA-Lifting-Loading&Unloading With CraneDocument3 pagesJSA-Lifting-Loading&Unloading With CraneUMUTNo ratings yet

- Attendance Sheet: Name Company Position Id No. SignatureDocument1 pageAttendance Sheet: Name Company Position Id No. SignatureUMUTNo ratings yet

- Pln-Hse-Pta-0001 Hse PlanDocument109 pagesPln-Hse-Pta-0001 Hse PlanUMUT100% (1)

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Armaflex Sheet and Roll MSDSDocument1 pageArmaflex Sheet and Roll MSDSUMUTNo ratings yet

- JSA-Substructure Concrete WorksDocument5 pagesJSA-Substructure Concrete WorksUMUTNo ratings yet

- EC Safety Data SheetDocument9 pagesEC Safety Data SheetUMUTNo ratings yet

- E-Z Weld 786 CPVC CementDocument12 pagesE-Z Weld 786 CPVC CementUMUTNo ratings yet

- Safety Data Sheet: Acetylene (Dissolved)Document2 pagesSafety Data Sheet: Acetylene (Dissolved)UMUTNo ratings yet

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (2)

- Heavy Duty Solvent Cement For PVC Plastic PipeDocument2 pagesHeavy Duty Solvent Cement For PVC Plastic PipeUMUT100% (1)

- Control of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeDocument4 pagesControl of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeUMUTNo ratings yet

- JOB Hazard Analysis C: ArpenterDocument2 pagesJOB Hazard Analysis C: ArpenterUMUTNo ratings yet

- 7.7 MSDS Armaflex 520Document11 pages7.7 MSDS Armaflex 520UMUTNo ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- Module3-Safety Personnel Assessment-SPADocument37 pagesModule3-Safety Personnel Assessment-SPAfarrukhNo ratings yet

- Guidelines Intershield300Document24 pagesGuidelines Intershield300biondimiNo ratings yet

- 09 Catalog Krisbow 9 Ladder ProductDocument6 pages09 Catalog Krisbow 9 Ladder ProductEnrique da MattaNo ratings yet

- Monsoon Preparedeness Plan Mumbai-ProjectDocument8 pagesMonsoon Preparedeness Plan Mumbai-ProjectHAMON COOLING SYSTEMSNo ratings yet

- Risk Assessment Forms - Appendix 5 (22102016)Document2 pagesRisk Assessment Forms - Appendix 5 (22102016)Sơn Nguyễn-Lê100% (1)

- CPCCLSF3001 Intermediate ScaffoldDocument107 pagesCPCCLSF3001 Intermediate ScaffoldArdamitNo ratings yet

- New Candidates Observation SheetsDocument6 pagesNew Candidates Observation SheetsRay Mathews0% (1)

- Scafflding Safety Farouk ArabicDocument25 pagesScafflding Safety Farouk ArabicMoh_Elberry100% (1)

- 016 Procedure ScaffoldingDocument13 pages016 Procedure ScaffoldingHSE CERINo ratings yet

- !!scaffolding Software - Home PageDocument4 pages!!scaffolding Software - Home PageasmaNo ratings yet

- Konza Site DS Weekly HSE Status Report 29.01.2024 Rev 1Document18 pagesKonza Site DS Weekly HSE Status Report 29.01.2024 Rev 1kiragukabereNo ratings yet

- Cop Safe Work On Roofs Part 2 0308Document44 pagesCop Safe Work On Roofs Part 2 0308Scooby DooNo ratings yet

- Catalogo de MaterialesDocument35 pagesCatalogo de MaterialesCarlos Andres Orellana DiazNo ratings yet

- Construction - Scaffold Checklist - HSEDocument6 pagesConstruction - Scaffold Checklist - HSEroldskiNo ratings yet

- Vedanta Limited: Cairn Oil & GasDocument32 pagesVedanta Limited: Cairn Oil & GasOws AnishNo ratings yet

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Document46 pagesNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- Building Constructio N LDocument55 pagesBuilding Constructio N LOliver Del CarmenNo ratings yet

- Catalogo Overview PERI UPDocument36 pagesCatalogo Overview PERI UPAlberto Diaz Herrera100% (1)

- Attachment 16. Site HSSE PlanDocument79 pagesAttachment 16. Site HSSE PlanCristianMontoyaMujica100% (1)

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- JSA Form FilledDocument3 pagesJSA Form FilledSanthoesh srinivasanNo ratings yet

- Construction Checklist: SL. NO. Check ItemDocument2 pagesConstruction Checklist: SL. NO. Check Itemenjoy begening lifeNo ratings yet

- Lesson 8 - Form Scaffolding and StagingDocument7 pagesLesson 8 - Form Scaffolding and StagingROMNICK HANDAYANNo ratings yet

- SG10 - 08 Brick GuardsDocument1 pageSG10 - 08 Brick GuardsMIKE HarwoodNo ratings yet

69 - RA For Installation of Fire Fighting Piping in Confined Space

69 - RA For Installation of Fire Fighting Piping in Confined Space

Uploaded by

UMUTOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

69 - RA For Installation of Fire Fighting Piping in Confined Space

69 - RA For Installation of Fire Fighting Piping in Confined Space

Uploaded by

UMUTCopyright:

Available Formats

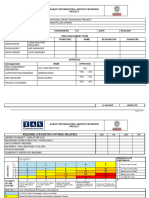

RISK ASSESSMENT FORM

NOTE: THIS DOCUMENT SHOULD BE ATTACHED TO THE METHOD STATEMENT. WHEN APPROVED IT

MUST BE KEPT AT THE WORKING PLACE FOR REFERENCE PURPOSES

PROJECT BIA –Modernization Program

TASK DESCRIPTION Installation of Fire Fighting Pipes in Confined Space

SUBCONTRACTOR Sonmez Metal

LOCATION Project wise

ASSESSMENT NO 069 REVISION NO 00 DATE 29/08/2017

RISK ASSESSMENT TEAM

NAME DESIGNATION SIGNATURE NAME DESIGNATION SIGNATURE

Tajummal Khan SONMEZ HSE Manager

SONMEZ Construction

Cenk Gencal

Manager

APPROVAL

DESIGNATION NAME APPROVED COMMENTS

RISK ASSESSMENT

ORIGINATOR

Tajummal Khan N/A

CONSTRUCTION / DİSCİPLİNE

MANAGER

Serkan Vanizor YES NO

HSE MANAGER Ufuk EROL YES NO

PROJECT ENGINEER YES NO

REQUIRED AND EXISTING CONTROL AVAILABLE ADEQUATE ATTACH TO MS DOCUMENT

MEASURES YES NO YES NO REMARKS

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:1 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

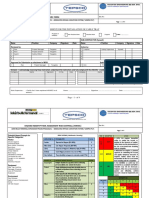

RISK ASSESSMENT FORM

METHOD STATEMENT – STEPS OF THE TASK

PROCEDURES (WORK INSTRUCTION, VENDOR

SPECS.)

SPECIAL PERMITS REQUIRED

EQUIPMENT / TOOLS REGISTERS AVAILABLE

TRAINING REQUIRED

COMPETENCY CERTIFICATES REQUIRED

SEVERITY FREQUENCY OF LIKELIHOOD

1 1 2 3 4 5 1 Very Low (once in a year)

LIKELIHOOD

2 2 4 6 8 10 2 Low (once in three months)

3 3 6 9 12 15 3 Medium (once in a month)

4 4 8 12 16 20 4 High (once in a week)

5 5 10 15 20 25 5 Very High (Every day)

1 2 3 4 5 X

SEVERITY Serious (S) (Hospital

OF THE Very Low (VL) (first aid Low (L) (First aid is given, Medium (M) (Hospital Very serious (VS) (death,

treatment is needed, more

is given. Work may be 1 or 2 days of leave is treatment is needed, 3 days loss of limb, occupational

HAZARD carried on) given) leave is given)

than three days of leave is

diseases)

given)

Risk Class = Severity of the Hazard X Frequency of Likelihood

L Low Risk; No need to take emergency action, on-site training

M Medium Risk; Measure shall be taken, on-site training, warning signs, document

H High Risk; Stops the work, emergency measure shall be taken, strict measures, change in work schedule, training

Very High Risk: stops the work immediately, emergency measure shall be taken, inspection of site risks and decreasing the risk class with the new measures to be taken, drafting new work

VH schedule

Risk Analysis Control Measures Residual Risk Additional control

Description of Measures

No Activity Hazards (Hierarchy of Measures; Elimination, Scor

the Risk S L Score S L

Substitution, Engineering Controls, e

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:2 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

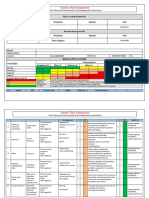

RISK ASSESSMENT FORM

Administrative Controls, PPE)

Tidy site; clear defined walkways,

Suitable and sufficient steps into huts and

kept in good condition,

Aware of first aid station, site emergency

assembly point, drinking water station, toilet

rest shelter and temporary facilities. Construction

Drinking water station or water cooler to be Manager /Site

provided. Engineer must

Genaral activity in Slip/Trip and Serious injury, Periodically breaks in hot weather. ensure the

1 workplace and falls, extreme unconciusness/ 4 3 12 3 1 3 necessary welfare

Awareness to workers to use plenty of

welfare facilities temprature fainting cooled drinking water and ORS – if required. arrangment.

Work perform by buddy system (two or

more workers crew). Effective fulltime

All necessary PPE worn as per project supervision

requirement.

Adequate illumination (access & task) if any

work to be carried out after sunset.

Mobilization/demobilization form to be used.

Work perform by buddy system (two or

more workers crew).

Drinking water station or water cooler to be

provided.

Awareness to workers to use/ drink plenty

of cold drinking water and ORS – if required.

extreme Periodically breaks in hot weather to be

temprature/ heat provided.

5 4 20 4 1 4

Work in Hot stress, lack of unconciusness/ Aware of first aid station, site emergency Pre-task briefing

weather welfare facilities, fainting, death assembly point, drinking water station, toilet to be conducted

2

no supervision, rest shelter and temporary facilities.

working alone Tool box training to be conducted.

Air fan and shaded rest place to be

provided.

Emergency response plan to be

communicated.

5 3 15 Designated route to be determined by 3 1 3

Collision Contractor

3 Conflict between Adequate traffic management plan

various users. Back up alarm while reversing heavy

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:3 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

Being hit by equipment

Plant movement moving Serious Injury Trained flagmen

machinery and Property Damage Follow Client’s guidelines. Toolbox Talk

vehicles. Risk of Proper signage to be installed, Training

crushing when Proper lighting will be installed (Ref:

heavy equipment BIA.HSE.PL01-section 26. PLANT AND

is reversing. EQUIPMENT INTEGRITY)

4 While manual lifting of material use proper

handling techniques.

(Manual Use buddy system to lift the load.

handling) Keep back straight and mold the knees

Serious injury, while manual lifting the load. Manual Handling

Poor handling Muscular skeletal Maximum 20 Kg can be allowed to lift Training and Tool

3 3 9 3 1 3

techniques, fall of disease/ back manually. Box Talks

personnel, bone injury,

Material shall be temporarily stored in

material from property damage

proper packing on flat area over wood

height

spacers to avoid damage

Manual Handling, Use proper PPEs.

lifting & shifting

Obtain lifting permit for HIAB truck.

by HIAB truck and

Conduct pre-task briefing.

fork lifter

(Mechanical HIAB truck and forklift to be appropriate for

Lifting) loads and situated so they do not over sail

adjacent buildings without necessary

precautions.

Topple of HIAB Only trained workers to be engaged.

truck or forklift Radius to be cleared from any movement.

4 3 12 Activity to be carried out according to MS 4 1 4

Collapse onto and Work should be stopped it there is any

buildings & over Serious injury deviation in work methodology.

sailing existing Property damage Original 3rd party certificates to be verified

structures/public prior to engage any lifting equipment,

areas operator, riggers and all lifting gears. Toolbox Talk

Daily inspection to be done by operator. Training and

Load droppings Certified Rigger to be assigned. close monitoring

Tag lines are used to control the load. by supervisor

Struck by moving Lifts are not allowed with wind speed in

machinery or fix excess of 10 meter/ second.

object Exclusion zone with caution signs.

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:4 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

Area shall be barricaded and personnel

entry shall be controlled where pipe or other

material being lifted.

To be make sure that fire extinguisher is

mounted on the HIAB truck and forklift

(Ref: BIA.HSE.PR14-Crane & Lifting

Procedure)

For CSE work;

BIA.HSE.PR12 Confined Space

Entry Procedure and Attached

Rescue Plan to be followed.

Confined space permit to be obtained &

gas testing to be conducted.

Explosive proof light to be provided inside

the tank for illumination.

Milan rescue device and life line to be

inspected before use.

Trained entry attendant must be assigned

and all personnel shall sign at in/out log.

Preparation and Work in All personnel shall enter into confined space

Entry into excavation may wearing the full body harness (FBH).

Confined Space Unconciouseness

cause/ include Workers shall never entered into tank/ Training,team

Physical Injury,

Fall hazard 4 4 16 Confined space if oxygen level is less than 4 1 4 briefing and

property damage,

Poor access to 19.5 %. Mechanical ventilation will be moniroting

fire,

the tank, oxygen arranged during work inside CSE.

deficiency Environment test will be done after each 02

5

hours and reading will be recorded.

Appropriate ladder for entry into confined

space for preparation of scaffolding and gas

testing to be used. Ladder to be secured

from top.

Control un-authorized entry.

Only trained operatives to be engaged.

Proper access to be provided into and

outside the tank.

Correct tools to be used.

Work to be done as per approved MS.

Proper PPE to be worn by workers

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:5 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

6 Third party certificate for chain block to be

verified and secured.

Store/ handle chain block correctly.

Only trained operative to be engaged.

Inspect chain block prior to use.

Failure of chain Pipes shall be resting freely on supports and

block carefully aligned prior to final connection.

Serious Injury,

Fall of load Check that the bottom hook will reach its Team briefing and

fatality and 5 4 20 4 1 4

Fall of load on lowest point without running the chain fully moniroting

property damage

working crew out.

All temporary support shall be installed

carefully.

Area to be cordoned off for unauthorized

Pipe Installation entry.

Required PPE to be worn.

Activity to be carried out according to MS

and Work should be stopped it there is any

deviation in work methodology.

Scissor lift to be inspected by operator, third

party certificate to be verified and secured.

Area to be barricaded and sign shall be

posted.

The platform is properly guarded and not

Fall of material

Serious injury or altered/ damaged.

and personnel

fatality All scaffolding to be erected and dismantled

from height, Pre-task briefing

5 4 20 by only certified scaffolders. 4 1 4

topple of mobile

Property damage All scaffolding to be inspected by competent

scaffolding and

and certified scaffolding inspector and tag to

scissor lift

be installed.

FBH must be used and anchored.

Ensure scaffolding is safe to use prior to

start the work at height.

All workers must be trained for confined

space entry.

Don’t stay between pipe and tanks walls

when pipe is lifted.

4 3 12 4 1 4

Only trained operator to be engaged/

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:6 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

assigned.

Power tools All tools to be inspected and color coded.

(cutter, drill Area shall be inspected prior to start of

machine) work.

operation for All flammable and combustible material shall

hangers and be removed from work area.

support cutting Serious Injuries Suitable fire extinguisher to be placed.

and installation (eye and body), Site portable electrical tools shall be 110V.

Toolbox Talk

may cause electrocution All cables kept off the ground or

Training

electric Shock hearing underground to avoid tripping hazard.

Slip trip and fall impairment, Work at height safety measures shall be

Sharp Edge property damage taken.

Flying objects, All tools to be disconnected from power

noise, damaged source when not in service/ use.

grinding disk, Combustible material to be removed and

proper housekeeping to be maintained.

Suitable PPEs including ear muffs/ plugs

shall be worn by the operatives.

7 Hydrotesting Improper Seious Injury 4 3 12 Inspection and ensure proper connections 4 1 4 Toolbox talk and

(Pressurizing and connection of Water Logging before starting the work. close moniroting

depressurizing) hose and (Soil Approved hydro testing procedure to be

accessories, Hose Contamination) followed.

rupture, Hose Secure the hoses with whip checks and

leaks. safety pins

Un calibrated Use only rated capacity hoses for the job.

pressure Ensure that only trained and competent

gages/test personnel to arrange/fix the pipeline

manifold. pressure test equipment and instruments.

Defective Ensure fittings and joints are appropriate for

pressure gage. the pressurization of unit.

Over Follow the approved hydro testing

pressurizing. procedures/ method statements.

Ensure the pressure monitoring device is

Spillage and slip installed at weakest portion of the segment

to be hydro-tested.

Use calibrated pressure gauges.

Use pressure gauges on its intended

purpose only.

Monitor the pressure gauge from a safe

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:7 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

distance away from the potential source of

high pressure jetting (Such as Flange Joint,

Spade, and Coupling etc.)

Do not leave the pressurized hose or pump

unattended when the hydro-test is on-going.

Isolate the equipment from all source of

energy when not in use.

Pressurized the line maximum up to desired

pressure limit 14 Bars. (Ref. to Method

statement for the subject activity).

Depressurized system before disconnecting

hoses and removal of any fittings.

Use rated manifolds with test pressure

certificates

Keep warning signs and testing area to be

Barricaded.

Pressurizing to be done slowly and steadily

Engage competent personnel on the job.

Pressure fluid shall be drained according to

method statement.

Proper supervision

Slipping and Injury, property and

Wind-up and

8 Tripping, poor damage, air 3 3 9 All loose material to be secured and dispose 3 1 3 implementation of

housekeeping

housekeeping polution on regular basin in approved bins. housekeeping

policy

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page:8 of 9

HSE Manager : Construction Team: Next Rev. Date: 28.02.2018

RISK ASSESSMENT FORM

RISK ASSESSMENT COMMUNICATIONS FORM

I, THE UNDERSIGNED HEREBY ACKNOWLEDGE THAT THIS RISK ASSESSMENT HAS BEEN DISCUSSED WITH ME AND THAT I UNDERSTAND THE CONTENTS

AND THE RISKS INVOLVED IN THE TASK TO BE PERFORMED. I HAVE ALSO BEEN INSTRUCTED ON THE SAFE METHODS TO PERFORM THIS TASK.

NAME COMPANY POSITION SIGNATURE

Doc. No. : BIA.HSE.PR04.FR01 Rev. No: 00 Rev. Date: 29.08.2017 Page: 9 of 9

You might also like

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Ansi A 10.8 2001 PDFDocument107 pagesAnsi A 10.8 2001 PDFCompetencias Bureau Veritas100% (2)

- SCAFFOLDING Method Statement Fv2Document4 pagesSCAFFOLDING Method Statement Fv2blackwellkid100% (1)

- Cuplok Scaffold System: User GuideDocument11 pagesCuplok Scaffold System: User Guideezzularab100% (1)

- Piling Works, Pile Head Cutting and Trimming at Pipe BridgeDocument28 pagesPiling Works, Pile Head Cutting and Trimming at Pipe BridgeAlif Shahril100% (1)

- General Principal and Concept of Occupational Safety & Health and Environment (OSHE)Document79 pagesGeneral Principal and Concept of Occupational Safety & Health and Environment (OSHE)aimamNo ratings yet

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- 4.2 Safety Data sheet-FEVICOL AC DUCT KING DUCT SELEANT-3278Document3 pages4.2 Safety Data sheet-FEVICOL AC DUCT KING DUCT SELEANT-3278UMUTNo ratings yet

- CG8 - 18 Preparation of QuotationsDocument2 pagesCG8 - 18 Preparation of QuotationsArdamitNo ratings yet

- Doka Automotif Climbing FormworkDocument32 pagesDoka Automotif Climbing FormworkRafa Rahmat FaddisNo ratings yet

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (2)

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Risk Assessment For Excavation and BackfillingDocument5 pagesRisk Assessment For Excavation and BackfillingBulent AkNo ratings yet

- Safe Work Method Statement (SWMS)Document5 pagesSafe Work Method Statement (SWMS)CK TangNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- Risk and ContingencyDocument34 pagesRisk and ContingencyMary Ingrid Arellano RabulanNo ratings yet

- Excavation ChecklistDocument4 pagesExcavation ChecklistCINQO HSENo ratings yet

- Change Risk Assessment TemplateDocument12 pagesChange Risk Assessment TemplateAlvaro Duviel AldanaNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)contrax8No ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- RAID Register - SapphireDocument11 pagesRAID Register - SapphireMuhammadMuzammalJamilNo ratings yet

- Change Risk Assessment TemplateDocument10 pagesChange Risk Assessment TemplatePhụng LêNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- Safe Work Method SWMS 30jun17Document2 pagesSafe Work Method SWMS 30jun17professional accountantsNo ratings yet

- Nosaexecutivereport040713 4191Document8 pagesNosaexecutivereport040713 4191Marius BuysNo ratings yet

- Generic Risk Assessment Rescues From Tunnels and Underground StructuresDocument5 pagesGeneric Risk Assessment Rescues From Tunnels and Underground Structurestumelo makgabutlaneNo ratings yet

- Risk ManagementDocument5 pagesRisk ManagementmominNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- 215 Using of P.P.E.Document10 pages215 Using of P.P.E.grantNo ratings yet

- 334 - Manual Handling of GRP PipingDocument7 pages334 - Manual Handling of GRP Pipingcontrax8No ratings yet

- 330 - Element 5.02 Using of Stanley Knife (EPCM)Document8 pages330 - Element 5.02 Using of Stanley Knife (EPCM)grantNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- RA For Block WorkDocument4 pagesRA For Block WorkMd.Imtayaj AhmadNo ratings yet

- 210 On and Off Loading of Vehicles and TrucksDocument15 pages210 On and Off Loading of Vehicles and TrucksgrantNo ratings yet

- Cable Tray InstallationDocument3 pagesCable Tray InstallationIzzy TudtudNo ratings yet

- QUALITY RISK ASSESMENT BlankDocument3 pagesQUALITY RISK ASSESMENT BlankAlbert NajjarNo ratings yet

- Block Work Risk AssessmentDocument4 pagesBlock Work Risk Assessmentabdelghafour megaacheNo ratings yet

- Department of Social Welfare and Development Integrity Management Committee Name of Office/Agency/Division/UnitDocument10 pagesDepartment of Social Welfare and Development Integrity Management Committee Name of Office/Agency/Division/UnitNELSON NISPEROSNo ratings yet

- IG2 - SOP For Risk Assessment 3SLSADocument14 pagesIG2 - SOP For Risk Assessment 3SLSAMahbub KhanNo ratings yet

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- F-025 TCM Incident Investigation Report Form Rev A3Document4 pagesF-025 TCM Incident Investigation Report Form Rev A3Mohammed AbdulNo ratings yet

- 331 - Element 5.02.17 Handling and Storage of HCS and Flammable LiquidDocument8 pages331 - Element 5.02.17 Handling and Storage of HCS and Flammable LiquidgrantNo ratings yet

- Sample Use: ExcavationDocument4 pagesSample Use: ExcavationMd FahadNo ratings yet

- 2-HEMP-Hazards and Effects ManagementDocument17 pages2-HEMP-Hazards and Effects ManagementShahid IqbalNo ratings yet

- 11 - Commission Inspection ModeDocument10 pages11 - Commission Inspection Modeyoen_anNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- EMS Risk RegisterDocument5 pagesEMS Risk RegistermominNo ratings yet

- Jigcc-Abd - A05-Hs-Ra - 01Document13 pagesJigcc-Abd - A05-Hs-Ra - 01Shovon khanNo ratings yet

- Job Hazard Analysis (JHA) : Feb 5 2021 HTS Engineering MT Dennis - THESL RoomDocument3 pagesJob Hazard Analysis (JHA) : Feb 5 2021 HTS Engineering MT Dennis - THESL RoomCharity KingNo ratings yet

- RA For ROAD WORKS - EXCAVATION AND PIPES INSTALLATIONDocument14 pagesRA For ROAD WORKS - EXCAVATION AND PIPES INSTALLATIONLawrence adeleke OmisakinNo ratings yet

- APP J Risk RegisterDocument1 pageAPP J Risk Register--No ratings yet

- Adac Asgtc 2018 Ra 07 Hot WorkDocument3 pagesAdac Asgtc 2018 Ra 07 Hot Workabubakrelsaid90No ratings yet

- Msra IneltecDocument23 pagesMsra IneltecAmit BhattNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- 212 Using of Portable Electrical EquipmentDocument12 pages212 Using of Portable Electrical EquipmentgrantNo ratings yet

- SFC Doc1Document25 pagesSFC Doc1Don Rulas MosotiNo ratings yet

- RA - The AtelierDocument45 pagesRA - The AtelierMd ShahinNo ratings yet

- Engineering Change Request: Oil & Gas Development Company LimitedDocument4 pagesEngineering Change Request: Oil & Gas Development Company LimitedSyed Mustafa HussainNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Total Risk Management Kingdom DrillingDocument15 pagesTotal Risk Management Kingdom Drillingbengam100% (3)

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- Accelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsFrom EverandAccelerating Complex Problem-Solving Skills: Problem-Centered Training Design MethodsNo ratings yet

- Job Safety Analysis (JSA) : Sl. No. Department Equipment Location Job DescriptionDocument1 pageJob Safety Analysis (JSA) : Sl. No. Department Equipment Location Job DescriptionUMUTNo ratings yet

- COVID-19 Prevention & Protection Plan: New PTA Complex ProjectDocument15 pagesCOVID-19 Prevention & Protection Plan: New PTA Complex ProjectUMUTNo ratings yet

- JSA-Lifting-Loading&Unloading With CraneDocument3 pagesJSA-Lifting-Loading&Unloading With CraneUMUTNo ratings yet

- Attendance Sheet: Name Company Position Id No. SignatureDocument1 pageAttendance Sheet: Name Company Position Id No. SignatureUMUTNo ratings yet

- Pln-Hse-Pta-0001 Hse PlanDocument109 pagesPln-Hse-Pta-0001 Hse PlanUMUT100% (1)

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Armaflex Sheet and Roll MSDSDocument1 pageArmaflex Sheet and Roll MSDSUMUTNo ratings yet

- JSA-Substructure Concrete WorksDocument5 pagesJSA-Substructure Concrete WorksUMUTNo ratings yet

- EC Safety Data SheetDocument9 pagesEC Safety Data SheetUMUTNo ratings yet

- E-Z Weld 786 CPVC CementDocument12 pagesE-Z Weld 786 CPVC CementUMUTNo ratings yet

- Safety Data Sheet: Acetylene (Dissolved)Document2 pagesSafety Data Sheet: Acetylene (Dissolved)UMUTNo ratings yet

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (2)

- Heavy Duty Solvent Cement For PVC Plastic PipeDocument2 pagesHeavy Duty Solvent Cement For PVC Plastic PipeUMUT100% (1)

- Control of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeDocument4 pagesControl of Substance Hazardous To Health (COSHH) Procedure: Bahrain International Airport Modernisation ProgrammeUMUTNo ratings yet

- JOB Hazard Analysis C: ArpenterDocument2 pagesJOB Hazard Analysis C: ArpenterUMUTNo ratings yet

- 7.7 MSDS Armaflex 520Document11 pages7.7 MSDS Armaflex 520UMUTNo ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- Module3-Safety Personnel Assessment-SPADocument37 pagesModule3-Safety Personnel Assessment-SPAfarrukhNo ratings yet

- Guidelines Intershield300Document24 pagesGuidelines Intershield300biondimiNo ratings yet

- 09 Catalog Krisbow 9 Ladder ProductDocument6 pages09 Catalog Krisbow 9 Ladder ProductEnrique da MattaNo ratings yet

- Monsoon Preparedeness Plan Mumbai-ProjectDocument8 pagesMonsoon Preparedeness Plan Mumbai-ProjectHAMON COOLING SYSTEMSNo ratings yet

- Risk Assessment Forms - Appendix 5 (22102016)Document2 pagesRisk Assessment Forms - Appendix 5 (22102016)Sơn Nguyễn-Lê100% (1)

- CPCCLSF3001 Intermediate ScaffoldDocument107 pagesCPCCLSF3001 Intermediate ScaffoldArdamitNo ratings yet

- New Candidates Observation SheetsDocument6 pagesNew Candidates Observation SheetsRay Mathews0% (1)

- Scafflding Safety Farouk ArabicDocument25 pagesScafflding Safety Farouk ArabicMoh_Elberry100% (1)

- 016 Procedure ScaffoldingDocument13 pages016 Procedure ScaffoldingHSE CERINo ratings yet

- !!scaffolding Software - Home PageDocument4 pages!!scaffolding Software - Home PageasmaNo ratings yet

- Konza Site DS Weekly HSE Status Report 29.01.2024 Rev 1Document18 pagesKonza Site DS Weekly HSE Status Report 29.01.2024 Rev 1kiragukabereNo ratings yet

- Cop Safe Work On Roofs Part 2 0308Document44 pagesCop Safe Work On Roofs Part 2 0308Scooby DooNo ratings yet

- Catalogo de MaterialesDocument35 pagesCatalogo de MaterialesCarlos Andres Orellana DiazNo ratings yet

- Construction - Scaffold Checklist - HSEDocument6 pagesConstruction - Scaffold Checklist - HSEroldskiNo ratings yet

- Vedanta Limited: Cairn Oil & GasDocument32 pagesVedanta Limited: Cairn Oil & GasOws AnishNo ratings yet

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Document46 pagesNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- Building Constructio N LDocument55 pagesBuilding Constructio N LOliver Del CarmenNo ratings yet

- Catalogo Overview PERI UPDocument36 pagesCatalogo Overview PERI UPAlberto Diaz Herrera100% (1)

- Attachment 16. Site HSSE PlanDocument79 pagesAttachment 16. Site HSSE PlanCristianMontoyaMujica100% (1)

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- JSA Form FilledDocument3 pagesJSA Form FilledSanthoesh srinivasanNo ratings yet

- Construction Checklist: SL. NO. Check ItemDocument2 pagesConstruction Checklist: SL. NO. Check Itemenjoy begening lifeNo ratings yet

- Lesson 8 - Form Scaffolding and StagingDocument7 pagesLesson 8 - Form Scaffolding and StagingROMNICK HANDAYANNo ratings yet

- SG10 - 08 Brick GuardsDocument1 pageSG10 - 08 Brick GuardsMIKE HarwoodNo ratings yet