Professional Documents

Culture Documents

Flash and Fire Points by Cleveland Open Cup: Standard Method of Test For

Flash and Fire Points by Cleveland Open Cup: Standard Method of Test For

Uploaded by

РостOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flash and Fire Points by Cleveland Open Cup: Standard Method of Test For

Flash and Fire Points by Cleveland Open Cup: Standard Method of Test For

Uploaded by

РостCopyright:

Available Formats

Standard Method of Test for

Flash and Fire Points by

Cleveland Open Cup

AASHTO Designation: T 48-06 (2015)

ASTM Designation: D92-05a

This document is only for acquaintance

AASHTO T 48-06 (2015) is identical to ASTM D92-05a except for the following provisions:

1. All references to the ASTM standards listed in the following table shall be replaced with the

corresponding AASHTO standard:

Referenced Standards

ASTM AASHTO

D140 R 66

D1310 T 79

2. Add the following reference to Section 2.1:

C670, Standard Practice for Preparing Precision and Bias Statements for Test Methods for

Construction Materials

3. Replace the dimensions in Figure 1 with the following:

Millimeters Inches

Min Max Min Max

A—Diameter 3.8 5.4 0.15 0.21

C—Diameter 1.6 5.0 0.06 0.20

D 5.0 0.20

E 6.4, approximately 0.25, approximately

4. Replace the dimensions in Figure 2 with the following:

Millimeters Inches

Min Max Min Max

A 6.4, nominal 0.25, nominal

C 6.4, nominal 0.25, nominal

D—Diameter 54.5 56.5 2.15 2.22

F—Diameter 150, nominal 6, nominal

5. Replace the dimensions in Figure 3 with the dimensions below. Do not include a dimension

“G” as shown in Figure 3. However, include a dimension for the thickness of the flange of the

test cup that is not included in Figure 3. This dimension for the thickness of the flange shall be

designated “K” with the dimensional requirements as in the following table:

больше стандартов на www.matest.ru

TS-2b T 48-1 AASHTO

Millimeters Inches

Min Max Min Max

B 62.5 64.0 2.46 2.52

C 2.8 3.6 0.11 0.14

D—Radius 4, approximately 0.16, approximately

H 2.8 3.6 0.11 0.14

J 97 101 3.8 4.0

K 1.8 3.4 0.07 0.13

6. Add the following sentence after the first sentence in Section 11.1.1:

To aid in this operation, a Filling Level Gauge (A1.7) may be used.

This document is only for acquaintance

7. Add an additional note that immediately follows Section 11.1.1 as follows:

Note—The sample cup may be filled away from the apparatus provided the thermometer is preset

with the cup in place and the sample level is correct at the beginning of the test. A shim 6.4-mm

(0.25-in.) thick is useful in obtaining the correction distance from the bottom of the bulb to the

bottom of the cup.

8. Replace the first sentence of Section 11.1.3 with the following:

Light the test flame, and adjust it to a diameter of 3.8 to 5.4 mm (0.15 to 0.21 in.).

9. Replace Section 11.1.4 with the following:

11.1.4 Apply heat initially at such a rate that the temperature indicated by the temperature-

measuring device increases 10 to 20°C (18 to 36°F)/min. When the test specimen temperature

is approximately 56°C (100°F) below the expected flash point, decrease the heat so that the

rate of temperature rise during the last 28°C (50°F) before the flash point is 4 to 7°C (7 to

13°F)/min.

10. Replace the fourth sentence of Section 11.1.5 with the following:

The center of the test flame must move in a horizontal plane not more than 2.5 mm (0.10 in.)

above the plane of the upper edge of the cup and pass in one direction only.

11. Replace the last sentence of Section 11.1.9 with the following:

Continue heating the test specimen at 4 to 7°C (7 to 13°F)/min and testing the material every

2°C (5°F) as described in Section 11.1.5 until the flash point is obtained.

12. Replace Section 14 with the following:

14. Precision and Bias

14.1 Precision—Criteria for judging the acceptability of test results for the flash point of

asphalt binders obtained by this method are given in Table 1. Criteria for judging the

acceptability of fire point test results can be found in ASTM D92.

14.1.1 Single-Operator Precision (Repeatability)—The figures in Column 2 of Table 1 are the

standard deviations that have been found to be appropriate for the conditions of test described

in Column 1. Two results obtained in the same laboratory, by the same operator using the

same equipment, in the shortest practical period of time, should not be considered suspect

unless the difference in the two results exceeds the values given in Table 1, Column 3.

14.1.2 Multilaboratory Precision (Reproducibility)—The figures in Column 2 of Table 1 are

the standard deviations that have been found to be appropriate for the conditions of test

described in Column 1. Two results submitted by two different operators testing the same

material in different laboratories shall not be considered suspect unless the difference in the

two results exceeds the values given in Table 1, Column 3.

больше стандартов на www.matest.ru

TS-2b T 48-2 AASHTO

Table 1—Precision Estimates

Acceptable

Standard Range of Two

Deviation Results

Condition (1s)a (d2s)a

Single-Operator Precision:

Flash Point (°C) 3 8

Multilaboratory Precision:

Flash Point (°C) 10 28

This document is only for acquaintance

a

These values represent the 1s and d2s limits described in ASTM Practice C670.

Note: The precision estimates for Flash Point given in Table 1 are based on the analysis of test results from

eight pairs of AMRL proficiency samples. The data analyzed consisted of results from 98 to 148 laboratories

for each of the eight pairs of samples. The analysis included four binder grades: PG 52-34, PG 64-16,

PG 64-22, and PG 70-22. Average flash points ranged from 268.5 to 353.5°C. The details of the

analysis are in the final report for NCHRP Project No. 9-26, Phase 3.

14.2 Bias—The procedure of this test method has no bias because flash point and fire point

can be defined only in terms of this test method.

13. Replace Section A1.3 with the following:

A1.3 Ignition Source Applicator—The device for applying the test flame may be of any

suitable design, but the tip shall be 1.6 to 5.0 mm (0.06 to 0.20 in.) in diameter at the end and

the orifice shall have an approximate diameter of 0.8 mm (0.031 in.). The device for applying

the test flame shall be so mounted to permit automatic duplication of the sweep of the test

flame, the radius of swing being not less than 150 mm (6 in.) and the center of the orifice

moving in a plane not more than 2.5 mm (0.10 in.) above the cup. A bead having a diameter

of 3.8 to 5.4 mm (0.15 to 0.21 in.) shall be mounted in a convenient position on the apparatus

so the size of the test flame can be compared to it.

14. Add an additional Section A1.7 after Section A1.6 as follows:

A1.7 Filling Level Gauge—A device to aid in the proper adjustment of the sample level in the

cup. It may be made of suitable metal with at least one projection, but preferably two for

adjusting the sample level in the test cup to 9 to 10 mm (0.35 to 0.39 in.) below the top edge

of the cup. A hole 0.8 mm (0.031 in.) in diameter, the center of which is located not more than

2.5 mm (0.10 in.) above the bottom edge of the gauge, shall be provided for use in checking

the center position of the orifice of the test flame applicator with respect to the rim of the cup.

(Figure 4 shows a suitable version.)

15. Add a Figure 4 after Section A1.7.

больше стандартов на www.matest.ru

TS-2b T 48-3 AASHTO

This document is only for acquaintance

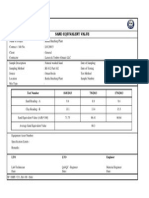

Figure 4—Filling Level Gauge

больше стандартов на www.matest.ru

TS-2b T 48-4 AASHTO

You might also like

- Design, Testing, and Construction of Slurry Seal: Standard Practices ForDocument8 pagesDesign, Testing, and Construction of Slurry Seal: Standard Practices ForaraNo ratings yet

- Is 1448 16 1990 PDFDocument10 pagesIs 1448 16 1990 PDFDario de SantiagoNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : AashloDocument3 pagesCutback Asphalt (Rapid-Curing Type) : AashloNacer KisyNo ratings yet

- 1.01 The Updated Tex-248-F Test ProcedureDocument13 pages1.01 The Updated Tex-248-F Test ProcedureDavid Vaca OyolaNo ratings yet

- International Society For Rock Mechanics Commission On Testing MethodsDocument26 pagesInternational Society For Rock Mechanics Commission On Testing MethodsDavid Almanza PerezNo ratings yet

- Astm D7116-16Document4 pagesAstm D7116-16Safiullah KhanNo ratings yet

- ASTM D2041 aashto T209 ефект процент битума PDFDocument4 pagesASTM D2041 aashto T209 ефект процент битума PDFanon_711474514No ratings yet

- ASSHTODocument3 pagesASSHTOmiguelangelNo ratings yet

- Civil Engineering MCQ'S: Ans. (D)Document1 pageCivil Engineering MCQ'S: Ans. (D)Nishikanta MondalNo ratings yet

- E1844Document4 pagesE1844DannyChaconNo ratings yet

- Method of Test For Saybolt Furol Viscosity of Emulsified Asphalt at 25°C (77°F) and 50°C (122°F)Document3 pagesMethod of Test For Saybolt Furol Viscosity of Emulsified Asphalt at 25°C (77°F) and 50°C (122°F)phanendra kumarNo ratings yet

- Astm C33 C33M 23Document5 pagesAstm C33 C33M 23عبدالمعز المليانNo ratings yet

- Bitumen Extraction Test PDFDocument4 pagesBitumen Extraction Test PDFAyat ANo ratings yet

- ASTM D4791 - 10 Flat and Elongated Particles in Coarse AggregateDocument6 pagesASTM D4791 - 10 Flat and Elongated Particles in Coarse AggregateParth GuptaNo ratings yet

- Astm d1856Document3 pagesAstm d1856Jose AruquipaNo ratings yet

- Seive Analysis of AggDocument9 pagesSeive Analysis of Aggmohammad hafodyNo ratings yet

- Aashto T 201Document3 pagesAashto T 201Mohammed AliNo ratings yet

- 11 Flash and Fire Point of Bitumen - SayeedDocument2 pages11 Flash and Fire Point of Bitumen - Sayeedlm hasnainNo ratings yet

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDocument1 pageC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- Percent Air Voids in Compacted Dense and Open Asphalt MixturesDocument4 pagesPercent Air Voids in Compacted Dense and Open Asphalt MixturesAhmad KhreisatNo ratings yet

- Aashto T 309-15Document3 pagesAashto T 309-15William VasquezNo ratings yet

- Chemical Admixtures For ConcreteDocument15 pagesChemical Admixtures For ConcreteKMNo ratings yet

- WSDOT FOP For AASHTO T 106Document14 pagesWSDOT FOP For AASHTO T 106malaya tripathyNo ratings yet

- Plymer Modified Bitumens BS en 14023 2010Document2 pagesPlymer Modified Bitumens BS en 14023 2010lyesNo ratings yet

- Aashto M 156-13 (2017)Document3 pagesAashto M 156-13 (2017)loukman salmaNo ratings yet

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesPreparation of Asphalt Mixture Specimens Using Marshall ApparatusAnbuchelvan CNo ratings yet

- Classifying Hot-Mix Recycling Agents: Standard Practice ForDocument2 pagesClassifying Hot-Mix Recycling Agents: Standard Practice ForRed Red100% (1)

- Viscosity Grade Bitumen, Bitumen VG 20, VG 30, VG 40 SpecificationDocument3 pagesViscosity Grade Bitumen, Bitumen VG 20, VG 30, VG 40 SpecificationParthiban GuruNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- ASTM D 2042 - 97 Standard Test Method For PDFDocument3 pagesASTM D 2042 - 97 Standard Test Method For PDFm_seyedNo ratings yet

- Sampling Bituminous Materials: Standard Method of Test ForDocument3 pagesSampling Bituminous Materials: Standard Method of Test ForEvert RiveraNo ratings yet

- Base CourseDocument3 pagesBase Courseprobook450_ehsanNo ratings yet

- Method of Test For Sand EquivalentDocument6 pagesMethod of Test For Sand EquivalentWissem TaktakNo ratings yet

- Asphalt Tests PDFDocument9 pagesAsphalt Tests PDFdishkuNo ratings yet

- Maximum Theoritical Specific Gravity at Different Asphalt ContentDocument4 pagesMaximum Theoritical Specific Gravity at Different Asphalt ContentFiras BarrajNo ratings yet

- D 139 AstmDocument3 pagesD 139 AstmNuMbNo ratings yet

- Is 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)Document17 pagesIs 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)arjun kumar50% (2)

- Highway Lab Report 5Document14 pagesHighway Lab Report 5Abdallah AlhasanNo ratings yet

- Asphalt ExtractionDocument4 pagesAsphalt ExtractionOsikur RahamanNo ratings yet

- D 2041 - 00Document4 pagesD 2041 - 00harisahamedNo ratings yet

- Laboratory Soils TestingDocument5 pagesLaboratory Soils TestingNavam NanthanNo ratings yet

- Astm D242 D242M 19Document1 pageAstm D242 D242M 19Mohamed SaadNo ratings yet

- Aashto T11Document3 pagesAashto T11jimbox88100% (2)

- Astm Ac20Document3 pagesAstm Ac20Juan QuiñonesNo ratings yet

- ASTM D2104-03 Tubo de Plástico de PE, Cédula 40Document7 pagesASTM D2104-03 Tubo de Plástico de PE, Cédula 40Marlon TurnerNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Rapid-Curing Type) : Standard Specification Fordong ganNo ratings yet

- LAB Manual PRCIIDocument61 pagesLAB Manual PRCIIUbaid RajputNo ratings yet

- Determining Demulsibility of Emulsified Asphalt: Standard Test Method ForDocument2 pagesDetermining Demulsibility of Emulsified Asphalt: Standard Test Method ForROBERTO MIRANDANo ratings yet

- Astm D 70Document4 pagesAstm D 70Mayra100% (1)

- Design of Hot Mix Asphalt Using Bailey Method of GradationDocument8 pagesDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocument44 pagesEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Hot Weather ConcretingDocument10 pagesHot Weather ConcretingIm ChinithNo ratings yet

- ASTM D3665-Standard Practice For Random Sampling of Construction MaterialsDocument5 pagesASTM D3665-Standard Practice For Random Sampling of Construction MaterialsJonathan LuisNo ratings yet

- CBR (California Bearing Ratio) of Soils in Place: Standard Test Method ForDocument7 pagesCBR (California Bearing Ratio) of Soils in Place: Standard Test Method ForpahrizanNo ratings yet

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickNo ratings yet

- HMA Mix Design Report-2Document11 pagesHMA Mix Design Report-2yustinokwingwa100% (1)

- T 48Document3 pagesT 48Katerin HernandezNo ratings yet

- A 126 - 95 r01 - Qteyni1sruqDocument5 pagesA 126 - 95 r01 - Qteyni1sruqQaisir MehmoodNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Steel Design 4 May 2022Document3 pagesSteel Design 4 May 2022tous les joursNo ratings yet

- Worksheet G8, Answer KeyDocument8 pagesWorksheet G8, Answer KeyZainab AsifNo ratings yet

- 1 Xpower Safirus Owners Manual enDocument8 pages1 Xpower Safirus Owners Manual enMarianela MasyRubiNo ratings yet

- Thermal Pollution CompleteDocument16 pagesThermal Pollution CompleteVartika VNo ratings yet

- Anodic Stripping Voltammetry - ASV For DeterminatiDocument5 pagesAnodic Stripping Voltammetry - ASV For DeterminatiFera nikaNo ratings yet

- Solidification of Metals (To Be Completed) : Prof. H. K. Khaira Professor, Deptt. of MSME M.A.N.I.T., BhopalDocument62 pagesSolidification of Metals (To Be Completed) : Prof. H. K. Khaira Professor, Deptt. of MSME M.A.N.I.T., BhopalIndranil Bhattacharyya100% (1)

- Protech Technologies SDI-76 Instruction ManualDocument15 pagesProtech Technologies SDI-76 Instruction ManualJMAC SupplyNo ratings yet

- MicromeriticsDocument109 pagesMicromeriticsSan GalNo ratings yet

- Tos Quarter 1Document4 pagesTos Quarter 1Jabeguero Marvelyn JessicaNo ratings yet

- Heat Pump Standard EN 15316-4-2 - From Compliance To Real ConsumptionDocument5 pagesHeat Pump Standard EN 15316-4-2 - From Compliance To Real ConsumptionMarcin BobińskiNo ratings yet

- Basic DWDM Components.Document16 pagesBasic DWDM Components.Pradeep Kumar SahuNo ratings yet

- Spontaneity: Decrease in The Enthalpy A Criterion For Spontaneity ?Document11 pagesSpontaneity: Decrease in The Enthalpy A Criterion For Spontaneity ?Prakhar GuptaNo ratings yet

- Supersonic Flow Over AirfoilsDocument2 pagesSupersonic Flow Over AirfoilsAnjali GopalakrishnanNo ratings yet

- A2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidDocument2 pagesA2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidSachitra Wijethunga100% (2)

- A. Introduction To Archl AcousticsDocument25 pagesA. Introduction To Archl AcousticsDan MarbellaNo ratings yet

- Practical Fabrication Tips For Steam PipingDocument7 pagesPractical Fabrication Tips For Steam Pipingmahendra493100% (1)

- Flow Meter Selection AshraeDocument62 pagesFlow Meter Selection AshraeDudi Adi FirmansyahNo ratings yet

- BAPC PaperDocument7 pagesBAPC PaperSam SadeqNo ratings yet

- Particles and Moisture Effect On Dielectric Strength of Transformer Oil PDFDocument6 pagesParticles and Moisture Effect On Dielectric Strength of Transformer Oil PDFalumnopitagorasNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- Chapter 1 - ExerciseDocument15 pagesChapter 1 - Exerciseحسن كميت hassankomeit lNo ratings yet

- 2-ERT252 Distance MeasurementDocument32 pages2-ERT252 Distance Measurementiffatul mahyaNo ratings yet

- Michelson PHYWE PDFDocument2 pagesMichelson PHYWE PDFLorran Neves100% (1)

- AIr NummericalDocument2 pagesAIr NummericalArnav TiwariNo ratings yet

- Module 3 Construction and DesignDocument5 pagesModule 3 Construction and DesignDhimas Surya Negara100% (1)

- Internals For Packed ColumnsDocument20 pagesInternals For Packed Columnskingcobra008No ratings yet

- Mysterious OceanDocument202 pagesMysterious OceanPedro Carlos PicapiedraNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument9 pagesEquivalents of Carbon Steel QualitiesGANESHNo ratings yet

- Week-2 Module-2 Principles of Image InterpretationDocument25 pagesWeek-2 Module-2 Principles of Image InterpretationAKASH MAURYANo ratings yet