Professional Documents

Culture Documents

Anti Mus Sol UDF Liq - e

Anti Mus Sol UDF Liq - e

Uploaded by

suvrodev812Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anti Mus Sol UDF Liq - e

Anti Mus Sol UDF Liq - e

Uploaded by

suvrodev812Copyright:

Available Formats

_______________________________________________________________________________

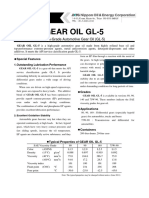

Technical Information

Antimussol UDF liq

Antimussol® UDF liquid

Silicon-based, processing-stable and economical antifoam

• prevents the formation of troublesome foam

• suppresses rapidly and efficiently existing foam

• is stable and effective in the presence of high amounts of electrolyte and alkali

• is applicable during scouring, dyeing and printing of textile goods

Clariant International Ltd 1 220380.12.06.e

1 Properties

Appearance milky emulsion

Chemical character silicon oils with non-ionic emulsifiers

Ionic character non-ionic

Density at 20°C approx. 1.0

Viscosity at 25°C ca. 700 mPa.s (Brookfield)

pH approx. 7

Dilutability readily dispersible in cold water

Storage stability good, if kept at temperatures between 0-50°C.

Extremes of heat and cold should be avoided.

Stability to

• hard water good

• acids good

• alkalis good

Compatibility with

• anionic, non-ionic and

cationic products good

Ecotoxicological data see Safety Data Sheet.

Clariant International Ltd 2 220380.12.06.e

2 Scope of application

Antimussol UDF liquid rapidly and efficiently eliminates undesirable foaming. It is very

economical in use. A small addition in preparation baths, dyebaths and printing pastes inhibits

foam formation and destroys any existing foam almost instantaneously.

Antimussol UDF liquid acts as an antifoam:

• in pretreatment for scouring and bleaching

• in dyeing at any pH and temperature, especially when dyeing cotton with direct or reactive

dyes, polyamide with acid dyes and polyester with disperse dyes at high temperature

• in printing

3 Application

For maximum efficiency and economy, it is advisable to pre-dilute Antimussol UDF liquid before

use. We recommend a dilution in cold soft water at for example a 1:9 ratio, the water being added

with slight stirring to the emulsion.

Dilutions are not stable for a long period, i.e. on prolonged storage a slight settling may occur. We

therefore recommend stirring or shaking the dilutions before use.

Recommended amounts

The quantity of Antimussol UDF liquid required to control foaming can only be determined by

experiment and depends on the process and machinery.

In general, however, between

0.1 - 0.5 g/l of neat Antimussol UDF liquid

is required, the higher amounts being required when processing under alkaline conditions.

Many of their dyestuffs, pigments and chemicals are patented by Clariant Ltd or its affiliates in numerous industrial

countries.

® Trademark registered by Clariant Ltd or Clariant GmbH in numerous countries.

* Trademark licensed to Clariant Ltd in numerous countries.

+ Manufacturer’s registered trade mark

The signs ®, * and + appear only at the first mention of the product.

The information and recommendations presented here were compiled with the utmost care,but cannot be extended to cover

every possible case. They are intended to serve as non-binding guidelines and must be adapted to the prevailing

conditions.

Clariant International Ltd 3 220380.12.06.e

You might also like

- The Loss Factor As Measure Mechanical Damping PDFDocument5 pagesThe Loss Factor As Measure Mechanical Damping PDFsalvatorgabriele100% (1)

- 4 EmulsionsDocument17 pages4 EmulsionsAmit AgarwalNo ratings yet

- Antimussol UDF Liq C - e PDFDocument3 pagesAntimussol UDF Liq C - e PDFAnonymous N0eiVk1SNo ratings yet

- Solusoft SE1 Liq - e TIDocument3 pagesSolusoft SE1 Liq - e TIekoyonatanNo ratings yet

- Defoamer Edw 707Document1 pageDefoamer Edw 707karla aguirreNo ratings yet

- MOLYKOTE 111 Compound 22-1087L-01Document2 pagesMOLYKOTE 111 Compound 22-1087L-01If ChenNo ratings yet

- MOLYKOTEDocument2 pagesMOLYKOTEDavid Palm PNo ratings yet

- TD OilDocument4 pagesTD OilPetrus MalailakNo ratings yet

- Coolant ManagementDocument12 pagesCoolant ManagementQuy NguyenNo ratings yet

- Tai County Silicones Co., LTD.: Description Applications PackagingDocument1 pageTai County Silicones Co., LTD.: Description Applications PackagingMark WuNo ratings yet

- Zonyl Fs 300 Tech Data SheetDocument2 pagesZonyl Fs 300 Tech Data SheetHarrieGorterNo ratings yet

- Zonyl FSO PDFDocument2 pagesZonyl FSO PDFarguijNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- TDS Dulux Silk EmulsionDocument2 pagesTDS Dulux Silk EmulsionpastorgeeNo ratings yet

- Adasil PMDocument2 pagesAdasil PMMuhammad Aasim Hassan100% (1)

- Surfynol® 440 Surfactant: Description Shelf LifeDocument2 pagesSurfynol® 440 Surfactant: Description Shelf LifeWangYunNo ratings yet

- TDS Hostapur OS LiqDocument2 pagesTDS Hostapur OS LiqRabah ABBASNo ratings yet

- Boiler Sludge Conditioner PDFDocument2 pagesBoiler Sludge Conditioner PDFShashi Naganur100% (1)

- PEG-150 DistearateDocument2 pagesPEG-150 Distearateolabi abdullah100% (1)

- Foam Clear IndaPro SDocument2 pagesFoam Clear IndaPro SAdnan HaiderNo ratings yet

- Molykote 111 Compound 22-1087j-01Document2 pagesMolykote 111 Compound 22-1087j-01dantewow1No ratings yet

- Primal TT 615 Rheology ModifierDocument3 pagesPrimal TT 615 Rheology ModifierNelson LozanoNo ratings yet

- Dux CUT SW 130Document2 pagesDux CUT SW 130R.d. PoshiyaNo ratings yet

- Diazo SensitizersDocument2 pagesDiazo SensitizerskkkkrolikNo ratings yet

- Antiespumante Xiameter Afe-2210 EmulsionDocument4 pagesAntiespumante Xiameter Afe-2210 EmulsionOnesany TecnologiasNo ratings yet

- Silicone Fluid 200 (50-60,000cst) Product InformationDocument4 pagesSilicone Fluid 200 (50-60,000cst) Product Informationmohammed sabsabyNo ratings yet

- Molykote: 111 CompoundDocument2 pagesMolykote: 111 CompoundEcosuministros ColombiaNo ratings yet

- Ind 3003 2104eDocument2 pagesInd 3003 2104eRafael Flores HNo ratings yet

- Data Sheet Dowcorning 111Document2 pagesData Sheet Dowcorning 111Nyoman RakaNo ratings yet

- Rocol Dry Moly SprayDocument9 pagesRocol Dry Moly SpraysubodhasinghNo ratings yet

- Solusoft WA Liq - eDocument3 pagesSolusoft WA Liq - esuvrodev812No ratings yet

- Power Release Oil: Pacific Power Petrochem Development CorpDocument1 pagePower Release Oil: Pacific Power Petrochem Development CorpAnupam GhoshNo ratings yet

- Visicryl Ec 7062: Technical InformationDocument2 pagesVisicryl Ec 7062: Technical Informationsriatul2006No ratings yet

- Diaoxy Hi-Build Amine Cured EpoxyDocument4 pagesDiaoxy Hi-Build Amine Cured Epoxybublooo123No ratings yet

- Walocel MC 60 2014Document2 pagesWalocel MC 60 2014jas020No ratings yet

- Multinoc Sdx-Nlgi 2 PDFDocument2 pagesMultinoc Sdx-Nlgi 2 PDFangga hwNo ratings yet

- Dermaprimer: Product DescriptionDocument2 pagesDermaprimer: Product DescriptionSaud NawabNo ratings yet

- TDS Dulux EmulsionDocument2 pagesTDS Dulux EmulsionpastorgeeNo ratings yet

- Sandoclean LFDI LiqDocument2 pagesSandoclean LFDI Liqriqpwri1120% (1)

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- 1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)Document4 pages1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)bublooo123No ratings yet

- TDS 2.2.2 PDFDocument2 pagesTDS 2.2.2 PDFShripadNo ratings yet

- E3) Epimastic5100 4292Document2 pagesE3) Epimastic5100 4292Syed FaridNo ratings yet

- DT 552 - Quick Dry UndercoatDocument3 pagesDT 552 - Quick Dry UndercoatAMER SALEEMNo ratings yet

- Synolac 755 WD 60Document2 pagesSynolac 755 WD 60monrmNo ratings yet

- PR Cleaner Degreaser PDS 122316 CDocument3 pagesPR Cleaner Degreaser PDS 122316 CMidyanNo ratings yet

- Acronal 7095Document3 pagesAcronal 7095kishanptlNo ratings yet

- LAWA007Document3 pagesLAWA007Fadilla AzhariNo ratings yet

- DuPont Oil Well Productivity GlicolicoDocument12 pagesDuPont Oil Well Productivity GlicolicoFederico ArqueroNo ratings yet

- Afe 2017 Xiameter-Afe-3168-Antifoam-EmulsDocument2 pagesAfe 2017 Xiameter-Afe-3168-Antifoam-EmulsZhan FangNo ratings yet

- Acrysol Adt-100Document3 pagesAcrysol Adt-100wtwilightwNo ratings yet

- High-Grade Automotive Gear Oil (GL-5)Document3 pagesHigh-Grade Automotive Gear Oil (GL-5)muh fadliNo ratings yet

- Avesta Pickling Gel PDFDocument2 pagesAvesta Pickling Gel PDFmekag94No ratings yet

- Xcel 762 - Anti FoamDocument1 pageXcel 762 - Anti FoamSuhairi AnasNo ratings yet

- Resina 9515 TDS 0503Document3 pagesResina 9515 TDS 0503funson123No ratings yet

- Cicobond HSDocument2 pagesCicobond HSmud444100% (1)

- Xiameter AFE-1520 Antifoam Emulsion - Ficha Tecnica - Dow - InglesDocument3 pagesXiameter AFE-1520 Antifoam Emulsion - Ficha Tecnica - Dow - Inglesluisa aguirreNo ratings yet

- Caustic Soda SolutionsDocument2 pagesCaustic Soda SolutionsSahil ShahNo ratings yet

- Ultratex UHS Hydrophilic Softener: Technical Data SheetDocument5 pagesUltratex UHS Hydrophilic Softener: Technical Data SheetSon NguyenNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Solusoft WA Liq - eDocument3 pagesSolusoft WA Liq - esuvrodev812No ratings yet

- Knit Fabric Production ParametersDocument10 pagesKnit Fabric Production Parameterssuvrodev812No ratings yet

- CSE-Lab Report 3 (Working With Data Color)Document8 pagesCSE-Lab Report 3 (Working With Data Color)suvrodev812No ratings yet

- Cover PageDocument2 pagesCover Pagesuvrodev812No ratings yet

- Calculation For Steel Lift Pit at Concourse LevelDocument5 pagesCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNo ratings yet

- Lesson Plan For Fluid Mechanics 4th Sem 2Document2 pagesLesson Plan For Fluid Mechanics 4th Sem 2Naresh Kumar SinghNo ratings yet

- Pratik Pawar Physics ProjectDocument8 pagesPratik Pawar Physics ProjectaagneysuchitaNo ratings yet

- Seminar ReportDocument43 pagesSeminar ReportRamaswamy Koodalloor Parasuraman67% (3)

- M.B.M Engneerng College Jodhpur, Rajasthan: Project Report On Recent Advanced Hghway MateralsDocument49 pagesM.B.M Engneerng College Jodhpur, Rajasthan: Project Report On Recent Advanced Hghway MateralsvrrrruNo ratings yet

- Article - JKR Approach Towards Energy Efficiency in BuildingsDocument14 pagesArticle - JKR Approach Towards Energy Efficiency in BuildingsHanifah AbdullahNo ratings yet

- DEECET (DIETCET) 2010 Question & Answer Key Paper DownloadDocument10 pagesDEECET (DIETCET) 2010 Question & Answer Key Paper DownloadpavaniNo ratings yet

- STTDocument11 pagesSTTamr kouranyNo ratings yet

- Worksheet - Chap3 - Fluid MechanicsDocument3 pagesWorksheet - Chap3 - Fluid Mechanicstibebubeza44No ratings yet

- Taller 1Document1 pageTaller 1CAROLINA PINILLA ROJASNo ratings yet

- Al Si 7 MG 03Document2 pagesAl Si 7 MG 03CSayanavaramNo ratings yet

- Aerodynamics 1 Chapter#2Document46 pagesAerodynamics 1 Chapter#2kianNo ratings yet

- (Isao Ando) Annual Reports On NMR Spectroscopy, Vo (BookFi)Document337 pages(Isao Ando) Annual Reports On NMR Spectroscopy, Vo (BookFi)Rogério SiqueiraNo ratings yet

- Control and Monitoring PointsDocument27 pagesControl and Monitoring Pointsamhosny64No ratings yet

- Variational Calculus With Engineering Applications - UdristeDocument224 pagesVariational Calculus With Engineering Applications - UdristeJuan Rodriguez100% (1)

- Lab NotesDocument216 pagesLab NotessangarfreeNo ratings yet

- A and P Lab Report 2Document7 pagesA and P Lab Report 2Trenishia RiveraNo ratings yet

- Selection, Design, and Installation of Exterior Dimension Stone Anchors and Anchoring SystemsDocument16 pagesSelection, Design, and Installation of Exterior Dimension Stone Anchors and Anchoring Systemssebastian novoaNo ratings yet

- AP10005 - Physics I AP10008 - University Physics I: Angular MomentumDocument18 pagesAP10005 - Physics I AP10008 - University Physics I: Angular MomentumShibu AlexanderNo ratings yet

- Supp Elements 17 For Machine DesignDocument35 pagesSupp Elements 17 For Machine DesignCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- RT Pit PDFDocument35 pagesRT Pit PDFBalachandar ArumugamNo ratings yet

- Synthesis 3Document10 pagesSynthesis 3altisinNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Document1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Luis Miguel GaviñoNo ratings yet

- FM Unit 1Document14 pagesFM Unit 1Zaky MuzaffarNo ratings yet

- SASTRA Deemed To Be UniversityDocument1 pageSASTRA Deemed To Be UniversitySiva PrasannaNo ratings yet

- U2401 Trespa Facades Exterior Solutions 03 2010 Tcm19-9828Document56 pagesU2401 Trespa Facades Exterior Solutions 03 2010 Tcm19-9828zli_zumbulNo ratings yet

- Master Time Table Wef 17-08-2018Document3 pagesMaster Time Table Wef 17-08-2018Hareesha N GNo ratings yet

- Subject - English: Maharaja Agarsain Public School Phase - Iv, Ashok ViharDocument10 pagesSubject - English: Maharaja Agarsain Public School Phase - Iv, Ashok ViharNimish BansalNo ratings yet

- Camag TLC Visualizer PDFDocument8 pagesCamag TLC Visualizer PDFtobingNo ratings yet