Professional Documents

Culture Documents

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Uploaded by

Mauricio Ariel H. OrellanaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Step by Step Hydraulic CalculationDocument26 pagesStep by Step Hydraulic CalculationKarkare89No ratings yet

- SprinkCalc TutorialsDocument170 pagesSprinkCalc Tutorialsmancas500% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assignment 10@Document4 pagesAssignment 10@Berjame Tan May33% (3)

- Prince Valves PDFDocument82 pagesPrince Valves PDFMauricio Ariel H. OrellanaNo ratings yet

- BS en 12056-4 2000 Drainage System Inside BuildingDocument22 pagesBS en 12056-4 2000 Drainage System Inside Buildingnaser71250% (2)

- Ped StarterDocument19 pagesPed Starterjasons92No ratings yet

- Pipe FittingsDocument32 pagesPipe Fittingsalinor_tn100% (5)

- 2.3.2.5 Specification For Piping, Flanges, Fitting and Bulk Materials Rev.A4Document21 pages2.3.2.5 Specification For Piping, Flanges, Fitting and Bulk Materials Rev.A4Andreas Schlager100% (2)

- Hedland Petroleum Flowmeter DatasheetDocument8 pagesHedland Petroleum Flowmeter DatasheetMauricio Ariel H. OrellanaNo ratings yet

- DT Con Freno Manual de ServicioDocument4 pagesDT Con Freno Manual de ServicioMauricio Ariel H. OrellanaNo ratings yet

- Hedland Catalog 2015 FebDocument80 pagesHedland Catalog 2015 FebMauricio Ariel H. OrellanaNo ratings yet

- MN 022311FTRDocument6 pagesMN 022311FTRMauricio Ariel H. OrellanaNo ratings yet

- Conectores TuberiasDocument98 pagesConectores TuberiasMauricio Ariel H. OrellanaNo ratings yet

- Presostato de PresionDocument4 pagesPresostato de PresionMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Publication T1-728 Dated: April 15, 2002Document10 pagesInstallation and Operating Manual: Publication T1-728 Dated: April 15, 2002Mauricio Ariel H. OrellanaNo ratings yet

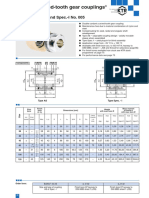

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Document1 pageBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaNo ratings yet

- Dokumen - Tips Blower Tuthill ManualDocument48 pagesDokumen - Tips Blower Tuthill ManualMauricio Ariel H. OrellanaNo ratings yet

- T100 VDocument2 pagesT100 VMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Document10 pagesInstallation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Mauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Engine Air StartersDocument17 pagesInstallation and Operating Manual: Engine Air StartersMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: From Tech Development IncDocument6 pagesInstallation and Operating Manual: From Tech Development IncMauricio Ariel H. OrellanaNo ratings yet

- Service Procedure #THP-100: Commercial Steering SystemsDocument2 pagesService Procedure #THP-100: Commercial Steering SystemsMauricio Ariel H. OrellanaNo ratings yet

- Mounting Subplates BA: Single and ModularDocument3 pagesMounting Subplates BA: Single and ModularMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Air OnlyDocument11 pagesInstallation and Operating Manual: Air OnlyMauricio Ariel H. OrellanaNo ratings yet

- Ficha MartilloDocument5 pagesFicha MartilloMauricio Ariel H. OrellanaNo ratings yet

- Tas 85 Manual 1Document4 pagesTas 85 Manual 1Mauricio Ariel H. OrellanaNo ratings yet

- Directional Control Valves: Log Splitter Control ValveDocument4 pagesDirectional Control Valves: Log Splitter Control ValveMauricio Ariel H. OrellanaNo ratings yet

- Book1 11Document38 pagesBook1 11chandradeep yadavNo ratings yet

- Industrial Hydraulics SG HY01 1001Document68 pagesIndustrial Hydraulics SG HY01 1001Arnaldo BenitezNo ratings yet

- VH 30Document12 pagesVH 30Faiyaz Bin Mazid AhmedNo ratings yet

- Fittings: "Bull". The "Run" Is The Left-To-Right or The Length of The Tee. The "Bull" Is The TopDocument3 pagesFittings: "Bull". The "Run" Is The Left-To-Right or The Length of The Tee. The "Bull" Is The TopJulie Mae SupranesNo ratings yet

- Pulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualDocument25 pagesPulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualTrinh Đình VũNo ratings yet

- Supreme Agri 2021Document1 pageSupreme Agri 2021Mukesh HalpaniNo ratings yet

- 750-180 OM Boiler Feed Systems 10-08Document23 pages750-180 OM Boiler Feed Systems 10-08Sumit ChaurasiaNo ratings yet

- Product Catalog THFDocument48 pagesProduct Catalog THFEdy Quispe QuentaNo ratings yet

- SBMDocument24 pagesSBMseehariNo ratings yet

- Flared Separable FittingDocument9 pagesFlared Separable FittingbenNo ratings yet

- Travel Motor, Installation: Service InformationDocument4 pagesTravel Motor, Installation: Service InformationDmitryNo ratings yet

- D 3311 - 94 - RdmzmtetotqDocument22 pagesD 3311 - 94 - RdmzmtetotqPrakash MakadiaNo ratings yet

- CWP Illustrated Parts Manual 2010-08Document391 pagesCWP Illustrated Parts Manual 2010-08Atticus SmithNo ratings yet

- BSD-Steel Guide 2011 2Document112 pagesBSD-Steel Guide 2011 2Kiran Kumar K T0% (1)

- Bonstrand #2412 Keylock System PDFDocument28 pagesBonstrand #2412 Keylock System PDFKamatchi NathanNo ratings yet

- Water Kiosk DesignDocument1 pageWater Kiosk DesignAbdirahman Mohamed NurNo ratings yet

- Proposed ONE-Storey Residential Building: Project: Location: Owner: SubjectDocument5 pagesProposed ONE-Storey Residential Building: Project: Location: Owner: SubjectMT JasonNo ratings yet

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Document2 pagesBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980No ratings yet

- TRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFDocument94 pagesTRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFInt PueNo ratings yet

- Pipe SizingDocument8 pagesPipe SizingJer Si100% (3)

- Multiflo W: Horizontal Multistage PumpsDocument14 pagesMultiflo W: Horizontal Multistage Pumpsbayu enasoraNo ratings yet

- EGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirDocument20 pagesEGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirMathias OnosemuodeNo ratings yet

- Tb1e 077GG0Document2 pagesTb1e 077GG0danieldario33No ratings yet

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Uploaded by

Mauricio Ariel H. OrellanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Installation and Operating Manual: Publication T30-717, Revision 1 Dated: May 16, 2001

Uploaded by

Mauricio Ariel H. OrellanaCopyright:

Available Formats

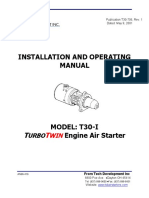

Publication T30-717, Revision 1

Dated: May 16, 2001

INSTALLATION AND OPERATING

MANUAL

MODEL: T30-P

TURBOTWIN Engine Air Starter

AN96-423 From Tech Development Inc

6800 Poe Ave. ·Dayton OH 45414

Tel: (937) 898-9600 ·Fax: (937) 898-8431

Website: www.tdiairstarters.com

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

TABLE OF CONTENTS

SECTION SUBJECT PAGE

1.0 General Information 1

2.0 Orientation of Starter 1

3.0 Installing the Starter 2

4.0 Starter Operation 3

5.0 Model T30 Warranty 5

6.0 Trouble Shooting Guide 6

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

1 T30-P Envelope Drawing 7

2 T30-P Installation Diagram 8

T30-P Performance Curves 9

Publication T30-717, Rev. 1

Issued May 16, 2001

Page: i

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

1.0 GENERAL INFORMATION 1.2 INSTALLATION and SERVICE

This manual provides instructions for the The TDI TurboTwin™ T30 Series starters

installation and operation of the TDI provide distinct advantages of size and

TurboTwin™ Model T30-P engine air starter. efficiency compared to electric motor, vane-

If there are questions not answered by this type, or other turbine-type air starters. It is

manual, please contact your TDI important to properly install the starter to

TurboTwin™ distributor or dealer for receive full benefit of these advantages.

assistance. Repair technicians or service organizations

without turbine starter experience should not

The Model T30-P is a turbine driven air attempt to repair this machine until they

starter with a pre-engage starter drive. It is receive factory approved training from TDI,

well suited for starting diesel engines up to or its representatives. Proper operation and

20 Liters (1220 CID) or gasoline engines up repair of your TDI TurboTwin™ T30 Series

to 28 Liters (1709 CID). The Model T30-P is starter will assure continued reliable and

designed for installation on engines which superior performance for many years.

use an SAE 1, 2, or 3 mounting pad.

WARNING

The T30 Series starters are suited to The TDI TurboTwin™ T30 Series starter

operate within a wide range of inlet air must be installed and operated in

pressures and ambient temperatures. The accordance with the instructions given in this

engine size and parasitic loading will manual. Failure to properly install the

determine the exact minimum pressure that starter, or failure to operate it according to

will ensure reliable starting. these instructions may result in damage to

the starter or the engine, or cause personal

The T30 Series starters are designed for injury.

operation with compressed air or natural

gas. Moderate amounts of foreign matter or

liquid in the air stream will normally not NOTE

adversely affect T30 Series starters. As with THIS STARTER IS TO BE SERVICED ONLY BY

all other TDI TurboTwin™ models, no AUTHORIZED TDI TURBOTWIN™ DISTRIBUTORS,

DEALERS, AND REPAIR STATIONS. DO NOT

lubrication is required in the supply air. OPERATE THIS STARTER UNLESS IT IS PROPERLY

ATTACHED TO AN ENGINE.

You need to review the rest of this manual

before installing your TDI TurboTwin™ T30

Series starter. 2.0 ORIENTATION OF THE

STARTER

1.1 WARNINGS, CAUTIONS, & NOTES

Throughout this manual, certain types of If the factory orientation of the starter’s

information will be highlighted for your pinion housing, gearbox assembly, or

attention: optional exhaust port does not fit your

engine installation, these components can

WARNING - used where injury to be re-oriented.

personnel or damage to the

equipment is possible. 2.1 MODEL T30-P ORIENTATION

CAUTION - used where there is the A. Determine the required orientation of the

possibility of damage to the pinion housing, gearbox housing, optional

equipment. exhaust port.

NOTE - used to point out special B. Note that the pinion housing can be

interest information. rotated to twelve different positions relative

to the gearbox housing and the gearbox

Publication T30-717, Rev. 1 Page 1

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

housing can be rotated to four positions which connect the exhaust to the turbine

relative to the inlet port. Additionally, the assemble. Rotate the exhaust housing to

optional exhaust port can be rotated to eight the desired position relative to the inlet port.

positions relative to the inlet port.

Reinstall the seven or eight socket head cap

screws. Torque to 4.2 Lb-Ft. (5.7 Nm)

CAUTION

All screw threads are treated at the factory

with a fastener retention compound. Every

CAUTION

screw and tapped hole must be clean and Ensure that the O-ring on the exhaust

have a drop of Loctite 290 applied to the housing remains in position and is not cut.

threads before being reinstalled.

CAUTION

2.1.1 Pinion Housing Re-Orientation All screw threads are treated at the factory

with a fastener retention compound. Every

Remove the twelve-pinion housing to screw and tapped hole must be clean and

gearbox housing socket head cap screws. have a drop of Loctite 290 applied to the

threads before being reinstalled.

Rotate the pinion housing to the desired

position and reinstall the twelve cap screws. 3.0 INSTALLING THE STARTER

Torque the twelve socket head cap screws

to 9.4 Lb-Ft (12.7 Nm). A typical T30 Series installation is shown in

Figure 2. The components may vary in

CAUTION shape, but there must at least be a start

Ensure that the O-ring on the pinion housing switch, air tank, and air piloted relay valve to

remains in position and is not cut. correctly operate a T30 starter.

2.1.2 Gearbox Housing Re-Orientation

NOTE

Remove the four tie bolts that secure the Mounting the air piloted relay valve on the

gearbox housing to the inlet housing. starter is preferred in installations where

space is available.

Rotate the gearbox/pinion housing to the

desired position. TDI recommends mounting the air piloted

relay valve no more than 3 meters (10 feet)

from the starter’s inlet port, and as close to

NOTE the starter as possible. If the starter is being

The five radial screws which connect the installed on a vehicle where the air tank is

turbine and inlet housings must remain in within 3 meters (10 feet) of the starter, then

the same position, relative to each other. the relay valve may be mounted on the tank.

CAUTION A turbine driven starter does not require

Ensure that the O-ring between the gearbox lubrication in the supply air. Therefore, if a

housing and inlet/turbine assembly remain in vane-type starter motor is being replaced,

position and is not cut. TDI recommends that all lubrication devices

and lines are removed to minimize flow

Reinstall the four tie bolts. Torque the four restrictions.

tie bolts to 9.4 Lb-Ft. (12.7 Nm).

WARNING

2.1.3 Exhaust Housing Orientation If a fuel (pulse) lubricator has previously

been installed in the system, disconnect and

If this unit has an optional exhaust housing plug the line to eliminate spraying diesel fuel

remove the seven (if a 90o elbow) or eight (if on the engine.

a straight exhaust) socket head cap screws

Page 2 Publication T30-717, Rev. 1

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

Liberally grease the starter’s pinion teeth CAUTION

with chassis lure and then mount the T30

IN NO CASE SHOULD INLET OPERATING

Series starter on the engine. Tighten all

PRESSURE EXCEED 10.3 BAR (150

mounting hardware as appropriate.

PSIG).

After mounting the starter to the engine,

attach the supply air line from the tank, the WARNING

control air lines, and the solenoid to the Do not operate the TDI TurboTwin T30

ignition system and air piloted relay valve. Series air starter with air pressure greater

than the pressure rating on the nameplate.

TDI recommends installation of a “Glad This pressure is to be measured at the

Hand” / quick disconnect for auxiliary starter inlet while the starter is running.

pressurization of the air tank.

The static supply pressure will always be

Because turbine starters are sensitive to higher than the operating pressure. As a

flow restrictions, care must be taken to use guideline, the maximum pressure limit (proof

uniform hose or tubing and fittings for supply pressure) that the T30 Series starter may be

air line connection. Tees, elbows, and line subjected to is 20.7 bar (300 PSIG). System

length must be kept to a minimum. TDI pressure that exceeds the maximum

recommends that hose or flex couplings be operating limit must use a pressure reducer

installed to eliminate possible leakage device to ensure operating pressure limit to

caused by strain on the supply air line. the T30 Series starter is maintained.

Normally an air strainer is not required. In System pressure that exceeds the 20.7 bar

dirty environments, use of a #40 mesh Y- (300 PSIG) limit must, in addition to a

strainer is recommended. pressure reducer device, incorporate a

pressure relief valve, set below 20.7 bar

Only type approved metallic hose (300 PSIG), in the supply air line.

assemblies are approved in permanently

pressurized compressed air lines of starters. All appropriate local pressure codes and

Non-metallic hose assemblies are allowed pressure limitations on other system

only in case the piping system will be components must be adhered to and

emptied after the starting procedure. supersedes guidelines given in this manual.

Pipe unions must be type approved by GL. Follow the engine manufacturer’s

Downstream of the pressure regulator a instructions for starting the engine.

pressure relief valve is to be provided.

WARNING

WARNING Do not engage the starter while the engine

Recheck all connections for tight fit. is running.

Fill the air system tank. The T30-P Series If the starter fails to function properly when

starter is now ready to operate. first operated, or its performance

deteriorates with use, refer to the Operator’s

4.0 STARTER OPERATION Trouble Shooting Guide, Section 6.0. If you

cannot solve the problem, or repair is

The maximum operating pressure limit is necessary, contact your local TDI

that pressure measured at the starter inlet TurboTwin™ distributor or dealer.

pressure check port during the crank cycle.

In order to check the starter inlet pressure, a Turbine starters share a common

1/8" NPT pipe tap connection is provided in characteristic known as “coast-down”. Once

the inlet housing for attaching a pressure unloaded, turbines coast to a stop from their

gauge; refer to Figure 2. unloaded or free-speed. Turbines behave

Publication T30-717, Rev. 1 Page 3

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

differently in this respect, compared to

positive displacement devices, because the

WARNING

Re-engaging pre-engaged turbine starters

friction (drag) of rubbing, sealing surfaces

during coast-down can damage the starter

(piston rings or vanes) quickly stops an

pinion and the engine ring gear. Turbine air

unloaded machine. Less encumbered by

starters must NEVER be re-engaged during

drag, and typically decelerating from much

coast-down or before the starter comes to a

higher operating speeds, turbines can take

considerably longer to come to rest. complete stop.

When pre-engaged starters are used, a To insure correct starter operation, users

procedure specifying a 30-second delay may choose to incorporate an electronic or

between engine crank attempts is sufficient pneumatic control device to prevent

to insure correct operation. This is common accidental re-engagement during coast-

practice by many users and delays are down. In addition, operators and

typically programmed into fully automated technicians should be educated about the

starter control systems. effects of coast-down.

This "30 Second Rule" should also be

strictly followed when using the starter in a

"manual mode" or to perform routine

maintenance tasks such as engine timing,

inspections, valve adjustments, etc.

Page 4 Publication T30-717, Rev. 1

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

5.0 WARRANTY

TDI TURBOTWIN ENGINE STARTER WARRANTY

Tech Development Inc. (TDI) warrants to the original user of the TDI TURBOTWIN™ Model T30

Series air starters to be free from defects in material and workmanship for a period of one year

from the date of installation. The warranty period shall not extend beyond two years from the

date the unit was manufactured. (i.e.: a unit with a manufactured date of July 1999 (SN: 9907-

101) will not be covered under warranty after July 2001). The conditions of this warranty are: a)

TDI is notified within this period by return of such product to TDI or its authorized

distributor/dealer, transportation prepaid by user; b) the starter has been installed according to

TDI’s specifications; c) the starter has not been misused, abused, or improperly maintained by

user; d) the defect is not the result of normal wear and tear; e) the starter has been repaired with

parts manufactured or authorized by TDI; and f) TDI installation and repair procedures as outlined

in the appropriate manual were properly followed.

Tech Development Inc. will repair, or at its option, replace the unit during the

warranty period at no charge to the customer, provided it is returned to TDI

with the proper return procedure.

Tech Development Inc. makes no other warranty, and implied warranties including any warranty

or merchantability or fitness for a particular purpose are hereby disclaimed.

This warranty constitutes the entire obligation of Tech Development Inc. relating to the sale and

use of such product, and TDI’s maximum liability is limited to the purchase price of such product

at the date of purchase. In no event shall TDI be liable for incidental, indirect, consequential, or

special damages of any nature arising from the sale or use of such engine starter product.

Publication T30-717, Rev. 1 Page 5

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

6.0 OPERATOR’S TROUBLESHOOTING GUIDE

TROUBLE PROBABLE CAUSE SOLUTION

1. Air always flow through A. Relay valve improperly A. Check typical installation

exhaust installed. diagram and correct

B. Relay valve not sealing B. Check for damaged sealing

properly. ring, replace relay valve or

damaged parts.

C. Solenoid is not sealing, C. Check solenoid potential at the

pressure remains in APP port of lead to ground should be 0. If not,

relay valve. fix ignition switch problem.

2. Starter engages but does not A. Bad relay valve A. Replace relay valve.

run,

3. Starter does not run, small air A. Nozzle blockage. A. Remove blockage or obstruction

flow from turbine exhaust or from nozzles.

drive housing.

4. Starter does not run. Normal A. Excessive bends in the A. Shorten length or straighten

air flow from exhaust. supply line. supply air line.

5. Pinion does not engage A. Air pressure is too low A. Increase air pressure to 40 -

150 psig.

B. Control lines to starter ports B. Check installation diagram and

reversed. correct.

C. Solenoid valve not operating C. Check wiring and solenoid

or plugged. operation. Correct wiring, remove

blockage, or replace solenoid

valve as needed.

D. Damaged pinion teeth. D. Replace pinion or starter drive

as necessary.

6. Starter runs but engine cranks A. Air pressure too low A. Increase air pressure to 40 –

slowly or not at all. 150 psig.

B. Excessive back pressure. B. Check Exhaust Closure Plate.

C. Worn or broken starter drive. C. Replace starter drive.

D. Nozzle blocked or damaged. D. Remove blockage or replace

damaged parts.

7. Starter continues to operate A. Solenoid valve is not sealing A. See 1C above

after start button is released. correctly.

B. Relay valve is not sealing B. See 1B above

correctly.

8. Air tank pressure decays after A. Air connections are too tight. A. Tighten loose fittings. Repair or

extended shut down. replace damaged fittings.

B. Damaged air lines: crushed, B. Replace damaged lines.

frayed, and kinked.

C. Relay valve is not sealing C. See 1B above

correctly.

D. Solenoid valve is stuck open. D. See 1C above

Page 6 Publication T30-717, Rev. 1

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

Figure 1. T30-P TURBOTWIN Air Starter Envelope Drawing

Publication T30-717, Rev. 1 Page 7

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

Figure 2. TURBOTWIN T30-P Installation Diagram

Page 8 Publication T30-717, Rev. 1

Issued May 16, 2001

TDI TURBOTWINÔ

FROM TECH DEVELOPMENT, Inc

TORQUE

T306 Performance Curve POWER

Nm LB.FT 6 Nozzles, Compressed Air, 9.0:1 RATIO HP KW

204 150 50 37.2

Inlet Pressure SCFM Nm3/h

150 150 PSIG 600 1020 45 33.5

psi 120 PSIG 478 813

170 125 g 90 PSIG 365 621

60 PSIG 255 434 40 29.8

120 35 26.1

psi

136 100 g

30 22.4

90 p

102 75 s ig 25 18.6

20 14.9

60 p

68 50 si g

15 11.2

10 7.5

34 25

5 3.7

0 0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

T306 Performance Curve

TORQUE POWER

Nm LB.FT 6 Nozzles, Methane Gas, 9.0:1 RATIO HP KW

35 26.1

Inlet Pressure SCFM Nm3/h

120 PSIG 600 1020

170 125 90 PSIG

60 PSIG

465

330

791

561

30 22.4

120

136 100 psi

g 25 18.6

20 14.9

102 75 90 p

sig

15 11.2

60 ps

68 50 ig

10 7.5

34 25

5 3.7

0 0 0 0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

Publication T30-717, Rev. 1 Page 9

Issued May 16, 2001

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Step by Step Hydraulic CalculationDocument26 pagesStep by Step Hydraulic CalculationKarkare89No ratings yet

- SprinkCalc TutorialsDocument170 pagesSprinkCalc Tutorialsmancas500% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assignment 10@Document4 pagesAssignment 10@Berjame Tan May33% (3)

- Prince Valves PDFDocument82 pagesPrince Valves PDFMauricio Ariel H. OrellanaNo ratings yet

- BS en 12056-4 2000 Drainage System Inside BuildingDocument22 pagesBS en 12056-4 2000 Drainage System Inside Buildingnaser71250% (2)

- Ped StarterDocument19 pagesPed Starterjasons92No ratings yet

- Pipe FittingsDocument32 pagesPipe Fittingsalinor_tn100% (5)

- 2.3.2.5 Specification For Piping, Flanges, Fitting and Bulk Materials Rev.A4Document21 pages2.3.2.5 Specification For Piping, Flanges, Fitting and Bulk Materials Rev.A4Andreas Schlager100% (2)

- Hedland Petroleum Flowmeter DatasheetDocument8 pagesHedland Petroleum Flowmeter DatasheetMauricio Ariel H. OrellanaNo ratings yet

- DT Con Freno Manual de ServicioDocument4 pagesDT Con Freno Manual de ServicioMauricio Ariel H. OrellanaNo ratings yet

- Hedland Catalog 2015 FebDocument80 pagesHedland Catalog 2015 FebMauricio Ariel H. OrellanaNo ratings yet

- MN 022311FTRDocument6 pagesMN 022311FTRMauricio Ariel H. OrellanaNo ratings yet

- Conectores TuberiasDocument98 pagesConectores TuberiasMauricio Ariel H. OrellanaNo ratings yet

- Presostato de PresionDocument4 pagesPresostato de PresionMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Publication T1-728 Dated: April 15, 2002Document10 pagesInstallation and Operating Manual: Publication T1-728 Dated: April 15, 2002Mauricio Ariel H. OrellanaNo ratings yet

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Document1 pageBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaNo ratings yet

- Dokumen - Tips Blower Tuthill ManualDocument48 pagesDokumen - Tips Blower Tuthill ManualMauricio Ariel H. OrellanaNo ratings yet

- T100 VDocument2 pagesT100 VMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Document10 pagesInstallation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Mauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Engine Air StartersDocument17 pagesInstallation and Operating Manual: Engine Air StartersMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: From Tech Development IncDocument6 pagesInstallation and Operating Manual: From Tech Development IncMauricio Ariel H. OrellanaNo ratings yet

- Service Procedure #THP-100: Commercial Steering SystemsDocument2 pagesService Procedure #THP-100: Commercial Steering SystemsMauricio Ariel H. OrellanaNo ratings yet

- Mounting Subplates BA: Single and ModularDocument3 pagesMounting Subplates BA: Single and ModularMauricio Ariel H. OrellanaNo ratings yet

- Installation and Operating Manual: Air OnlyDocument11 pagesInstallation and Operating Manual: Air OnlyMauricio Ariel H. OrellanaNo ratings yet

- Ficha MartilloDocument5 pagesFicha MartilloMauricio Ariel H. OrellanaNo ratings yet

- Tas 85 Manual 1Document4 pagesTas 85 Manual 1Mauricio Ariel H. OrellanaNo ratings yet

- Directional Control Valves: Log Splitter Control ValveDocument4 pagesDirectional Control Valves: Log Splitter Control ValveMauricio Ariel H. OrellanaNo ratings yet

- Book1 11Document38 pagesBook1 11chandradeep yadavNo ratings yet

- Industrial Hydraulics SG HY01 1001Document68 pagesIndustrial Hydraulics SG HY01 1001Arnaldo BenitezNo ratings yet

- VH 30Document12 pagesVH 30Faiyaz Bin Mazid AhmedNo ratings yet

- Fittings: "Bull". The "Run" Is The Left-To-Right or The Length of The Tee. The "Bull" Is The TopDocument3 pagesFittings: "Bull". The "Run" Is The Left-To-Right or The Length of The Tee. The "Bull" Is The TopJulie Mae SupranesNo ratings yet

- Pulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualDocument25 pagesPulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualTrinh Đình VũNo ratings yet

- Supreme Agri 2021Document1 pageSupreme Agri 2021Mukesh HalpaniNo ratings yet

- 750-180 OM Boiler Feed Systems 10-08Document23 pages750-180 OM Boiler Feed Systems 10-08Sumit ChaurasiaNo ratings yet

- Product Catalog THFDocument48 pagesProduct Catalog THFEdy Quispe QuentaNo ratings yet

- SBMDocument24 pagesSBMseehariNo ratings yet

- Flared Separable FittingDocument9 pagesFlared Separable FittingbenNo ratings yet

- Travel Motor, Installation: Service InformationDocument4 pagesTravel Motor, Installation: Service InformationDmitryNo ratings yet

- D 3311 - 94 - RdmzmtetotqDocument22 pagesD 3311 - 94 - RdmzmtetotqPrakash MakadiaNo ratings yet

- CWP Illustrated Parts Manual 2010-08Document391 pagesCWP Illustrated Parts Manual 2010-08Atticus SmithNo ratings yet

- BSD-Steel Guide 2011 2Document112 pagesBSD-Steel Guide 2011 2Kiran Kumar K T0% (1)

- Bonstrand #2412 Keylock System PDFDocument28 pagesBonstrand #2412 Keylock System PDFKamatchi NathanNo ratings yet

- Water Kiosk DesignDocument1 pageWater Kiosk DesignAbdirahman Mohamed NurNo ratings yet

- Proposed ONE-Storey Residential Building: Project: Location: Owner: SubjectDocument5 pagesProposed ONE-Storey Residential Building: Project: Location: Owner: SubjectMT JasonNo ratings yet

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Document2 pagesBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980No ratings yet

- TRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFDocument94 pagesTRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFInt PueNo ratings yet

- Pipe SizingDocument8 pagesPipe SizingJer Si100% (3)

- Multiflo W: Horizontal Multistage PumpsDocument14 pagesMultiflo W: Horizontal Multistage Pumpsbayu enasoraNo ratings yet

- EGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirDocument20 pagesEGP3-03.02 Instrumentation, Control Valve Stations and Instrument AirMathias OnosemuodeNo ratings yet

- Tb1e 077GG0Document2 pagesTb1e 077GG0danieldario33No ratings yet