Professional Documents

Culture Documents

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

Uploaded by

heliocoelhojrCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ECM3701 Electronic Communcation Technology: Minor Test No: 01 Year ModuleDocument4 pagesECM3701 Electronic Communcation Technology: Minor Test No: 01 Year ModuleTale Banks0% (1)

- Tequila BB PDFDocument2 pagesTequila BB PDFheliocoelhojrNo ratings yet

- Chaos Craft by Steve Dee and Julian VayneDocument211 pagesChaos Craft by Steve Dee and Julian VayneṨĸṳlḷ Kȉď100% (4)

- Designer MilkDocument30 pagesDesigner MilkParashuram Shanigaram67% (6)

- EN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseDocument3 pagesEN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseheliocoelhojrNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Beginning Low Loopers PDFDocument1 pageBeginning Low Loopers PDFheliocoelhojrNo ratings yet

- Beginning Low Loopers PDFDocument1 pageBeginning Low Loopers PDFheliocoelhojrNo ratings yet

- M.D.G., EMI Division © Yamaha Corporation 1994 VS67010 408PTCP25.2-01A0 Printed in JapanDocument76 pagesM.D.G., EMI Division © Yamaha Corporation 1994 VS67010 408PTCP25.2-01A0 Printed in JapanheliocoelhojrNo ratings yet

- Sweet Child O Mine Saxophone Quartet PDFDocument20 pagesSweet Child O Mine Saxophone Quartet PDFheliocoelhojrNo ratings yet

- Weather StationDocument12 pagesWeather StationheliocoelhojrNo ratings yet

- SherlineDocument48 pagesSherlineheliocoelhojrNo ratings yet

- Insulation Resistance (IR) Values - IndexDocument8 pagesInsulation Resistance (IR) Values - IndexAbdullah Al AsikNo ratings yet

- Case Study 03 MSDDocument4 pagesCase Study 03 MSDmohamedelwarithNo ratings yet

- For ConsultationDocument11 pagesFor ConsultationClarisse PoliciosNo ratings yet

- Dairy Farm10Document3 pagesDairy Farm10GarNo ratings yet

- Mels Subtype DescriptionsDocument11 pagesMels Subtype DescriptionsclaraNo ratings yet

- CDP Virtual Appliance Getting Started GuideDocument18 pagesCDP Virtual Appliance Getting Started GuideJulio RodanesNo ratings yet

- ch1 NEW Physics 12 Study GuideDocument16 pagesch1 NEW Physics 12 Study GuidemllupoNo ratings yet

- CAPtain Online ExplainedDocument13 pagesCAPtain Online ExplainedRebekaNo ratings yet

- Historiography On The Origins of The Cold WarDocument4 pagesHistoriography On The Origins of The Cold Warapi-297872327100% (2)

- Kindergarten Writing Lesson PlanDocument7 pagesKindergarten Writing Lesson Planapi-332051194No ratings yet

- What Is Tajweed - (PDFDrive)Document114 pagesWhat Is Tajweed - (PDFDrive)REYAZ HASSAN MIRNo ratings yet

- PROWESS User ManualDocument33 pagesPROWESS User ManualSachin Dhiman100% (9)

- Hafs and Warsh (Part 2)Document4 pagesHafs and Warsh (Part 2)Asad HoseinyNo ratings yet

- What I Need To Know? What I Need To Know?: Quarter 1Document16 pagesWhat I Need To Know? What I Need To Know?: Quarter 1Aileen gay PayunanNo ratings yet

- Political Culture in Post Communist Countries Albanian CaseDocument10 pagesPolitical Culture in Post Communist Countries Albanian CaseArditÇekaNo ratings yet

- Statement of PurposeDocument1 pageStatement of Purposeapi-397556034No ratings yet

- ACSI E-Business Report 2018Document10 pagesACSI E-Business Report 2018arakeelNo ratings yet

- A Handbook of Art SmithingDocument232 pagesA Handbook of Art SmithingArtisan Ideas100% (3)

- The Buddha's Wife - The Path of Awakening Together by Janet SurreyDocument2 pagesThe Buddha's Wife - The Path of Awakening Together by Janet SurreySuresh AmatyaNo ratings yet

- Integration of New Literacies in The CurriculumDocument10 pagesIntegration of New Literacies in The CurriculumMariel Mae PolancosNo ratings yet

- 001 GEYSERSD23Final PDFDocument100 pages001 GEYSERSD23Final PDFVasu ThakurNo ratings yet

- Design Calculations For The Cooling Water System of A Tug BoatDocument19 pagesDesign Calculations For The Cooling Water System of A Tug BoatAbhishek KumarNo ratings yet

- Narasimha HomaDocument40 pagesNarasimha HomaDurga PrasadNo ratings yet

- GCT LTE Module Software Development Guide: Aquila Solutions IncDocument26 pagesGCT LTE Module Software Development Guide: Aquila Solutions IncLionel MusonzaNo ratings yet

- Engin EKER, MDDocument23 pagesEngin EKER, MDWorldEventsForumNo ratings yet

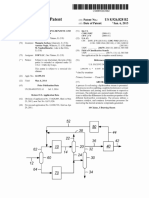

- United States Patent: Serban Et AlDocument9 pagesUnited States Patent: Serban Et AlMutia Herlisa14No ratings yet

- RTS Unit 1 NotesDocument24 pagesRTS Unit 1 NotesSAROJ RAJANo ratings yet

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

Uploaded by

heliocoelhojrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

CYCOLAC™ Resin - MG47F - Americas - Technical - Data - Sheet

Uploaded by

heliocoelhojrCopyright:

Available Formats

™

CYCOLAC RESIN MG47F

REGION AMERICAS

DESCRIPTION

Multi-purpose, injection molding ABS providing a favorable balance of engineering properties. FDA compliant.

TYPICAL PROPERTY VALUES Revision 20190925

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

MECHANICAL

Tensile Stress, yld, Type I, 5 mm/min 44 MPa ASTM D 638

Tensile Stress, brk, Type I, 5 mm/min 33 MPa ASTM D 638

Tensile Strain, yld, Type I, 5 mm/min 2 % ASTM D 638

Tensile Strain, brk, Type I, 5 mm/min 24 % ASTM D 638

Tensile Modulus, 5 mm/min 2270 MPa ASTM D 638

Flexural Stress, yld, 1.3 mm/min, 50 mm span 70 MPa ASTM D 790

Flexural Modulus, 1.3 mm/min, 50 mm span 2300 MPa ASTM D 790

Hardness, Rockwell R 112 - ASTM D 785

Tensile Stress, yield, 50 mm/min 47 MPa ISO 527

Tensile Stress, break, 50 mm/min 35 MPa ISO 527

Tensile Strain, yield, 50 mm/min 2.6 % ISO 527

Tensile Strain, break, 50 mm/min 25 % ISO 527

Tensile Modulus, 1 mm/min 2370 MPa ISO 527

Flexural Stress, yield, 2 mm/min 70 MPa ISO 178

Flexural Modulus, 2 mm/min 2200 MPa ISO 178

IMPACT

Izod Impact, notched, 23°C 320 J/m ASTM D 256

Instrumented Impact Total Energy, 23°C 30 J ASTM D 3763

Izod Impact, notched 80*10*4 +23°C 22 kJ/m² ISO 180/1A

Izod Impact, notched 80*10*4 -30°C 8 kJ/m² ISO 180/1A

Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm 26 kJ/m² ISO 179/1eA

Charpy -30°C, V-notch Edgew 80*10*4 sp=62mm 9 kJ/m² ISO 179/1eA

THERMAL

Vicat Softening Temp, Rate B/50 99 °C ASTM D 1525

HDT, 0.45 MPa, 3.2 mm, unannealed 94 °C ASTM D 648

HDT, 1.82 MPa, 3.2mm, unannealed 80 °C ASTM D 648

CTE, -40°C to 40°C, flow 8.82E-05 1/°C ASTM E 831

CTE, -40°C to 40°C, xflow 8.82E-05 1/°C ASTM E 831

Vicat Softening Temp, Rate B/50 98 °C ISO 306

Vicat Softening Temp, Rate B/120 100 °C ISO 306

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 81 °C ISO 75/Af

Relative Temp Index, Elec 60 °C UL 746B

Relative Temp Index, Mech w/impact 60 °C UL 746B

Relative Temp Index, Mech w/o impact 60 °C UL 746B

PHYSICAL

©Specific

2019 Copyright

Gravityby SABIC. All rights reserved 1.04 - ASTM D 792

Mold Shrinkage, flow, 3.2 mm 0.5 – 0.8 % SABIC method

Melt Flow Rate, 230°C/3.8 kg 5.6 g/10 min ASTM D 1238

Melt Viscosity, 240°C, 1000 sec-1 2250 Poise ASTM D 3825

Density 1.04 g/cm³ ISO 1183

Charpy -30°C, V-notch Edgew 80*10*4 sp=62mm 9 kJ/m² ISO 179/1eA

THERMAL

Vicat Softening Temp, Rate B/50 99 °C ASTM D 1525

HDT, 0.45 MPa, 3.2 mm, unannealed 94 °C ASTM D 648

HDT, 1.82 MPa, 3.2mm, unannealed 80 °C ASTM D 648

CTE, -40°C to 40°C, flow 8.82E-05 1/°C ASTM E 831

CTE, -40°C to 40°C, xflow 8.82E-05 1/°C ASTM E 831

Vicat Softening Temp, Rate B/50 98 °C ISO 306

Vicat Softening Temp, Rate B/120 100 °C ISO 306

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 81 °C ISO 75/Af

Relative Temp Index, Elec 60 °C UL 746B

Relative Temp Index, Mech w/impact 60 °C UL 746B

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

Relative Temp Index, Mech w/o impact 60 °C UL 746B

PHYSICAL

Specific Gravity 1.04 - ASTM D 792

Mold Shrinkage, flow, 3.2 mm 0.5 – 0.8 % SABIC method

Melt Flow Rate, 230°C/3.8 kg 5.6 g/10 min ASTM D 1238

Melt Viscosity, 240°C, 1000 sec-1 2250 Poise ASTM D 3825

Density 1.04 g/cm³ ISO 1183

Melt Flow Rate, 220°C/10.0 kg 18 g/10 min ISO 1133

ELECTRICAL

Arc Resistance, Tungsten {PLC} 6 PLC Code ASTM D 495

Hot Wire Ignition {PLC) 3 PLC Code UL 746A

High Voltage Arc Track Rate {PLC} 3 PLC Code UL 746A

High Ampere Arc Ign, surface {PLC} 0 PLC Code UL 746A

Comparative Tracking Index (UL) {PLC} 0 PLC Code UL 746A

FLAME CHARACTERISTICS

UL Yellow Card Link E121562-100324185 - -

UL Recognized, 94HB Flame Class Rating 1.5 mm UL 94

INJECTION MOLDING

Drying Temperature 80 – 95 °C

Drying Time 2–4 hrs

Drying Time (Cumulative) 8 hrs

Maximum Moisture Content 0.1 %

Melt Temperature 220 – 260 °C

Nozzle Temperature 220 – 260 °C

Front - Zone 3 Temperature 215 – 240 °C

Middle - Zone 2 Temperature 205 – 225 °C

Rear - Zone 1 Temperature 190 – 210 °C

Mold Temperature 50 – 70 °C

Back Pressure 0.3 – 0.7 MPa

Screw Speed 30 – 60 rpm

Shot to Cylinder Size 50 – 70 %

Vent Depth 0.038 – 0.051 mm

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed

otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE

PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller

materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is

intended, or should be construed, to grant any license under any patent or other intellectual property right.

© 2019 Copyright by SABIC. All rights reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ECM3701 Electronic Communcation Technology: Minor Test No: 01 Year ModuleDocument4 pagesECM3701 Electronic Communcation Technology: Minor Test No: 01 Year ModuleTale Banks0% (1)

- Tequila BB PDFDocument2 pagesTequila BB PDFheliocoelhojrNo ratings yet

- Chaos Craft by Steve Dee and Julian VayneDocument211 pagesChaos Craft by Steve Dee and Julian VayneṨĸṳlḷ Kȉď100% (4)

- Designer MilkDocument30 pagesDesigner MilkParashuram Shanigaram67% (6)

- EN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseDocument3 pagesEN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseheliocoelhojrNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Beginning Low Loopers PDFDocument1 pageBeginning Low Loopers PDFheliocoelhojrNo ratings yet

- Beginning Low Loopers PDFDocument1 pageBeginning Low Loopers PDFheliocoelhojrNo ratings yet

- M.D.G., EMI Division © Yamaha Corporation 1994 VS67010 408PTCP25.2-01A0 Printed in JapanDocument76 pagesM.D.G., EMI Division © Yamaha Corporation 1994 VS67010 408PTCP25.2-01A0 Printed in JapanheliocoelhojrNo ratings yet

- Sweet Child O Mine Saxophone Quartet PDFDocument20 pagesSweet Child O Mine Saxophone Quartet PDFheliocoelhojrNo ratings yet

- Weather StationDocument12 pagesWeather StationheliocoelhojrNo ratings yet

- SherlineDocument48 pagesSherlineheliocoelhojrNo ratings yet

- Insulation Resistance (IR) Values - IndexDocument8 pagesInsulation Resistance (IR) Values - IndexAbdullah Al AsikNo ratings yet

- Case Study 03 MSDDocument4 pagesCase Study 03 MSDmohamedelwarithNo ratings yet

- For ConsultationDocument11 pagesFor ConsultationClarisse PoliciosNo ratings yet

- Dairy Farm10Document3 pagesDairy Farm10GarNo ratings yet

- Mels Subtype DescriptionsDocument11 pagesMels Subtype DescriptionsclaraNo ratings yet

- CDP Virtual Appliance Getting Started GuideDocument18 pagesCDP Virtual Appliance Getting Started GuideJulio RodanesNo ratings yet

- ch1 NEW Physics 12 Study GuideDocument16 pagesch1 NEW Physics 12 Study GuidemllupoNo ratings yet

- CAPtain Online ExplainedDocument13 pagesCAPtain Online ExplainedRebekaNo ratings yet

- Historiography On The Origins of The Cold WarDocument4 pagesHistoriography On The Origins of The Cold Warapi-297872327100% (2)

- Kindergarten Writing Lesson PlanDocument7 pagesKindergarten Writing Lesson Planapi-332051194No ratings yet

- What Is Tajweed - (PDFDrive)Document114 pagesWhat Is Tajweed - (PDFDrive)REYAZ HASSAN MIRNo ratings yet

- PROWESS User ManualDocument33 pagesPROWESS User ManualSachin Dhiman100% (9)

- Hafs and Warsh (Part 2)Document4 pagesHafs and Warsh (Part 2)Asad HoseinyNo ratings yet

- What I Need To Know? What I Need To Know?: Quarter 1Document16 pagesWhat I Need To Know? What I Need To Know?: Quarter 1Aileen gay PayunanNo ratings yet

- Political Culture in Post Communist Countries Albanian CaseDocument10 pagesPolitical Culture in Post Communist Countries Albanian CaseArditÇekaNo ratings yet

- Statement of PurposeDocument1 pageStatement of Purposeapi-397556034No ratings yet

- ACSI E-Business Report 2018Document10 pagesACSI E-Business Report 2018arakeelNo ratings yet

- A Handbook of Art SmithingDocument232 pagesA Handbook of Art SmithingArtisan Ideas100% (3)

- The Buddha's Wife - The Path of Awakening Together by Janet SurreyDocument2 pagesThe Buddha's Wife - The Path of Awakening Together by Janet SurreySuresh AmatyaNo ratings yet

- Integration of New Literacies in The CurriculumDocument10 pagesIntegration of New Literacies in The CurriculumMariel Mae PolancosNo ratings yet

- 001 GEYSERSD23Final PDFDocument100 pages001 GEYSERSD23Final PDFVasu ThakurNo ratings yet

- Design Calculations For The Cooling Water System of A Tug BoatDocument19 pagesDesign Calculations For The Cooling Water System of A Tug BoatAbhishek KumarNo ratings yet

- Narasimha HomaDocument40 pagesNarasimha HomaDurga PrasadNo ratings yet

- GCT LTE Module Software Development Guide: Aquila Solutions IncDocument26 pagesGCT LTE Module Software Development Guide: Aquila Solutions IncLionel MusonzaNo ratings yet

- Engin EKER, MDDocument23 pagesEngin EKER, MDWorldEventsForumNo ratings yet

- United States Patent: Serban Et AlDocument9 pagesUnited States Patent: Serban Et AlMutia Herlisa14No ratings yet

- RTS Unit 1 NotesDocument24 pagesRTS Unit 1 NotesSAROJ RAJANo ratings yet