Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsColchester Triumph 2000 Footbrake Manual

Colchester Triumph 2000 Footbrake Manual

Uploaded by

Tomek DekaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cup 03 BB3 Uk WebDocument7 pagesCup 03 BB3 Uk Webschumiizz2bestNo ratings yet

- (FPD-1654a (E) - Water Injection Pumps LRDocument11 pages(FPD-1654a (E) - Water Injection Pumps LRschumiizz2bestNo ratings yet

- Handbook SKFDocument452 pagesHandbook SKFschumiizz2bestNo ratings yet

- Paul Huet 1Document1 pagePaul Huet 1schumiizz2bestNo ratings yet

- Info Sur Le FiletAgeDocument19 pagesInfo Sur Le FiletAgeschumiizz2bestNo ratings yet

- Develop3D Ebook - The Importance of Drawings - tcm27-2694Document4 pagesDevelop3D Ebook - The Importance of Drawings - tcm27-2694schumiizz2bestNo ratings yet

- X105 CR Mo 17 ChromeDocument2 pagesX105 CR Mo 17 ChromeAbdennasser RahibiNo ratings yet

- Distribution À Soupapes PDFDocument39 pagesDistribution À Soupapes PDFschumiizz2best100% (1)

- Z6CND16 05Document2 pagesZ6CND16 05schumiizz2bestNo ratings yet

- Pajero EngineDocument54 pagesPajero Engineschumiizz2bestNo ratings yet

- Mitsu Pajero Engine 4D5Document54 pagesMitsu Pajero Engine 4D5schumiizz2bestNo ratings yet

- Z30C13Document2 pagesZ30C13schumiizz2bestNo ratings yet

- Traitement Thermique Engrenage Juillet 2011Document7 pagesTraitement Thermique Engrenage Juillet 2011schumiizz2bestNo ratings yet

- Methodes de Fonderie Defaut Retassures Souflure Criques InclusionsDocument14 pagesMethodes de Fonderie Defaut Retassures Souflure Criques Inclusionsschumiizz2bestNo ratings yet

- Couples GalvaniquesDocument1 pageCouples Galvaniquesschumiizz2bestNo ratings yet

- Lexique Mecanique Francais AnglaisDocument226 pagesLexique Mecanique Francais AnglaisAnonymous LfeGI2hMNo ratings yet

Colchester Triumph 2000 Footbrake Manual

Colchester Triumph 2000 Footbrake Manual

Uploaded by

Tomek Deka0 ratings0% found this document useful (0 votes)

6 views64 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views64 pagesColchester Triumph 2000 Footbrake Manual

Colchester Triumph 2000 Footbrake Manual

Uploaded by

Tomek DekaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 64

COLCHESTER

TRIUMPH

2000

TER lease a ee

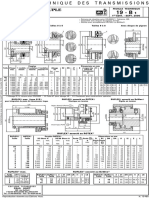

BETRIEBSANLEITUNG & ERSATZTEIL—LISTE

MANUEL D’ENTRETIEN ET DE RECHANGE

THE COLCHESTER LATHE COMPANY LTD., COLCHESTER, ENGLAND

OLCHESTER

RIUMPHU

Phin x 30in oF 50in (190mm x 750mm or 1250mm)

© 16 spindle speeds in geometric progression, @ Induction hardened and precision ground bed

252000 r.p.m.

@ Bed lengths 30in or 60in (760mm or 1260 mm)

@ 7%; h.p. motor between centres

@ Gin.D.1 Camlock Nose Mounting

ore

Models available

‘Code Word Bed Type shee between | Overall ongth ‘Warght

Contres of Machine

“Taomph 2000 Thiey — Swaight ‘Sant 2050 760 258016

“Triumph 2000 Thiey — Gap Gu (75000) (1880) (9704)

“Tiumph 2000 Fifty ~ Sveight Biraight 50m 36in "28201

‘Triumph 2000 Fity — Gap ep (1250) (2438) 12804!

Product Code

STANDARD With English pitch loedscraw: dil graduations in inches.

‘avaliable Inthe Max. With Engh pitch ladscrove dil graduations in milmetr

following versione: METRIC ‘With Met pitch eedecrew; dial graduating in mlimetres.

Specification

Haghtot centres Tin _1is0mm) | Waath of beawave Tin 280mm)

Swing over bea ee Se BBE

Swing over eros aide Skin BAOmmi | Total travel of top side hin (120m)

Spindle bore imax. bar dia) Zhin_ me Total aval of wletock bare! Bihin Een)

Spindle nose mounting ‘in D1 Carlock Number of spindle speed 16

TTaperin spindle nose bush No. 4 Morse ange of sbinde speeds 25— 2000p.

Taporin aistook barrel No.4 Moree Overall wit of machine Ein (965mm

GAP BED MODELS Overall eight of machine [in 11280men

‘Swingin gap 2iin_edmm) | Drive Yee bolts and cliches

Wath in ont of faceplate Bin (188mm) | Motor The.

These Nombor of Mose picves @

Threads: eweorth threads s Fonge of Mode itches 0.3-3.5 mes.

ange of Whitworth thraeds 2epi— 7p. | Foods!

Number of Dametea pitches 2 ange of siding feeds 0.0916in—0.040in

Range of Diametal pitches soe, perrev. of spindle (0.04mm—1.0me)

‘Number of Metric pitches 9 Range of surfacing feeds 0.00076in—0,020n

Range of Mat pitches 0.2~14emm per rov- of spindle {0.02rym—0.5men)

Standard Equipment (unless otherwise specitied)

Slotted toolbiock. Driving pate. Centre bush. Two No. 4 Moree Taper conties. Thread indicator. Electrical equipment for standard 3 phase 60 cycle ac

‘supply 110 volt control End guard limit switch. Set of spanners ana keys. Instruction ond spare parts manual. Accuracy chart. Electric coolant, pum,

tank and fitings. Splash quors. Chuck guard. 250mm 3:w chuck, Apron dal (English or Matic). Emergency Stop Button, Lockable aoltor switch

Oneshot seddle lubrication, Apion adjusteble knack-ot Foot actueted spinal brake.

INSTRUCTION & PARTS MANUAL

* * TRIUMPH 2000 LATHES Lathes

This manual applies only to the machine having

the serial number shown; this is stamped on the

front of the lathe bed at the tailstock end and

MUST be quoted in ali communications.

Machine Serial Number

*

THE COLCHESTER LATHE COMPANY LTD.

Colchester Essex England

TRI-20-6805 1 PRINTED IN ENGLAND.

BRIEF SPECIFICATION

Height of centres Tein.

Distance between centres 30 in. or 50 in.

‘Swing: over bed 154 in,

‘over crossslide 9p in.

ingap

(gap-bed fathes) 224 in.

Spindle nose 6 in. D1 Camlock

Spindle bore

(max. bar diam.) 2tin,

Taper of centres No. 4 Morse

Drive: TEhp.

Weight (approx):

‘Short Bed 2520 Ib. (1143 kg.)

Long Bed 2600 Ib. (1180 kg.)

‘Standard equipment, supplied with lath

late, spindle nose centre bush

forse taper centres, threading

toolholder, drivin

and two No. 4

front

dial indicator, toolkit with full set of spanners and

weenche:

chart, A

page 22,

INDEX

GENERAL LAYOUT OF LATHE

FOUNDATION PLAN

INSTALLATION

CLEANING

LIFTING.

INSTALLING

ELECTRIC SUPPLY CONNECTION

LUBRICATION CHECKS

CHUCKS AND CHUCK MOUNTING

OPERATION

LATHE CONTROLS

ELECTRICAL CONTROLS

SPEED CONTROLS

‘TRI-20-6805,

lin, of retouch p:

I list of lathe accessories is given on

Page

Noauaa

.. lathe accuracy

THREADS AND FEEDS

THREADING DIAL INDICATOR

MULTL-START THREADS

APRON CONTROLS

CROSS-SLIDE AND TOP-SLIDE

TAILSTOCK

SERVICING & MAINTENANCE

LATHE ALIGNMENT

END GEAR TRAIN

DRIVING BELTS

LEADSCREW SHEARPIN

DRIVE CLUTCHES

CROSS-SLIDE NUT

LUBRICATION SYSTEM

GENERAL LUBRICATION

LUBRICATION DIAGRAM

WIRING DIAGRAM

10

"

"

12

12

13

14

14

14

15

16

16

7

18

19

20

TRI-20-6805

LEGEND

Headstock

Spindle

Topslide

Splash guard

Tailstock

Bed

Mounting feet

Tai-end plinth

Leadscrew

Coolant tray

Saddle and cross-slide

Apron

Footbrake

Head-end plinth

Gearbox

End cover (gear train)

NWId NOWvaNnOS

‘TRI-20-6805

CLEANING

Before operating any controls, remove the anti-

corrosion coating from all slideways and the end

gear train, see Fig. 1, using white spirit or

Kerosene,

DO NOT USE CELLULOSE SOLVENTS FOR

CLEANING AS THEY WILL DAMAGE THE PAINT

FINISH.

Oil all bright machined surfaces immediately after

cleaning using machine oll or slideway lubricant;

use heavy oil or grease on the end gears.

LIFTING

Use the bed-clamping plate and eyebolt to sling

the lathe as in Fig. 2. Position the saddle and

tallstock along the bed to obtain balance,

IMPORTANT: DO NOT USE SLINGS AROUND

BED AS LEADSCREW AND FEEDSHAFT MAY

INSTALLING

Locate the machine on a solid foundation, allow-

ing sufficient area all round tor easy working and

maintenance (see Foundation Plan). The lathe

may be used free-standing or bolted to the

foundation.

Free-standing: Position lathe on foundation and

adjust each of the eight mounting fest to take

‘equal share of the load. Then using an engineers’

precision level on the bedways (as in Fig. 3)

adjust the feet to level up machine. Periodically

check bed level fo ensure continued lathe

accuracy.

Fixed iristallation: Position lathe over eight bolts

(Ein. of 18mm. diam.) set into the foundation to

correspond with holes in the mounting feet;

dimensions are shown on Foundation Plan. Ac-

curately level the machine, as in Fig. 3, then

tighten hold-down bolts. Re-check bed ievél.

TRI-20-6805

INSTALLATION

Fig, 3

ELECTRIC SUPPLY CONNECTION

Input wires should be connected to mains ter-

minals of the isolator switch on the electrical

panel in back of the bed, below the headstock,

see Fig. 4.

Main motor rotation must be clockwise viewed

from the pulley end. Shoud motor run in wrong

direction, interchange any two of the three phase

lines. Appropriate wiring diagrams are included

in Servicing and Maintenance Section of this

manual.

LUBRICATION CHECKS

Before operating the machine make the following

important checks:

1, That the oil tank in the head-end plinth is filled

to correct level indicated by dipstick with Shell

Tellus Oil 27.

That the gearbox js filled to level marked on

oil sight window with Shell Tellus Oil 27.

3. That the carriage apron is filled to level mark

‘on oil sight window with Shell Tonna 33.

4, In addition, apply an oil can to the points

shown on lubrication diagram which require

daily oiling. Use light machine oil or way

lubricant.

5. Before each working shift, operate the manual

lubrication pump to ensure adequate \ubrica-

tion of carriage slideways.

NOTE: When the lathe motor is switched on, the

oil sight window in front of the headstock should

{ill with oit—indicating that the pump is operative.

Wf this does not occur stop the machine and

investigate the cause.

TRI-20-6805 6

TRIUMPH 7000

CHUCKS AND CHUCK MOUNTING

WARNING: GREY CAST-IRON CHUCKS MUST

NOT BE FITTED ON THIS HIGH-SPEED LATHE.

USE ONLY DUCTILE IRON CHUCKS RECOM:

MENOED BY THE COLCHESTER LATHE CO.

LTD. (See Accessories Section).

When fitting chucks or faceplates, first ensure

that spindle and chuck tapers are’ scrupulously

clean and that all cams lock in the correct post

Hons: see Fig. §; It may be necessary when mount-

ing @ new chuck to re-set the camlock studs (A).

To do this, remove the cap-head locking screws

(B) and set each stud so that the scribed ring

(C) is flush with the rear face of the chuck—

with the slot lining up with the locking screw hole

(see inset, Fig. 5).

Now mount the chuck or faceplate on the spindle

nose and tighten the six cams in turn. When fully.

tightened, the cam lock line on each cam should

be between the two V marks on the spindle nose.

i any of the cams do not tighten fully within these

marks, remove the chuck or faceplate and

teadjust the stud as indicated in the illustration.

Fit and tighten the locking screw (B) at each

stud before remounting the chuck for work.

A seference mark should be made on each cor-

rectly fitted chuck or faceplate to coincide with

the reference mark scribed on the spindle nose.

This will assist subsequent remounting. DO NOT

INTERCHANGE CHUCKS. OR FACE. PLATES

BETWEEN LATHES WITHOUT CHECKING FOR

CORRECT CAM LOCKING,

IMPORTANT: Take careful note of speed limita:

tions when using faceplates; 21 in. faceplates

should not be run at speeds greater than 625

rev/min, and 14 in, faceplates at not more than

840 rev/min.

Fig. 5

‘CAM RELEASE DATUM

connect

CAM LOCK LINE

BETWEEN ARROWS

WRONG

TURN STUO IN

ONE TURN

‘TRI-20-6805

REFERENCE MARK ON SPINOLE NOSE

TuRN stup our]

ONE TURN

OPERATION

Fig. 6

ELECTRICAL CONTROLS (See Fig. 7)

With the exception of the lathe isolator, all elec-

trial controls are fitted into the front face of the

headstock:—

aD pane the GREEN button to stari the main drive

motor.

LATHE CONTROLS (Bee Fla. 6) 2. The Indicator lamp glows whilst the motor ts

sunnieg,

4. Spindle speed selector 8. Press the RED mushroomdead button to stop

2, Electrical push buttons the main motor and also electical supply fo

3. Apron, surfacing or sliding feeds ancillary services.

4, Gearbox, threads and feeds i Coser pubes OW Ger peer: viNtors.

&, Spindle rotation (reverse only)

6. Spindle rotation (forward and reverse)

7, Footbrake

‘TRI-20-6805 3

Fig. 8

SPEED CONTROLS (Standard lathos)

Spindle Aotation: Selected by the lever controls

A and B (Fig. 8). The apron lever {A} for

forward, free and reverse selections, the lever

(B) for reverse and free selections only,

With the main motor Huang move lever A out

and down to engage forward rotation of spindle,

or straight upward to engage reverse rotation.

Lever B can be moved only upward to engage

reverse rotation or retumed to the central position

to disengage drive.

Footbrake: A foot pedal between plinths operates

‘the spindie brake and at the same time returns

selector levers A and B to the central (disen-

gaged) position.

Height of the foot pedal depends upon the posi

tion of a pin engaged in the bar (Fig. 9); a choice

‘of three positions is provided.

Spindle speets: Selected by the grouped dial

‘gontrois on the headstock (Fig. 10), c

‘The sixteen available speeds are shown directly

on the Jever-operated dial (A), In four groups-—

each of which is further divided into it dis

played spindle speeds. Rotate thls dial, using the

large handle, to bring the required specd-group

uppermost snd opposite tho, lixed section, (B).

yw rotate the other handled dial (CG) until the

appropriately coloured arrow is aligned with the

required speed on the uppermost dial group.

DO NOT MOVE SPEED-SELEGTOR CONTROLS

WHILST THE SPINOLE 1S ROTATING.

To free the spindle for hand rotation, set any one

Of the blank spaces on the group-dial Yo tho mide

position of the fixed section (B).

TRI-20-6805 9

THREADS AND FEEDS

All the threads and feeds directly available from The | position of lever (Y) provides a range of

the gearbox are shown on the dat

‘on the front of the headstock (Fig, a

setting of control levers is shown in Fig. 12. spindle speods higher than

‘Threads available:

45 Whitworth threads <

39Metricthreads

18 Metric modules:

21 Diametal pitches:

(0.

Spe ee

ea

it HEE G8 35

re

HEE

Ee

ii

ns EEE GE He

Ht Sin Sat

a

Fly, 11

Bottom sHarT [>

54338-0 5427-0

Gear 30/207 collars (two) 4622-0

541320 54130-0 keys -2

bushes-2 | §4353-0 54349-0 54347-0 54345-0 $4370-9 bush 4335-0 (17-002)

(0-018) Qear 227 gear 201 gear 237

Gear 267 shaft (10-018) gear 19/451

5476-0 54350-0 §4348-0 4346-0 54341-0 54340-0 54339-0 50460-0

GHEE, garter gear zur gearz7 gear zag

r26T gear 37T nut

54732-0 shaft 54362-0 54368-0 84751-0 54360-0 s4iee-0

337 acer year 367 ‘reli

S200 wey 9480 27 gea spacer gear 36 arse,

(02-886) gear22T gear 227 gear22T (1-745) (02-894)

Ret: TR-2-6811

12

SADDLES |; assume: Issue No. 11-68

| 55514-0 screw &nut assy. ENG.

ENG.55250-0 nutassy, 5516-0 screw &nut assy. MET.

5653-0 screws. MET. 55253-0 nut assy.

(48-248)

'35876-0 washer (85-743)

55580-0.

Serew(39-350)

55338-0

olter (23.924)

55491-0 $5698-0 brg. shield

saddle casting assy.

5580-0, B rew

38580°0, Sp 55527-0 lockscre

55097-0 bushes

(10-920)

58429-0

Riper assy. lat

55910-0

Wiper assy. vee

Aa

CP ss00120 screws

ht

£5401-0 pinion

55230°0 keep assy

55242-0 key

(07-060)

55126-2 clamp

55386-0 pin

5553020 nut (21-660)

55660-0 spacer 55698-0 shield

EERE LNT En) SENET

sstsa-oeus.

SHEERS

25200

ney

5300-0 nut (21-662)

5769-0

5879-0 washer

(85-739)

556990 shield

55878-0 washer (86-744)

'535038-0 besring(dk-051)

‘55876-Owasher (85°74)

95590-0 screws (47-228)

55081-0 bracket —_ 55488-0

saddle casting

assy. (R.H.)

55660-0

plug

55782-0 dise~

(e2-062)

3580-0 ©,

'55429-O plug

58580-0 55846-O washer

(3-359), 55802-0 strip

55188-0gib

—~ 55134-0 clips

'55867-0 washers (86-762)

535860-0 screws (73-573)

55678-0

shaft

55186-0 gid

55533-0 gib screws

55170-0 gear

5099-0 bushes 0-08)

| 2381-0 serew (67-119)

55801-0 stip

| Ret: TR: 2- 6812

3

SADDLE) LusAcaTION 1s

1¢ No. 71-68

535586-0 screw (60-361) 553920 pin (14-125)

\ stozs-o val $8785-0 spring (2-840

(01-768)

I 55090-0 valve a

5355-0 osring (27-879),

5536-0

restrictor screw

55870-0 washer

(08-769),

55437-0 plunger ass

aiaed 55412-0 collar & pipe assy. (ch.saddle}

55407-0 collar &pipe assy. (Lh saddle)

8542-0 plate '55872-0 washer

(86-770)

55615-0 screws (73-582)

55072-0 bolt a

55708-0 sleeve

(29-039)

55624-0 intake valve assy.

55027-0 ball (01-794)

'55318-0 nut (29-027)

Ret: TR-2-6013

4

SLIDES; assemaums Issue No. T1- 68

55307-0 nut (21-665)

2-0 washer (85-739)

55058-0 bolt assy.

55726-0

solid topstide

or

55727-0

slotted topstide

55140-0 collar

55060-0 bolt

55726-0

solid topslide

sso

Bo ssozs-0

: balls (01-788)

a

(§-55769-0 spring

f $5212

Mim

ssess-0-f f AY

55293-0 nut assy.

55377-0 pad

55609-0 screw.

(47-227)

55530-0 screws

~O.

5196-09 S5521-08

55289-0 nut,

55759-0

‘swivel slide 55244-0 hey

(07-539)

ef 55657-0

iS spacer

'55505-0

screws (46214)

55070-0 bolt & nut

5417-0 pivot

ccm ssso-o | & 755239-0 keep assy

(68-431)

55536-0 screw

55592-0 screw (47-227)

35720-0,

cross-silde ass

* 55374-0 locking pad

5359-0 o-ring (27-890)

55530-0 screws citer 23°84)

55193-0 gib

55720-0 cross-slide assy.

Ret: TR-2- 6814

15

TAILSTOCK Issue No. 11-68

_ S7319-OENG. 57955-0 s7056-0 7984-9 STI4E-Okeep —_$7018:0 ball (01-7

250-0 7322-0 rareck ‘ating screws

screw screen (46-214) (46-214) 57399-0

Index ring

57303-0 ENG.

57305-0 METRIC

nut

57090-9

S7190-0 ENG ID Sr8

§7193-0 MET. bush (10-028)

57210°0 oilers (29+

57220-0 o-ring (27-182) * 4 oie

57133-0

handwheel

‘assy.

57173 -0 lever assy.

57233-0 pad

57285-0

plug

57448-0 wasner, assy.

(05-720)

57356-0 screw’

(73578)

'57418-0

57129-0

57097-0 casting

57169-0

lever assy: 57041-0 base

57070;0 bolts

57360-0 screws 57443-0 washer

(238) testa

7444-0 spr. whe.

eons

57353-0

(73"582)

cirelip (1-748)

57440-0 washer

(85-737)

57465-0 wiper assy.

Tftat)

57263-0 pivot block

37348-0 screw

(73-533) 57271-0 clamp

'57075-0 bolt (08-017)

574410 washer (88-741)

57068-0 bolt assy.

57273-0 clamp plate

Ref: TR-2- 6815

16

CANINET & PANELS

63070-0 support —-57545-0 cover

sh guard - 50”

on 230"

63072-0 support plate

63025-0 bolts(o8-171)

7 S000 washers

-

51720-0 o-ring.

(27-882)

57905-0

*57857-0 tray- 30"

57855-0 tray -50"

87573-0 ——__

$7704-Orail-30"

57684-0 plug

57866-0

tray, tal

57654-0 plate-30"

'57653-0 plate-50"

57530-0 chute

57540-0 cover

5763-0 screws 5786-0 tray 30"

0 7885-0 tray 50”

US =>

56164-0 collars

coy SWE

(85-738) CH

56820-0 spring

56950:0

Spyfappttt owen

Ep

~@) 56763-0 trip shatt

. : ( 36330-0 bey

56235-0 clutch gear or | Ss (17-023)

56450-0 oil seal

| C7s-e98y

wre samecasing

@ 56605-0 rod |

q a

56409-0 nut a

fh 26640:0 screw 48-204)

Pa 5075 oir sha

Ret: TR-2-6624

APRON: THmmacina OIALe Taaue No.11-68

6853-0

dial stem as

5494-0 pin

ENGLISH

56882-0,

‘stud 56272-0

guard

5641-0 nut

(21-678)

6236-0

dial gear Sei oEtO

clamping nut

56630-0

sa ‘thumbscrew

56883-0

stud

56654-0

dial stem assy.

56273-0

METRIC > eer

56407-0

clamping nut

For setting

instructions 6245-0

read the plate

on front of the

guard, and on

top surface 56239-0

dial gear 167

dial gear 227

$6243-0

dial gear 207

5680-0 spacer

36237-0

ial

58241-0

dial gear 187) 56408-0 nut

Ret: TR 2-6828

Spare Parts List— Appendix 1

SPECIFICATIONS OF STANDARD ITEMS

Ref. Now

1-788 Ball, steel 1/4 in, dia.

O1~789 Ball, steel 5/16 in. dia.

1-790 Ball, steel 3/8 in. dia.

1-794 Ball, steel 7/32 in, dia,

02-881 Bearing, FAG 6008

02-884 Bearing, FAG 6206

02-886 Bearing, FAG 160-05

02-894 Bearing, FAG 160-03

02-895 Bearing, FAG 620,

02897 Bearing, FAG 6004 22

02-898 Bearing, FAG 6006

02-899 Bearing, FAG 6007

02-900 Bearing, FAG 6301 22

03-898 Bearing, Needle, INA SC 18

03-918 Bearing, Needle, HK 3020

03-932 Bearing, Gamet, 131093%/131152 XC

03-933 Bearing, Gamet, 133075/133130 P

03-934 Bearing, Needle, INA HK 2220

O89] Bearing, Thrust, INA AXK 1528

04-892 Bearing, Thrust, INA AXK 2035

04-903 Bearing, Thrust, INA AKK 3047

04-904 Bearing, Thrust, FAG 52104

07-930 Belts, Vee A31

07-931 Belts, Vee A32

07-972 Belts, Veo A72

07-973 Belts, Veo 474

08-013 Bolt, Hex head 1/2 UNC x 1.1/4 in.

B-0L6 Bolt, Hex head 1/2 UNC x 2 in,

08-017 Bolt, Hex head 5/8 UNC x 3¢ in,

08.032 Bolt, Hex head 1/4 UNC x 5/8 in.

08-048 Bolt, Hex head 5/16 UNC x 3/4 in.

08-069 Bolt, Hox head 3/8 UNC x1 in.

08-112 Bolt, Hex head 5/8 UNC x 1.

08-170 Bolt, Hex head 7/16 UNC x 1.

08-171 Bolt, Hex head 5/16 UNC x 1/2 in

10-016 Bush, Glacter, MB 1825 DU

10-017 Bush, Glacter, MB 3030 DU

T0018 Bush, Glacier, MB 1215 DU

10-019 Bush, Glacier, MB 3020

10-020 Bush, Glacter, MB 2525

10-021 Bush, @acier, MB 2215

10-022 Bysh, Oilite, BS2 x 1.1/2 in.

10-023 Bush, Glacier, MB 2025

10-025 Bush, Glacier, 22 DU 16

10-026 Bush, Glacier, 09 DU 03

10.027 Bush, Oilite, CT 474 x 1/2 in.

10-028 Bush, Glacier, MB 2015 DU

10-986 Bush, Glacier, MB 1515 DU

‘TR2 - 768

Ref, ho.

1-731

11-732

11-736

11-739

11-743

11-745

11-746

21-749

11-751

11-754

11-753

11-776

1-77

11-786

11-788

11-791

11-848

11-855

11-860

11-864

11-865

11-866

11-867

11-869

12-795

12-836

12-837

12-838

12-839

12-840

14-103

14-104

14-125

Lnldd

14-605

14-610

14-616

14-649

14-664,

14-668

15-110

25-11

15-117

15-122

159123

15-124

15-126

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Cirelip,

Circlip,

Circlip,

Cirelip,

Cirelip,

Cirelip,

Circlip,

Cirelip,

Circlip,

Cirelip,

Circlip,

Ctrelip,

Circlip,

Girelip,

Cirelip,

Cirelip,

Circlip,

Circlip,

Girclip,

Cirelip,

Ctrelip,

Circlip,

Circlip,

Cirelip,

Girelip,

Cireltp,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

Spring dowel,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

external,

internal,

internal,

internal,

internal,

internal,

intemal,

3/8 in. Anderton 1400

1.V4 in. Anderton 1400

1/2 ine

Anderton 1400

1,3/8 in, Anderton 1400

5/8 in, Anderton 1400

3/4 in. Anderton 1400

1,1/2 in, Anderton 1400

‘V8 in, Anderton 1400

15/16 in. Anderton 1400

1.1/8 in. Anderton 1400

1,5/8 in. Anderton 1400

5/8 in, Anderton 1500 © 485

3/4 in. Anderton 1500 E 580

343/16

in, Anderton 1400

3.3/8 in, Anderton 1400

349/16

in. Anderton 1400

3/16 in, Anderton 1400

1/16 in. Anderton 1500 £ 343

25 nm.

18 m,

30 mn,

17 om,

35 mm.

12 nm.

2.7/16

47 ume

42 mm.

55 mm.

62 mm.

37 om.

3/8 in, Anderton

Anderton 900-106

5/16 in SL Narromore & Tozier

3/8 in. SL Narromore & Tozier

Anderton 1000 - 15

Anderton 1400

Anderton 1400

Anderton 1400

Anderton 1400

Anderton 1400

Anderton 1400

in, Anderton 1300

Anderton 1300

Anderton 1300

Anderton 1300

Anderton 1300

Anderton 1300

1900

V8 dia. x 1/2 in.

V8 dia. x 3/4 in.

V4 dia. x 1.1/2 in,

3/16 dia. x 1.1/4 in,

3/16 die, x 3/4 in.

3/32 dia. x 1/4 in,

3/32 dia. x 3/4 in.

3/A6 dia. x 5/8 in.

V4 dia. x 3/4 in,

V4 dia. x 1.1/4 in,

K &M, Push button disc. Black '1' No. 3

K &M, Push button disc. Red '0! No, 2

Fuse unit c/w cartridge 20 amp.

Reset button $q.D.. Pt, No. 2760 D6 GL

Terminal Klippon type SAK 4 Cat. No. 1932

‘Terminal indicator cartridge Klippon SAK 5

Plastic brit. Klippon WK Cat flo. 1846

AL

‘TR2 - 768

17-037

17-039

17-040

17-041

17-042

17-043

18-847

19-175

19-176

19-177

19-178

19-179

19-180

19-181

19-182

20-260

20-621,

20-622

20624,

20-626

20-635,

2648

21-658

21-660

21—662

21-665

21-678

21-680

21-685,

21-688

21689

21-690

21-691

21-692

21-693,

222693

22-700

220702

22-703

230124

Bp 542

24-544

2p 589

24-765

Woodruff No. 3 BS 404

Woodruff No. 9 35 606

‘4 x W/4 x 1 long. Feather

Woodruff Letter 'A' BS 807

3/16 x 3/16 x 1.3/4 Plein.

3/16 x 3/16 x 5/8 long BS 46

Key, 3/16 x 3/16 x 3/4 long BS 46

Key, Woodruff BS 505

Key, 1/8 x 1/8 x 3/4 Jong. Round end, BS 46

Key, 3/4 0/D x 3/26 Tak BS 46 No, 606

Key, Woodruff BS 46 404

Key, Woodruff BS 46 303

Knob, Bluemel type D 119

Motor, A.E.I, 7.1/2 hp. D112 M , 220/240/380/420/3/50cy

Motor, A.E,I. 7.1/2 hp. D112 M. 500/550/3/50cy

Motor, A.E.I. 7.1/2 hp. D112 M. 220/240/380/420/3/60cy

Motor, Newman 7.1/2 bp. © 213 T 206/3/60cy

Motor, . € 213 T 230/260/3/60ey

Motor, © 213 T 230/460/3/60cy(C,S.4, approved)

Motor, C2137 305/37 p0ey (On Sod proved)

Motor, © 213 T 208/3/60cy(C.S.a, approved)

Nut, 1/4 UNC Standard

Kut, 5/16 UNC Standard

Nut, 3/8 UNC Standard

Nut, 1/2 UNC Standard

Nut, 5/8 UNC Standard

Nut, 1/4 UNC Thin

Locknut, 1/4 UNF

Locknut, 1/4 UNC

Locknut, 3/8 UNC Simmonds Aero

Locknut, 1/2 UNC Standard Nyloc NI/N1166

Locknut, 5/8 UNC Standard NP/N206

Locknut, 5/8 UNC Thin Armaloe 4-5 CAPZ

Locknut, 3/8 UNC Thin Philidas JUCJ

Locknut, 5/8 UNC Thin 'T! NI/N206

Locknut, 1/2 UNC Simmonds

Locknut, 5/8 UNC Philides c/w Plastic cap. Type QUCN

Locknut, 1/2 UNC Simmonds NT/N162

Locknut, 1/4 UNC Armaloc 4-4 CAPZ

Locknut, 3/8 UNC Armaloc A~6 CAPZ

Locknut Simmonds P1/H166

Nut, 3/8 BSF

Nut, 1 in, Conduit

Nut, 7/16 BSF L/ii

Nut, 3/4 Flex, Conduit thread

V4 dia. Springvell ofler

Mille pin, 3/16 dia, x 3/4 GP3

Mille pin, 3/16 dia, x 1 GP3

Mille pin, 3/8 dia. x 1.1/2 GP3

Mills pin, 11/32 dia, x 1.1/2 GPL

TR? - 768

iat

Ref, Now

25=600

25-602

25-616

25-617

25=620

25-622

25-623,

25-625

25626

25-627

25628

26-862

26-931

26-947

27-182

27-866

27-870

27-871

27-879

28-880

27-883

27-885

27-888

27-889

27-890

27-891

27-892

27-893

29.027

29-031

29-034

29-039

29-041

29-043

29-044,

29-046

29.047

29-048

29-051,

292052

29.053

29-054,

29-057

292058

45-201

45-202

45-203

45-204,

45-205

45-206

45-207

45-210

Dowel, 1/2 x 1.1/2 in, Grade 3

Dowel, 3/8 x 1.1/8 in.

Split pin, 1/8 x 1/2 in.

Split pin, 3/16 x 1/2 in,

Roll pin, 5/32 x 1.1/2 in,

Roll pin, 1/8 x 1/2 in.

Dowel, 3/8 x 1.3/4 in. Grade 3

Dowel, 1/8 x 1/4 tn. Boneham & Turner

Roll pin, 1/4 x 1.3/4 in.

Roll pin, 3/16 x 1.1/4 in,

Roll pin, 3/32 x 1/4 in

Otl-ring, Pioneer P0/13711213

Oil-ring, Dowty No. 20

OLl-ring, Dowty No. 4

OLl-ring, Dowty List 5 MKLOpp4ge

Ofl-ring, Dowty List 5 MKL2pp.496

Oil-ring, Dowty List 5 MK6pp 490

Oil-ring, Dowty List 1 MK7pp Sle

Oll-ring, Dowty List 1 MK6pp Sle

Otl-ring, Dovty List 5 MK2pp 490

Oil-ring, Pioneer 6-017/MP 908

Otlering, Dowty List 4 MKLSpp 730

Ollering, Dowty List 5 MK29pp 490

Ot1-ring, Dowty 5 MK28pp 490

Oil-ring, Dowty List 5 MK4pp 49¢

Oil~ring, Dowty List 4 MK2dpp 73c

Oil-ring, Dowty List 4 MKL7pp 73¢

Oll-ring, Dowty List 5 Mk8pp 49¢

Nut, union &VOTS B-1741-C

Tecalemit 90° M & F Elbow type 43336/3

Socket plug =NOTS B-17240

Tubing sleeve sNOTS 22

Breatheg No. MB 2030 1/8 BSP

Pipe 45° bend 1/2 BSP Male/Female

Plug 1/2 BSP Tecalemit 4377/4

O11 pipe Gripflex, Surlon No. NF4O

O11 pipe Gripflex, Surlon No. NF 70

Coupling =NOTS w 1122

Hlbow 1 in, BS 1740

Parallel nipple BS 1740 1 in, BSP x 2.1/2 in.

Nat BS 17401 in. BSP

Nut BS 1740 1/4 in, BSP

Tubing nut 2OTS 221

Tubing sleeve ANOTS 27

Cap screw, 10-24 tep.de x

Cap sorew, 10-24 t.p.i. x

Gap screw, 10-24 t.p.i. x

Cap screw, 10-24 t.p.d. x 3/4 in.

Cap screw, 10-24 t.p.d. x

Cap screv, 10-24 t.p.d. x

Cap screw, 10-24 t.p.d. x

Cap screw, 10-24 t.p.t. x

‘TR? - 768

ty

53-300

53-303

54-309

54-310

54-312

5-316

58-345

59-350

59-352

59-354

59-356

59-357

602361

60-362

60-364

61-370

61371

62.379

67-419

screw, 1/4 UNC x 1/2 in,

screw, 1/4 UNC x 5/8 in,

serew, 1/4 UNC x 3/4 ing

sorew, 1/4 UNC x we in.

screv, 1/4 UNC x1 4

screw, 1/4 UNC x 1. Vian,

screw, 1/4 UNG x 1.1/2 in,

screw, 1/4 UNC x 1.3/4 in.

screw, 1/4 UNC x 2 in,

screw, 1/4 UNC x 2.1/4 in.

screw, 5/16 UNC

5/16 UNC

5/16 UNC

5/16 UNC

5/16 UNC

5/16 UNG

5/16 UNC

5/16 TNC

5/16 UNC

3/8 UNG

3/8 UNC

3/3 mac

3/8 UNG

3/8 UNC

Cap screw, 1/2 UNC

Countersunk screv,

Countersunk screw,

Countersunk screw, 1/4 UNC x 5/8 in.

Countersunk screw, 1/4 UNC x 3/4 in.

Countersunk screw, 1/4 UNC x 1 in.

Countersunk screw, 1/4 UNC x 1.3/4 in,

Cup-point screw, 10-24 t.p.i. x 3/8 in,

Oup-point serev, 1/4 UNC x 1/4 in.

Gup-point screw, 1/4 UNC x 3/8 in.

Cup-point screw, 1/4 UNC x 1/2 in,

Cup-point screw, 1/4 UNC x 3/4 in,

Cup-point screw, 1/4 UNC x1 in,

Cup-point screw, 5/16 UNC x 5/16 in.

Oup-point screw, 5/16 UNC x 3/8 in,

Cap-point screw, 5/16 UNC x 1/2 in,

Cup-point screw, 3/8 UNC x 3/8 in,

Cup-point screw, 3/8 UNC x 1/2 in,

Gup-point screw, 7/16 UNC x 1/2 in,

Dog screw, 1/4 UNC x 3/8 in,

TR? - 768

Refs Now

68-429

68-431

TO kss

T3013

73-525

73-533

3-549

73554

73=568

73-570

B57.

3-572

B53

357

3-575

73-576

B-579

73-582

73584

73~585

3-586

B-587

73-588

735589

3-590

3-51

73-596

73-597

3-598

B59

73-600

3-601

73~602

3-603

73604

605

79-895

19-89%

19-897

80-872

81-151

81-156

81-157

81-158

81-159

81-160

81-164

81-165

81-167

81-266

81-169

Dog screw, 5/16 UNC x 3/8 in.

Dog screw, 5/16 UNC x 1/2 in,

Dog eerey, 1/2 UNC x 1/2 in,

Domed head screw 1/4 UNC x 3/8 in.

Cone point Skt, set screw, Wedglok 1/2 UNC x 1 in, x 90°

Full dog Skt, set screw 3/8 UNC x 1/2 in,

Cheese head acrev, Brass 1/4 UNF x 3/4 in,

Cup point Skt, set screw, Wedglok 5/16 UNC x 3/8 in.

Domed head screw 1/4 UNC x 3/4 in.

Cap head screw, Wedglok 5/16 UNC x 1.1/4 in.

Cap head screw 1/4 UNC x 3.1/2 in,

Hex Skt. cone point Wedglok 10-24 UNC x 5/16 in.

Hex head screw 5/26 UNC x 1.1/2 in,

Skt, set screv, Wedglok 1/2 UNC x 3/4 in.

Cap hd. screw, Wedglok 10-24 UNC x 1/2 in,

Hex Skt cap head, Wedglok 1/4 UNC x 3/4 in,

Hex Skt, button head screw 1/4 UNC x 1/2 in,

Domed head cadium plated screw 10-24 UNC x 1/2 in,

Half dog screw, Wedglok 3/8 UNC x 1/2 in,

Half dog screw, Wedglok 1/4 UNC x 3/8 in.

Cheese head screw 1/4 UNC x 1/2 in,

Knurled cup point Skt. set screw 7/16 UNC x 1/2 in,

Hex head screw 5/16 UNC x 3/4 in.

Cup point set screw 1/4 UNC x 1/d in,

Skt. C/Sunk head screw, Wedglok 1/4 UNC x 5/8 in,

Self Tapping screw, NPK type Z No. 6 1/4 in,

Slotted cheese head screw 4 om. Dia x 8 mm

Slotted cheese head screw 4 mm dia x 15 mm

Slotted cheese head screw 4 mm dia x 35 mm

Round head screw 10-24 UNC x 3/8 in

Round head screw No. 832 UNC x 1/2 in.

Half dog Skt set screw 4BA x 3/16 in,

Skt. 0/Sunk serew No, 6 UNG x 1/2 in,

Skt. C/Sunk serew No. 4 — 40 UNC x 3/8 in.

Half dog screw 6BA x 1/8 in,

Skt. domed head screw No, 4-40 UNC x 2/g in,

O41 seal, Burtonwood TR31/M40~62-10/PA

O11 seal, Burtonvood 135~50-10

O11 seal, Burtonwood ¥12-28-8

OLleight, Tecalemit IC 4611

Open end spanner 15/16 A/F x 3/4 4/F

Allen key 3/8 4/F

Allen key 5/16 4/F

Allen key 7/32 A/F

Allen key 3/16 /F

Allen key 5/32 A/F

Box spanner 15/16 x 1.1/8 4/F

Ring spanner 1/2 x 3/4 4/F

Allen key 1/4 4/F

Standard spanner 1.5/16 x 15/16 4/F

Standard spanner 9/16 x 7/16 4/F

‘TR? - 768

82-809

82-830

82-842

820843

82-850

82-856

82-857

82-858

82.859

82-860

82-862

82-863

82-864

82-865

83-179

83-182

83-183

83-185

83-186

83-188

83-190

83-192

83-194

83-201

83-202

83-210

83-211

83=212

83-213

83-214

83-215

84-703

84-704

84-719

85-691

85=692

85-693

85-695

85-720

85-729

85-733,

85-734

85-735

85=737

85-738

85-739

85-740

85-741

86-119

86-738

86-743

B674L

86-750

Spring, Flexo 243608

Spring, Flexo 123306

Spring, Flexo 82905

Spring, Flexo 92812

Spring, Flexo 83104

Spring, Flexo 82703

Spring, Flexo AR 3748

Spring, Flexo 103203

Spring, Flexo 83005

Spring, Flexo 123204

Schnorr disc spring type K 16.34 x 22.5 x 0.8 mm

Spring, Flexo 123006

Spring, Flexo AM 3220

Spring, Flexo 92814

& M Push button unit. type DT - X/AK-G

& M Contactor type Dil 00a ~ 459

& M Overload Relay type Z0-0-21

& M Contactor green series Dil-a~1/41/61

4M Overload Relay type 20-16

& M Overload Relay type 20-12

&M Isolator switch type 126-3/62v

-D Push button unit red, Class 9001.TP4IR. 110¥ é0cy

Sq. D Starter Class 8501 type D0-40 relay

Pump starter overload 9065 CO-1R

Pump starter overload COLL

K &M Push button unit type PL-N/AK-G

Neon signal lamp 220v c/w int. resistor

Neon signal lamp 346; 380; 420; 550v o/w separate resistor

Brookhurst igranic type A4 Cat D100 transformer

Push button unit red, Class 9001 TR4A

Push button uoit red. Class 900] TR2AL

K

K

K

K

k

K

K

Sq,

Lock washer, 5/16 dia, bore single coil

Tock washer, 3/8 dia bore single coil

Lock washer, 3/4 dia. bore double coil

Washer, 1/4 dia. bore.

Washer, 5/16 dia. bore

Washer, 3/8 dia. bore

1/2 1/D x 1 0/D x ,092

2 BA standard plain

, 1/2 standard light gauge

5/16 I/D large series 15 SWG

V/2 1/D x1 0/0 x 13 Swe

V4 dia. bore,

5/8 I/D x 1.1/4 0/D x 15 SWG

#8 we x ay on = 15 SWG

5/8 I/D x 1.1/4 0/D x 11 Swa

3/4 I/D x 1.1/2 0/D x 15 Swe

5/8 I/D x 1.3/8 0/D x 11 SWG

Fan disc 1/2 1/D

V4 bore shakeproof

TWA thrust AS 1528

INA thrust GS 1528

INA thrust AS 2035

TR? - 768

vii

86-752

86-756

86-760

86-761

86-762

86-763

86-764,

86-766

86-767

86-768

86-769

86-770

86-71

86-772

86-773

86-774

86-775

86-776

86-777

86-778

87-827

872631

88.059

88~062

88-063

88-064,

88-080

88-081

88=062

88-089

88-090

88-091

88-092

88-093

88-094

88-095

88-096

88-097

88-098

88-099

88-100

crinkle, 7, Haddon type DP/10008A

fibre 5/8 O/D x 5/16 I/D x 1/16

fibre 1.1/16 1/D x 1.3/8 0/D x 1/16

thrust AS 3047

5/16 1/D x 5/8 0/D x .040

Schnorr 8 mm

V4 /D x 9/16 0/D x 056

fibre OTS MF 110

fibre ENOTS 1386 G

V2 1/D x1 0/D x .062

sealing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cup 03 BB3 Uk WebDocument7 pagesCup 03 BB3 Uk Webschumiizz2bestNo ratings yet

- (FPD-1654a (E) - Water Injection Pumps LRDocument11 pages(FPD-1654a (E) - Water Injection Pumps LRschumiizz2bestNo ratings yet

- Handbook SKFDocument452 pagesHandbook SKFschumiizz2bestNo ratings yet

- Paul Huet 1Document1 pagePaul Huet 1schumiizz2bestNo ratings yet

- Info Sur Le FiletAgeDocument19 pagesInfo Sur Le FiletAgeschumiizz2bestNo ratings yet

- Develop3D Ebook - The Importance of Drawings - tcm27-2694Document4 pagesDevelop3D Ebook - The Importance of Drawings - tcm27-2694schumiizz2bestNo ratings yet

- X105 CR Mo 17 ChromeDocument2 pagesX105 CR Mo 17 ChromeAbdennasser RahibiNo ratings yet

- Distribution À Soupapes PDFDocument39 pagesDistribution À Soupapes PDFschumiizz2best100% (1)

- Z6CND16 05Document2 pagesZ6CND16 05schumiizz2bestNo ratings yet

- Pajero EngineDocument54 pagesPajero Engineschumiizz2bestNo ratings yet

- Mitsu Pajero Engine 4D5Document54 pagesMitsu Pajero Engine 4D5schumiizz2bestNo ratings yet

- Z30C13Document2 pagesZ30C13schumiizz2bestNo ratings yet

- Traitement Thermique Engrenage Juillet 2011Document7 pagesTraitement Thermique Engrenage Juillet 2011schumiizz2bestNo ratings yet

- Methodes de Fonderie Defaut Retassures Souflure Criques InclusionsDocument14 pagesMethodes de Fonderie Defaut Retassures Souflure Criques Inclusionsschumiizz2bestNo ratings yet

- Couples GalvaniquesDocument1 pageCouples Galvaniquesschumiizz2bestNo ratings yet

- Lexique Mecanique Francais AnglaisDocument226 pagesLexique Mecanique Francais AnglaisAnonymous LfeGI2hMNo ratings yet